Friday, 13:32, 23/12/2022

I will try to finish this now, I swear.

Again, not mfixing grammar mistakes.

Well, the Project Log 16 bug definitely deleted all the things I wrote at topics 2 and 3, it is not like I just wrote the title and didn't work on anything at all. hehe. >.>

The project logs that I wrote are basically this meme, lolololol.

- Hydraulic accumulators.

Basically, one could simply use a cheap 12V tire inflator/air compressor to fill up a bladder hydraulic accumulator. But these are expensive, and I don't know how long a 300 PSI air compressor for tires will take to fill up homemade sketchy bladders. Also, pneumatics are kinda dangerous, they can explode.

Also, one doesn't really neeed bladders, I could simply use a car spring that is pulled by a electric motor. Like a electric jack/linear actuator. When the spring is pulled, the hydraulic oil will be forced in by vacuum action, then I just need to release the spring and the compression of the spring will compress the hydraulic fluid and that's it.

Kinda of, I need to find a way of calculating that. I remember once reading an scientific paper of a "novel design of hydraulic accumulator" or something among these lines, I need to find it again. Maybe they have a model/equation that I can use to guess how much pressure it will generate, if there isn't already an option that I can buy online. For some reason, the electric jack/lineart actuator is more expensive than the hydraulic jack... Bruh.

Found the article: "A novel pump design for an efficient and compact Electro-Hydraulic Actuator IEEE aerospace conference".

No, actually, I think it was this one: "Development of a novel compact hydraulic power unit for the exoskeleton robot".

Or I could simply use a electric jack directly compressing the hydraulic fluid... I could also make a homemade pulley that pulls the hydraulic accumulator spring. Homemade because the fricking electric pulleys use the same 1hp electric motors the high pressure hydraulic pumps use, so... bruh. Dunno what is the best option, I will need to calculate every single one of these. I hope the people I invited to this project could be able to give me a hand, we probably know as much as each other, but 4 heads think more than 1. - Costs.

I was thinking a little bit here about the overhaul cost of this mech. A single car in Brazil can cost 100,000 Reais, but in the US it costs around 30,000 Dollars (as foretold by google). If we can make this thing under 10,000 Reais (or just 2000 Dollars), doesn't that mean it is actually very cheap to make one in comparisson to cars?

hum 🤔 For example, if I used 72 5 ton hydraulic jacks that normally cost 100 Reais (19 Dollars) each, I would be expending 7200 bucks on the actuators alone, more 2000-3000 on the electronic parts including the hydraulic pump. This means this thing would cost kinda okay...? 🤔 (Not okay to me, I'm broke).

Off-topic:

Anyway, my brain is ADHD, and I will elaborate, and I won't make things clearer.

So, with this said, let's get back to continuum robots:

I found this continuum robot from the article: "Multi-Segment Parallel Continuum Manipulator".

You could replace the disk with cables/wires, no?

How to make this thing lift 1 ton, tho?

And it is cable-driven by electric motors, not artificial muscles...

Would it stumble the same problem I talked on Project Log 16? Where you need it to be so resistant to bending motion that it would simply become solid?

I don't know, it is morning right now, my brain isn't working properly (when it does, tho?)...

There must be a way of making this crap safe to be around that doesn't require the mech to look like a Michelin Man...

You know, it is not because it will look stoopid or anything like that, it is because it is not a definitive measure, it is merely an after-thought on the mech's core design.

It is merely an attempt to fix an unsafe design, instead of inserting the safety on its core design and mechanisms of operation.

Also, when I don't get an answer, my brain gets itchy.

It is like math: there is a solution, I just can't find the right equation for it.

Well, I just found this weird looking prothesis:

Not entering the merit of "if someone seriously gave me this thing after amputating my arm, I would beat them with it until they talk directly to jesus", but the structural design seems interesting.

Yes, I did say in Project Log 16 that "making something that bends at axis of rotation wouldn't change the fact that the limb should need to be stiff enough to not bend at 1 ton, and if it is stiff enough to not bend at 1 ton, it is surely hard as a rock".

However, I was wondering here that it would be possible to make these solid sections out of silicon rubber (or anything like that), and make it stiff by pulling the inner cable, and thus, creating tension that would create structural stiffness.

Doesn't even need to be actuated by artificial muscle/electric motor or anything like that, just a bunch of sections of a 30cm long "donuts" of rubber a inner cable of steel, aramid or carbon fiber would be pulled until tension and hold in place by a nut and bolt.

