Youtube channel with short videos

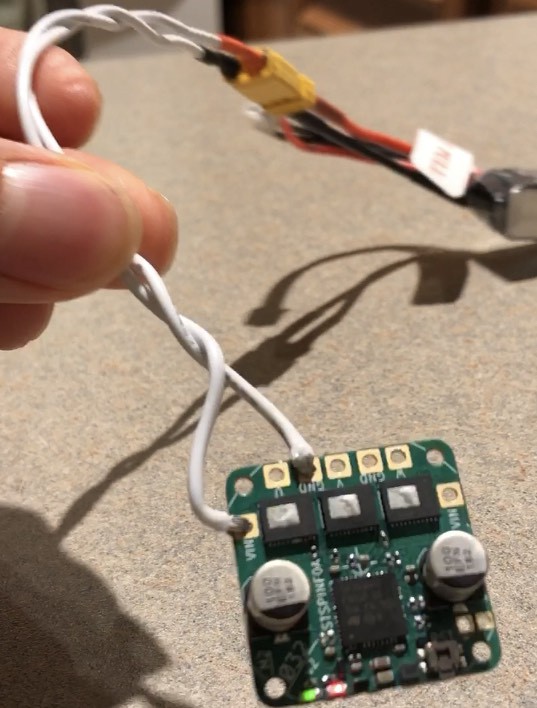

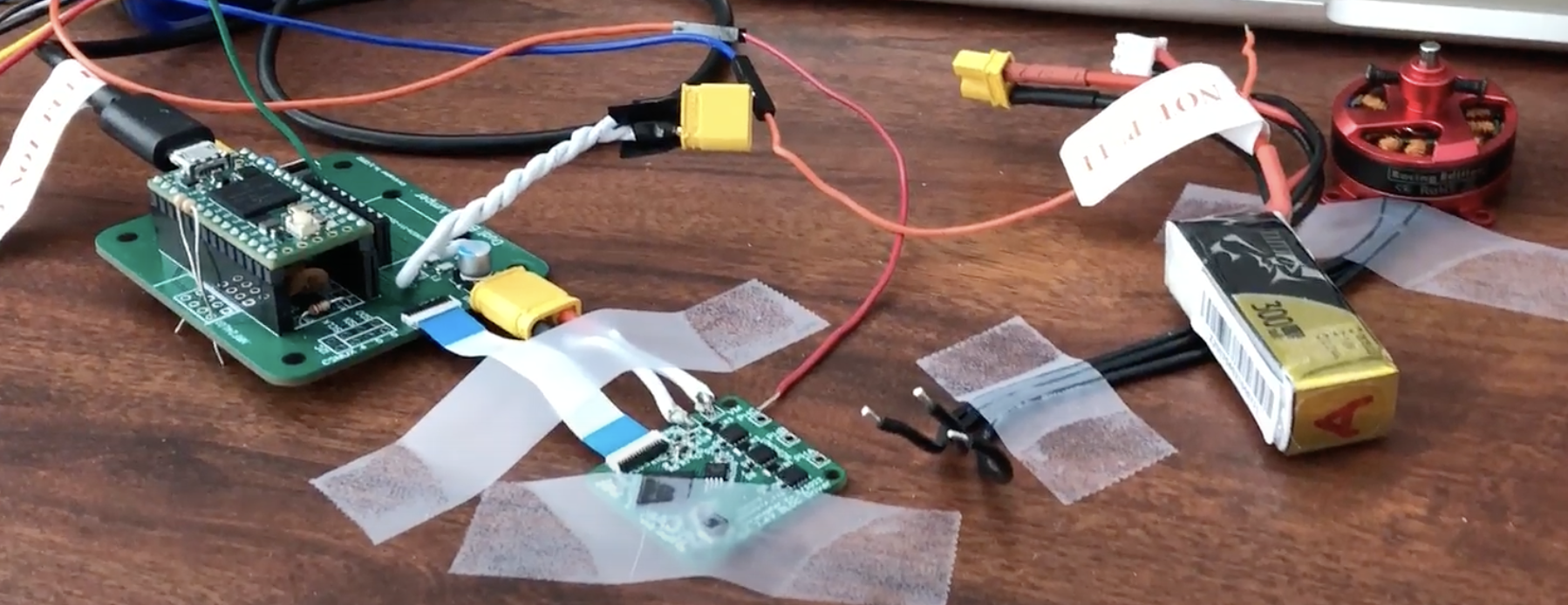

