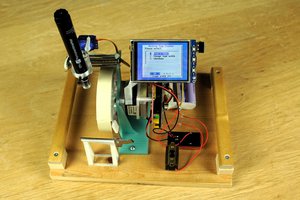

Big roller based plotter/vinyl cutter

~700mm plotter with roller based Y movement

~700mm plotter with roller based Y movement

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

While drawing frame in last of the big drawing attempts i observed the paper shifting. I guess movement being close to edge thus biggest leverage, having opposite movement directions on the sides, and doing so multiple times was the worst case scenario.

To minimize this I wanted to try increasing the force from top rollers. This made me return to making springs, but this time extension springs. Using a 3d printed jig after a little bit of practice I got somewhat decent looking springs. https://www.printables.com/model/468530-extension-spring-jig To better accommodate increased forces I beefed up some other parts of top roller mechanism, which accidentally made them look like birds.

I didn't test yet how much it helped with that kind of paper shifting. But it seemed like the increased force made the problem of slightly misaligned top rollers steering paper sideways and thus bunching up between multiple rollers. I am not fully sure that the bunching up is caused only by misaligned top rollers and not the spiral wrapping of bottom rollers, or bottom roller misalignment.

First test to try confirming that the problem comes from top rollers was replacing them with plastic spoons. Turns out in the last few years single use plastic utensils have been more or less banned. I don't mind that, but it made this step a bit more trickier than I expected.

Next step was making 3d printed arms with a spherical sliding pads, covered with HDPE tape for less friction. After testing it properly that was a failure. Unless I set the spring force very low, motor would skip steps. With pads pressing sufficiently lightly not to stall motors, even lightly holding the paper with a finger was enough for it to shift and rotate.

Iteration v10 was wider rollers wrapped in HDPE tape. Somewhat worked but bunching up was still a concern. In one of the tests I switched to a new crisp sheet of paper, from the old crumpled and flattened one. It started to work much better. This made me realize that there is a lot more to the paper rigidity than just g/m^2. Since the paper was cut from 700mm roll (and the plotter can handle maximum of ~690-680) I had to feed it sideways so that paper want's to up from left and right sides, instead of front and back like you would get if roll was sufficiently narrow to be fed directly. With the fresh paper things went much better than before, but as I was moving it back and forth at one point suddenly combination of way paper was curling and folding when hitting the wall behind caused paper to be pulled in folder over itself. The second lesson here was managing how ends of paper fold is important. Minor sideway pull from the paper folding badly can cause paper to be pulled in wrong and make a crumpled mess.

So I switched from having the plotter on my table, to placing it on pair of stools. That way paper can freely hang down on both sides without anything getting in the way. I guess I will also have to take into account direction in which paper wants to roll. This is slightly annoying because material often comes in 700mm wide rolls which is a tiny bit more than what plotter can handle and I will have to cut of a centimeter or two from one side.

In parallel with previous tests I had order some PTFE tubing. So that I can replace HDPE wrapped rollers with PTFE. That would not only reduce coefficient of friction but also eliminate seam which the tape wrapping had.

An exploded view and one of schematics drawings for Tektronix 2215. Paper size 68x54cm. Margins could have been smaller but it was late already late and at that...

Read more »Bonus video

The trickiest part was separating everything from cutting mat. Adding few more layers of tape, so that blade cuts only top layers helped.

Open the video in youtube if embedded version keeps buffering.

CAD

Hardware was design using FreeCad 0.20 , no assembly workbenches. With most of the parts being axis aligned and no complex swinging motion using a hierarchy of parts/transformation was sufficient.

Firmware choice

Controller board is using Marlin firmware and g-code. Why Marlin and g-code not some other firmware and hpgl or gpgl?

Due to the popularity of 3d printers there is wide variety controller boards for them available. Chose Marlin mainly because it supports wide range of controller boards and is actively maintained. G-code usage is mostly result of that. One thing that's slightly less convenient compared to others is that configuration is mostly done using compile time macros.

