The second iteration of the cyclone dust extractor takes the first iteration and improves upon that. This seems to have been successful and the 40 hours that this took to print was not a waste of time.

Mounting the extractor.

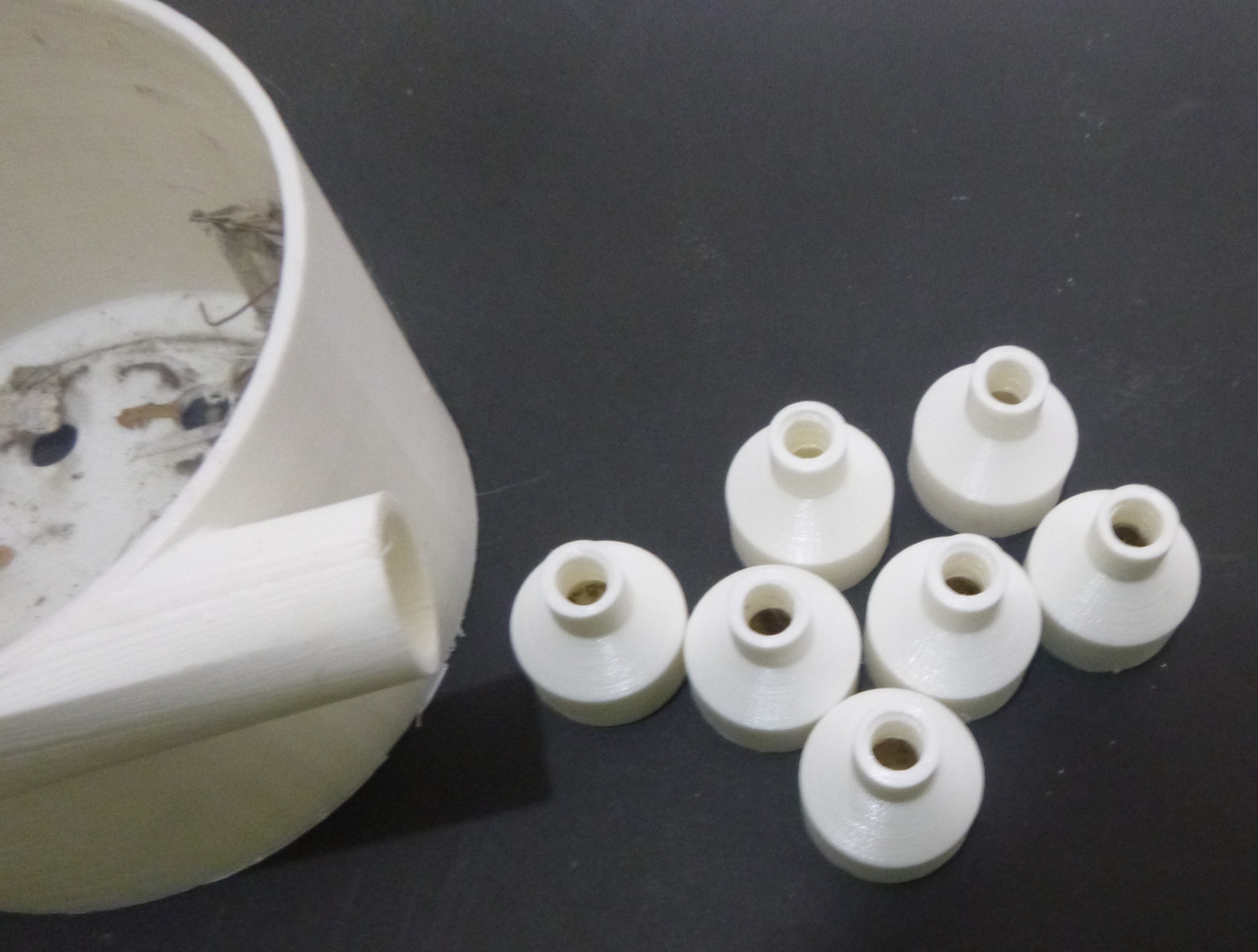

Using the same mounting points as the first attempt. A printed bracket was versioned to fit and then attach to the extractor by drilling four 3mm holes piloted by the bracket. The bracket was then bolted to the extractors chamber fine element chambers screwed on sealing the chamber and extractor mechanism. No gaskets or silicone seals used at this time.

