What a drift car is capable of out of the box and how it works, I showed in the first part of my video.

What a drift machine is capable of:

-The charge of the native battery is enough for 10 minutes, after 7 minutes the car just drives without drifting;

- Discrete control;

- Police lighting;

- Drift around;

- Drift eight.

What do I want to do?

-Make front and rear lights;

-Introduce completely your own homemade electronics with proportional steering and gas control;

-Write a program for the typewriter and remote control;

-Put 3S battery;

-Add music to the machine with the ability to switch it from the remote control;

- Make the backlight on the addressable LEDs with the ability to switch it from the remote control;

- Servo steering wheel control;

- And perhaps everything!

Drift car device and prototype

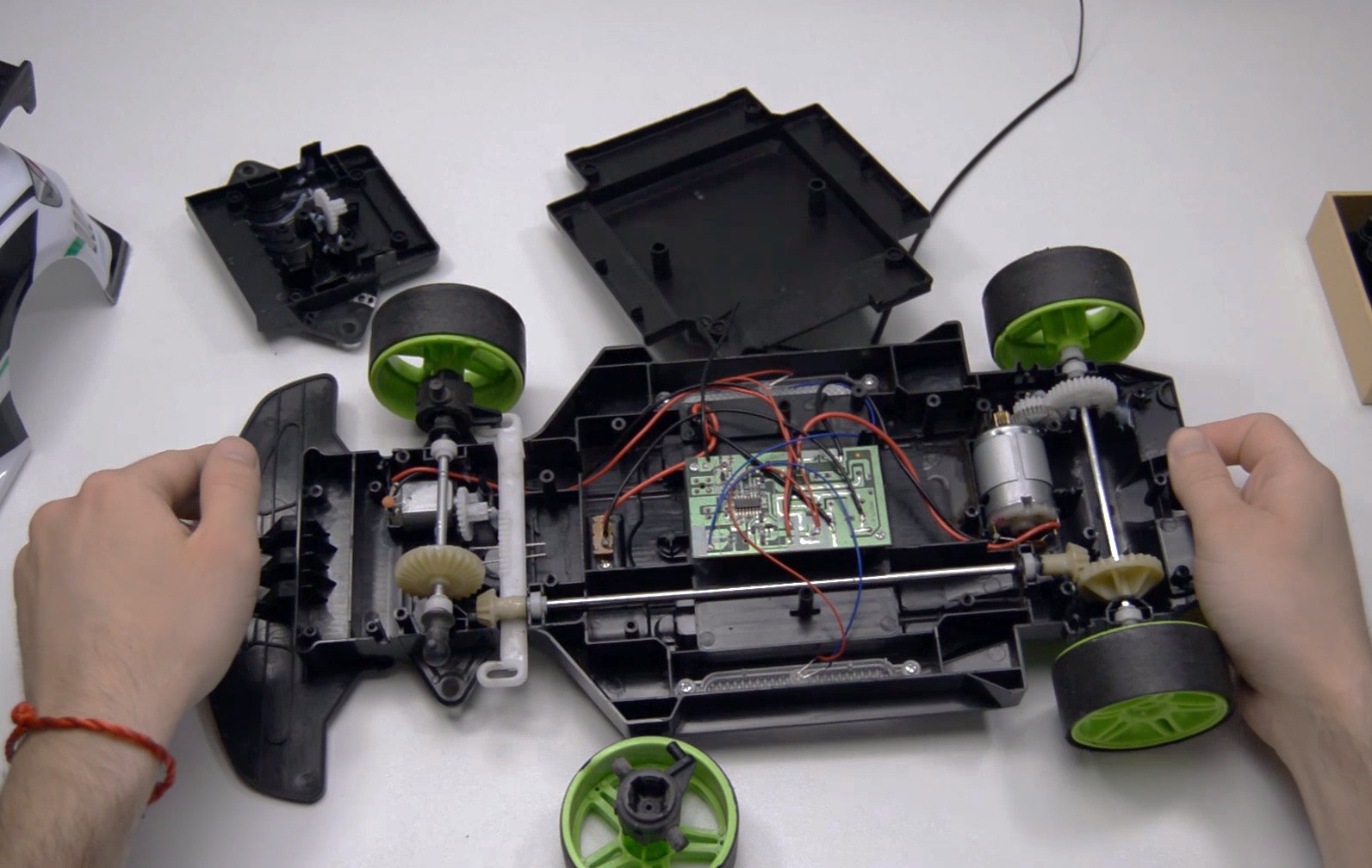

I started reworking the machine by disassembling and studying its device. I took off all the native electronics with the steering mechanism and began to think about how and where to place all the components.

In this project, I have identified two difficult places for rework:

1. Steering.

- I have a rough idea of how the steering should work on a servo, but how to place it and will the small servo have enough power? For me, these were the main questions and fears.