Like those packaging/cable tensioners:

Now, imagine this, but a cable/wire/rope going through the the limb "tube" and hold everything in place.

The cable/wire/rope can actually even be a spring.

But again, this still won't be enough (I think), because, as I said myself, it would be required to be stupidly resistant to bending action (aka "stiff") of 1 ton that it would probably be as dangerous as a fucking metal bar.

I know that is annoying for you, reader, to read me rambling again and again with the same result again and again, but it is also annoying for me as well.

I'm no scientist, but the scientific method is trying to prove your own thesis is wrong more than it is about proving to others that your thesis is "righter" than everyone's else.

And I try to follow this method, because if I deny that I'm wrong or anything that I do/did is incorrect, eventually I will make the machine in real life and I will eventually face the consequences of that.

I'm trying the best I can to make this thing work, but it is more likely that I will fail. But I'm going through it anyway :)

I just remembered one thing: If you put each page of a phone book one above the other, they will have so much friction between theen that not even two tanks can separate the books.

With steel cables is the same thing.

So, maybe, if you put the "rubber donuts" and the inner steel cables under tension to keep everything under tension and under friction, maybe you will be able to make it safe.

Nah, it will run in the same problem...

Everything would be so fricking easier if this was just a domestic robot or something like that...

But nooo, I need because I need a mech that can lift 1 ton...

Hey, looking at the bright side, this now seems very, very safe to use as an Exoskeleton. But forget about super human strength and feats, neither this nor your body will be able to withstand the forces involved.

Another off-topic even more off-topically:

I was wondering, if I use an oxygen concentrator and an air compressor to fill an air tank...

... And burned it in a rocket nozzle...

How much would that compressed oxygen gas fuel tank last? hehe

(I know, quite the stretch, let's just focus on making this thing work before thinking on how to make this thing rocket-dash)

Well, great, now my stupid ADHD brain is telling me to make a Hackaday project with flying ships...

A mech can be built in my garage, all the technologies already exist (hydraulics, electronics, actuators etc), but a flying ship?!

I would need to use a mix of hot air balloons (that have more bouyance than helium or hydrogen) and helicopter blades. I doubt I would be able to make such thing in my backyard...

70,000 liters of helium/hydrogen/hot air to lift 1 person weighting around 80-100kg, a bus sized balloon for every 100 kg.

I bet I won't be able to make a floating house any time soon. y-y

Why we can't have those in real life? Y_Y

Artist is Paul Chadeisson on Artstation, by the way.

... Although I could use the coanda effect with compressor blades instead of helicopter blades... 👀

Even though I kinda wanted to use the way cooler ionic thrusters... And I feel like I actually can make ionocrafts at home, since they don't need complex manufacturing and expensive materials... hehe 😏

Forget it, these aren't efficient, you would need 1 watt per gram.

I just found out something incredible interesting (at least for me).

AS YOU CAN SEE ON THE MINUTE MARK 7:28, when you mix galinstan (gallium alloy), aluminium and water, you get pure hydrogen and aluminium oxide, and you can reuse galinstan as many times as you want.

Which this means, that you can make an hydrogen engine generator (or catalyzer) merely using aluminium and water.

And galinstan is pretty easy and cheap to make:

This is really really cool for power generation!

Enough of tangets! Let's get back to the real topics before I put too much stuff on this project log and end up with the same problem as Project Log 16!

Oh... Oh no...

The site is already lagging.

Me running to tell everyone 30 pages worth of random useless facts that nobody cares:

1. Hydraulic Accumulators:

I know that I said that pneumatics are dangerous, but as shown on the video below, the bigger the area the pneumatic actuator applies, the lesser the pressure required to do the said work.

At time 3:51, they show almost a ton being lifted with just 1-2 PSI of air pressure in the air cushion.

Meaning that I don't really need super strong, big and havy hydraulic accumulators in order to supply this thing.

I just need a bunch of "pancake" like hydraulic accumulators stacked or around the pilot's cockpit in order to supply the mech's body.

My only concern is finding out if the hydraulic pump is capable of supplying enough pressure/liquid to the thing.

Luckily, I found some online Hydraulic Accumulator Volume Calculator, so let's list what we need.

- Since the area will be so big, I intend on making it like an actual pancake with 1 meter in diameter.

- 5 to 10 cm of height.

- All of this would have a capacity of 10 gallons or 40 liters.

- The pressure inside the balloon will be 1-2 PSI.

