-

6: Planting

02/07/2017 at 05:47 • 0 commentsFinally, the posts were ready, so I called 811 and got my utilities marked, pulled up the rotting posts, and started to dig my holes. Part of the reason for the digging was that I wanted to move where one of the posts was, but I also needed to dig deeper. I had made these posts extra-long to make sure they wouldn't ever start to slump over in the dirt.

It turns out that there are USPS regulations on where mailboxes should be, and I followed them to the letter. This meant digging a hole about 36 inches deep. I got lucky, and didn't hit any huge rocks or unmarked gas lines.

Once put into the hole, we had to fill in around the posts. It turns out that it's non-trivial to pack dirt back around a post, but we made this a little easier by tamping down the dirt with the end of some left-over rebar as we filled the hole in.

With the mailbox posts secured, I then set about attaching the mailboxes and numbers. Rather than drilling holes in my nicely-painted concrete, I used some thick two-part epoxy to glue everything on. One complication was the polystyrene mailbox material, which almost no adhesive wanted to stick to. With a little trial and error, I eventually got the mailboxes and numbers to stay attached, with some tape to hold things while the epoxy cured.

Overall, I think they look ok, although I do wish I had found a way to get more wood-grain or joint lines into the concrete. They've been exposed to weather for over 6 months now, and they show no signs of coming apart. With an luck, they'll last a long time, or at least until a car drives into them.

![]()

![]()

-

5: Etching, patching, painting

02/07/2017 at 05:34 • 0 commentsAfter some research on the internet, I decided to acid-etch the surface of the concrete before painting. This apparently helps with the pH, and helps mechanically roughen the surface for the paint as well. I don't have any good pictures of this, as I was mostly trying to make sure I didn't acid myself. It was a pain to do, and I'll never know if it mattered or not. I also have most of a jug of muratic acid left over that I'll never use.

Edit: the acid etch may not have been a good idea, per comment from user Martin. Do your own research on that.

![]()

While I was at it, I did a crazy thing - I got the lowest grit beltsander belt that I could find, and set about ruining it. It turns out that beltsanders do work on concrete, but understandably, it does bad things to the belt. It did work long enough to put a nice little chamfer on the edges of my concrete though.

Once the posts were etched and dried, I painted them white. The painting was done to make them look more like a normal mailbox post (although I still really like the natural concrete look), but also to keep water from saturating the concrete every time it rains. I rollered on some paint and realized that my creation... looked like crap.

![]()

All of the little air bubbles on the surface had blended into the natural concrete color, but with white paint on everything, they visually stuck out and looked bad. I fretted about what to do, and eventually decided to try filling in the holes with drywall spackle. It actually worked really well, and so I spackled and sanded both mailbox posts twice before giving them two more coats of paint.

The overall result is much better with the spackle:

![]()

![]()

-

4: A Cure for Concrete

02/07/2017 at 05:23 • 0 commentsSo, it turns out that concrete takes a while to get to full strength. It keeps curing for a long while after being cast, and for best results, you're supposed to keep the concrete damp for several days to give it time to cure most of the way in ideal conditions.

I didn't want to ruin my form, and I needed to make a second mailbox post, so I kept my form damp for a day (wrapped in plastic), then attacked it with a hammer and some determination to get the mailbox post and the form apart.

The only really tricky part was the triangle that forms the inside of the arm. These three critical pieces of wood were a giant pain to make, as they have some really strange angles on them. This meant that I was doing everything I could to get them out without damaging them. One trick I learned was to use masking tape to seal up the concrete-facing gaps between these pieces, preventing cement from flowing into the cracks and locking them into place. With some chiseling and whacking, I eventually got them out mostly undamaged.

The result? We have a mailbox post! It even has some wood grain, although not as much as I would have hoped. The surface has more air bubbles than I'd like, but it still looks okay. This is the first part where I thought this project might actually work out!

But I couldn't admire my work too long - I sprayed it down with water, wrapped it in a thin plastic dropcloth, and left it to cure while I made a second mailbox post. When they were both cast, the second one was wrapped as well, and they were both left damp with water to fully cure for almost a month.

![]()

![]()

![]()

-

3: Time to work on my form

02/07/2017 at 05:10 • 0 commentsOk, so the first pour was a trainwreck. I did learn one thing though: concrete is a lot runnier when it's being shaken around. This explains all the concrete-vibrating equipment that I've seen references to - it's not just useful for getting the air bubbles out, it also helps the concrete act like a liquid. It's like when you played with wet sand as a kid and could make it all liquid-y by patting the surface.

So, I grabbed a beat-up corded drill, and turned it into a concrete vibration machine. I found a long bolt, screwed a bunch of heavy washers and nuts on, and bent an angle in it so the weight would be offset. I then secured this in the drill chuck, and when running at full speed, it'll just about shake your hands off. Using clamps, we could hold this up against the wood form, shaking the entire form.

