Hello everyone!

It’s been a while since I’ve uploaded a new post. During the time, I was working on a project and it has been just over a year since I started. I wanted to challenge myself to build a hardware/software product from scratch.

Introduction

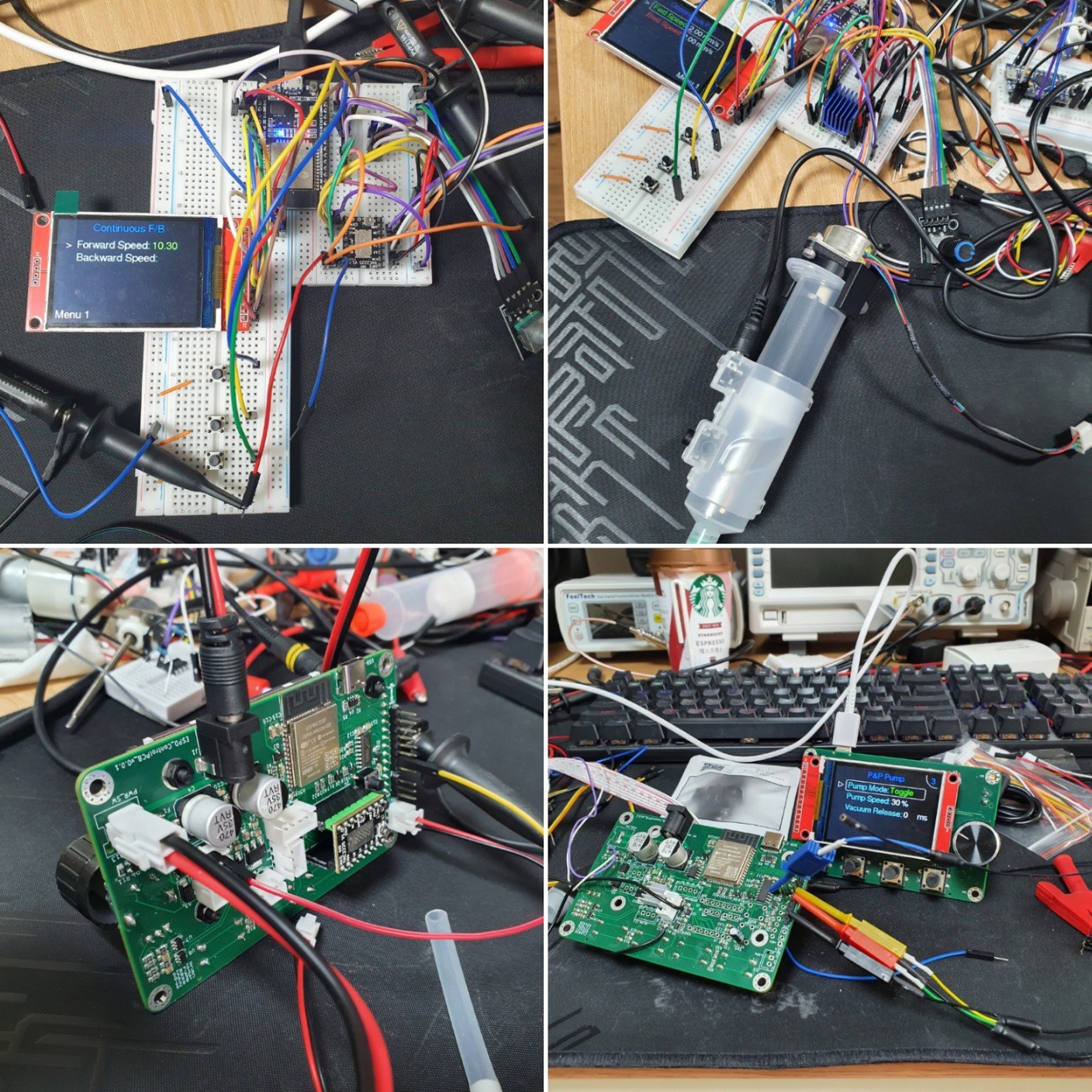

The project is named “ESPD”(electronic solder paste dispenser) 2 in 1 device, paste dispenser with pick-and-place pen

This project is targeted for people who are into one-off prototype PCBs, PCB rework/repairs, hobbyist and more!