Klipper would check many of the same boxes as Marlin. For now chose against it, because having the controller board+RPi seemed like slightly larger complexity and at the time of source parts getting a Raspbery Pi was a problematic. Also with Klipper architecture it seemed somewhat wasteful to have more feature rich controller board, since with clipper some of it would be shifted to the RPi (or the alternative SBC).

RepRap firmware also seems nice, but the developers are focusing mainly focusing on their own high end Duet3d boards. While the support for some other boards in theory exists, they are not listed in the official reprap firmware website. Compatible boards link leads directly to Duet3d product page. I wasn't quite ready to buy in the ecosystem of their boards or running it on a board with unofficial support. I appreciate that some people where able to make a company around an open source project, even when any community contributions are almost non existing (more so than typical open source project)

Original Grbl project at this point seems more or less dead. But there a couple of promising forks each with slightly different goals and target hardware in mind.

Thinking about all this led me into the rabbit hole of looking into what CNC and 3d printer firmware are out there and what is still being maintained. After cloning few dozen firmware repositories I managed to create this. I don't promise that it is accurate or exhaustive, especially early reprap project firmware history in 2008-2010 was somewhat messy. Due to small size it's hard to distinguish what's a new version, unique fork, or insignificant manufacturers modifications. Mach3 included only because it's early versions where supposedly derived from the same government funded public domain project that LinuxCNC also used.

(Click to make bigger)

Marlin

Marlin is the firmware running on controller board. It is primarily targeted for 3d printers, but like most such projects it has some functionality for other kind of CNC devices.

For the most part didn't have to do too much customization. Just disabled unused 3d printer functionality and configured 2 servos. Had to make some patches to fix compilation with only 2 axis enabled (no Z axis). Might be interesting too look into whether some of the spindle/laser code could be reused for the tool activation (lifting/raising), but for now I am just using M280 gcode directly.

InkCut

Inkcut is the software taking in SVG and converting to something that a plotter or vinyl cutter can understand...

Frame

The frame is mostly made from 700mm and 200mm 2020 aluminum profiles and various brackets. Then end plates where initially made with hand tools and a drill, but later versions are laser cut. This was still at the time when I tried to avoid 3d printed parts. If you are considering to reproduce project you might want to redesign them, to match the fabrication tools and techniques available to you.

If you are considering to order them from a laser cutting service, they can be ordered as two pairs of identical parts. And afterwards cutting a rough hole in one of them for the motor.

Drive rollers

Note I know that many plotters work push and pull with single line of rollers and it works assuming the rollers are sufficiently close to the tool, when using a thick material or light tool pressure. But the current roller size is limiting how close I can get support surface and tool movement line. And in some of the the earlier single roller tests (not having top rollers engaged) I did observe paper pushing up against the tool, which didn't happen when both side where pulling. I will be doing more tests to find out which combinations of material and tools need or don't need both rollers.

First version of drive rollers where made from 8mm aluminum rods wrapped in long balloons (the ones used for making balloon animals). Getting the balloon on the metal rod was a bit tricky. I tried soap water but it didn't work very well and also caused the rubber to spin more easily which is something you don't want. The method that worked best was: filling the balloon with air and letting it to sit for while, inserting tube slightly bigger than in the rod in the neck of balloon while its still filled, and then quickly inserting the rod through the tube before the air fully escapes and balloon fully shrinks. After quickly releasing air for short time balloon will be in partially stretched out state, in combination with any air that might get trapped it will help with the process. Once balloon is evenly stretched across the metal rod open cut open the end and push out any remaining air bubbles.

As mentioned before at 700mm length without support everything bends especially thin aluminum rod. So the every ~10-15 cm the rollers where supporter by pair small bearings. It was quite tedious to align all 12 of them.

Balloons where very grippy and worked well from that perspective. But they where quite fragile. One of the causes of it breaking was rubber gripping the paper better than aluminum resulting in it stretched and pinched. Other common cause of breaking was edges of support rollers cutting it.

After rubber balloons I tried rubber tube. Whatever the local hardware store had at appropriate size (probably pvc). It was more slippery than balloon, but that wasn't the bigger problem. After sitting idle for while both the top rollers and support rollers made dents in the spots they where resting. This caused rattling when the rollers where spinning.