2. Alteration of the remote control.

- Since the native equipment of the drift car has discrete control, it will be difficult, according to my feelings, to convert it to proportional control, because you need to somehow build variable resistors into the remote control, but what if it doesn’t work out? Well, as they say, the eyes are afraid, but the hands do!

It is very important in projects to find difficult places or things that cause the most problems, these things need to be done first and after solving all the difficult tasks, do everything else. It would be very stupid to abandon the project at an almost finished stage, when all the simplest things have already been done, but you cannot complete the project because of 2 difficult tasks that you decided to postpone. As a result, you get an abandoned project that needs to be redone or finalized.

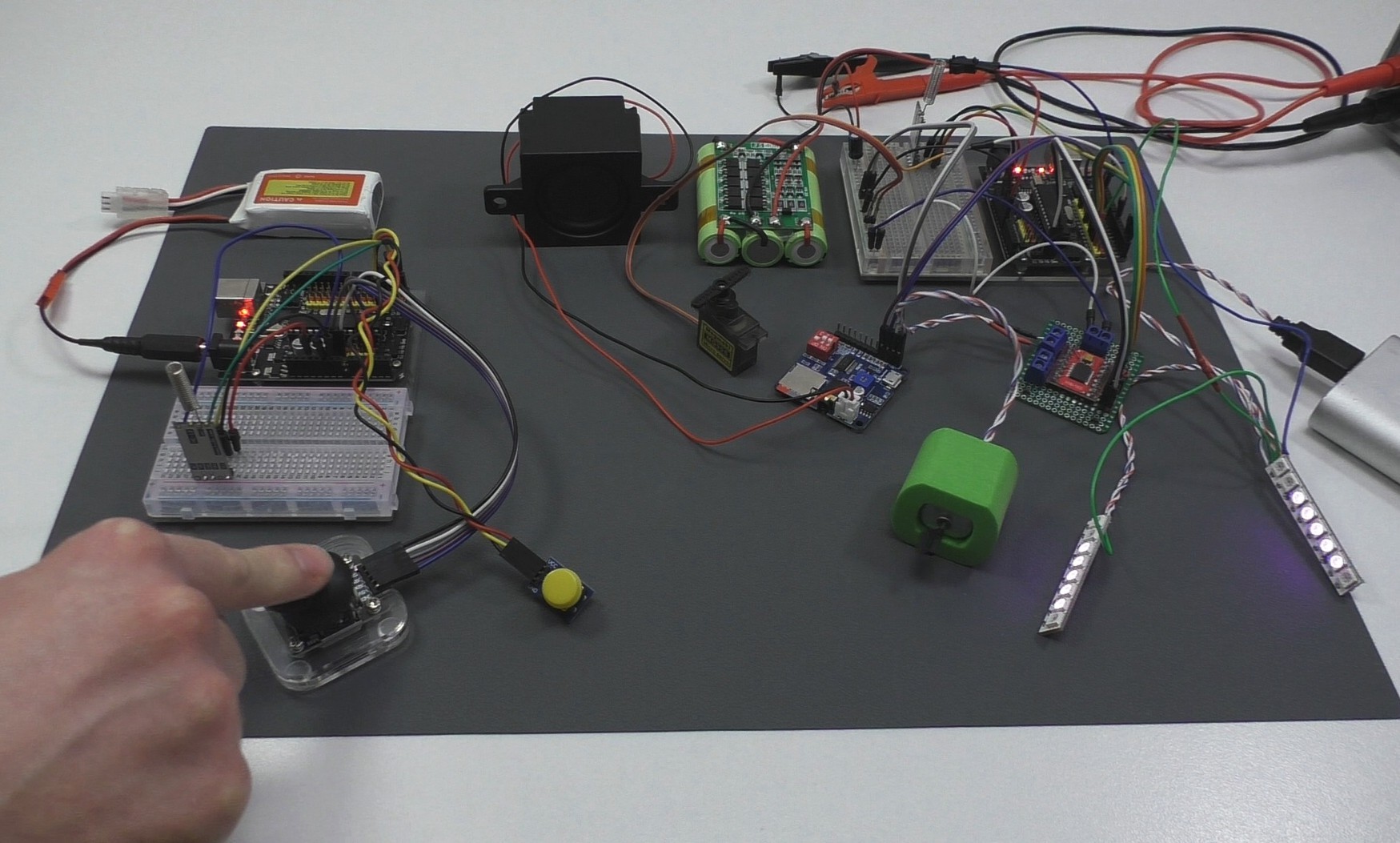

After studying the device, I had several options for the location of the components, first of all, I tested the servo and decided on its power. I thought over the steering mechanism, the location of the servo drive and the device of the control panel. In order to finally decide on the device of the machine and the remote control, then it is necessary to prepare the electronics. I wrote a program in the Arduino IDE, assembled and debugged the prototype, after that I made a circuit diagram of the electronics of the drift car and the remote control.

