Introduction and motivation

A thorough description of the platform, including some experimental results, can be found in our conference paper.

The project is still in development phase. We make a lot of changes, still we want to let you know about our work and give a snippet of it. If you are interested please do not hessitate to ask a question.

We publish all our work on our facaulty GitLab https://gitlab.fel.cvut.cz/SlotcarPlatooning

The project is divided in several parts and each part has its own git repository. These repositories then are added as submodules to slotcar.git for connecting versions.

Description of each repository

- slotcar-fs.git Slotcar Filesystem, cover filesystem for RPi CM (slotcar), and RPi (Wi-Fi AP). Eclipse project

- slotcar-fw.git Firmware for STM32F401. Eclipse project

- slotcar-sw.git Java SW for slocar APP and GUI. Eclipse project

- slotcar-ctrls.git Java controllers . Eclipse project

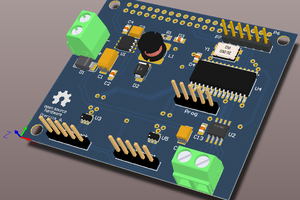

- slotcar-hw.git PCB designed in EAGLE

- slotcar-doc.git Documentation and papers

fs, fw, sw, ctrls are developed in Eclipse and project settings are included in these repositories. Therefore we would recommend you the same.

For working with java you need to have Maven, Git (optional) and CDT plugins. Additionaly we are using ANT scripts and SCP, therefore you need to add JSCH. Download it and add it to Eclipse

Window -> Preferences -> Ant -> Runtime -> Classpath -> Ant Home Entries -> Add External JARs...

For working with STM you need to have cross compiler and plugin, more information here.

You can easily add the projects into Eclipse by

File -> Import -> General -> Existing Projects into Workspace

Hardware

In this chapter we describe hardware solution and electronics.

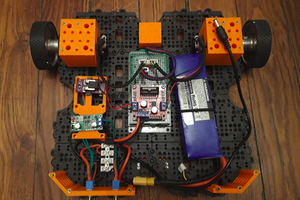

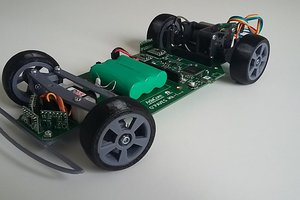

The mechanics are well known slot cars (as show on pictures below), nothing new.

The overall electronics consists of two boards (top and bottom) and two distance sensors and one Infrared encoder (IRC).

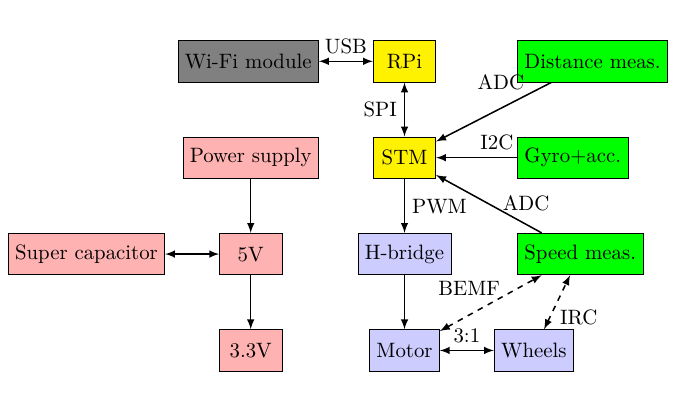

PCB: On the top board there is the Raspberry Pi Compute Module (RPi), which is a very popular for embedded projects. It is the main computation unit. Next there is the USB connector for a Wi-Fi dongle (IEEE 802.11g), which is used as the main communication interface among all cars and with GUI/user pc. We also equipped the car with alternative communication interface Zig-Bee but we are not currently using it.

On the bottom board there is the rest of the electronics. Namely power supply chain (rail voltage (12V) → 5V → 3.3V → 1.8V), The ARM processor STM32F401 (STM), Motor driver, sensors for acceleration and rotation, magnetometer and super capacitor.

STM is there as a low level worker, who does simple yet very important job. It behaves like a sensor and low level controller for speed loop. It is a complement to RPi since it doesn't have any ADC. Moreover some measurement task needs to be done in very high frequency with precise timing, approx. from ones to tens of kHz which is not possible on RPi, because there is a non-RT OS, which can't acquire such precision. However, for purpose of controlling slower dynamical system like our car, then we are able to achieve good precision of timing compared to the period of the control loop.

There is also a 1.5F super capacitor for being a backup power supply when a loss of power happens. It backups only the digital parts not motor. It lasts for 6s.

Speed measurement is done by two methods. First is based on a homemade binary infrared encoder ( black and white circle on rear axle). The second method is based on measuring back EMF from motor, which is then multiplied by motor constant and the result is angular speed, which is then easily transferred to translation speed.

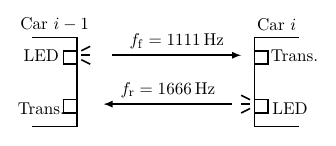

Distance sensors are based on measuring intensity of light.

where d stands for distance, s is intensity and c is just a calibration constant.

Motor driver: Stm drives the motor by 20 kHz PWM...

Read more » Zdenek Hurak

Zdenek Hurak

Pierrick BOISSARD

Pierrick BOISSARD

matop

matop

AdaCore

AdaCore

Dev Joshi

Dev Joshi

A platoon of connected automated vehicles (CAVs) is defined as a group of CAVs that exchange information, so that they can drive in a coordinated way, allowing very small spacings and, still, travelling safely at relatively high speeds. The concept of vehicle platooning is not new. https://insulin-store.com/