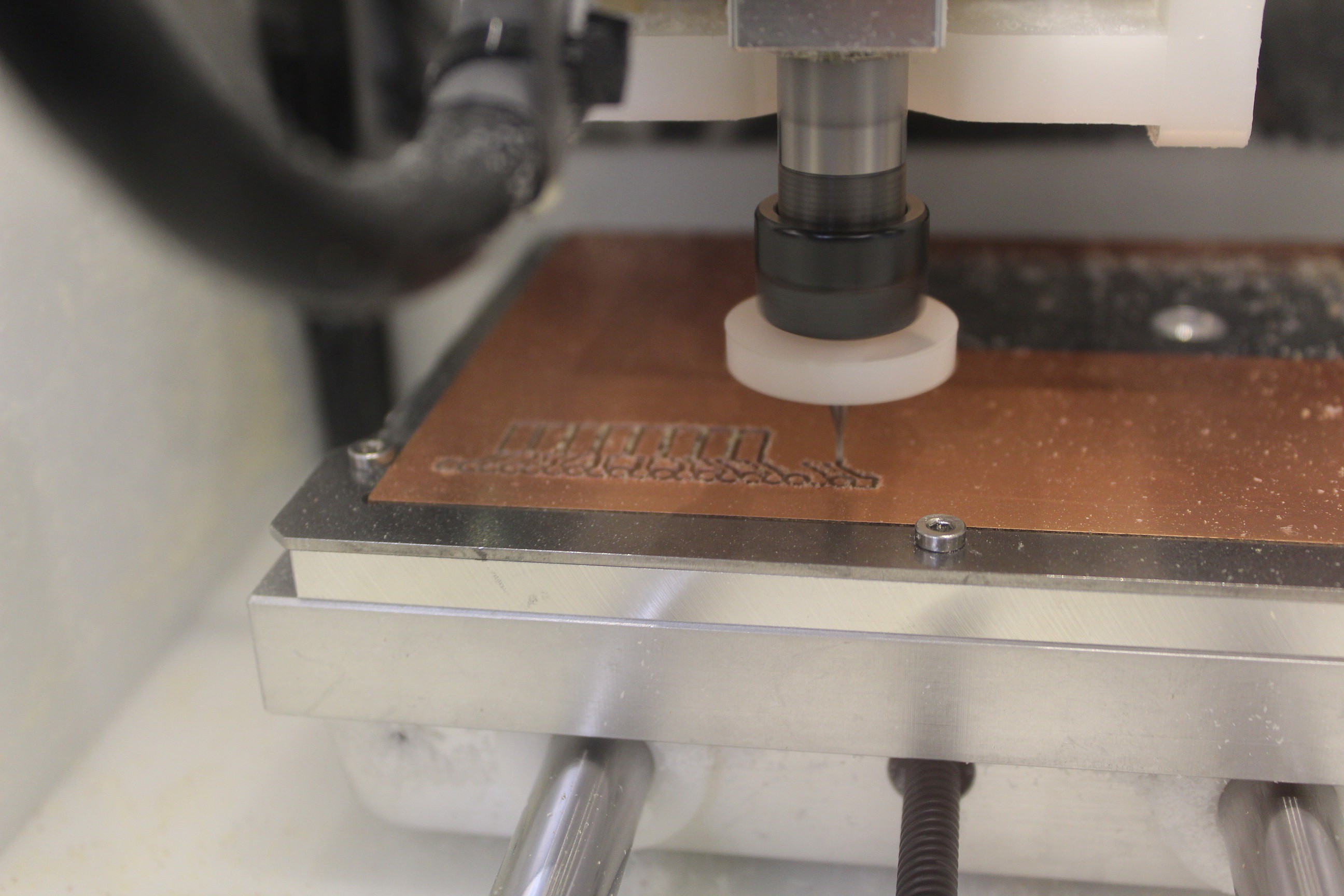

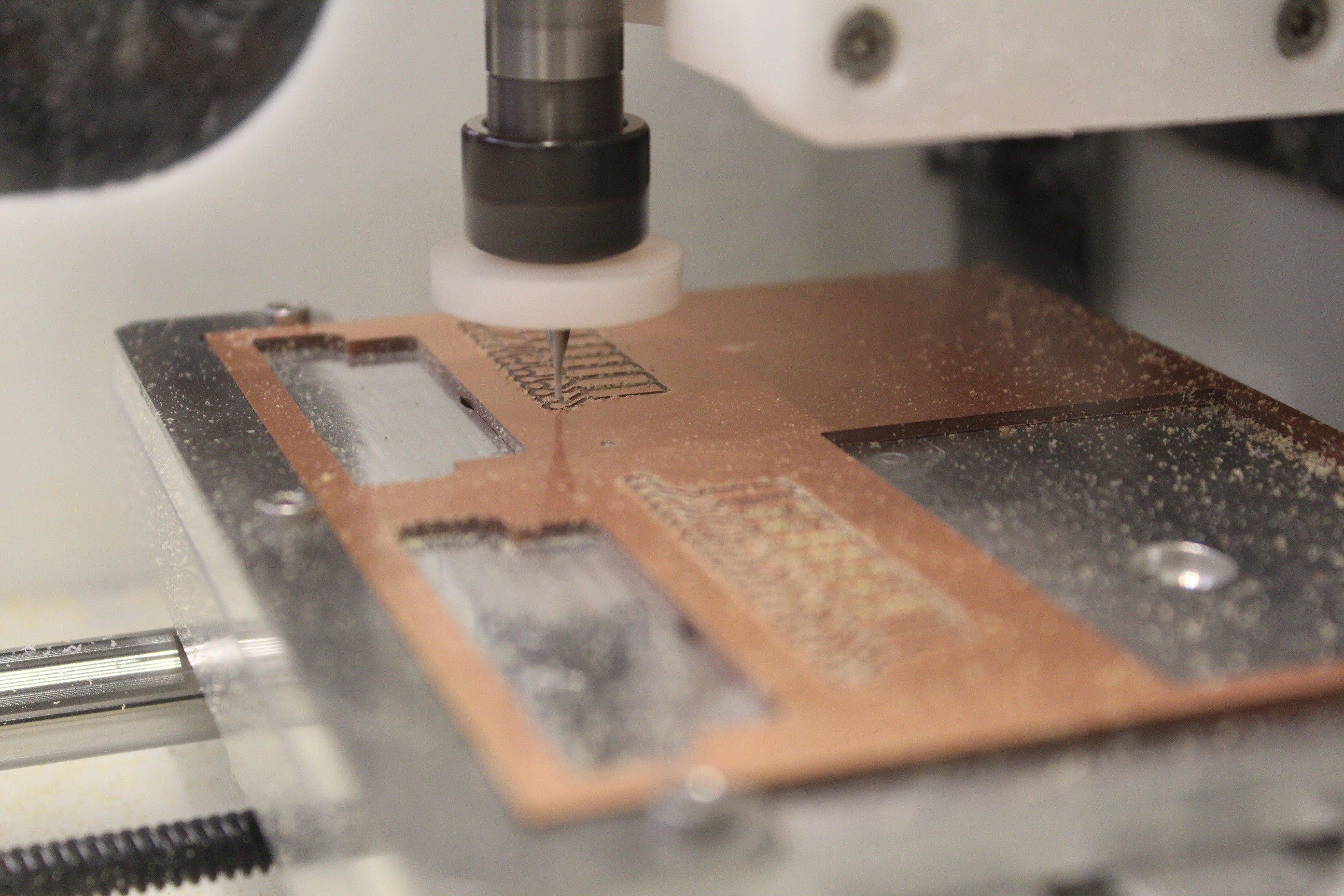

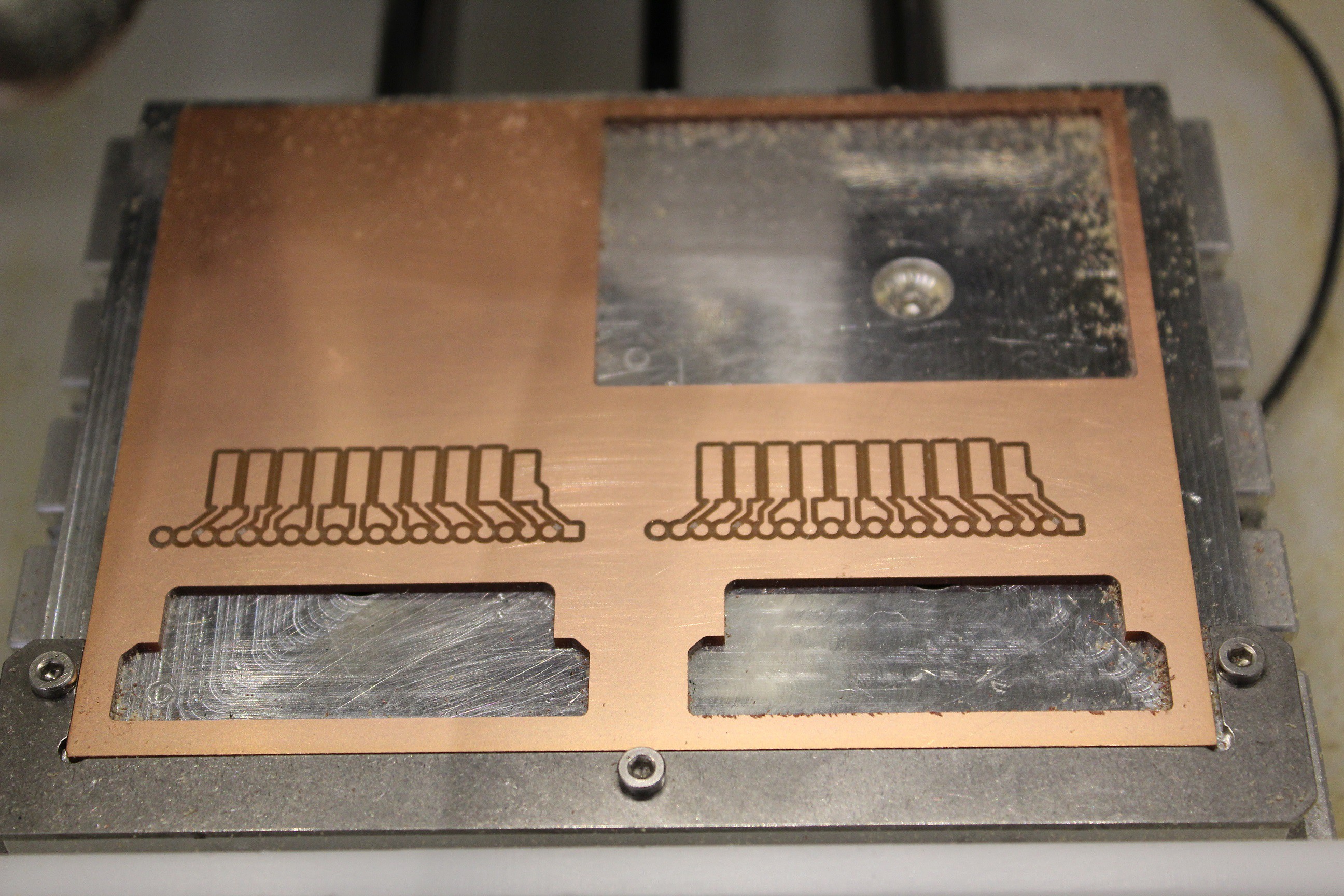

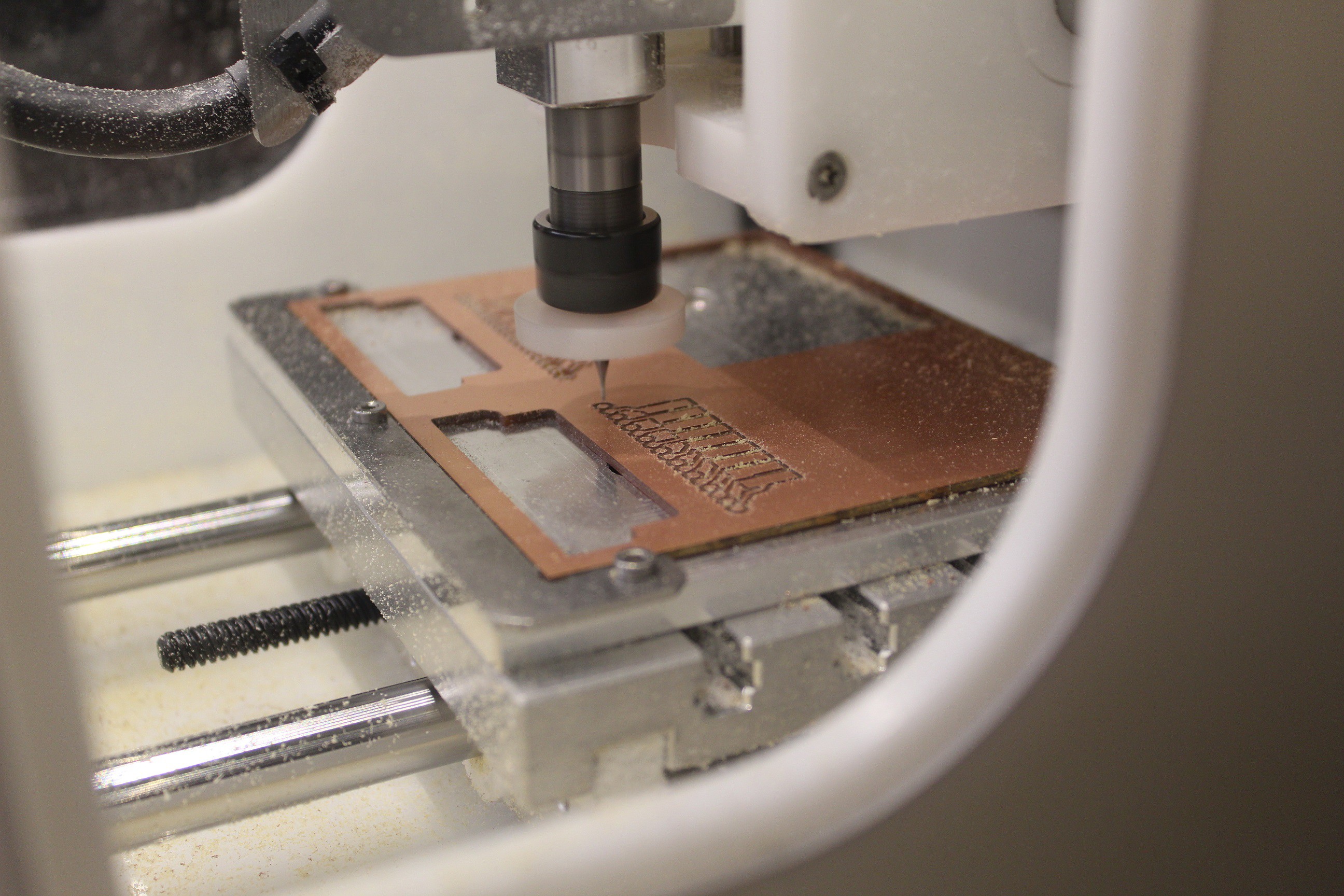

So one of the features I absolutely have to have is what's called a card edge connector. Inspired heavily by the Nintendo cartridges of old. My first system was Atari with the only game of ET.... so we don't count that. Either way it's a feature I really wanted for... reasons. Now after having several default footprints in KiCad be anything but friendly when i go to fit check everything I decided to skip looking hard for anything that might work and instead get my calipers and just do some observation work. Then I had a fun time juggling top and bottom layers while placing pads. Then off to the OtherMill!