- The pressure we can produce is 0,4 MPa, or 58 PSI, or 4 bar.

- We can achieve only 8-15 Liters per minute of fluid flow per pump (if I don't buy an actual hydraulic pump).

- We need a fluid flow of 900 liters per minute.

Accordingly to the calculator above, I would only be able to provide 0.04 gallons of hydraulic fluid, which is 0,1514165 liters.

I need 43.2 liters to actuate all muscles at once.

I guess I will be forced to severely increase the pressure inside the acumulator (or find a better calculator).

The thing is that I don't actually need to make the pressure inside the accumulator to be the same as the final pressure in the muscle (0,4), I can increase the pressure of the liquid more more when it is inside the accumulator and then use a pressure gauge to reduce the flowing pressure to just 0.4-0.8 mpa.

The problem is that I can only produce 4 bars with the pump...

Accordingly to this Online Hydraulic Accumulator Calculator, I would need to charge the Hydraulic accumulator with 16 bar of pressure.

Maybe I will need to use an hydraulic pump fill the hydraulic accumulator, and then a pneumatic pump to fill up tires that achieves 300 PSI (2 MPa or 20 bar) to fill the bladder.

And then when the accumulator is empty, I will need to empty it with a solenoid valve and repeat the entire process. Again.

By the way, if I increased the pressure up to 300 PSI in the first calculator, I would get 1,72 gallons, or 6 liters.

Now I finally get the severity of the situation I've put myself in...

All of this work and headache, for a single actuation of all muscles in a single second.

43 liters per second... 900 liters per minute...

It seems I will need to use that 3000 watt/hour 1 horse power electric motor to generate enough pressure for a couple of contractions for every minute.

Oops, I just forgot, it is not 43 liters, it is 5 liters to actuate all the muscles at once.

We are back on schedule bois!

dang...

Now I need to figure out how many pancakes I would need. Since only one pancake is meant for 1 second of actuation of all muscles at full strength, which won't happen, but it is a good margin of error.

So, if one pancake has 40 liters of capacity and the hydraulic pump that I plan to use has 10 liters per minute of capacity, I would need 4 minutes just to fill up the damn thing and more 8-10 minutes to fill the pneumatic bladder. I say 8-10 minutes because the mini-air compressor that fills up tires normally says they can fill a tire (of unknown size) in 8 minutes or less, but knowing what marketing does, it is probably more, way more.

However, these same mini-compressors are like, 50-80 brazilian bucks (more or less 10 dollars), so I can use multiple of them on the same bladder. So I can actually reduce the charging time to 5 minutes or something.

10 minutes of charging for 3-5 steps...

Then I need 2 hydraulic pumps, with 20 liters per minute, and 4 fricking air compressors.

Then I will reduce the time of charging to 2-5 minutes... And increase the cost of energy to...

Assuming each one of those consumes something around 100-200 watt hour, I would consume 800-1600 watts in an hour.

Well, I kinda feel like I would need the air compressor anyway, because:

- I don't need the hydraulic pump to work all the time.

- I don't actually need to make the entire system flow that fast.

- I would do the same thing of filling the bladder after filling the hydraulic accumulator with hydraulic fluid.

Assuming that these are working full throttle, non stop, for an hour...

Which won't happen, the stupid mini air compressors require something around 10 minutes of" rest" because their electric motors overheat (accordingly to the sellers themselves).

Well... It seems that the "bottle neck" here is the air compressor, ironically, the hydraulic compressor... That were meant to stop the bottle neck of the hydraulic pump...

I guess I will be forced to use 3000 Watt hour electric motors with hydraulic pump...

... Which may also not work.

Simply put, this consumes 3000 watt hour producing 900 liters a minute at pressure of 4 bars or less. This means that the hydraulic accumulators won't be able to hold enough pressure to spill enough hydraulic juice.

I need to keep that fricking thing at 300 psi in order to produce 6 liters a minute.

If I where to increase the pressure inside the hydraulic accumulators, I would need to increase the pressure in the hydraulic fluid, and to increase the pressure in the hydraulic fluid, I would need to reduce the rpm and increase the torque of the hydraulic pump.

... For 6 liters per minute of fluid flow...

Also: I didn't finish watching the videos teaching how to size a hydraulic accumulator, nor did I include the fact that it is a pancake hydraulic accumulator, which translates the large area of pressure into faster fluid flow with lower pressure.

