Today I need a high speed printer and I have one. Kingroon decided to share with me their entire line of 3D machines.Hello my friend! Today I decided to assemble a simple pneumohydraulic generator or ROSH Generator)) operating in air. On the Internet, it looks very nice. I doubt that the efficiency is greater than unity.

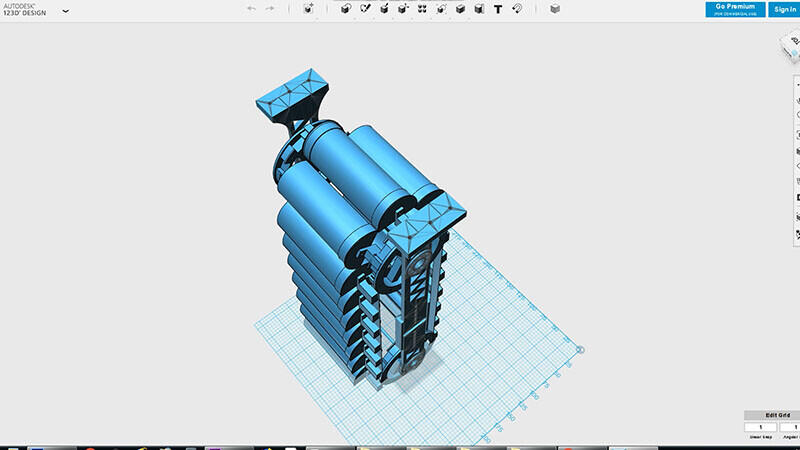

I will not draw a drawing on a piece of paper for you. There are many different sketches on the Internet. Let's move on to 3D modeling. I create gears in SolidWorks. If something simpler, then in a program from Autodesk.

Today I need a high speed printer and I have one. Kingroon decided to share with me their entire line of 3D machines.

This printer model is fundamentally different from previous versions. In my opinion, on such a machine, you can increase the speed by 2-3 times.

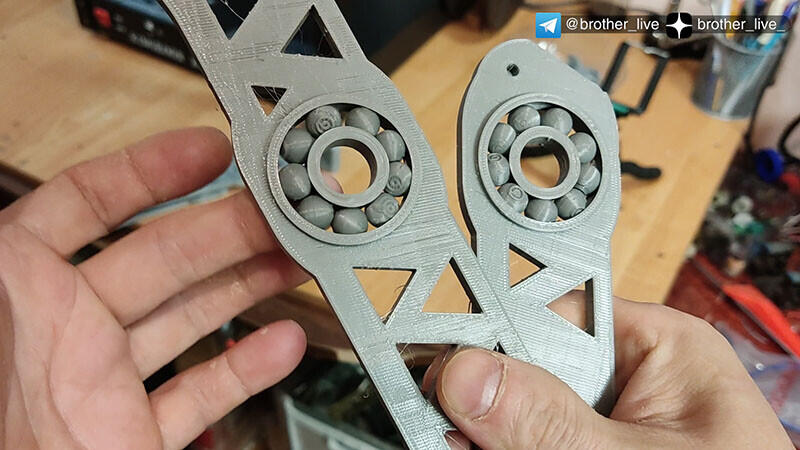

This whole structure will work in water, so I got the idea to imprint plastic bearings in the rack. 10 years ago, this would never have crossed my mind. I am still amazed by the technology of our time.

I typed for a very long time and tediously because, well, everything does not work out right away. Of course there were some errors in 3D modeling. The pieces just didn't fit together. Conveyor wheels reprinted five times. I will grind all the defective parts, pass them through the extruder and print something again. Thus, the polymer will not go to the landfill to pollute our beautiful planet!

That's how many spare parts have been printed on this machine and, most importantly, several times faster!

