This is based on the design of a strain wave gear, but it not an exact copy of a strain wave gear. Strain wave gears characteristically have an oval wave generator, a flex spline cup, and a circular spline. The wave generator engages 1/3 or more of the teeth at the same time. It does not seem attainable to engage that proportion of teeth in this current design.

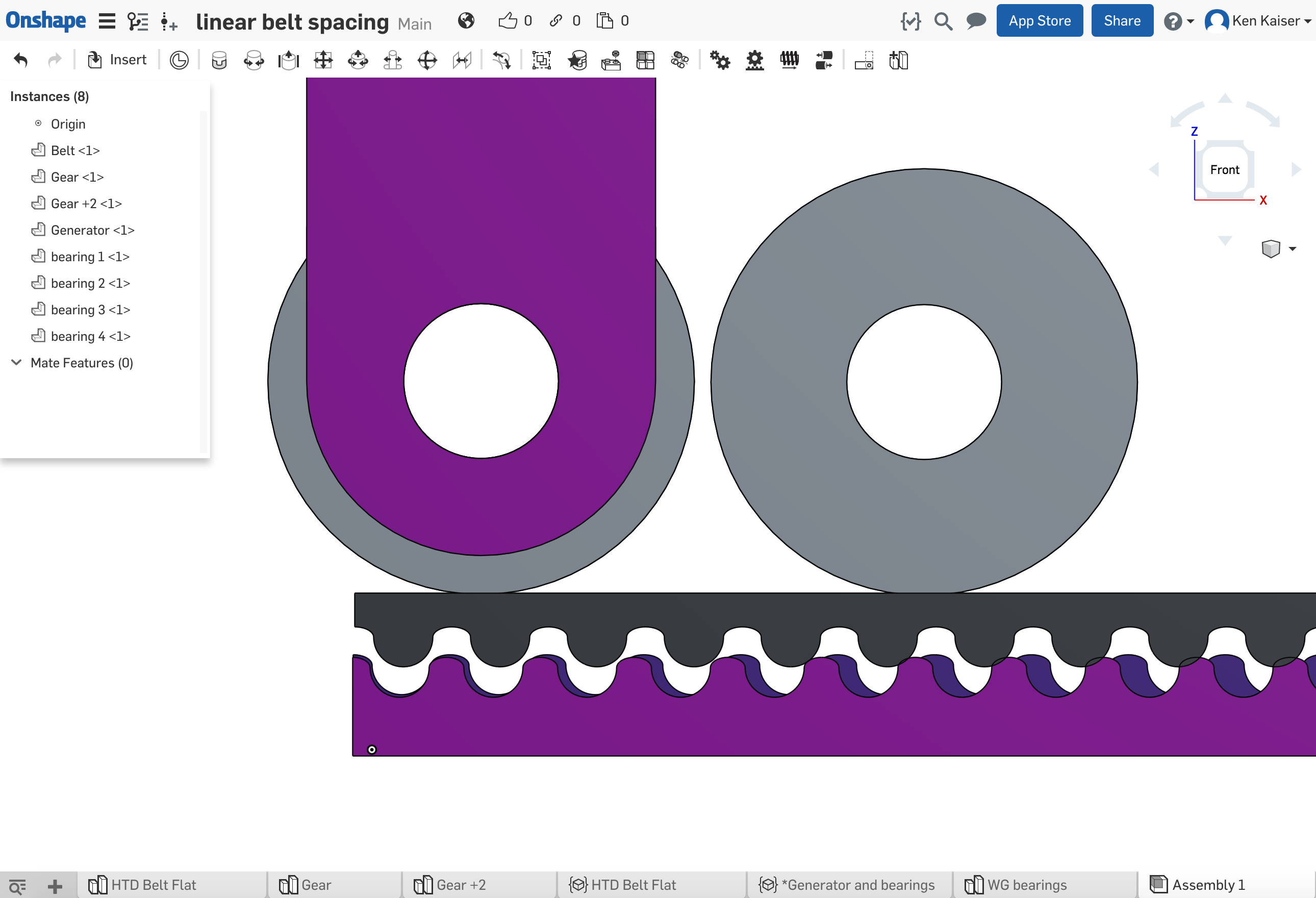

The input gear that matches the belt teeth is in the back dark blue/purple, the output gear with +2 teeth is pink.

