So, learning that PCBWay isn't going to notice a possible manufacturing issue until they actually try to manufactor it, I was more involved this time. For starters, if I self tap the 3D printed holes, the print is only $39.80. Considering that it seems that the minimum cost is around $37 for any part via this service, and it was the price nozzleboss paid for theirs, I think this is a win that this is under $40.

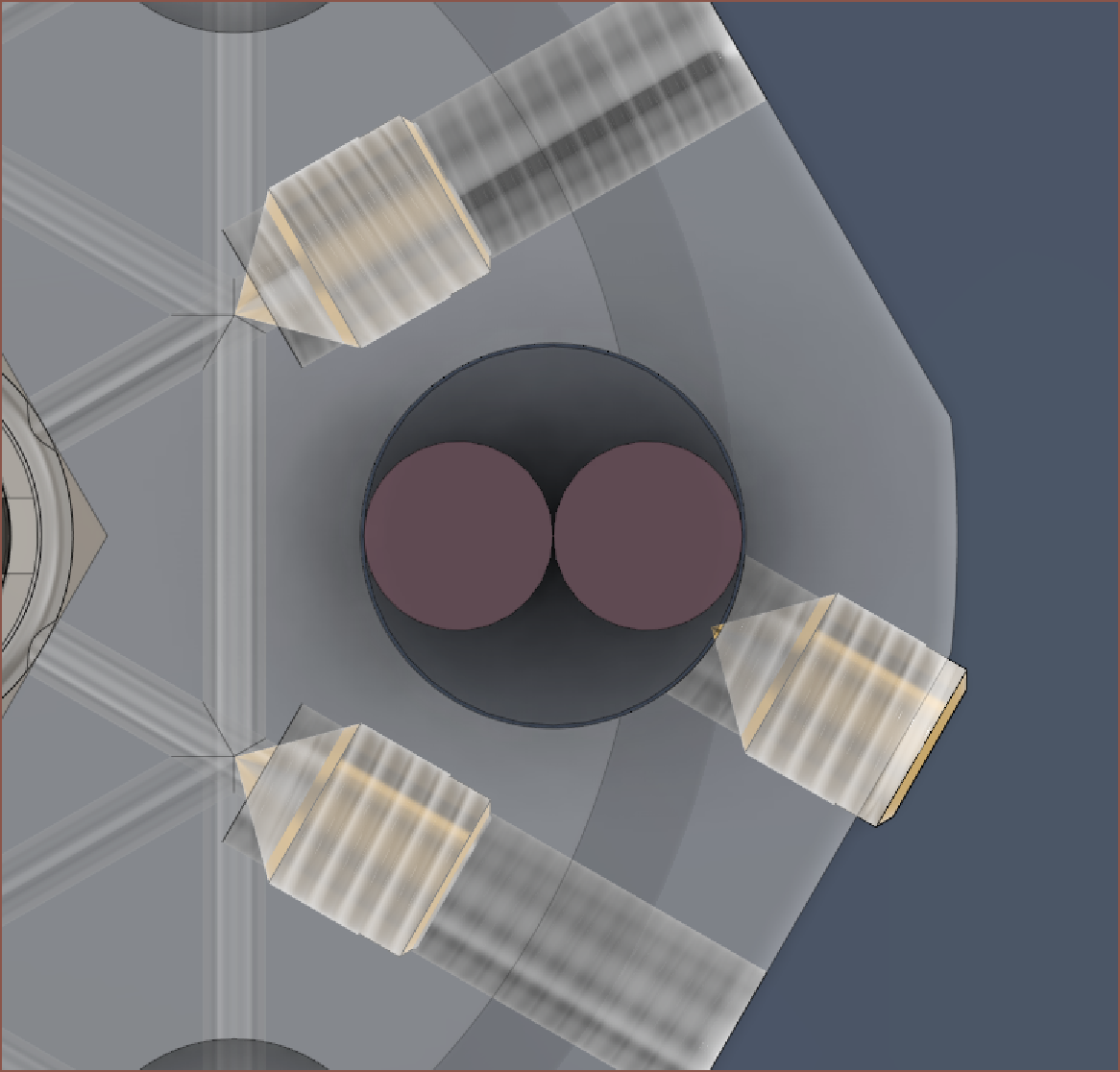

However, I had also recently watched the below video about SLM printing, and overhangs are essentially required for 90 degree overhangs.