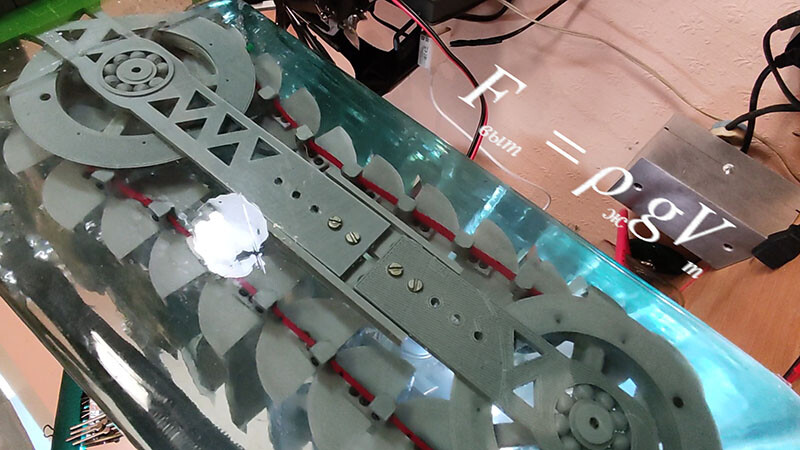

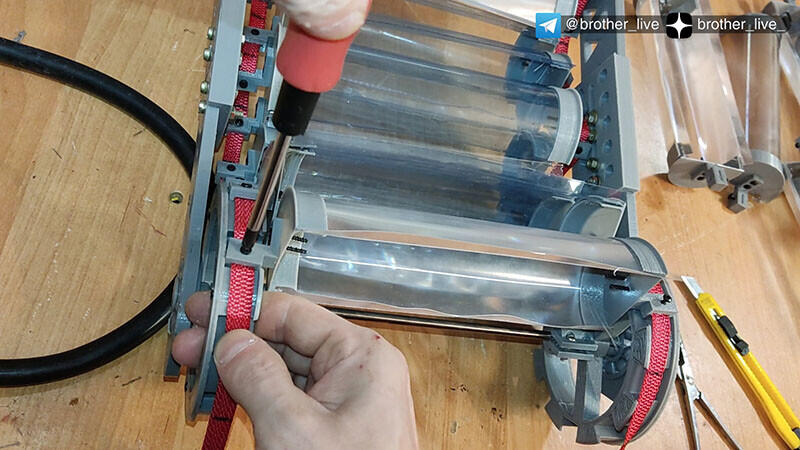

I took organic glass from an old LCD monitor. It remains to collect the air tanks, although what I say .. There is still so much to do. It turned out to be a very dreary, long, assembly.

You can’t do without PET bottles, this material is used in almost every homemade product. The bottles were previously worked out by pumping air into them. And heated with a hair dryer to align the plates. I had to perforate one side.

I decided to fasten all the tanks with tape. Hopefully this type of material is synthetic and won't stretch.

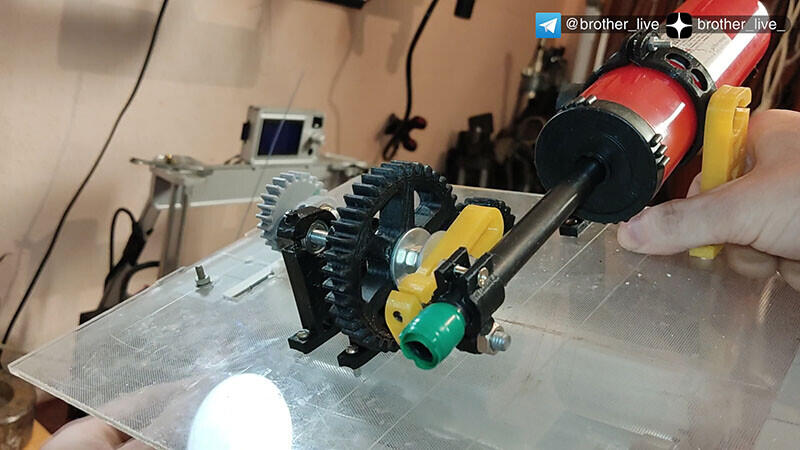

Let's try to adapt some of our pump to self-feed the generator. Will it suddenly work? And again I will resort to a simple program and print. In this case, I'll try to print ABS plastic for some reason, for some it's a very complex material. Nozzle temperature 240 degrees, became 90 degrees.

