Yes, that's a Phil Collins reference... :P

One neat aspect of this project has been investigating capacitive touch sensors.

I'm a big fan of slider controls, and actually hacked on a volume slider for my wheelchair to control the speed dial many years ago. What a nice upgrade it would be to have a capacitive touch slider with LED controls, don'cha think? :)

There are two popular forms of capacitive touch:

1) Resistive capacitive touch

2) Projected capacitive touch

The first one (I think most people agree with me) is quite terrible. If you remember touch sensor technology from the late 90s, where you had to press really hard or use a stylus, then you know exactly what I'm talking about.

Projected capacitive touch has been the clear winner for some time, and each new generation of ICs has made it easier to implement. In recent years, microcontrollers like the ESP32 have even integrated this feature.

Originally, I planned to just use the built in ESP32 touch GPIO pins, and didn't pay that much thought to planning it all out. However, capacitive touch sensors are delicate devices; they rely on minute electrical pulses from the human body to alter a pad capacitance to the tune of as little as 50-100pf!

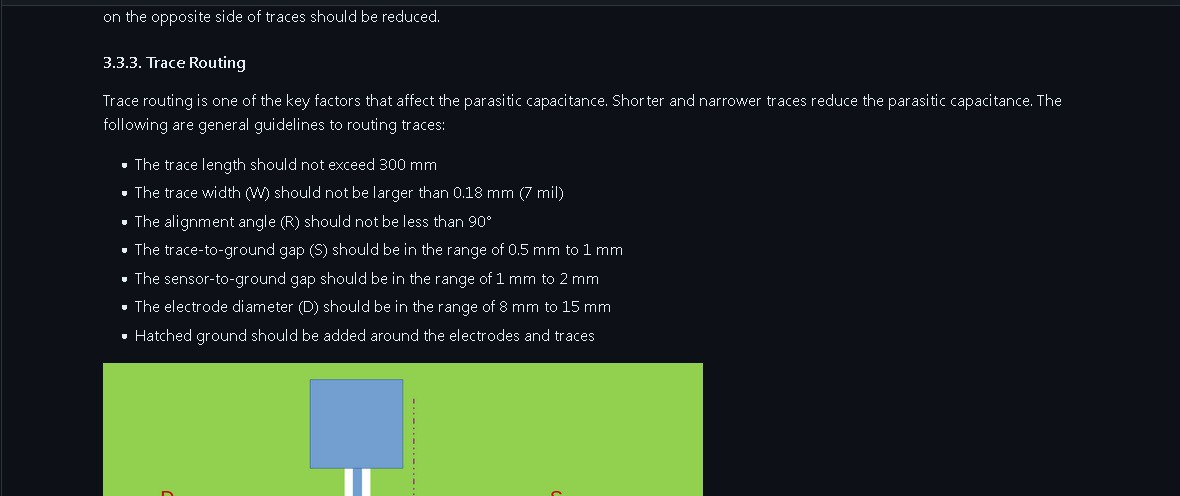

Trace layout, wire length, and grounding planes play a significant role in proper engineering of these PCBs. So it wasn't a massive surprise when I was reading the technical documentation from Espressif and saw that they recommend limiting the trace length to just 300mm:

This is a limitation that can be really frustrating to work with since I'm going to have wire harnesses all over the place. I'll be working in a cramped space and having to adapt to the wheelchair's previous engineering, so I certainly don't like the idea of adding new constraints.

Also, this being a medical device, I want to optimize any capacitive touch or motion control to be the best and as responsive as possible. I want traces to be very short, but I also don't want to be stuck mounting my microcontroller under the slider....

-- Enter the TTP223 --

This is a wildly popular IC manufactured overseas. The manufacturing quantities produced to meet the demand from people around the world for this part have made it incredibly affordable. It's also well-documented, easy to solder, has a small external part count, has built-in calibration futures, doesn't require I2C or any programming, and can be purchased for as little as <$0.20 if you buy 100pcs.