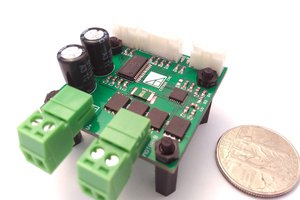

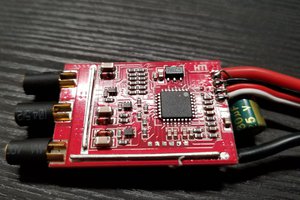

Application project of motor driver

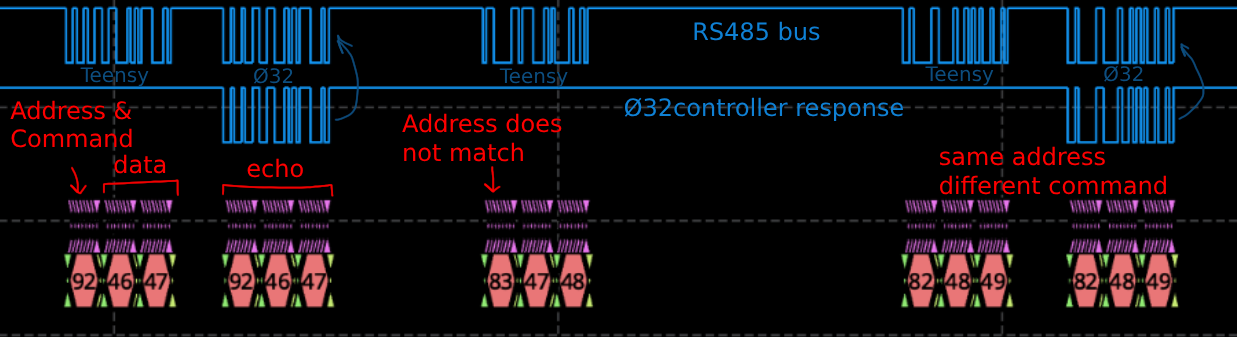