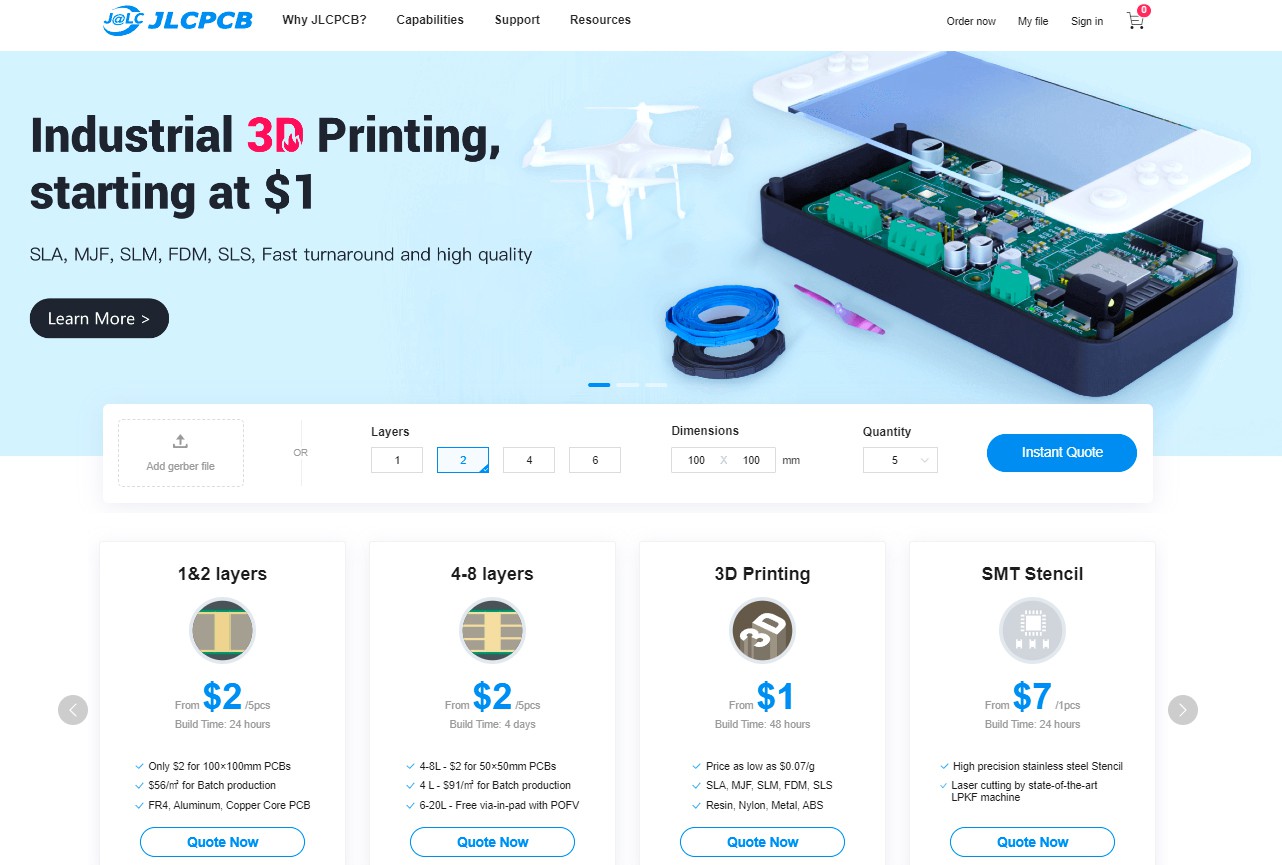

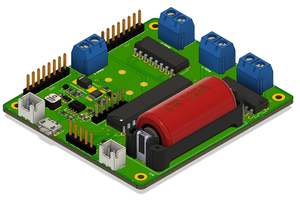

Printed circuit boards for electronics

In order not to suffer like me with the manufacture of boards on a breadboard, I recommend ordering the manufacture of printed circuit boards from https://jlcpcb.com/. This is the largest enterprise for the production of printed circuit boards of industrial quality, of any complexity, of any size. For just $2 plus shipping, JLC PCB will make you five 2-layer 100x100mm PCBs, or five 4-layer 50x50mm PCBs! JLC PCB can not only manufacture boards, but also assemble them on their surface mount equipment.