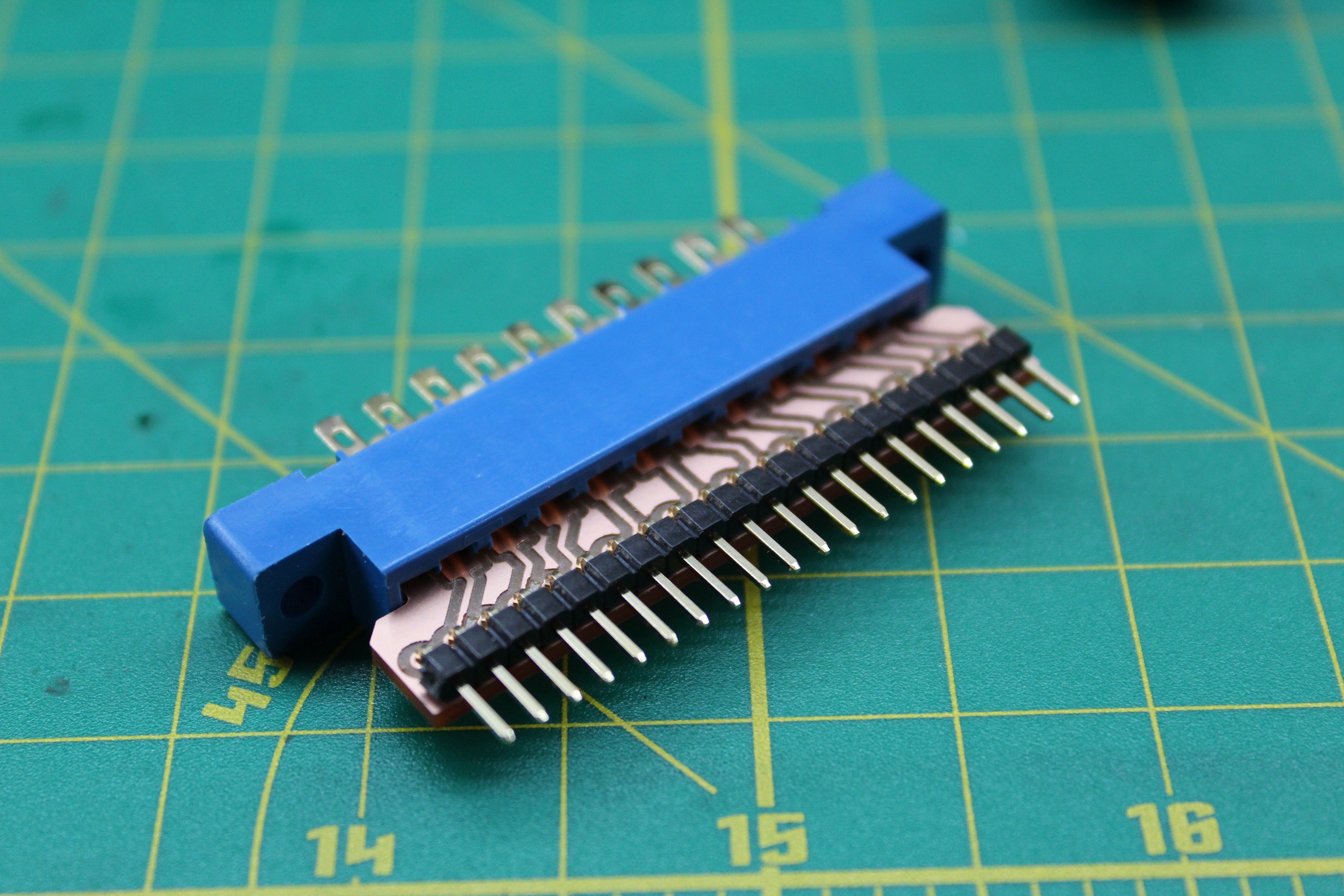

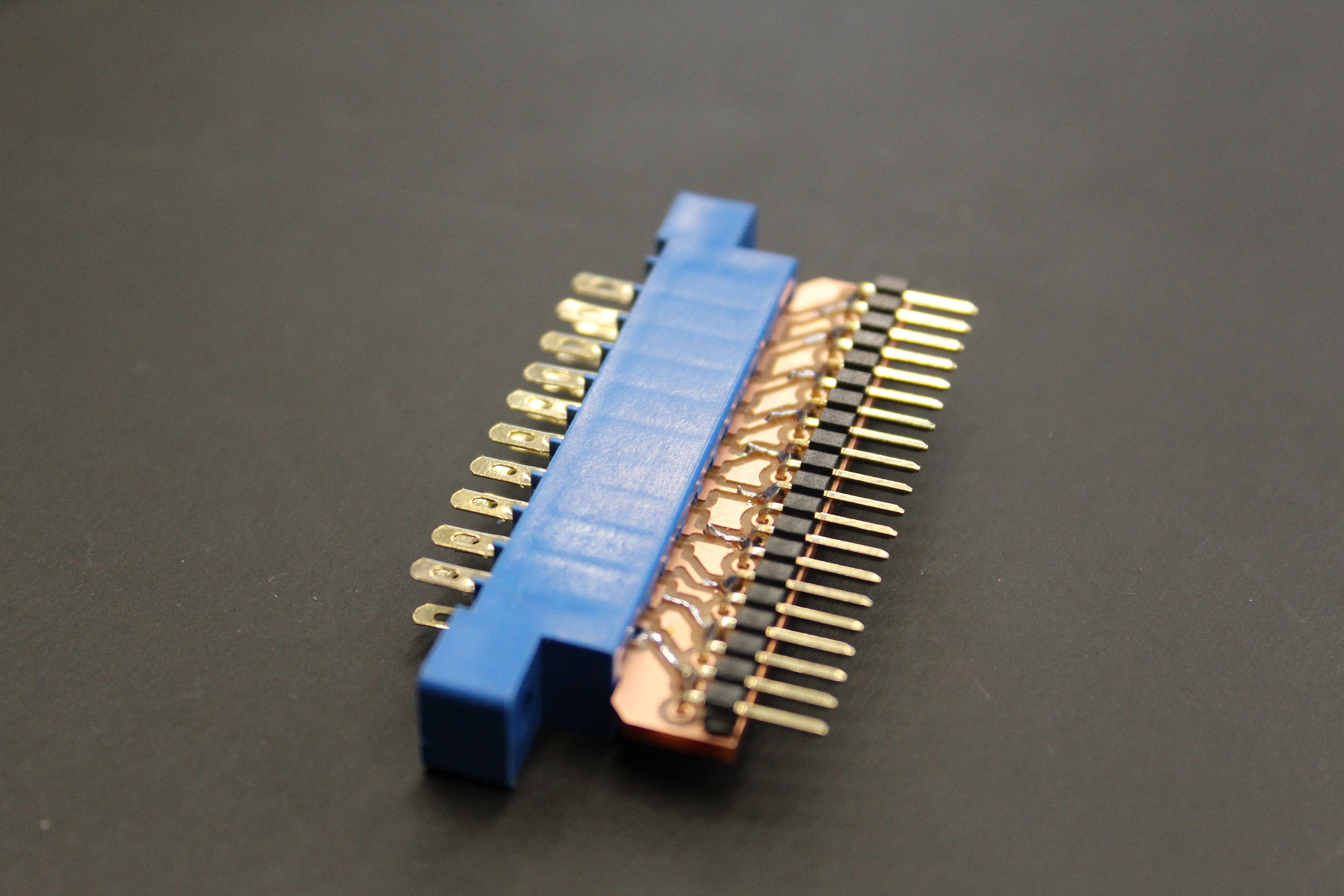