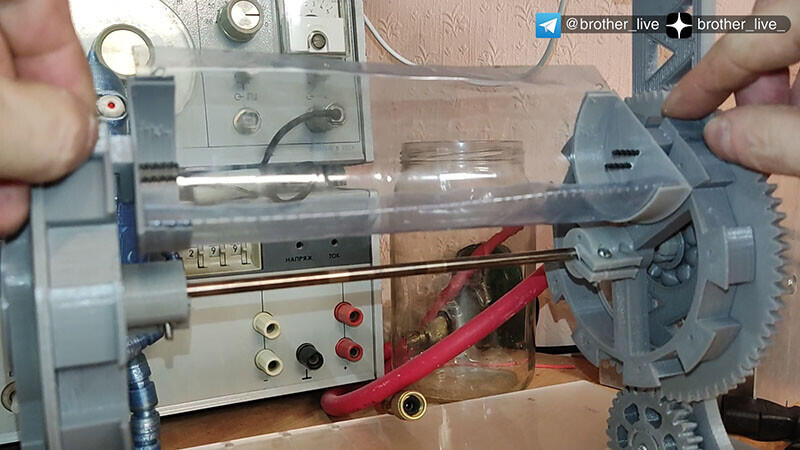

I have several pumps. I'll try to use the middle one, the more it swings in both directions.

In addition, I will put another air duct to try the start with an additional pump. And suddenly it starts...

In general, such a game turned out, a regular pump. For now, I will try to hook it with a launcher. Everything works fine without any load. Here you need to play with the gear ratio of the gears.

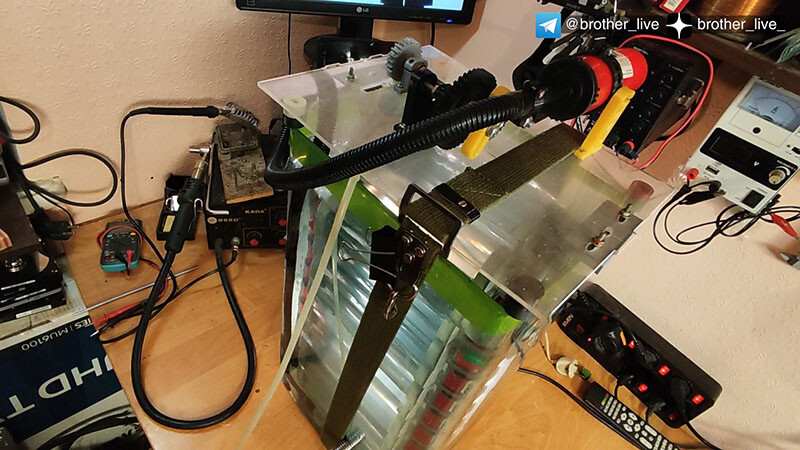

When I pump the auxiliary pump, air also comes out of the main tube. Unfortunately this is not enough. Look carefully, the pump that is hooked into the system also supplies air.

But, unfortunately, he cannot work for himself. ((

This test showed disappointment and victory at the same time. Now we see that this system does not work. Although with the correct calculations, it seems to me that it is quite possible. It was not possible to start autonomously, a little lack of air. Sometimes she does 2 turns herself. What do you think, is it possible to put such a device on self-starter? Maybe a reduction ratio? In general, I think that the capacity is very small.

brtv-z

brtv-z

Tinkers Projects

Tinkers Projects

Dominik Meffert

Dominik Meffert

While none of the perpetuum mobiles (or over-unity machines if you don't speak Latin) work they all do a very fine job in showing where their creator's understanding of Physics ends.