Latest board all seems to work :-)

The only bad news for me is that using a single 14500 3.7V 1200mAH AA battery instead of 2xHiMH batteries will effectively half the battery life (probably less as popular opinion seems to say these type of batteries exaggerate their mAH figures by about 50%) , though I'm happily still getting several days use during my testing, As I have effectively had the cases already made I am restricted to using an AA sized battery for this version, shame as there are some nice 2000mAH ones out there for less.

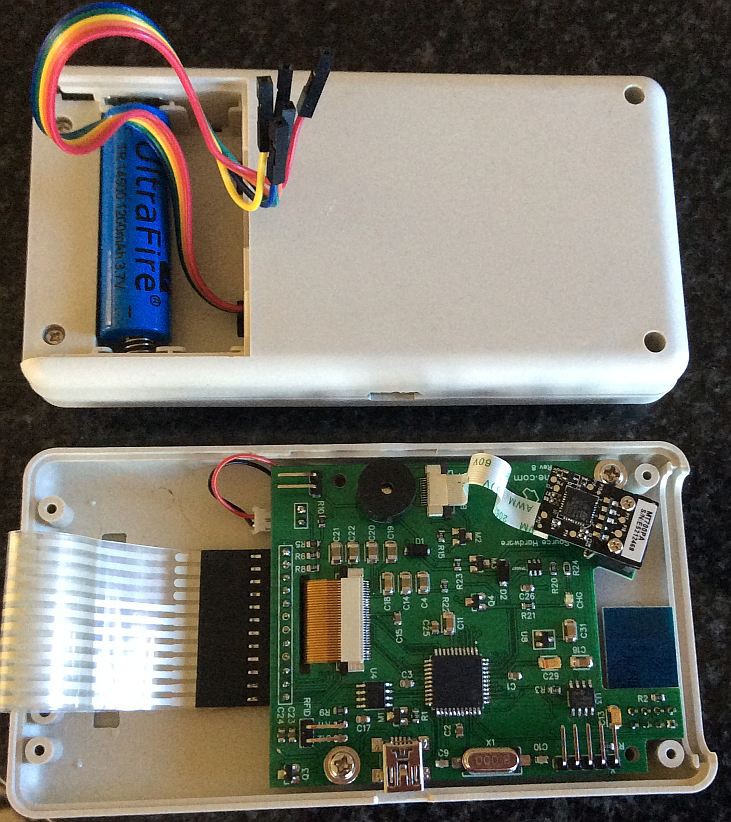

Picture below of the prototype, as you can see it is very low density and I have widened the spacings between most components to make it more hand solder friendly.

The wires sticking out are the ICSP programming cable which wont be in the normal version, luckily they fold under the battery cover for testing.

The ESP-01 (ESP8266) module fits perfectly at the top, away from all obstructions. the reason I chose the ESP-01 over the SMT versions of it was because I can program and test the firmware and module before soldering as my opinion of the quality of this unit is still not 100% I am using the V0.9.5.0 firmware which has V2.0 AT Command set. I will put this firmware bin file along with the documentation and on github once I'm happy it is at least as stable as the previous version.

Also note that as we power on the ESP8266 only to send queries we have to wait for the connection to establish each time so there is about a 2-4 second pause before the query can get processed (the SQL part to run several queries and return the results only takes 100mS or so) this is not really that noticeable to the user and has many advantages for me as it completely removes power to the ESP8266 effectively starting from a power on reset each time so we shouldn't get any cumulative stability problems introduced and power consumption is nil when we are not communicating. Same goes for the barcode scanner.

I have cut away a side hole for the USB connector which is a little messy.

Note there is a big whoops as I must have used the new sandbox version of EasyEDA to do my latest PCB routing as it does not show in the current link. unfortunately there is no backward compatibility with the old version but hopefully by the time you read this Dillon (the writer of the software) will have updated EasyEDA

(If not use http://sandbox.easyeda.com/project_view_Data-Entry-Terminal_neKEWQ8qI.htm )

You can also order a PCB from them (and help finance the project) by clicking on their shopping cart, the PCB's are made by seed studio and are really good quality) you can also fork off the PCB for editing and/or download the gerbers from here.

I have used the prototype and conducted a real life end-to-end test already ie

1. Scanned a barcode from a job sheet

2. Sent query via wifi to server and had server parse the query and return the details of the job

3. Updated the job status by selecting from a menu item

4. Send query via wifi to update job status and logs

This proves the concept is sound. There is also a blog post on the higher level stuff at my web site http://rodyne.com/?p=611

Note: I have not gotten around to testing the RFID, though this all worked fine in older prototypes so I don't expect any problems.

Boz

Boz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.