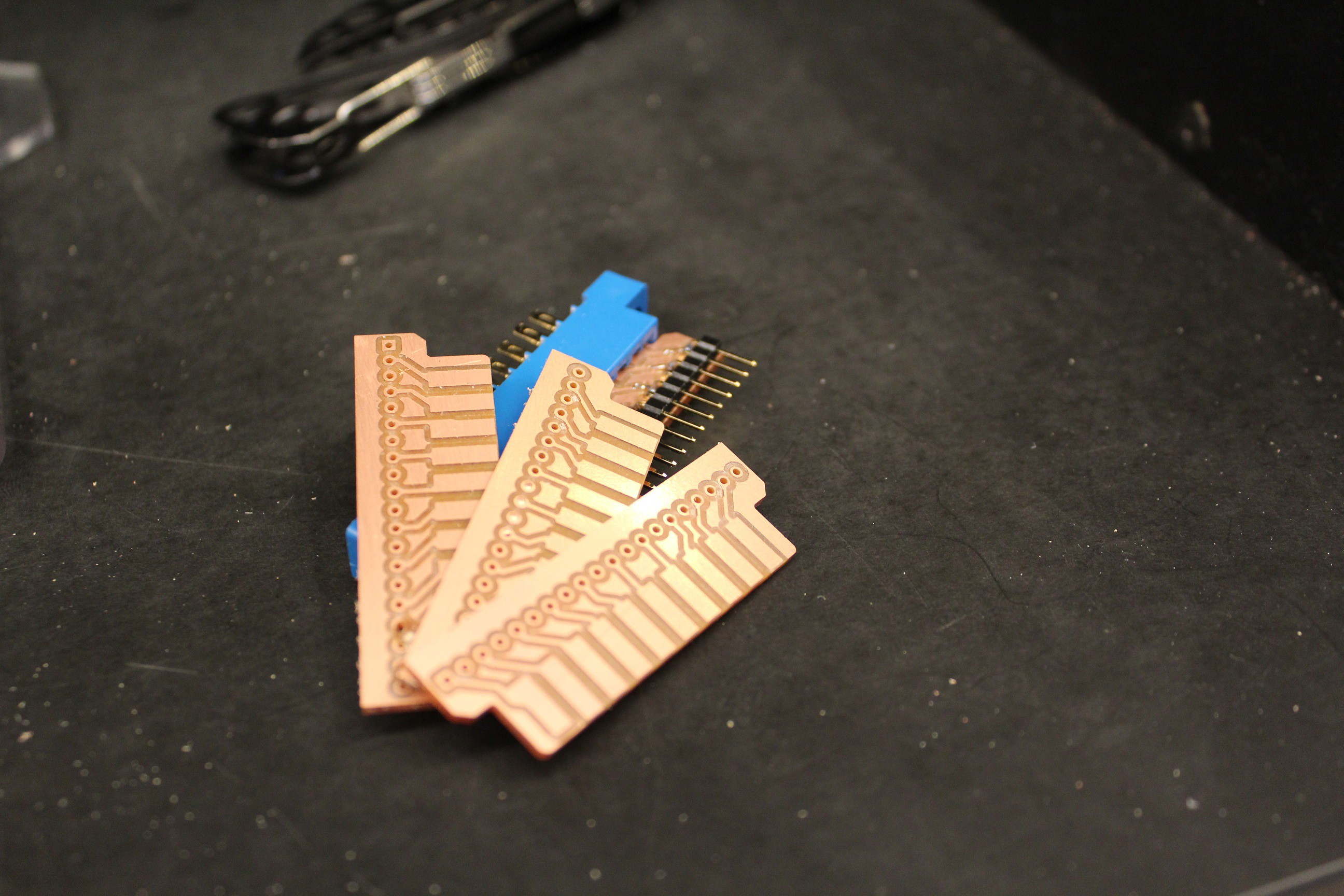

Starting to look like the breadboard friendly test piece.

