This is a project focused on sustainability, and in its first version I faced the challenges shown below:

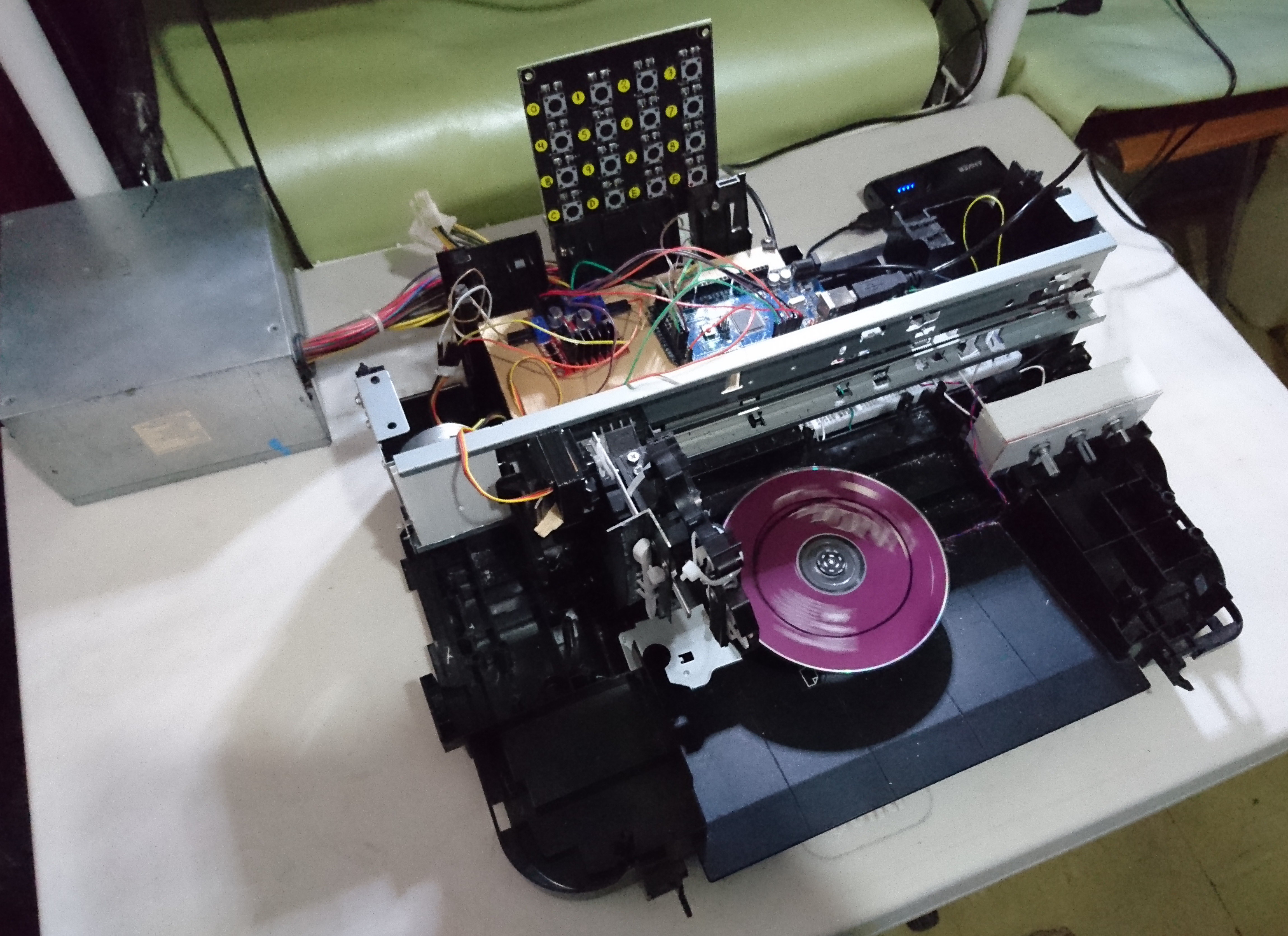

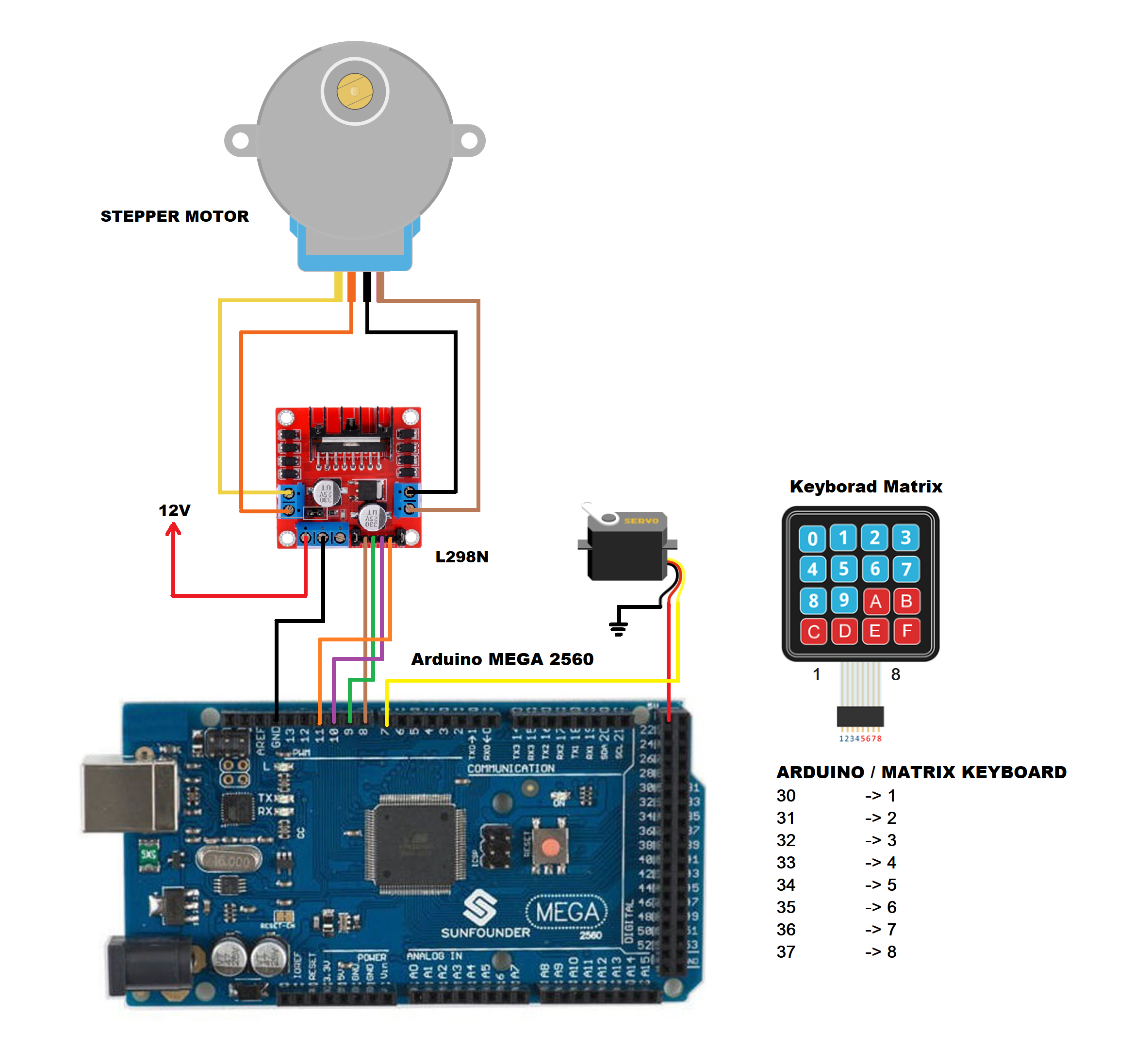