To place an order, you need to upload an archive with gerber files to the site, in the order itself you can configure the necessary parameters, such as the color of the mask, the thickness of the textolite, copper and order the assembly of boards, also JLC PCB is engaged in 3D printing, making stencils for SMT mounting and all this makes in the shortest possible time and with the best quality, so I recommend them.

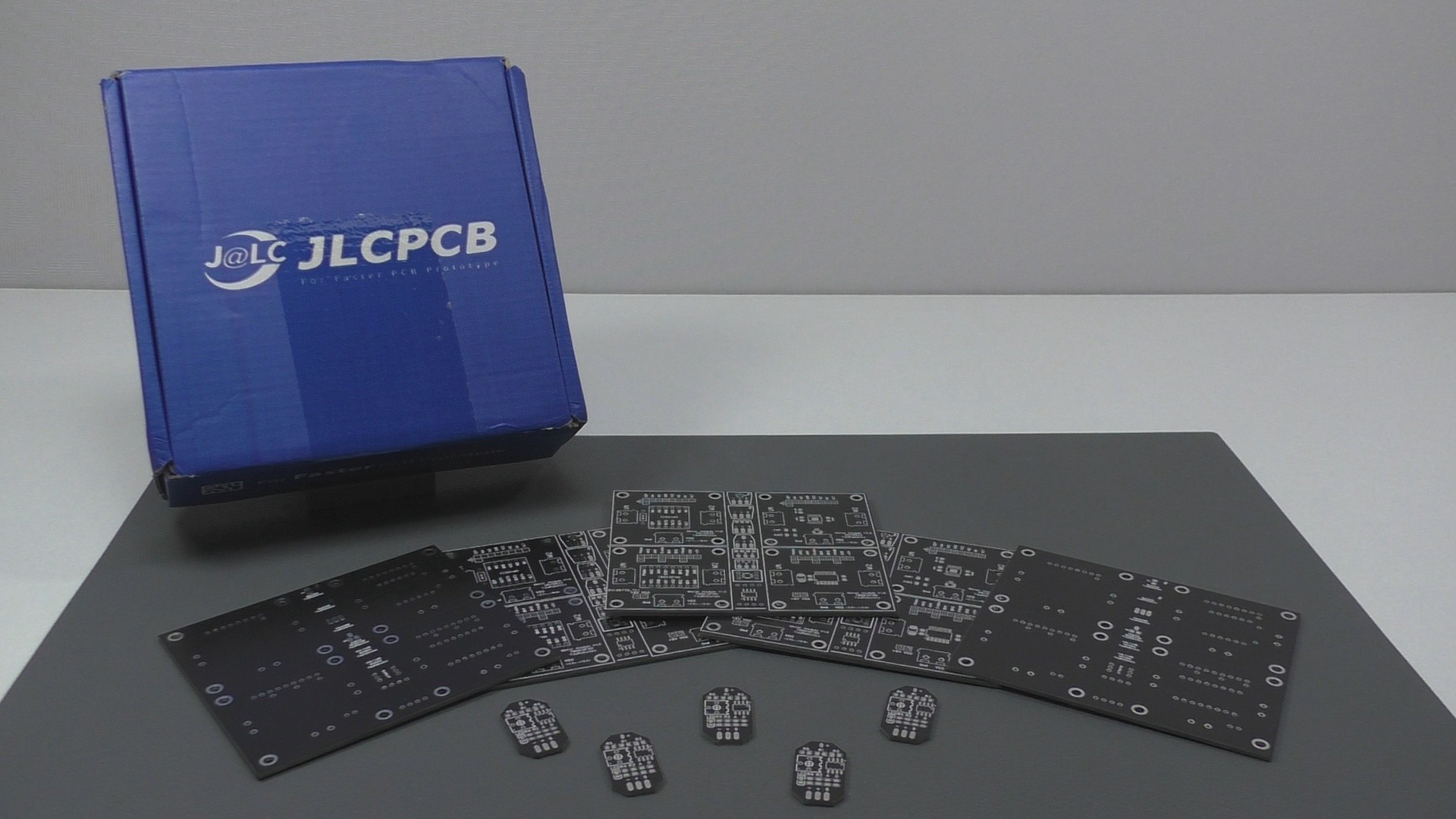

Printed circuit boards for electronics

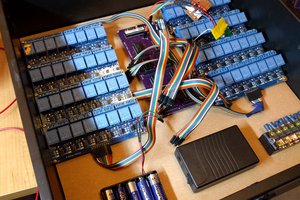

The following printed circuit boards are required:

- Power board - 1 piece;

- Control board - 1 piece;

- Board for connecting LEDs - 2 pieces;

- Printed circuit boards for buttons in the control panel.

I made all the listed printed circuit...

Read more » Valery

Valery

Silícios Lab

Silícios Lab

Steven Kibler

Steven Kibler

visualkev

visualkev