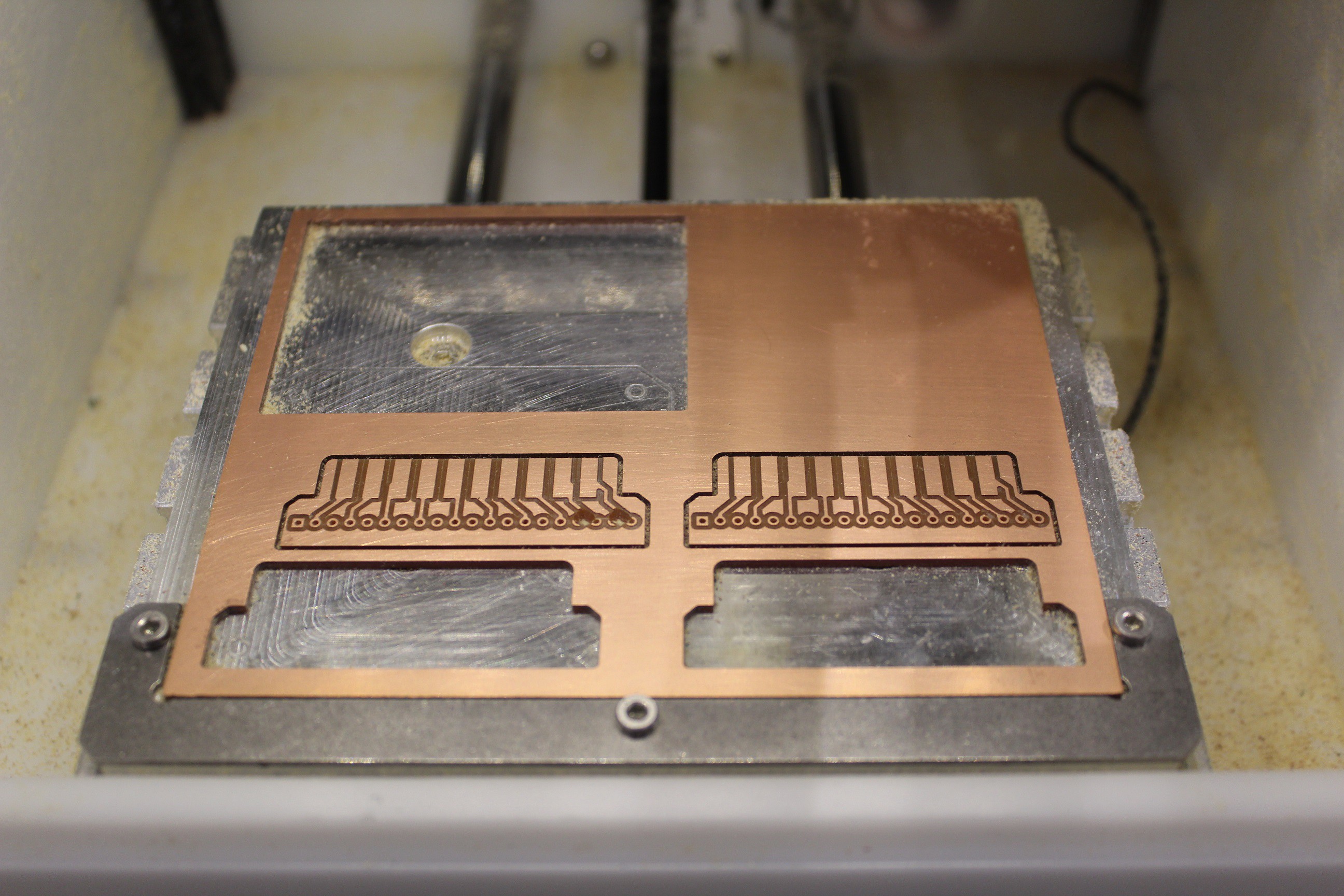

Side one is done, now to flip and cut side two.

