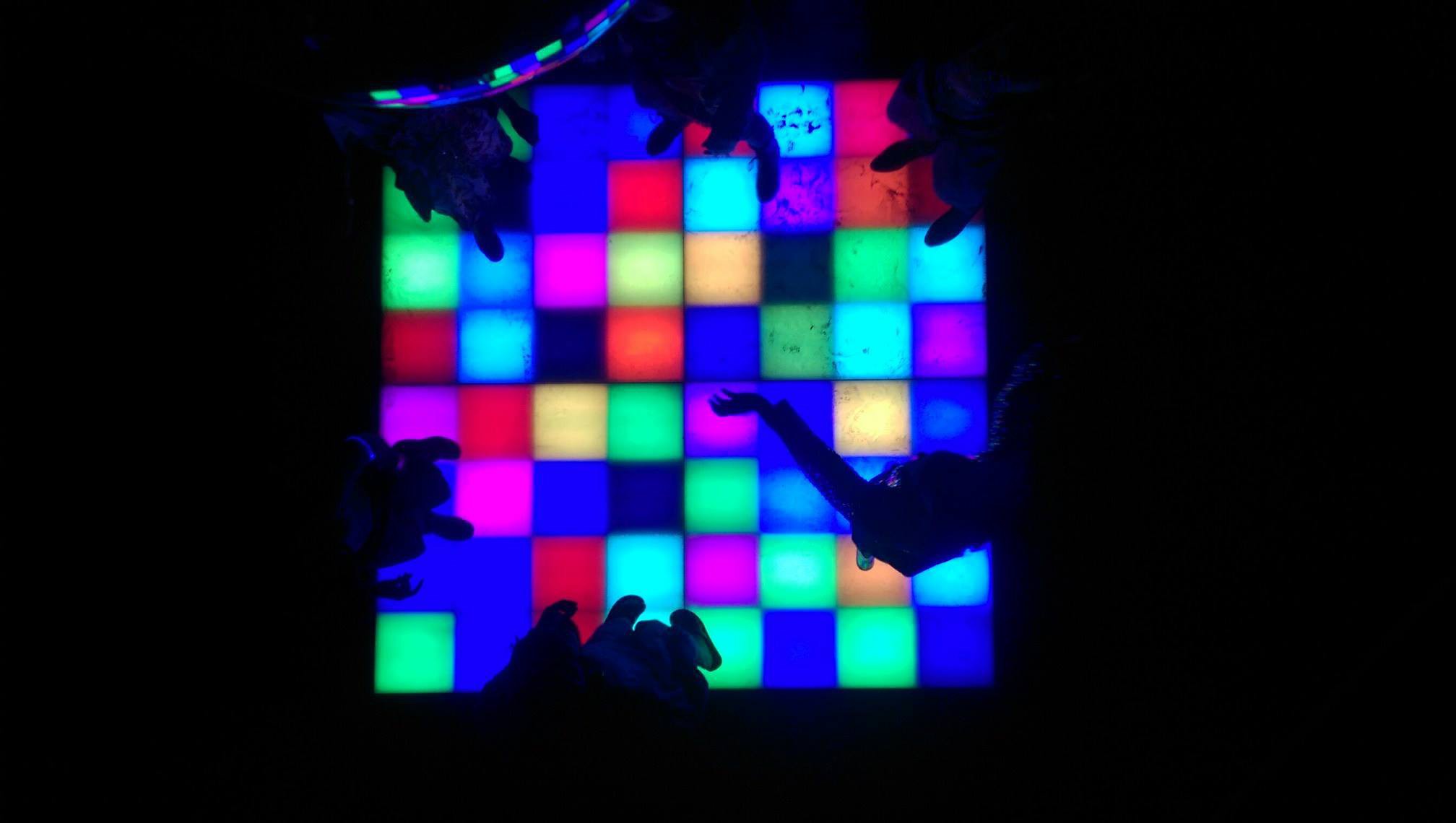

Back in 2016, I made the original interactive dance floor, and ever since then, I've wanted to rebuild it from scratch and make it better.