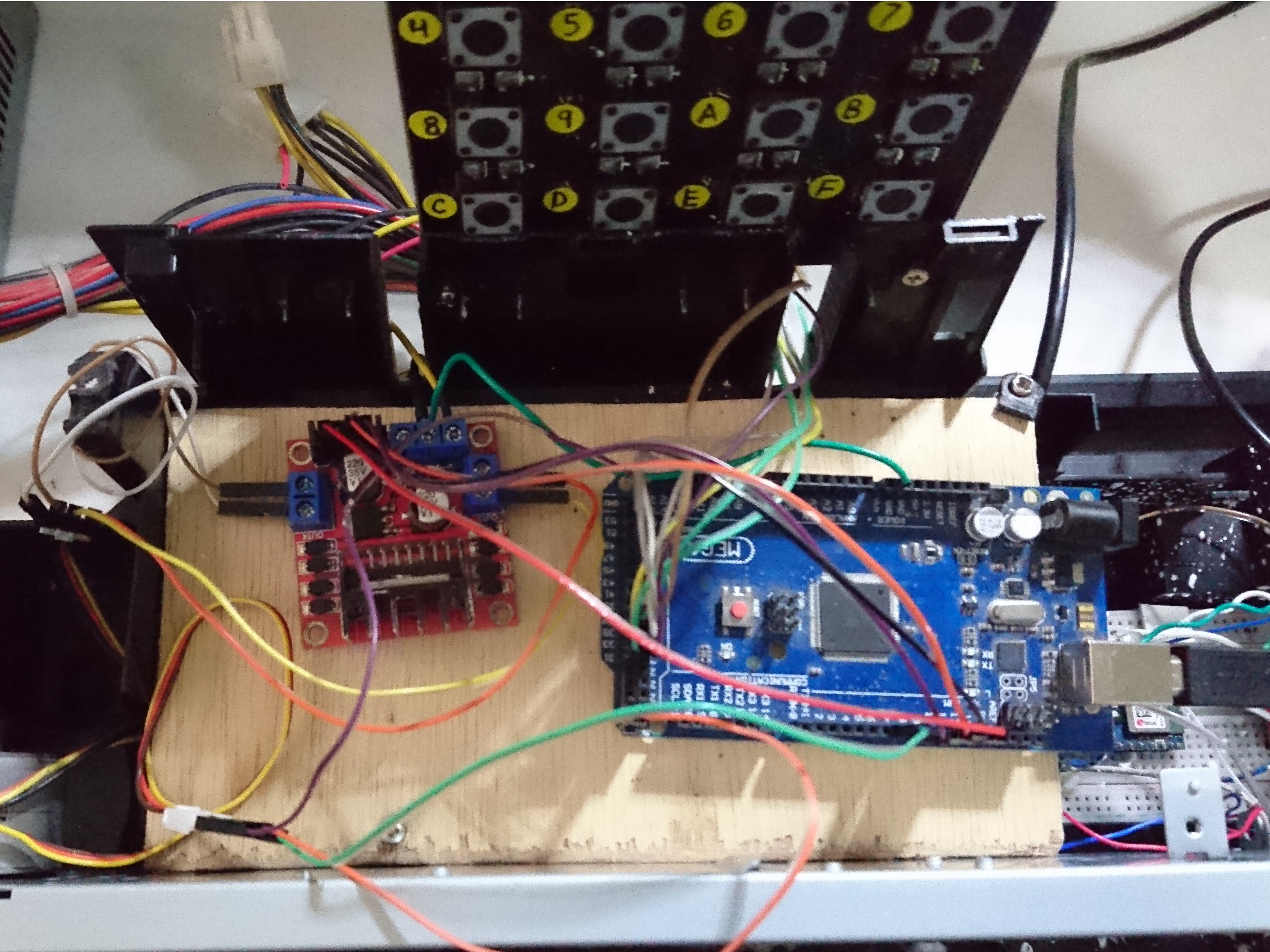

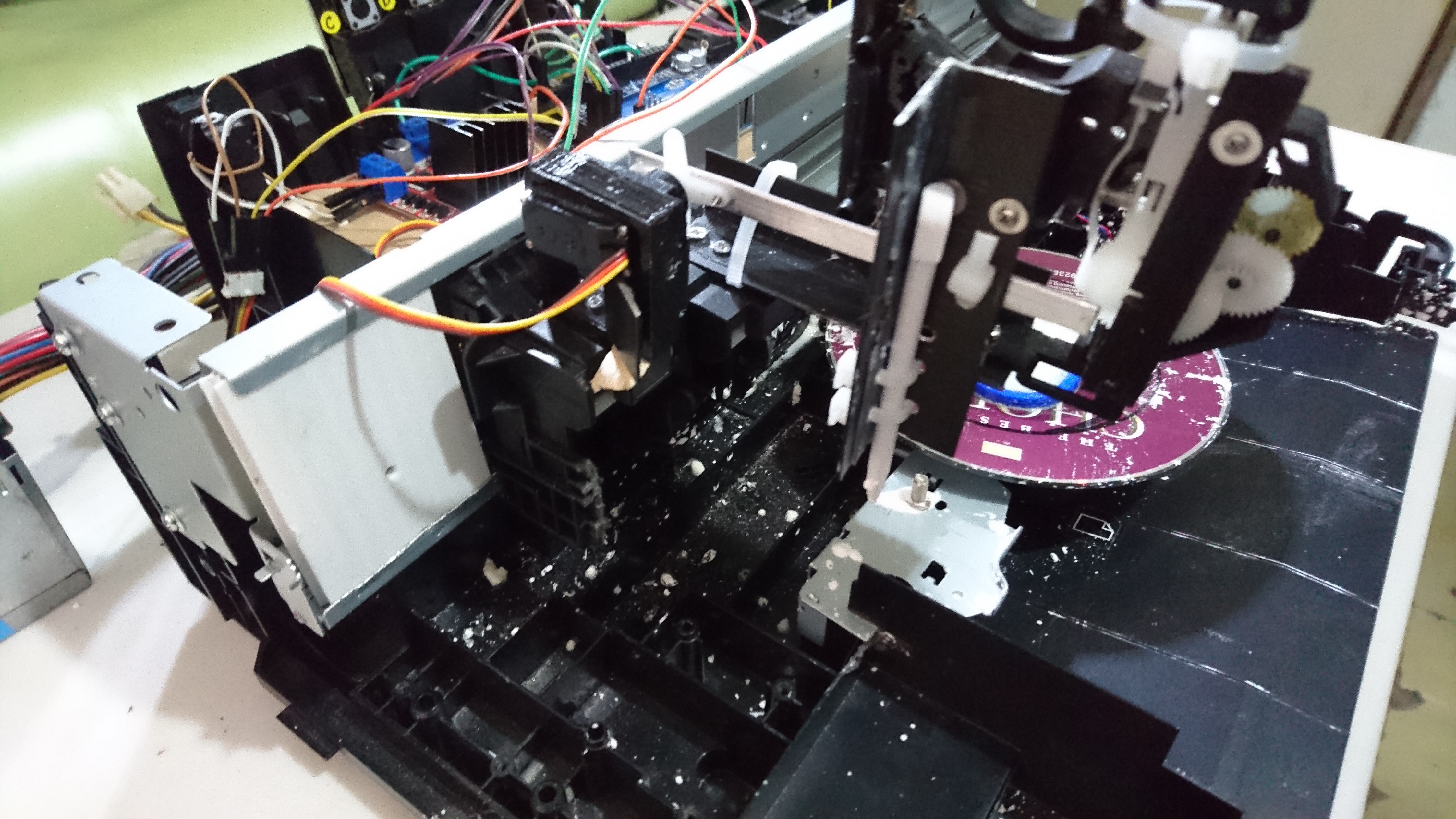