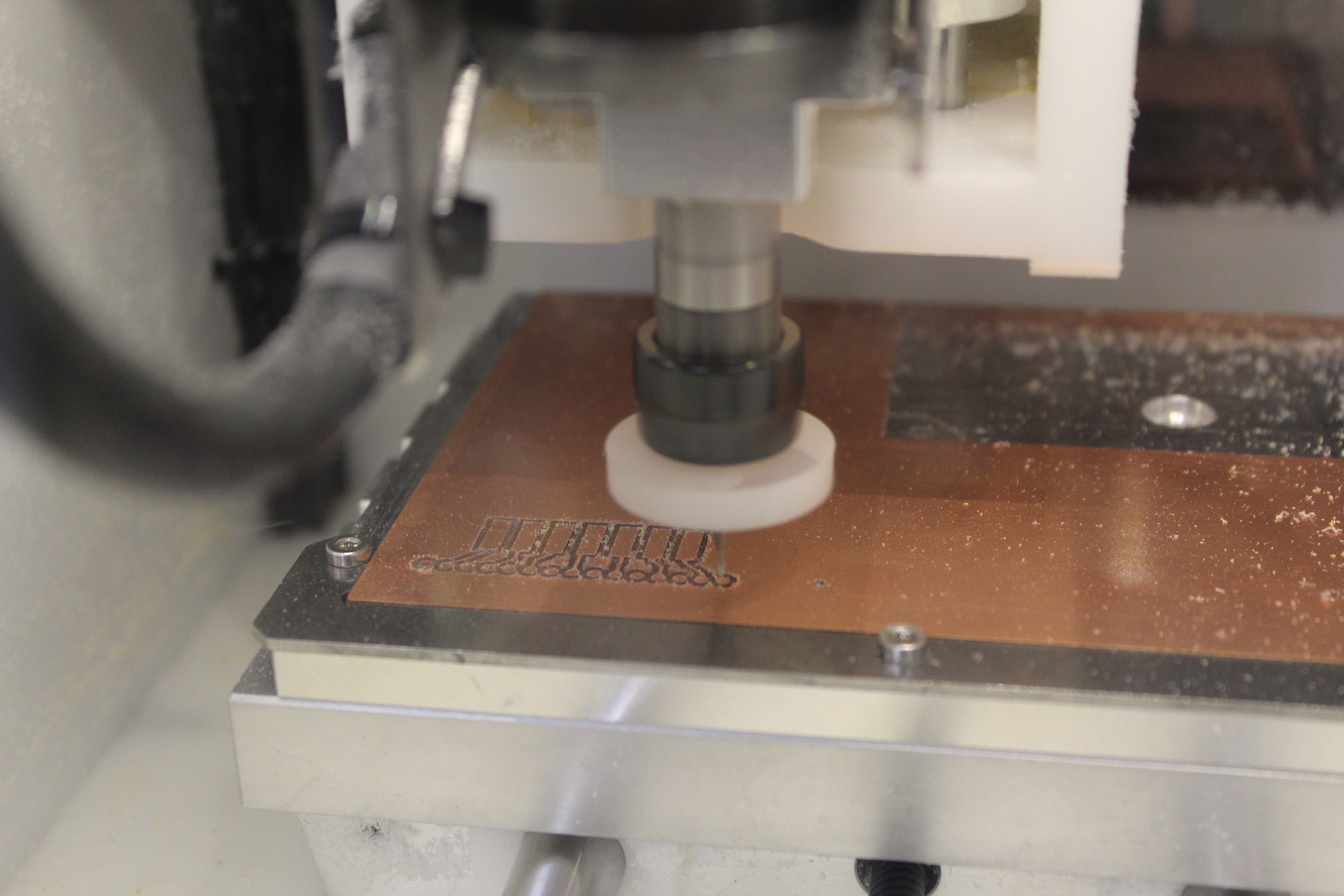

And on to side two. The cool thing in the Othermill software is just a toggle switch in the UI fro front/back. Also there are toggles for Traces, Holes, and Edgecuts. This is important to note because cutting out edges from board on first cut will cause for many a bad time.

And the first impression looks good.

Bring together parts I'll be mating.