Initial Assessment

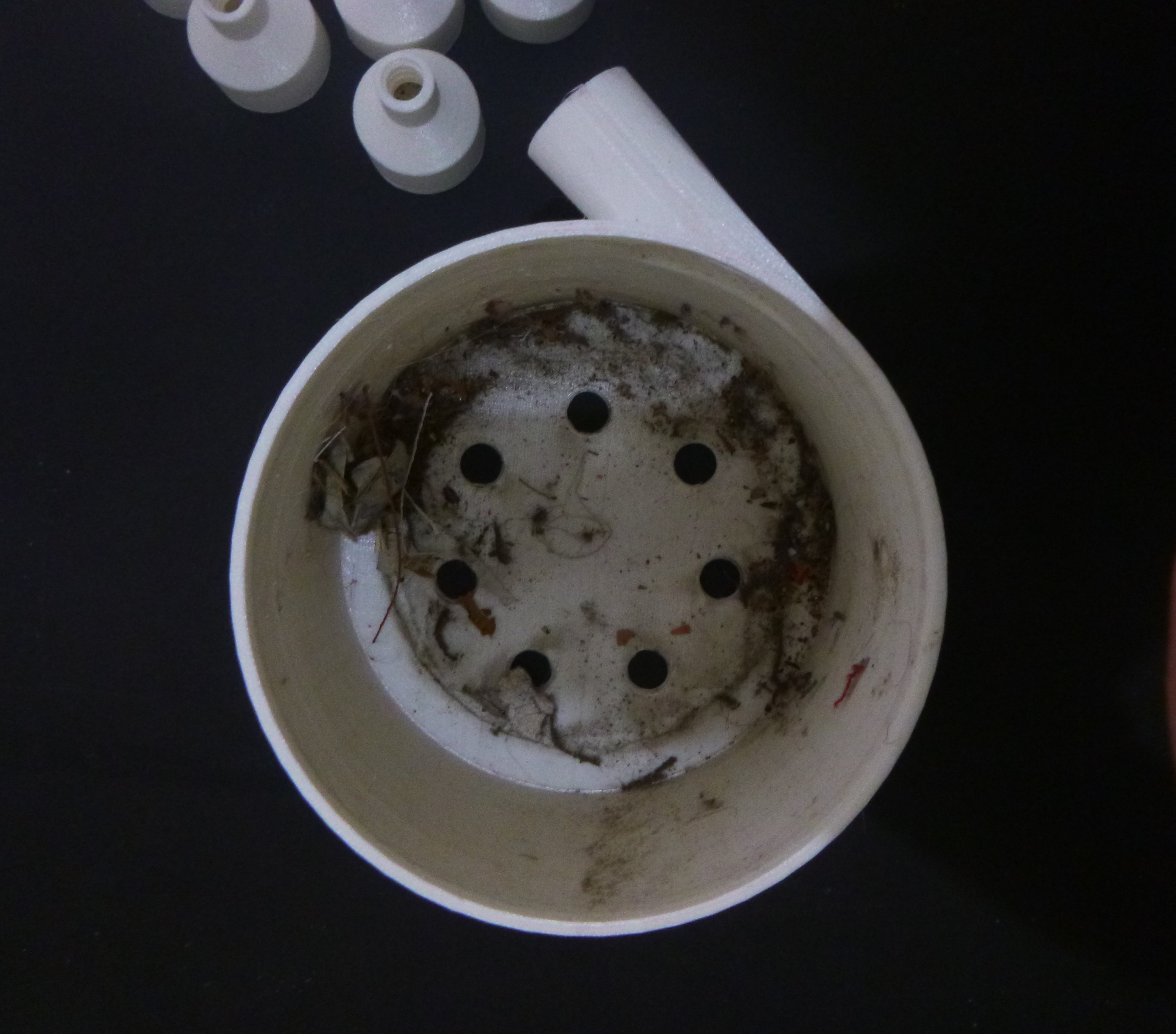

Apparent success! The above images were taken after the first short run of this extractor. They show most of the debris in the main chamber and the small chambers, difficult to see, holding a small amount of fine dust.

Initially when the extractor and the original chamber was taken off the vacuums chassis there did not appear to have any additional detritus around the filter. This was unlike the first iteration were it was obvious that material had made it through the extractor. So this was a good sign. Continued dismantling of the debris accumulating chambers revealed that most of the material was contained within the first chamber.

Possible problem/s

The size of the plumbing is smaller than is desirable due the restricted volumes that is being worked with. This may be making the motor work a little harder than preffered, however putting is a fresh clean filter may address this. An old dirty filter would put more strain of the motor than small diameter hoses and this should not require changing for a long time.

Analysis

A quick calculation of the costs and possible benefits.

The vacuum itself was about $280AU and subsequent replacement filters $23AU, postage about $10AU.

The filters are supposed to be replaced every 6 months. So over a 4 year period that is $92 + $10 for postage.

The major reason this device was made was because the filter needed cleaning every time the vacuum was used. This took about 10mins and if vacuuming once a week over a year that is 8.7 hours @ $22/hr, calculated on housekeepers wage, that's $190 for a year. Now it takes a minimal time and is way less shit.

On the assumption that the vacuum runs more efficiently and extend the life of the vacuum by 50% the total value of the extractor is,

140 + 1.5(102 + 190 ) = $578 over a 6 year period.

Nelson Phillips

Nelson Phillips

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.