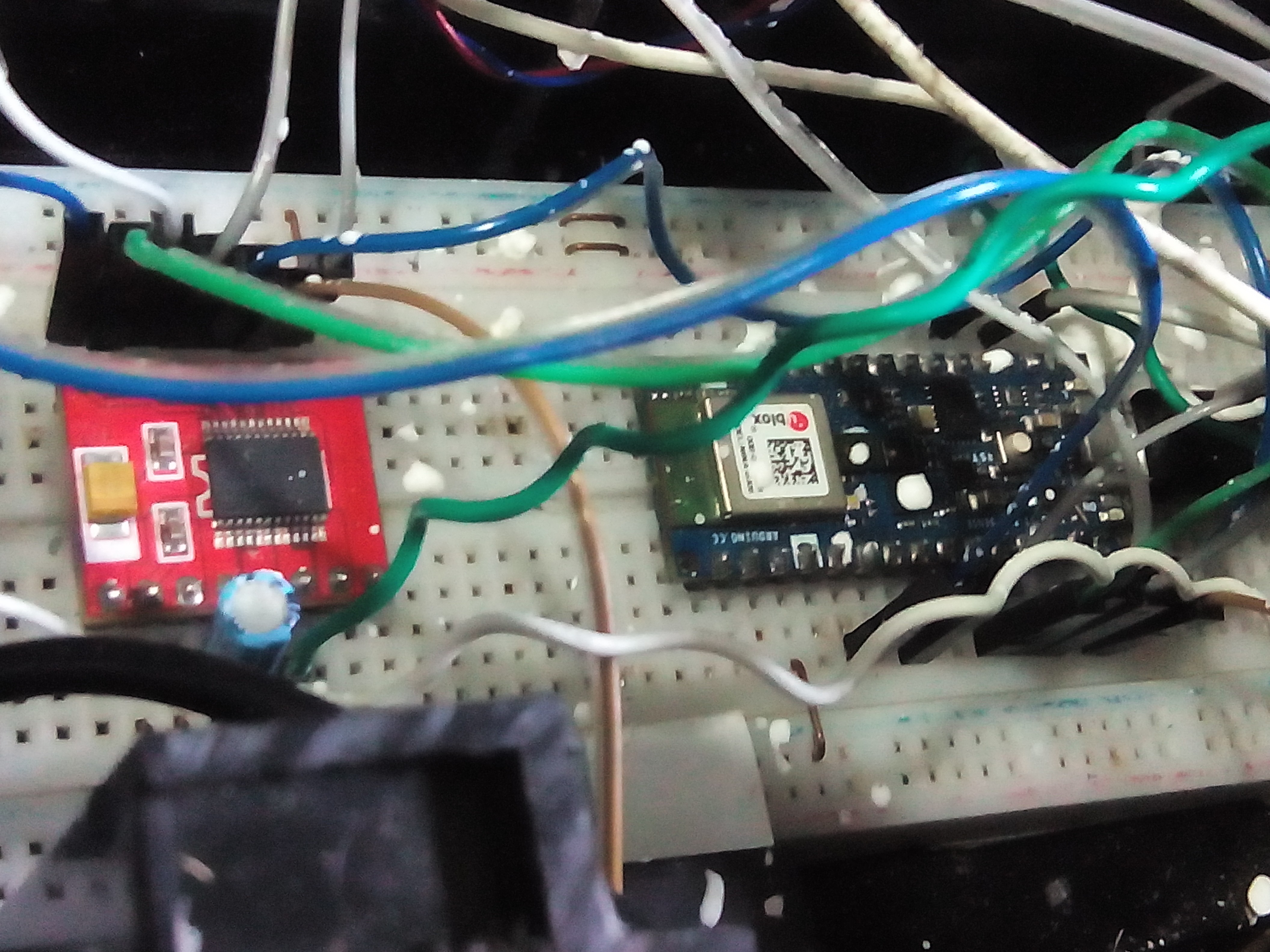

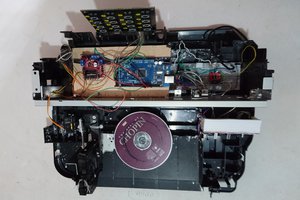

- Reuse and modify an old printer to place and organize the components and supplies for this project;