Project goals:

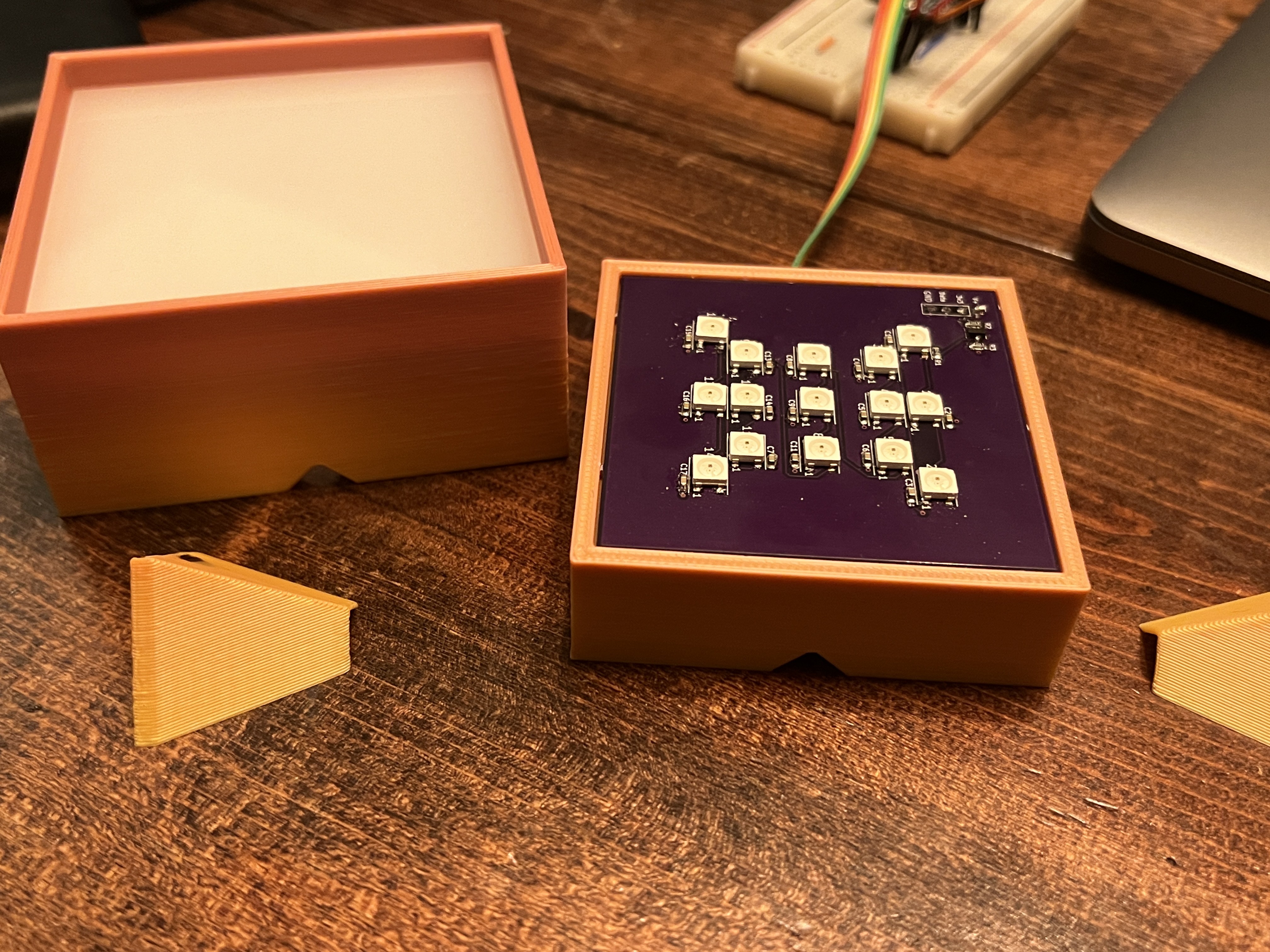

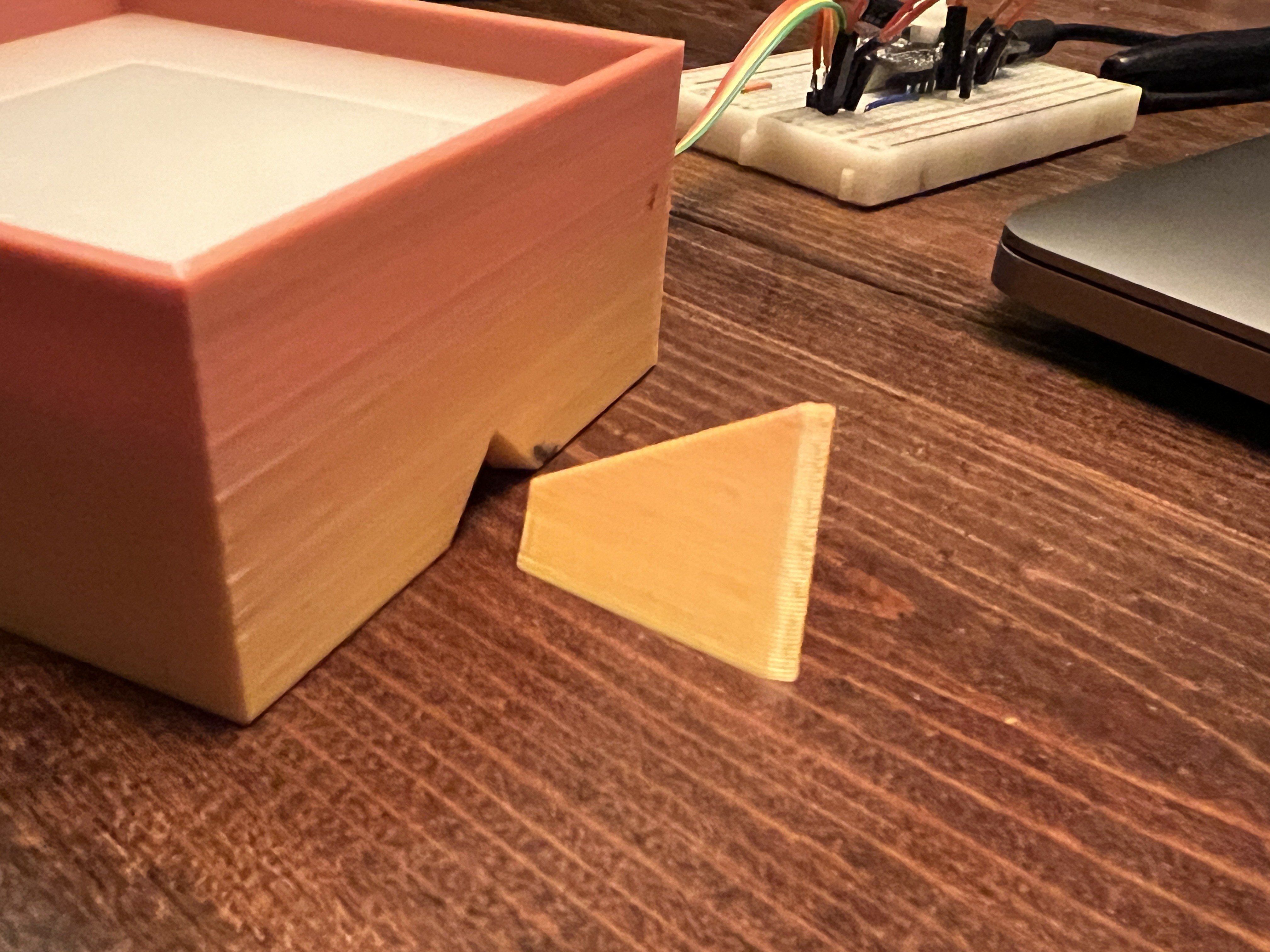

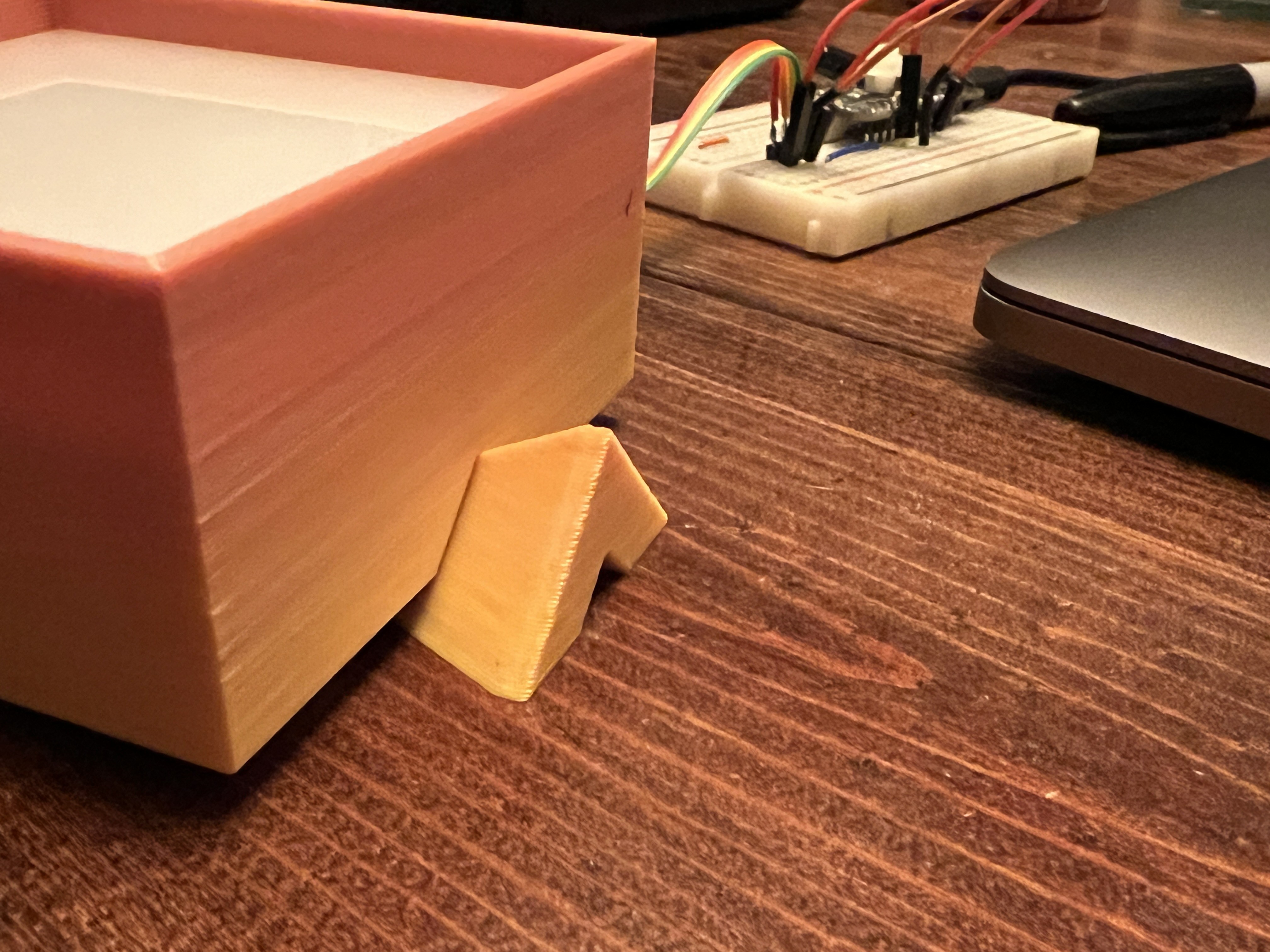

- The floor will be constructed of small modular panels that snap together (~15" x 15") .

- Each LED "pixel" on the floor will be between 1" to 2.5" squared.

- The entire floor will be a giant capacitive touch screen.

- Animation programming will be PixelBlaze compatible.

Jeremy

Jeremy

mclien

mclien

Ian Norton

Ian Norton

Alex Rich

Alex Rich

Jorj Bauer

Jorj Bauer