So I asked if the internal channels were printable, and my service rep Eleven indeed confirmed that there's a risk of blockage since support has to be there.

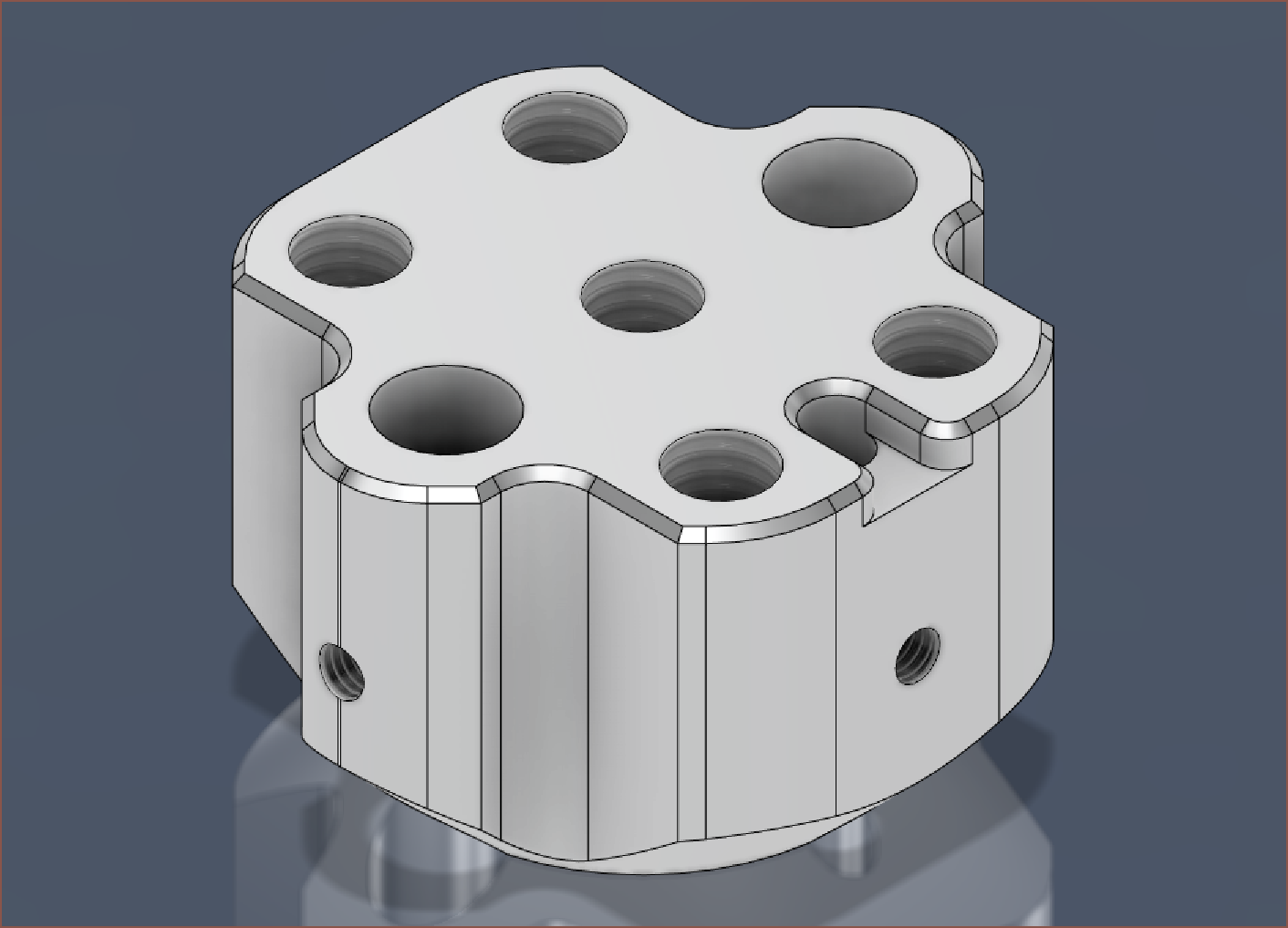

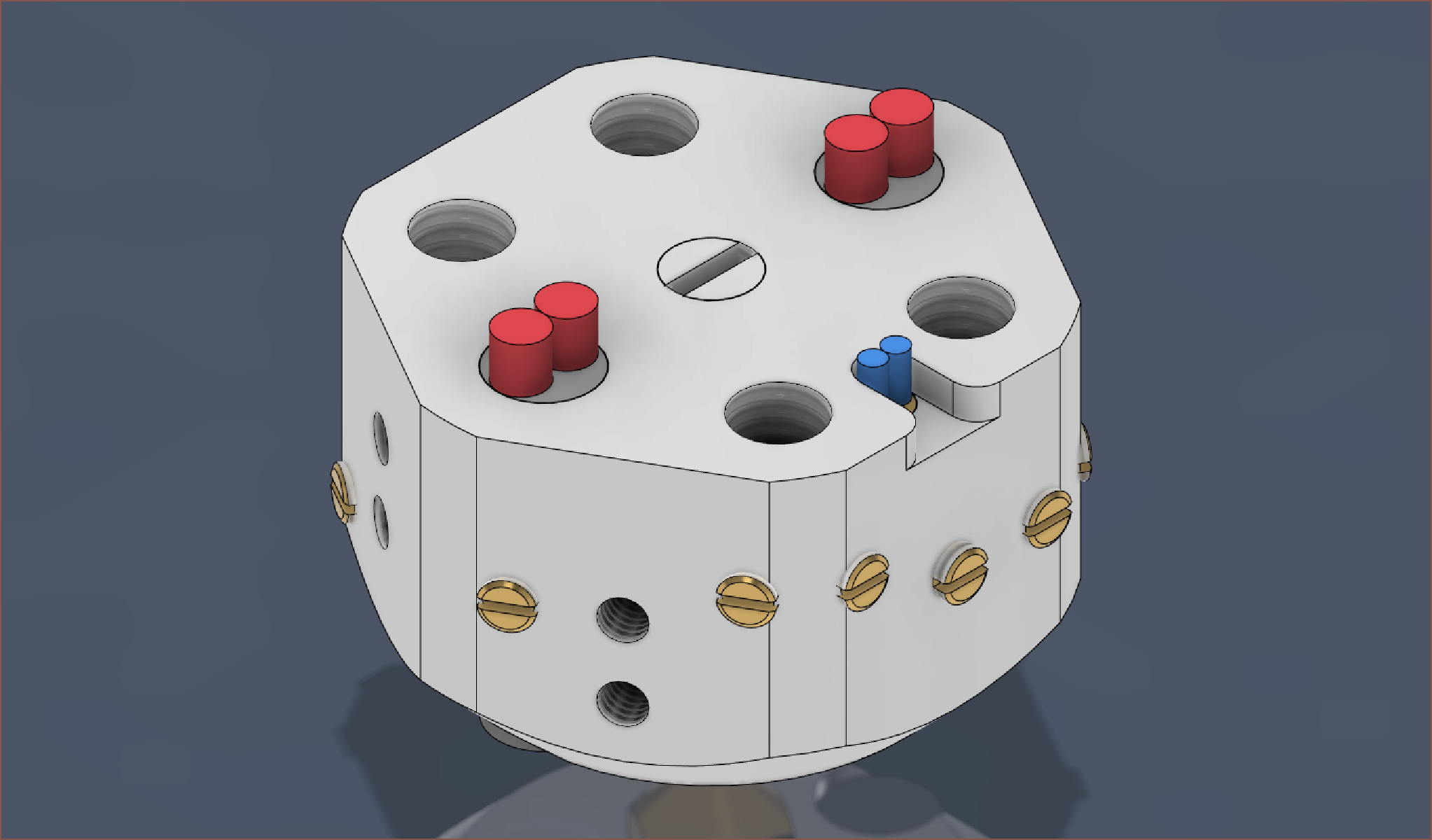

Now, just like how Apple sent off 2 teams to either start from the iPod or iMac to get to the iPhone, it seems I'm now trying to get a solution from both 3D printing and lathe machining. While the 3D printed version has a 5th filament input already integrated and doesn't have to worry about the 16 leak-plugging grub screws, I'd imagine that more schools / unis would have a metal lathe than a metal 3D printer (though I'd like to change that).