I also realized that a horizontal form would be much more sane, so I laid it down, took the right side off, and added a board for the 'bottom'. I also had to fix the pulled-out screws and gaps that formed during the first attempt. This made for much better visibility and didn't involve pouring concrete from the top of a ladder.

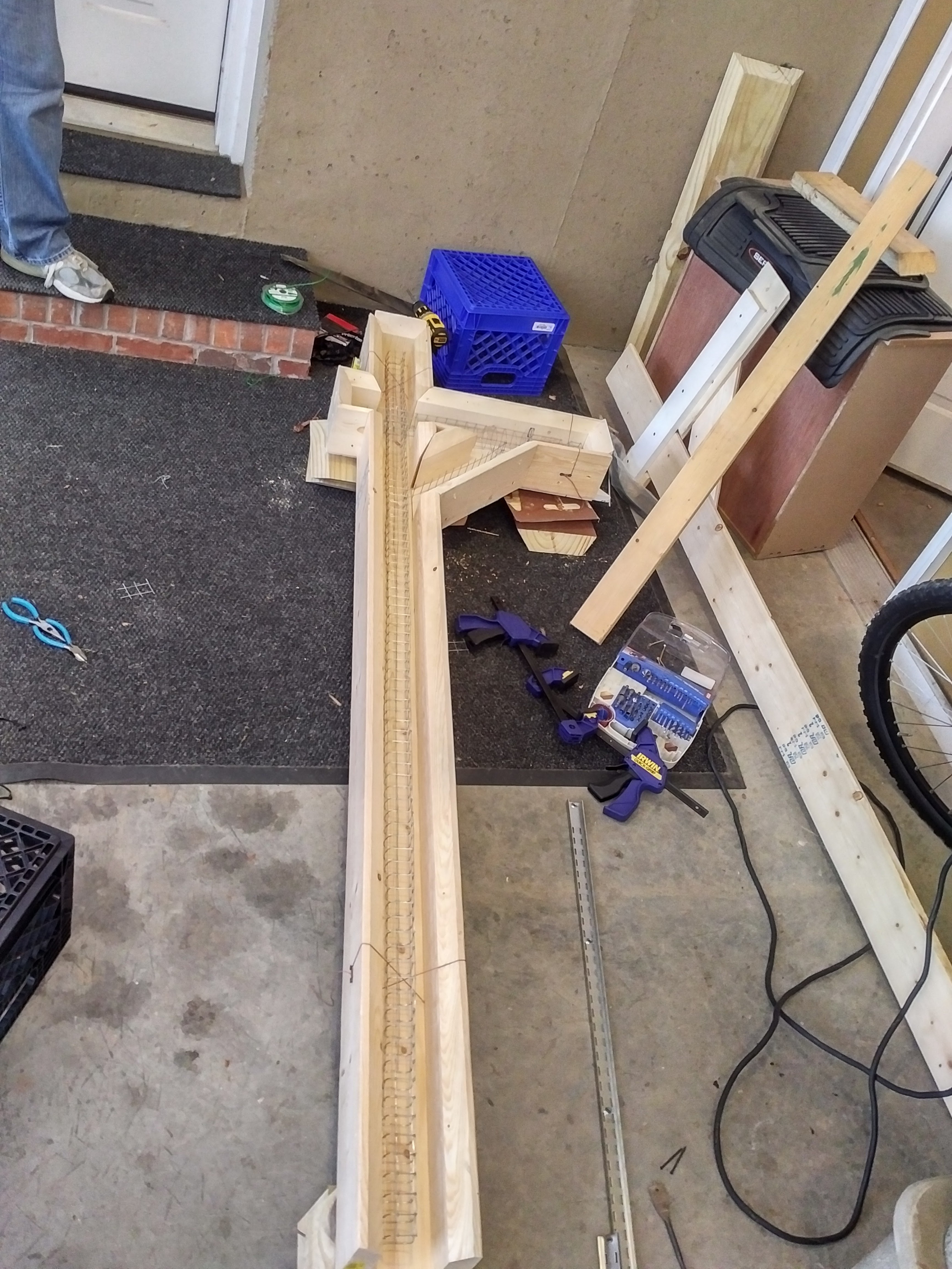

Finally, I learned that I needed better reinforcement. I got some real rebar, and cut it with a cut-off blade in a chopsaw. I the bent some 45-degree angles using some boards, a make-shift vice (a car), and some iron pipe. I laid out some rebar in my form, holding it in the middle of the form using some string, and tied it together as well as I could with bailing wire.

![]()

![]()

We started mixing concrete again. We used a sane amount of water this time (within the manufacturer's stated amount), and poured it into the form. One bucket was about a third of a mailbox post. It was massively thick, but upon firing up our drill-turned-vibrator, it all smoothed out over more than a minute. It was working!

We also had gotten a drill-attached paint mixer, and used that for mixing the concrete. It worked wonders, and meant that we could mix the concrete much faster, which gave us more time to mess with it before it started to thicken.