Works with my RS485 controller

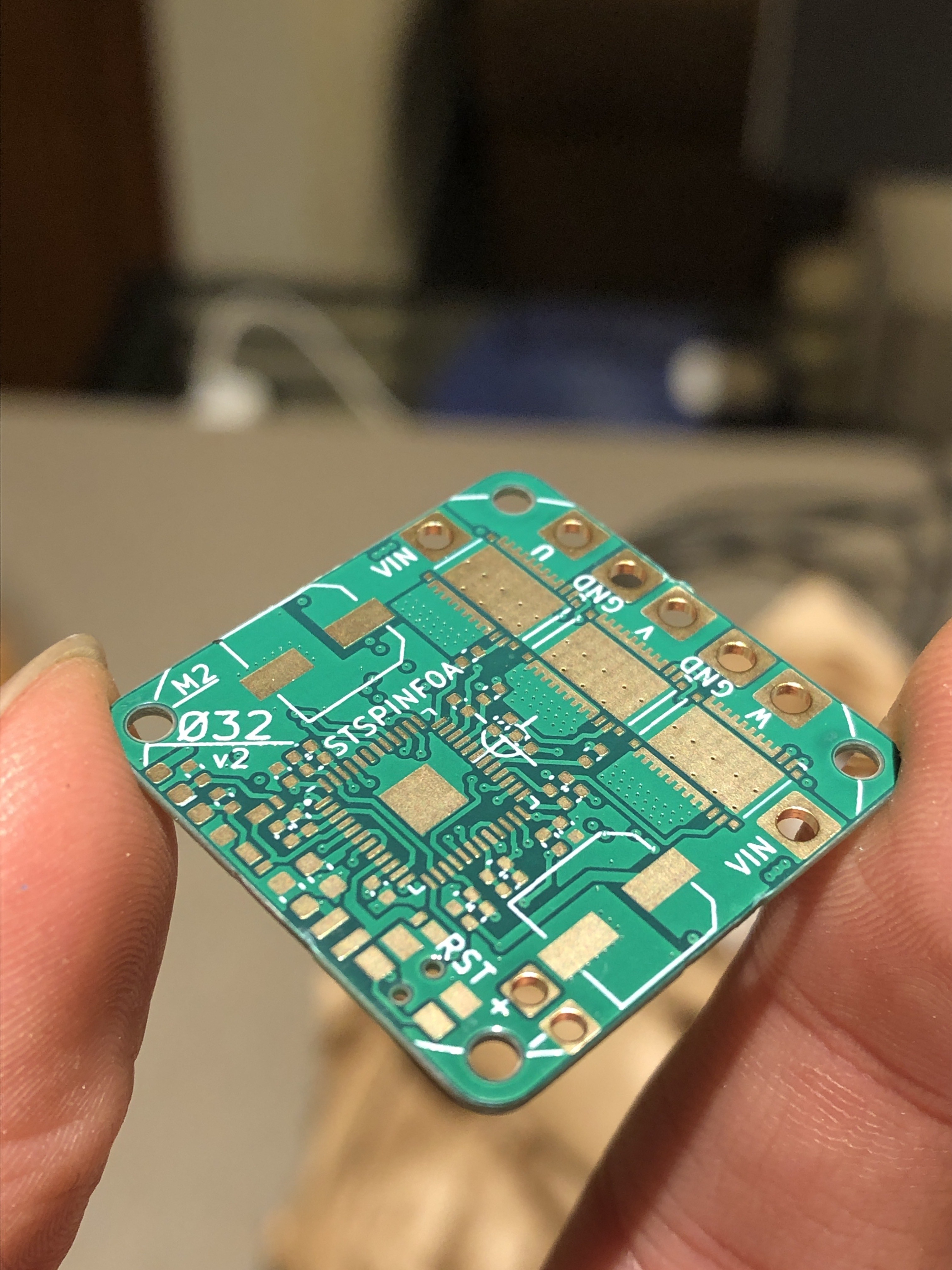

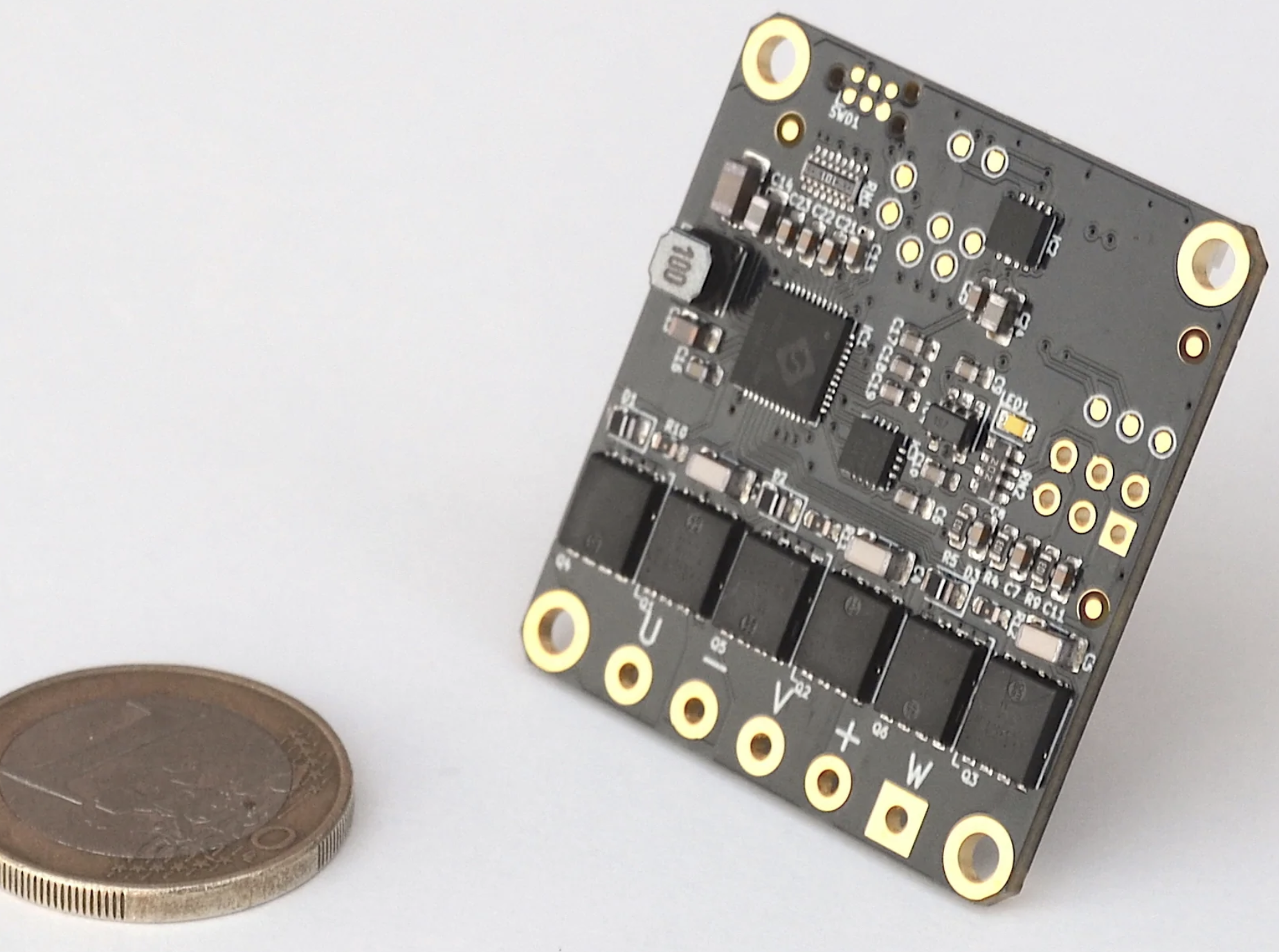

Specs:

- M2 mounting holes on a 32mm diameter circle

- 27mm x 27mm x 0.8mm, 4-layer, 1oz copper PCB

- 7-15V input, built-in voltage sensing

- Internal temperature sensor

- 12-bit magnetic angle sensor

- 3 shunt current sensing and overcurrent protection

- 2x 2-pin JST-SH connectors for I2C for RS-485 communication, allowing daisy chaining

- 1x 4-pin JST-SH connector for Serial Wire Debug programming and UART output

- External SPI for mounting encoder farther away

- NTC thermistor for monitoring coil temperature

Critical components:

- STSPIN32F0A BLDC gate driver and Cortex-M0 MCU

- MA702 magnetic angle sensor

- CSD88584Q5DC dual MOSFETs (40A continuous)

Tested:

- 12200 rpm with a 1800KV motor

- 12A bus current at full torque stall

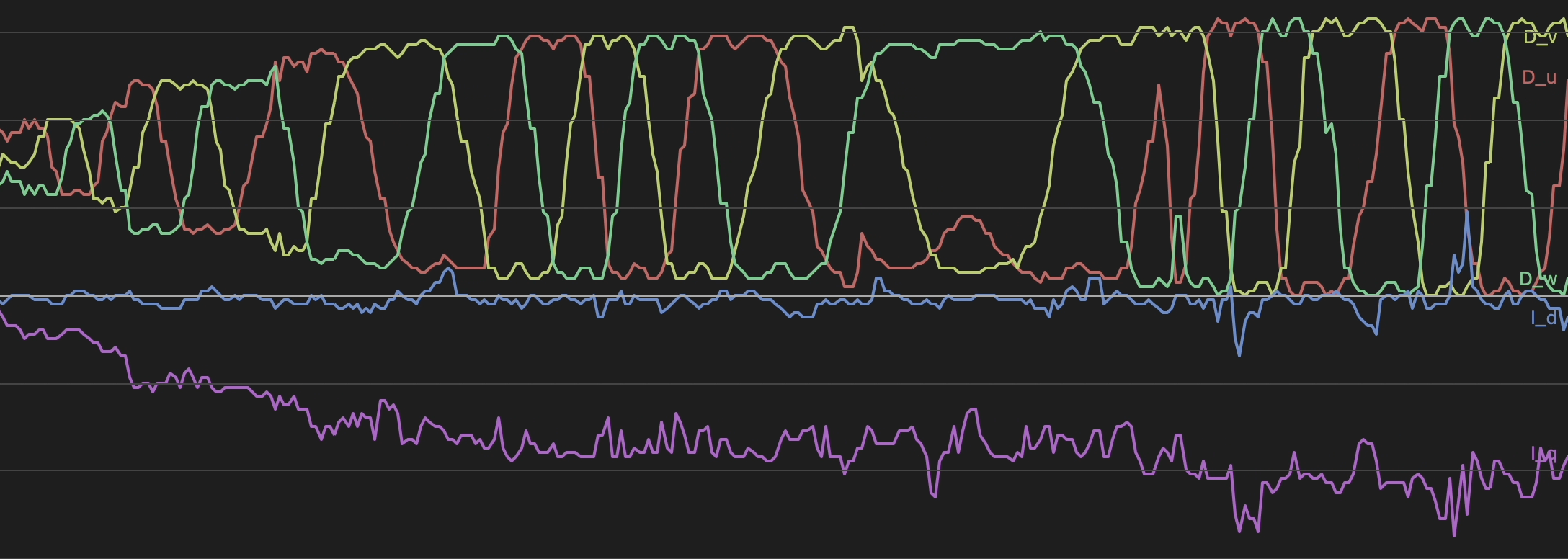

- Position, velocity, voltage, and current control over RS485

- Field oriented control (FOC)

Should be possible:

- 50A continuous, 110A peak phase current

- Temperature-dependent current limiting

Status: Currently working on NTC temperature monitoring and current control loop gains

Christopher Xu

Christopher Xu

ottoragam

ottoragam

Anthrobotics

Anthrobotics

Peter Wasilewski

Peter Wasilewski

Paul Gould

Paul Gould

Do you wanna make regenerative braking a feature in the future?