Actually, I will just ask around, this time there is no way people will get mad at me saying the question is stoopid.

(I already got a post removed from one of the websites I asked lol)

On this reddit question, someone said that this pancake hydraulic accumulator would produce 15 liters at 4 bars if I filled the bladder with 8 bars.

So, 4 minutes to fully fill the pancake, but that is kinda wrong, it doesn't have actually 40 liters of space inside that, because the bladder is occupying space.

So, let's say, 2-3 minutes to fill a single pancake that would allow for fully actuate all 72 muscles for a second 3 times.

Which would allow for 6 actuations if half the muscles were actuated instead of all of them.

And since this is 3 actuations per second, I would have ±2 seconds of autonomy.

So, if my brain is preoperly working (it is not), I would need around 60 pancake hydraulic accumulators and 60 pumps to fully work for 2 minutes without stopping.

Yeah, forget this system completly based on hydraulic accumulators guys...

I feel like I'm not putting enough effort on this project log, for some reason...

As google put it into better words:

Its function is not meant fo be used in the place of a hydraulic pump.

It would be meant for a "jump" or something like that in the case of a mech.

Besides, 3 actuations per second is the maximum number I estipulated if this thing where to be running at maximum speeds.

It could be only using 5 liters per second or even less while walking.

Anyway, If I where to use 3000 watts per hour (assuming it is actually 3000 watts and not a lesser number), I would need 1 car battery per hour.

Of course, if I were to work lifting weight, run and fight aliens all day, I would need 24 car batteries that have 3000 watts per hour of capacity.

Obviously, for matter of costs and practicality, I would be limited to 4-6 car batteries (or a battery pack with 18000 watts hours to consume 3000 hours throughout these 6 hours of ful "throttle" working.

Now we are reaching another bottle neck, I need to properly calculate the energy requirement for the hydraulic pump.

The problem is that I can't find that damned stupid dumb 1 hp DC motor from Project Log 16.1.

By the way, assuming the 1 horse power of that big ass DC electric motor that I showed on Project Log 16.1 actually consumes 743 watt hour and it is its actual power consumption, these 6 car batteries would allow for more or less 24 hours of work if you were to actuate all muscles at once continiously, without losses due to efficiency and so on.

But since you won't actuate everything at once, you would probably be able to last even more.

Also, another note: I do have plans on using DIY Thermoelectric Generators (also known as "Seebeck effect generators"), solar panels and maybe DIY Stirling Engines in order to squeeze more autonomy and cheaply recharge over time.

Or using the Galinstan-Aluminium-Water Hydrogen generator I talked about in the Off-topic part. But that is a headache for another time.

I just found this direct current 1 horse power 745 watt hour that can achieve 3000 RPM, however, I will keep it at 1000 RPM.

The details:

- Motor 24V DC - 750W

- Voltage 24 Volts DC

- Current (min) 4.5A

- Current (max) 40A

- Power 750W

- Speed 3000 RPM

- Torque 1.75 Nm

- right/left rotation

- Weight 4 Kg

Welp, it looks like a good candidate.

2. Costs:

Okay, one problem that I severely overlooked was the expandable braided sleeve. You know, the "core" of a McKibben artificial muscle.

Yes. I'm stoopid.

Basically, assuming that I will make every single one of the 72 muscles the same length (30cm) and without making mistakes (which I will), I would need 2160 cm of braided sleeving. Or 21,6 meters.

Which is not that much...

... If I weren't in use of costumized artificial muscles.

But as I said on Project Log 14: I would need muscles that have 14 cm of diameter.

I can only find at maximum 1 inch diameter braided sleeves made of nylon, which means I would either need to make it myself, or pay supplier for costumized braided sleeves out of steel.

However, there is another option, that I also don't like very much...

Using fabrics:

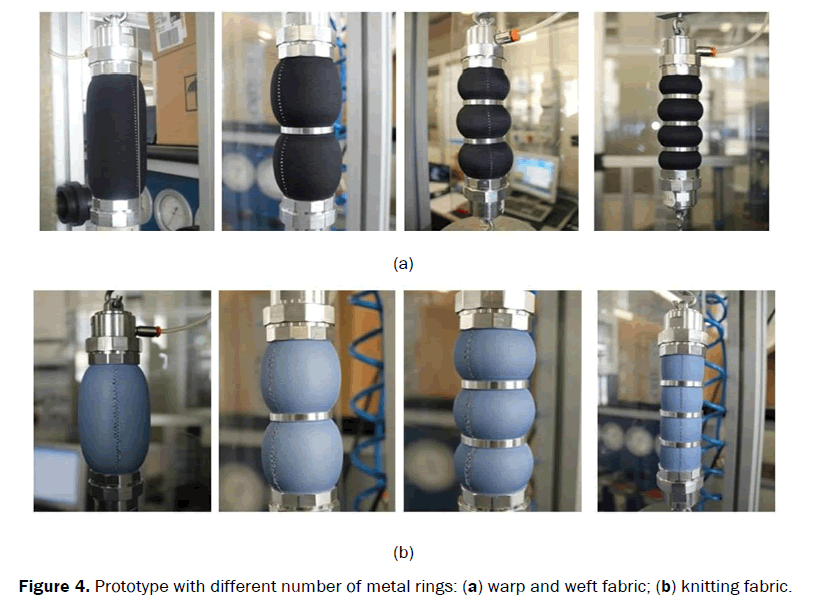

Taken from the article: "Textile Pneumatic Muscles" and "Soft Pneumatic Actuators for Rehabilitation".

I could use any kind of fabric, including those steel woven wire mesh screens:

Of course, I was thinking on using the 400 mesh.

But, as you could see in the first image: I would need to sew its sides, which will diminish the rate of contraction and it will be the first part to fail.

Well, right now I'm sending an email to some braided sleeve suppliers that I could find. Let's se how much it will cost...

And no, I definitely cannot buy or make a reliable braiding machine at home, just look at this thing working:

These two options could help me out:

The first is a handle, which I don't know if it would be suitable for expanadble sleeving.

The second is the Chinese Finger Trap that I talked about before.

The problem is that both are too different from the original McKibben sleeving, and could drastically change the final result.

But taking into consideration the points of failure and disadvantages each brainding method has, I believe that a single metal rope like in the first example.

Well, I received their answer today, and basically, they all say that "it is too big of a diameter to be able to make it custom" ( ͡° ͜ʖ ͡° ), and they also don't have the capacity of testing if such thing will be able to withstand 5 tons.

Well, hand made it is...

... Or maybe not.

You see, one problem of McKibben Muscles where the outer sleeve doesn't have holes smaller than 1 is that the inner bladder rubs itself on the sleeve; which increases the chances of rupture.

This shows a good example.

A solution would be to actually use multiple layers of net/sleeving in order to decrease the space inbetween the holes.

But it would come at the cost of increasing its resistance to expand the outer sleeve.

And yes, I'm also considering the Chinese Finger Trap braid. But again, it will come at a cost/disadvantage that I don't fully know yet...

ANYWAY, the actual subject: Costs.

Like every fricking Project Log, I will only make assumptions here.

- DC Electric motor 1hp 750 Watts = 1000 Reais (188,93 dollars)

- Each muscle uses around 2 meters of steel wire/cable/rope, so 144 meters of steel in total = a random bobbin of steel 2,4mm of diameter with 200 meters is 250 reais (50 dollars).

Actual winch rope that can withstand around 6 tons made of nylon or polyethylene is 200 reais per 10 meters, so 1440 reais (272,06 dollars) in total for all muscles (if I don't make mistakes and end up wasting rope).

Well, I added this last part because maybe that's the better option for redundancy, and also I don't actually need the rope to withstand 6000 kg, simply because there will be a lot of cables in a single muscle.

Only by testing I will have a definitive answer. - Each piston pump is a pneumatic piston that may or may not break during the extreme 1000 rotations per minute of continuous work = 50 reais (9,45 dollars) each. I need 10 = 500 reais (94 dollars) in total.

- Each car battery costs 1000 reais (188,93 dollars), I need 4 to 6 = 4000 reais (755,71 dollars) to 6000 reais (1133,56 dollars).

- So, 1000 + 250 + 500 + 4000 = 5750 Reais (1086,33 dollars) the hydraulic system alone.

Or 1000 + 250 + 500 + 6000 = 7750 Reais (1464,19 dollars).

Or 1000 + 1440 + 500 + 6000 = 8940 Reais (1689,01 Dollars).

Well, who would guess that mechs aren't cheap, imma right?

Of course, you could obviously wait for discounts, find parts on scrap yards and so on (which I'm planning to do) make the motors, pistons and batteries by yourself for way cheaper.

There is a lot of shortcuts for the prices, but I'm just listing here.

Anyway, I'm finally done with this god dang Project Log.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.