I contacted Remet Corporation because they work with both large and small investment casting shops, and they suggested pattern & sprue wax that should not crack investment casting shells when it's being fired out. After a week of building another shell I finally had some success - shell didn't crack. Unfortunately the wax burn out was very messy and required hours of cleanup, so Remet's advice on flash firing at 1000+ degrees must have been aimed at some equipment I don't have.

Fig. 1 - Botched patterns used to test the new waxes. I am still having some issues with wax patters breaking apart on de-mold, that will take a few more weeks to fully solve.

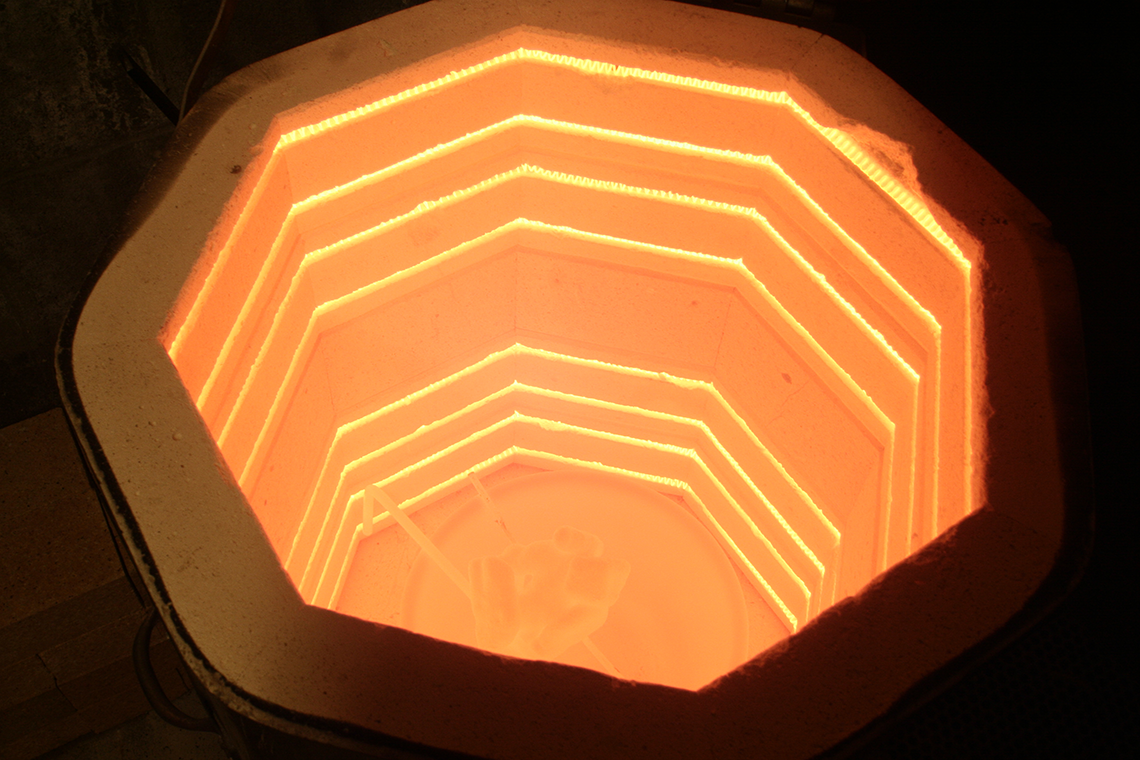

Fig. 2: Shell fired at 1500 F for a few hours after the wax burned out.

Fig. 3: Shell changed color from yellow (after air drying) to white (after firing out the wax and baking):

Fig 4: I will need to solve some issues with surface quality on the shell (probably by removing extraneous particles with filtering, maybe degassing, and viscosity control) but it's not bad.

Fig. 5: Almost all issues with incomplete fills have been resolved, but more research is needed into which surfaces are too thin and should be strengthened with sprue supports to help de-mold (and then are filed away).

Val

Val

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.