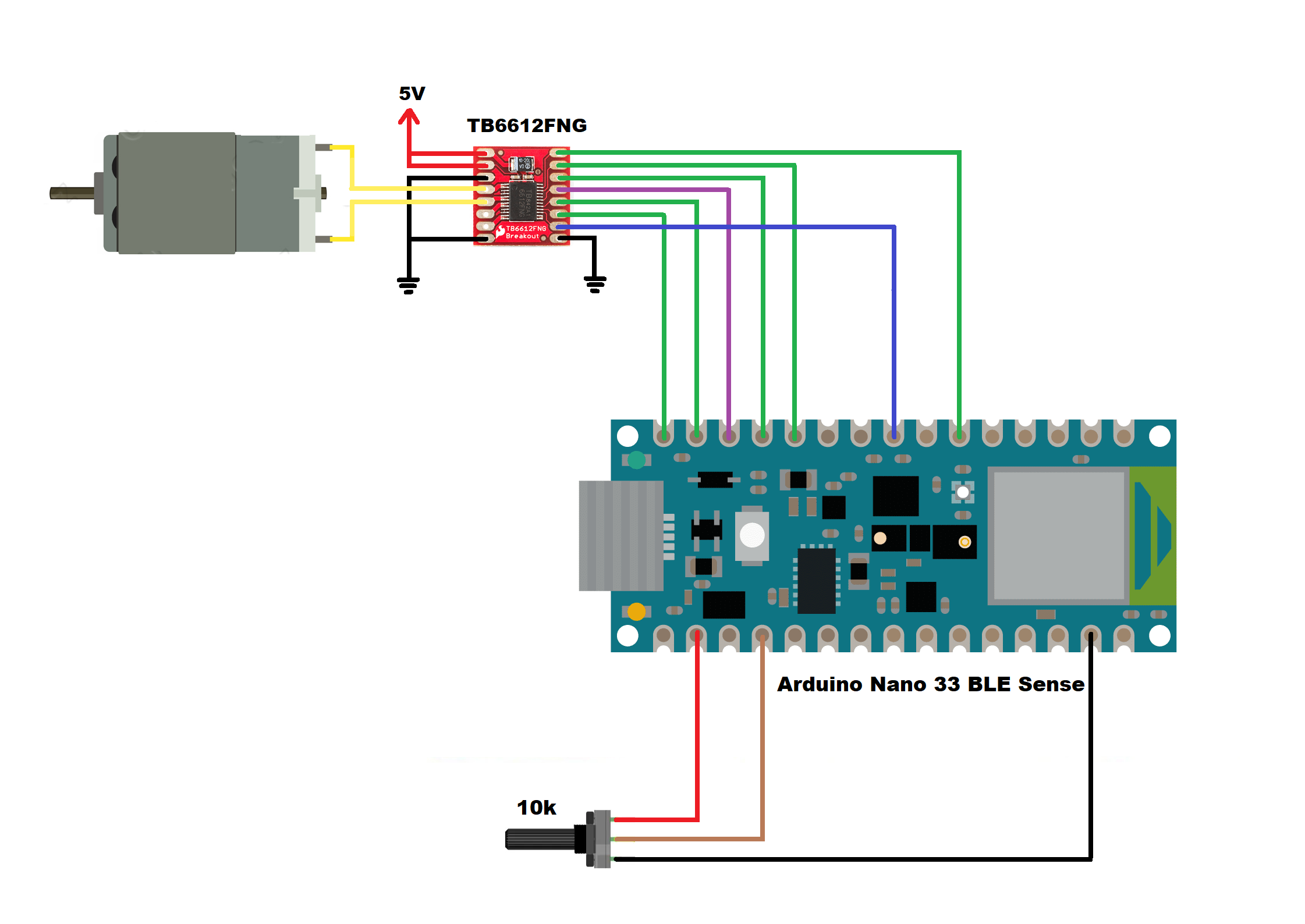

- Reuse an old cd-payer motor to work and experiment with miniature pottery;