We mixed two more buckets of concrete and added them in, moving the drill-vibrator to several places on the form, and loosing the feeling in our hands in the process. Once we got it 'full', we smoothed off the top using a board.

One disadvantage of pouring sideways was that the top side wouldn't get nice joints and wood grain from the form, which is important for a concrete post pretending to be wood. We stenciled in fake joint lines just to see if it helped the illusion of 4x4 post construction.

Now, we wait for it to cure.

![]()

![]()

![]()

Caution: Video of the vibration is loud.

![]()

![]()

-

2: A first attempt at concrete

02/02/2017 at 15:30 • 0 commentsSo, the form was ready, and it was time for me try actual pouring concrete.

I pulled out a couple of buckets, and started mixing the concrete at the ratio that they say is recommended. And I'm mixing. And mixing. And it seemed really dry. So I started adding more water, up the maximum amount listed as 'ok' to add. And it was still really dry. It wasn't the liquid-y pour-able concrete I was expecting; it was a thick, chunky mess. I added even more water, trying to salvage the situation, and decided to give this a pour to see what happens. And it was a trainwreck.

I got some concrete into the form, and some all over the outside. It was running down the form, but I had no idea how far. And it started getting stuck in the rebar, and it just got messier and messier. We shook the form, we jiggled the form, we picked up and droped the form repeatedly. We even stared to crack the form. Nothing was working as planned.

I called it after the first 5-gallon bucket's worth, about a third of what it would take to fill the form.

So, what did I learn? That concrete is really thick, and you need to vibrate it to get it to flow at all. And maybe fiber-reinforced concrete is a little thicker.

Once the concrete had cured, we opened the form to get a look at the mess.

![]()

![]()

![]()

![]()

![]()

Summary: The form worked, but there was just no reasonable way to pour concrete in the end. The concrete got caught in the rebar, and never had a chance to fill the 'arm' of the mailbox post. The additional water made for a terrible surface finish. Additionally, the rebar didn't make the concrete strong enough - we broke it by propping the ends up and standing in the middle of a three-foot span.

I later ran some actual calculations on the wire mesh, and it's a lot weaker than I thought. It's time to rethink the reinforcement, and rethink the form.

-

1: Prepwork: concrete, reinforcement, and forms

02/02/2017 at 15:14 • 0 commentsWhen my mailbox post showed signs of rotting and weathering, I knew I wanted a 4x4 concrete mailbox post. I had seen an MCI fiber marker made from concrete, and that post had stood up to at least 15 years, so why not a mailbox post? A quick google search didn't yield any source for such - so it was a chance to make my own.

I started off by making a form for what I wanted. I failed to take any good pictures, but imagine turning a stack of 2x6's into a fully enclosed form, where the open space in the shape of a typical mailbox post, made from three 4x4 post. I did my design work in inkscape (totally the wrong tool), yielding the following indecipherable template:

![]()

The design included all sides except the bottom, as I had some brilliant plan that I would flip the form upside down, and pour concrete in the bottom. This turned out to be a huge mistake, but you'll see pictures of that soon.

So, I spent several hours with a table saw, cut some crazy 45-degree angles, some even crazier 22.5 degree angles, and had a completed form.

One last detail - I wanted to be able to get my concrete to come out of the form later, so I smeared some grease all over the inside of the form. No idea if that was a good idea or not, but it made sense a the time.

I had also done some reading before all of this, and learned a little bit about concrete. Concrete is great a compressive (squishing) strength, but terrible at tensile (pulling) strength. Since my design was for a thin post, I knew I needed something to help with tensile strength.

The first option is fiber-reinforced concrete, which is basically bits of fibers (fiberglass or something else) mixed into the concrete. The idea is that the concrete grabs onto the fibers, and transfers tensile loads onto them. Unfortunately, looking at the numbers for the fiber-reinforced concrete I could actually buy, it didn't look like enough of an improvement to help me.

The next option is some kind of steel reinforcement. This is the category that rebar is in. You have some metal inside of your concrete, and you make sure the outside of the metal has a shape that the concrete can grab on to (like the ribs on rebar), and you're good to go.

The main drawback of steel reinforcement is that some chemistry has to happen to keep your steel from rusting, and it doesn't work for as long if your concrete gets wet a lot (like a malibox post will) and if the rebar is close to the surface (like in a thin 4x4 post). This ultimately led me to the decision to paint the posts when I was done, to try to slow down the chemistry to make these last longer.

I went ahead and purchased fiber-reinforced concrete (because why not - it's not much more expensive), but got some steel wire mesh from the hardware store, figuring it would be a decent reinforcement. It was something like 18 or 16 gauge steel wire on a 1" grid, and was also galvanized, meaning, I don't know, maybe it will last longer? I bent the wire mesh into a square-ish profile to make straight square tubes, and linked those together. I then used some string to hold the wire mesh in the center of the form.

![]()

![]()

![]()

Concrete Mailbox Posts

Making a concrete mailbox posts, and learning about concrete at the same time

Scott G

Scott G