I always opt to work with parts that are well-documented and affordable if I can, so this one looks ideal ! There's even a handy project right on it here on Hackaday by @mbsg99

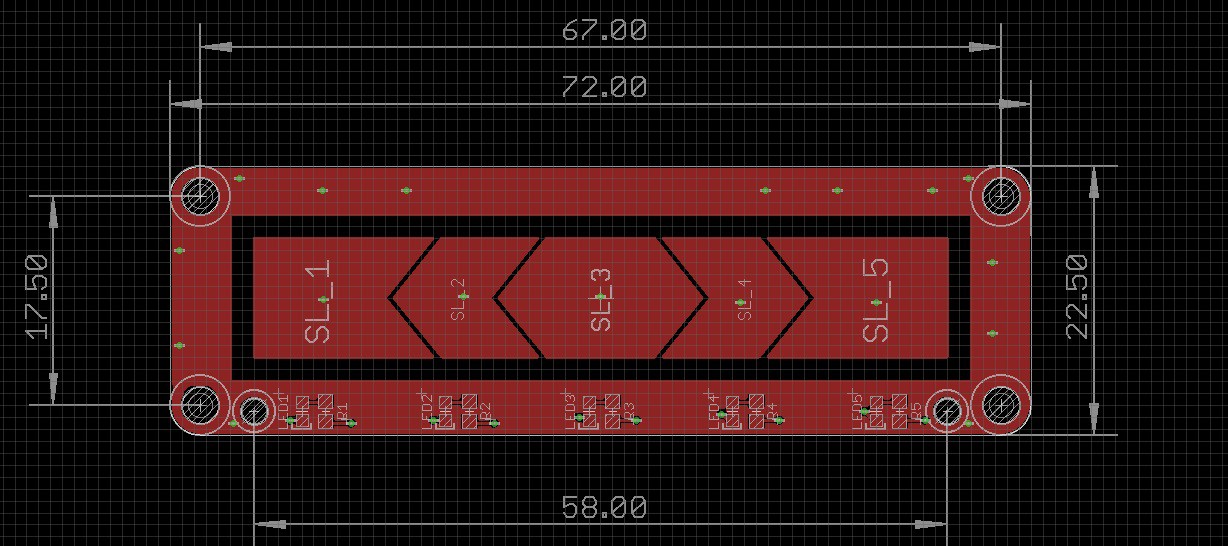

I've ordered a bunch to work with, and I'll be designing my own custom circuit board with 5x of them soon, as a daughter board add-on to this new capacitive touch slider PCB:

This is the handy PCB I designed, influenced from research on Sparfun's PCB and a really cool (although out of stock one) designed by Seeed Studios. Ultimately, I went for a modular approach which I'm quite proud of. This design incorporates 5x indicator LEDs and breakout solder tabs for a add-on board to attach to. The add-on board will have an additional ground plane to help limit any stray capacitance, and also make testing and debugging other ICs (should I dislike the TTP223) far easier.

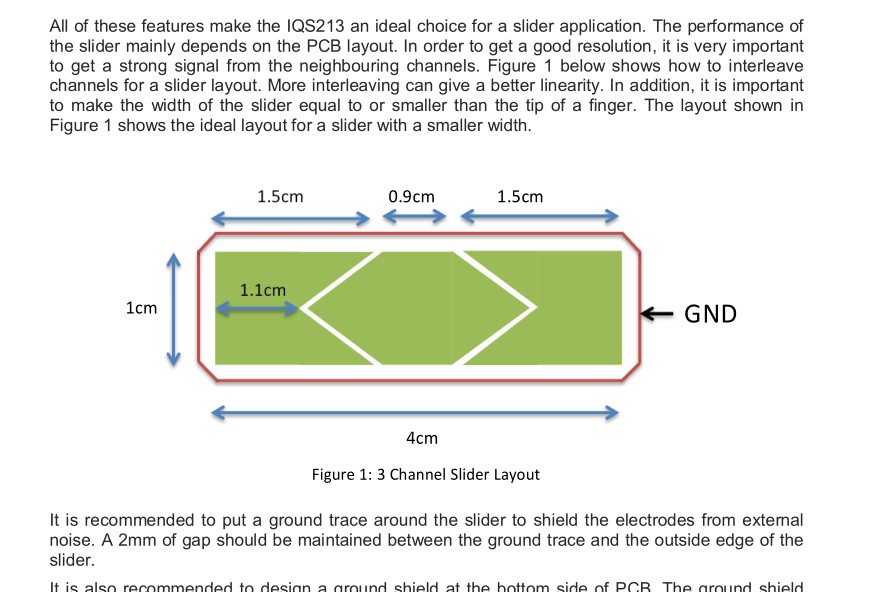

For the layout guideline, I resorted to an extremely helpful application note by Azoteq which a very nice friend told me about:

I'm optimistic about this one so far, and look forward to the PCBs. I just hope this one turns out to be a Solid Slider :)

CriptasticHacker

CriptasticHacker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.