Currently the motors are not in working condition. The diesel motor was removed from old Ford Escort with brute force. During removal no mercy was given to any cables or wiring. I labelled all bundles of wires but hopefully we can scrap nearly all of them as I will build the control system from the beginning.

The motor does not likely need a lot of external electronics to run; only power to solenoid valve, glow plugs and starter is needed as motor itself is quite old and simple.

The electric motor was bought at price of scrap metal so the condition isn't great. But I've been told it works so no need to spend too much money to buy a new one.

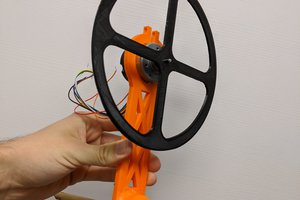

The motors will be connected by either axle or belt. The electric motor has already a big pulley stuck on its axle and it's not loosening even if heated and pulled with puller. It may be easiest to drill new holes to old pulley and attach an axle there. The diesel engine has its gearbox removed but clutch didn't separate with it so new mounts for pulley or axle are needed there also.

The generator will be built on easily movable platform like a trailer or something similar. Maybe we put a little motor there to making it easier to move around?

Jesse Tolvanen

Jesse Tolvanen

TK

TK

Rory

Rory

ARBartz

ARBartz

A.M. Smith

A.M. Smith

Is the diesel electric throttle or mechanical? If its mechanical, this'll be easy to run, wiring's simple on mechanical fuel injected diesels.

Electric throttle? That's a different beast, but will be more friendly to using like an Arduino to control startup and throttle up procedures.