Improvements planned, descending priority. I really need the first few before the local science fair thing.

Improvements:

- Restructure the code as it pre-dates when I learned Arduino sketches can be multiple files.

- Add LCD display to command interface, with legible menus. reading crib-sheet in the dark is problem.

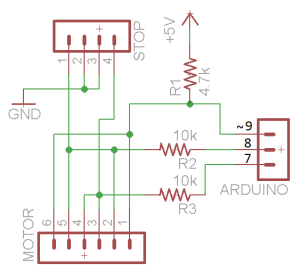

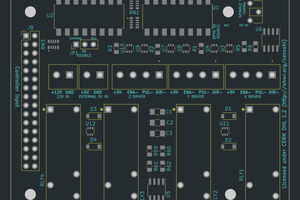

- Rewrite motor control to use PID rather than my wheel-reinvention stuff

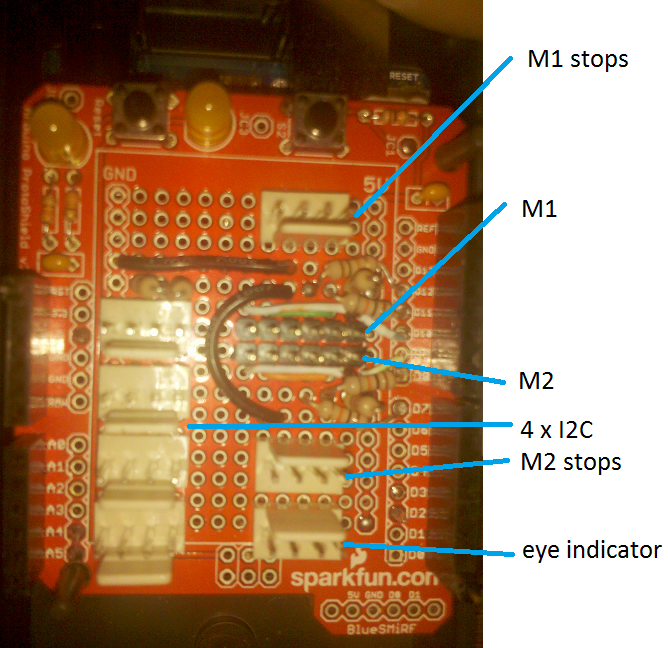

- Improve eye mechanics to remove back-running errors

Essential Repairs:

- Rebuild the eye damaged in weather.

- Repair/improve headset - wear and tear.

- Fix the gun.

- Boost the seat up a bit for better visibility

- New batteries

Wish-list:

- Cooling. Quietly. Somehow. Or a cup-holder.

- Program some autonomous modes.

- New dome (currently smashed and obviously glued back)

- Bluetooth remote for when I'm not inside.

- More height adjustment on chassis so it can be lower to the ground in "optimal Dalek terrain" while higher in mixed real-world stuff

- Quieter caster on the front. Daleks don't rattle!

- Eye camera and google-glass-type setup for improved creepiness and visibility.

- Back and side cameras.

- Stair abatement system.

- Laser cannon.

- Levitation coils.

- EXTERMINATE ALL HUMANS!

Alastair Young

Alastair Young

. An old welding helmet might work too. The shield part is discarded keeping the adjustable part that fits to your head, with the pivot points on either side.

. An old welding helmet might work too. The shield part is discarded keeping the adjustable part that fits to your head, with the pivot points on either side.

José Júnior

José Júnior

parasquid

parasquid

Mo Badr

Mo Badr