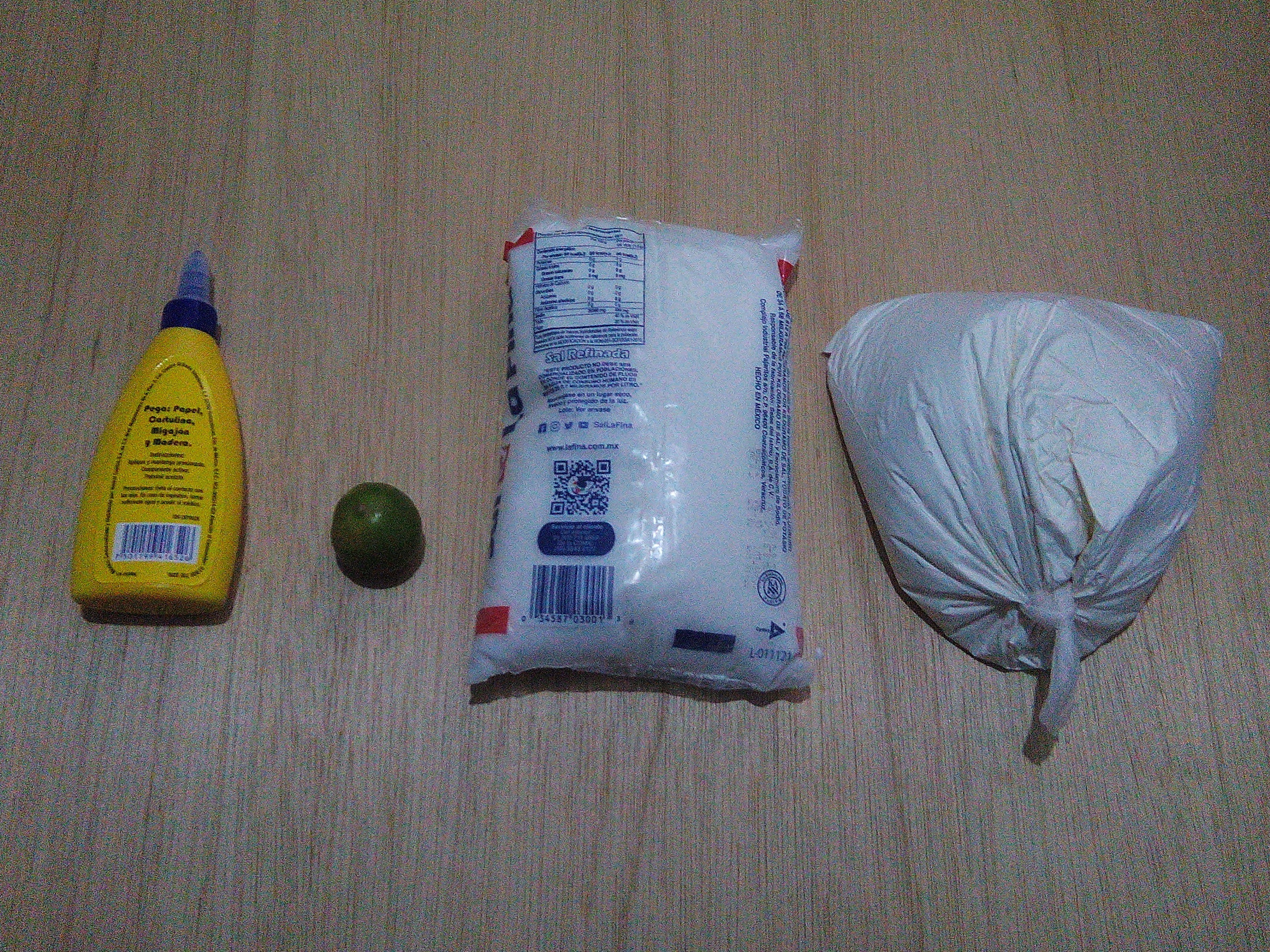

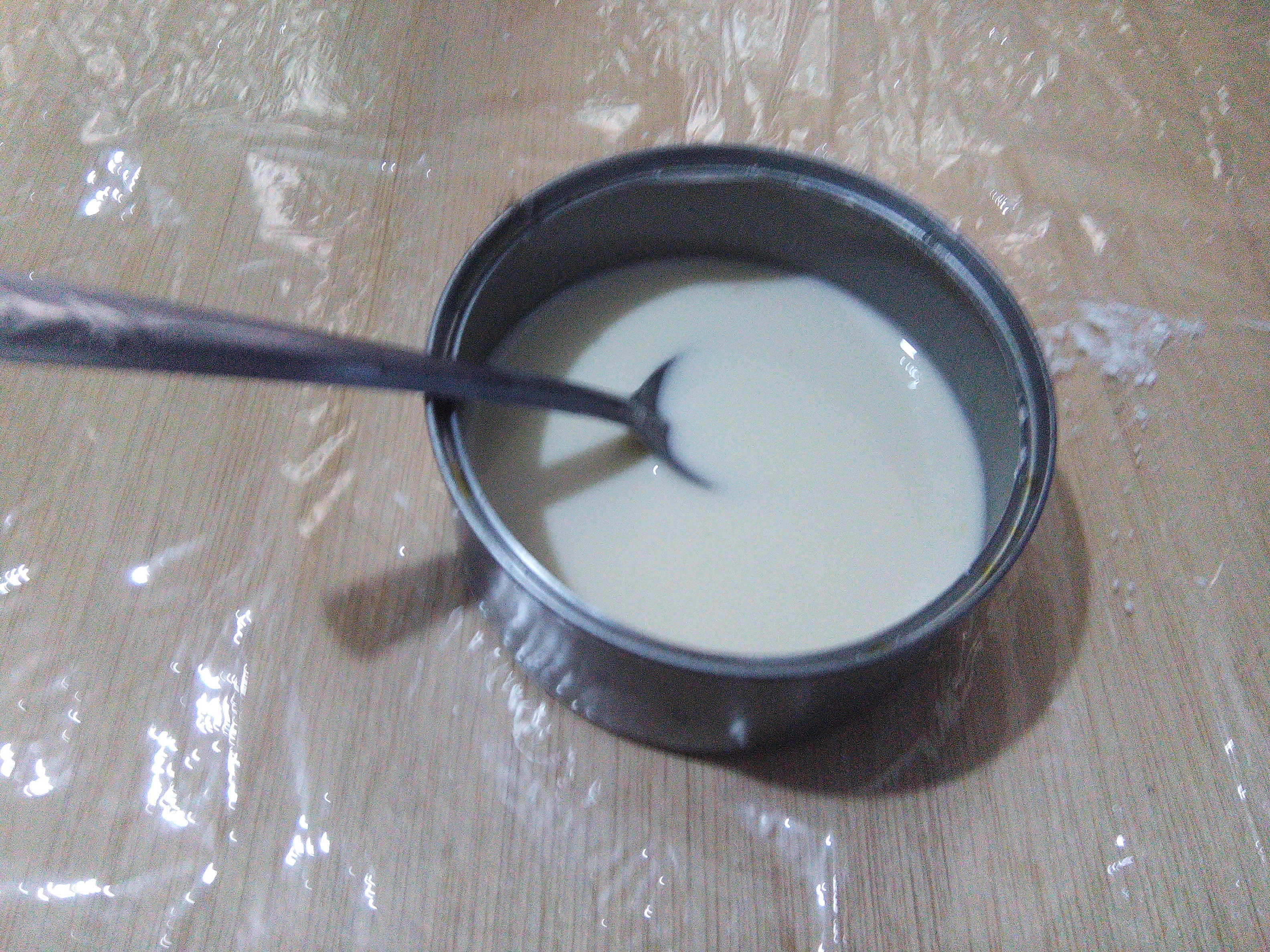

- Recycle organic matter such as cornstarch to create miniature pottery. To achieve this goal, I have experimented and found the amount of material necessary to obtain a good job, that is, of good quality and resistance; and

- This work promotes the circular economy, since it proposes a completely different approach that allows stimulating economic growth and generating self-employment without compromising the environment. When this material ends its useful life, then it will be returned to nature as compost without any problem.

In the video below I show you a journey through the second version of my project so you can get to know it.

Guillermo Perez Guillen

Guillermo Perez Guillen

Ossum

Ossum

jeff.ballard.86

jeff.ballard.86

DIY GUY Chris

DIY GUY Chris

This is an entertaining way of educating children because the limit is the imagination to create things: feel and touch, draw and shape, play and laugh... watching technology in another way