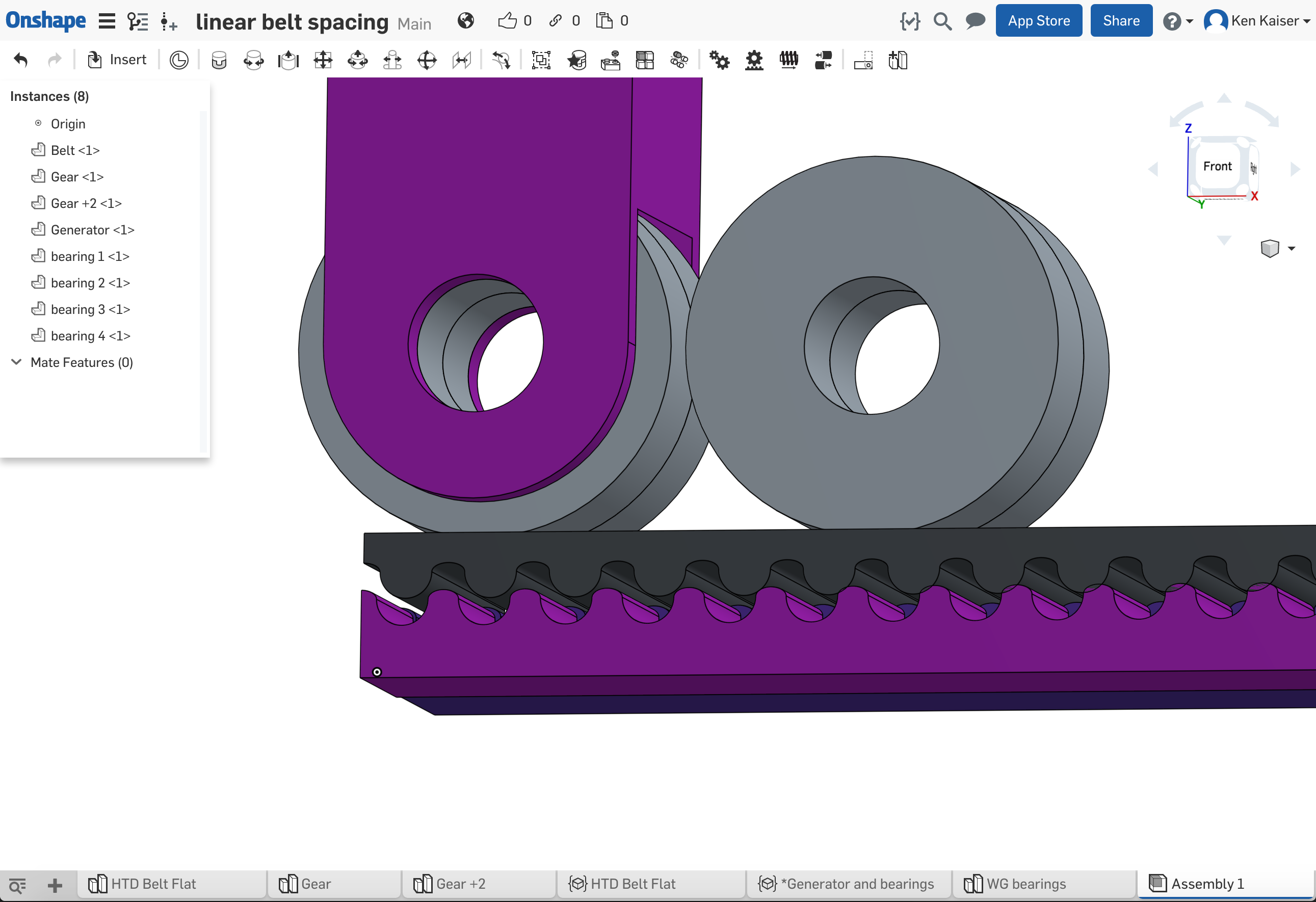

As you can see, the second bearing would be forcing the belt into 1/3 of the tooth of the outer gear, at the gears are positioned right next to each other. The belt tooth is directly over the output gear tooth at tooth 15 into a 60 tooth belt, a belt that is 300mm long with 5mm pitch.

The first revision increases the area that would engage from wider bearing(s) and belt. What is the force transmitted by a single tooth?

This design is a game changer, but we have to test torque. Even if this design can't handle torque, there is optic positioning, and anything that needs precision movement. I can see the times where I'd trade the speed and torque of a 200 step stepper to get 6000 steps of resolution from the simple gear in the videos.

Ken Kaiser

Ken Kaiser

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

There's a comment on the hackaday blog about the torque limitations of strain wave gears but acknowledges their potential precision.

We've discussed this in PMs but it's worth saying that you can use larger diameter bearings in the wave generator arm (or print a wheel to slip over the 608s and increase their effective diameter - don't forget to redesign the arm if you do).

Are you sure? yes | no