A brief description about the project

- 2 in 1 device, electronic solder paste dispenser with pick-and-place vacuum pen

- Stepper motor is driven by TMC2225 driver, enabling StealthChop2™ for silent motor operation (drive current, microsteps configured via UART mode)

- Maximum linear resolution of 156.25nm per motor step (theoretical value)

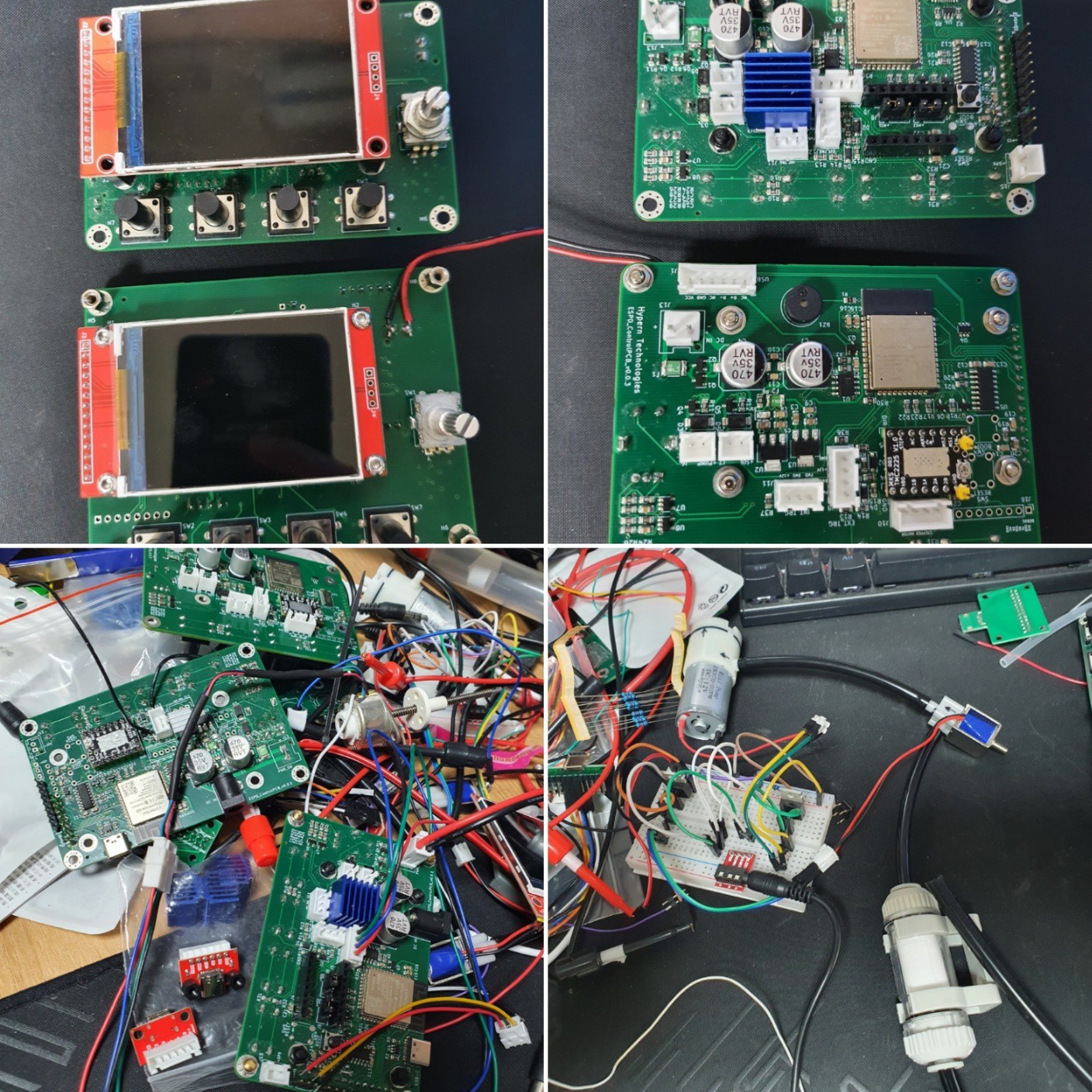

- VPD(viscous paste dispenser) is design around industry standard EFD 30CC syringe, incorporates twist-on locking design, easy to remove and replace between different syringes

- Lightweight VPD design, maximizing comfort for extensive use

- Interactive & user-friendly HMI/GUI interface, based on a 2.4inch 320x240 color TFT LCD display. 4 tactile buttons, forward, backward, menu, scroll, 1 rotary encoder with push button

- DFU via USB connection, (latest firmware version v0.0.12) general UI layout, 4 main menu screens 1. Continuous F/B, 2. Toggle F/B, 3. P&P pump, 4. Device parameters

- Independent internal air system, user replaceable inline air filter(inlet), 2 air lines, air in/out

- Control PCB v0.0.6, 5~24v forward, backward external trigger input. USB ESD protection, DC power-in fused, reverse polarity protection (new v0.0.7 on the way, added additional external trigger for existing menu, scroll, opto-isolation on all external trigger input pins

- Fully electronic, no external air supply needed

I need your help to make this project out to the market! Any feedback or questions would be very much appreciated!

Thanks!

Jung Hoon Lee

Jung Hoon Lee

Mirko

Mirko

Chris Chung

Chris Chung

h2w

h2w

ironBit

ironBit

Hello Jung

thanks for amazing project

I have some questions

What if solder paste have air bubbles, are it effect on motor force?

What's type of motor and are it have gearbox ?

I hope to make one like yours if you are able to share some information about it to build one like this will be appreciated