So the technician agreed that it's a bit tough to start a hole off-center to a cylindrical face. It does seem possible to create enough of a 32mm across-flat hex from a 35mm solid rod to cover the off-center positions.

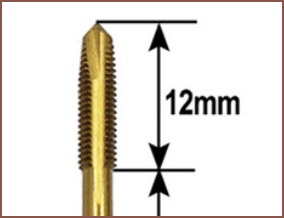

The next is that an M3 tap looks like this:

As you might be able to notice, the full width threads start maybe halfway down, yet the threads in the design are as short as 3mm need to go almost all the way to the end of the hole (the DIN914 cone grub screws thread doesn't go thoughtout the entire length).

I haven't found an official tool, but the tech is just planning to trim down the M3 thread. I forgot to ask what happens about the M6 threads though. Even if I got the thing printed, I'd still have to think about this issue.

Were going to try and make it in aluminium.

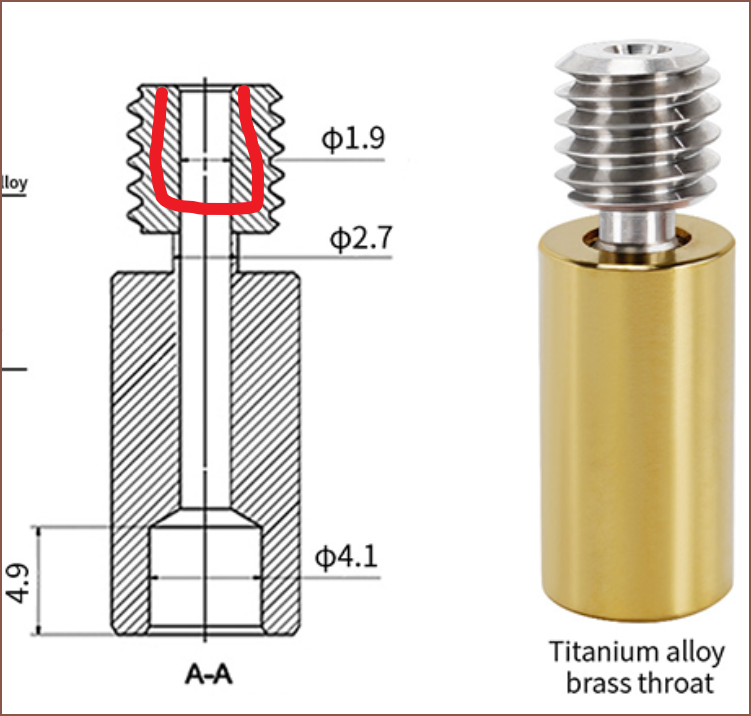

Oh right, speaking of that 5th filament input, it may be possible to do for the CNC edition by drilling a 4mm hole 4mm deep into a copper/brass and titanium heatbreak and then putting a 4mm OD x 2mm ID tube inside.

I would like to know how these kinds of throats are made in the first place and how the 2 materials are secured together.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.