I also tried wrapping the aluminum rod in various tapes, but that also was very noisy as the rollers crossed joints in the wrapping of tape. Those test pretty much eliminated the idea of bottom supporting rollers.

In the current version I switched to steel rods and placed a KP08 bearing block in the middle, which means ~350 mm of unsupported length. The bearing block in the middle increases the requirements for roller diameter to ~30mm. So the current approach uses 30mm aluminum tube with 3d printed endcaps wrapped in 180 grit sandpaper.

After thinking about this more, now that I have switched to larger radius tube, it flexes significantly less compared to 8mm solid rod. The middle support might not be necessary anymore.

Top rollers

Main purpose of top rollers is to press the paper or cutting mat against active bottom rollers without adding any additional friction or resistance.

On the left one of the earlier versions using a selfmade...

Motivation and other existing solutions:

If you have a practical usecase for any kind plotter this project isn't for you. Unlike with 3d printers where you might argue that a $1000 voron in some categories outperform commercial offering at similar price category, the market for various kinds commercial plotters and vinyl cutters is much more mature.

Small size (~300mm work width) vinyl cutter costs $150-$500 and should have good performance and reliability in a user friendly package. Should work great for small size vinyl cutting and other crafts projects.

Large size (500-1000mm) vinyl cutters. There are models available in the $300-$1000 range. Might not be the best thing out there but probably still better than any DIY solution. Less suitable for misc crafts projects. While the price is still somewhat accessible there is little reason for hobbyist to buy one unless you have very specific needs.

Hanging plotter designs. Very simple and cheap to make, large working area. High spped and acceleration may cause the tool to swing around due to being partially constrained by gravity. Unless very carefully designed positional accuracy might suffer as the amount of string on spools vary. Very compact when not in use.

DIY and semi DIY pen plotters with cross or H style X/Y axis. In some categories one of the better options for plotter art kind of stuff. Can be relatively simple as a DIY project. Making the tool reliably move (for a DIY devicee) in X, Y direction is much easier than any kind of roller based system. Also not a bad option for medium/large size plotter art stuff. Probably the biggest downside is that it takes as much table space as the paper you are drawing on. Although when not in use cross style designs like Axidraw can be somewhat compact, might be even possible to create one which easily disassembles or folds when not in use. Since the paper isn't moving as long as steppers don't skip steps (which shouldn't be a problem for reasonable speeds) there shouldn't be any shifting during drawing. If necessary you can lightly tack the corners with little bit of tape. No risk of smudging from the rollers even if you are using slowly drying ink. No fussing with cutting mat being too sticky or not enough sticky, or paper jams. Unlike roller based systems thickness of paper shouldn't be a problem, both very thin and very thick paper should be fine.

How is this project worse than everything listed above:

In terms of cost this project is probably more expensive (at least when taking into account money spent on iterations) compared to all the commercial solutions listed above.

In terms of performance and ease of use, one of the 3 options above will probably be better (assuming you know your usecase).

Reliably moving paper back and forth with rollers isn't easy. I am still fighting with occasional shifts and some kind of backlash like direction dependent offsets. Also thinner paper without a backing mat tends to bunch up or otherwise crumpling. As much as people like to laugh about inkjet printers being unreliable, I am starting to feel much more respect for their designers.

Top rollers introduce risk of smudging the drawing.

Initial design goals/wish list:

Future posts TODO:

More detail descriptions of current design and early failed iterations

Cleanup the CAD model from third party components with unclear licensing and publish it

Software

Demonstration of test output

Bonus picture. Drawing and cutting a devilish winter themed memory matching game. Snowflakes generated using...

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates

Ted

Ted

Paul McClay

Paul McClay

Thank you for the updates , I really like your project. you really did make progress on most of the work it takes to scale your project further and answer the basic question and research to get it to work.

One reason this is interesting to me is a do a lot of mylar cutting, specifically 7mil. Cricut software has been an issue and silhoutte cutter really lack force and both cost around $400. I wanted a offline, reliable and repairable plotter solution. I was thinking of trying to make something similar since i have a couple 3d printer boards lying around and your post answer all the question I had in mind.