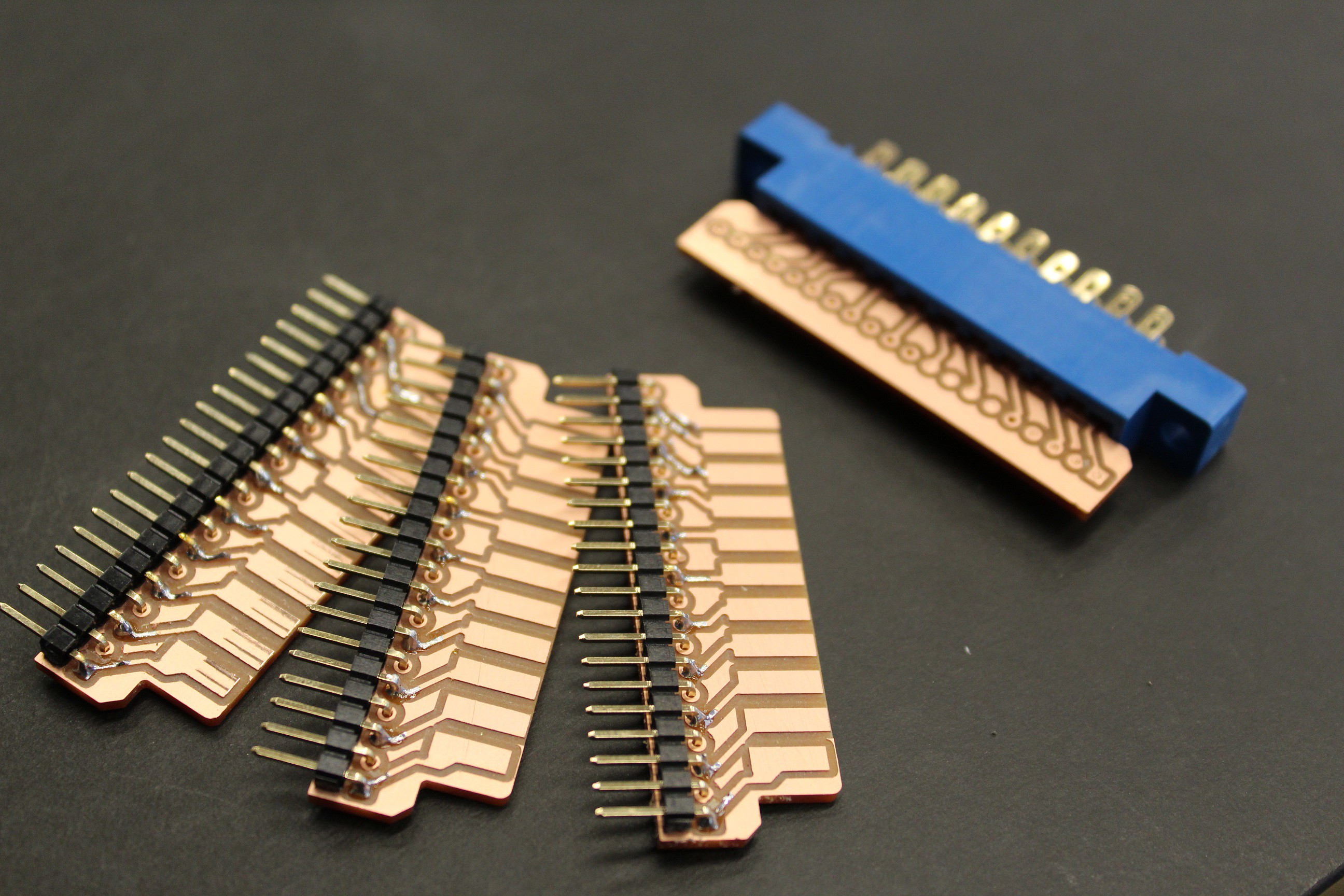

Just look at it!

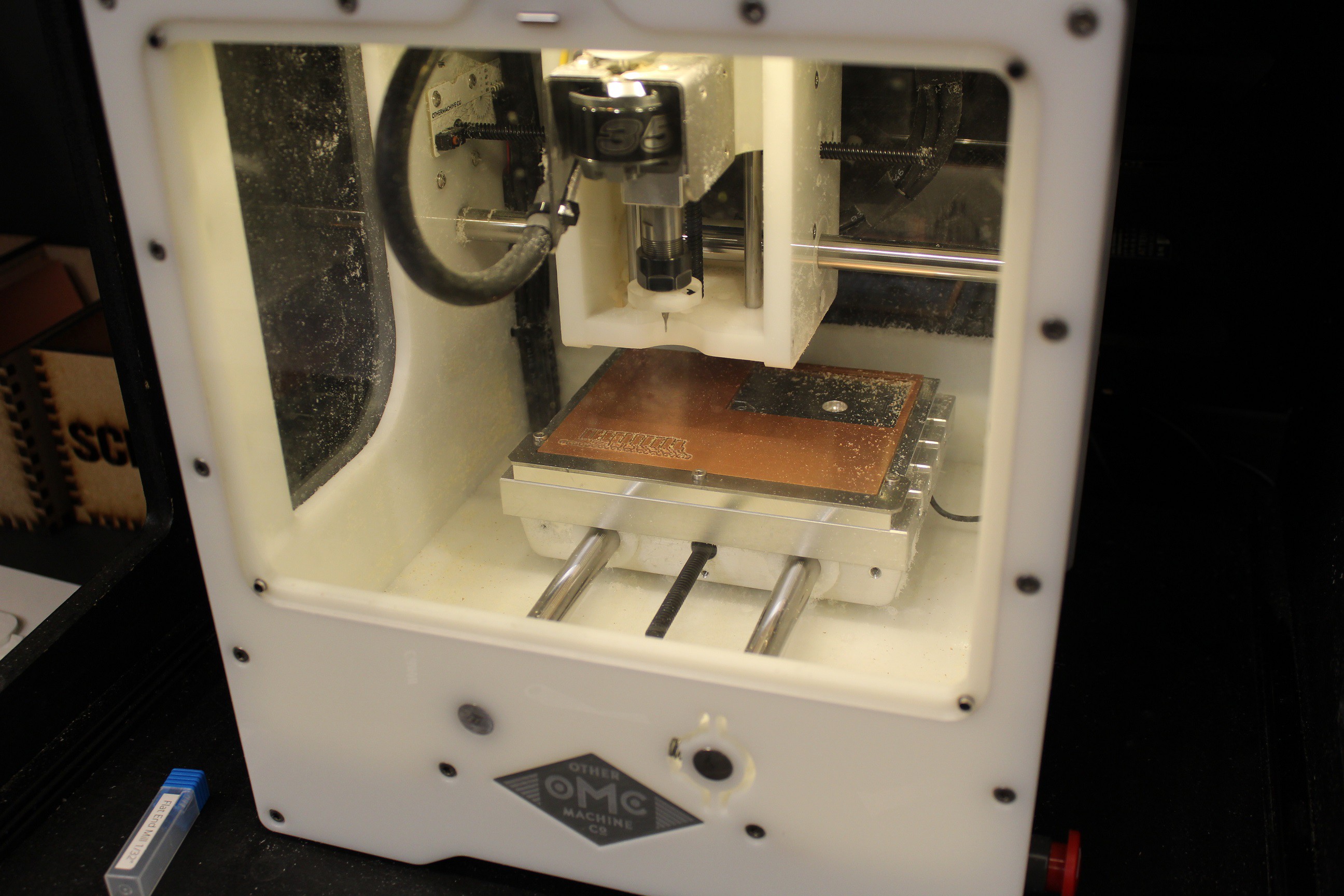

Time to cut out more for testing.

This is a better shot of first side cut. Notice that i recessed one tab, that is the +5v so that i'm better ensuring GND is connected before applying power.

Time to cut second side.

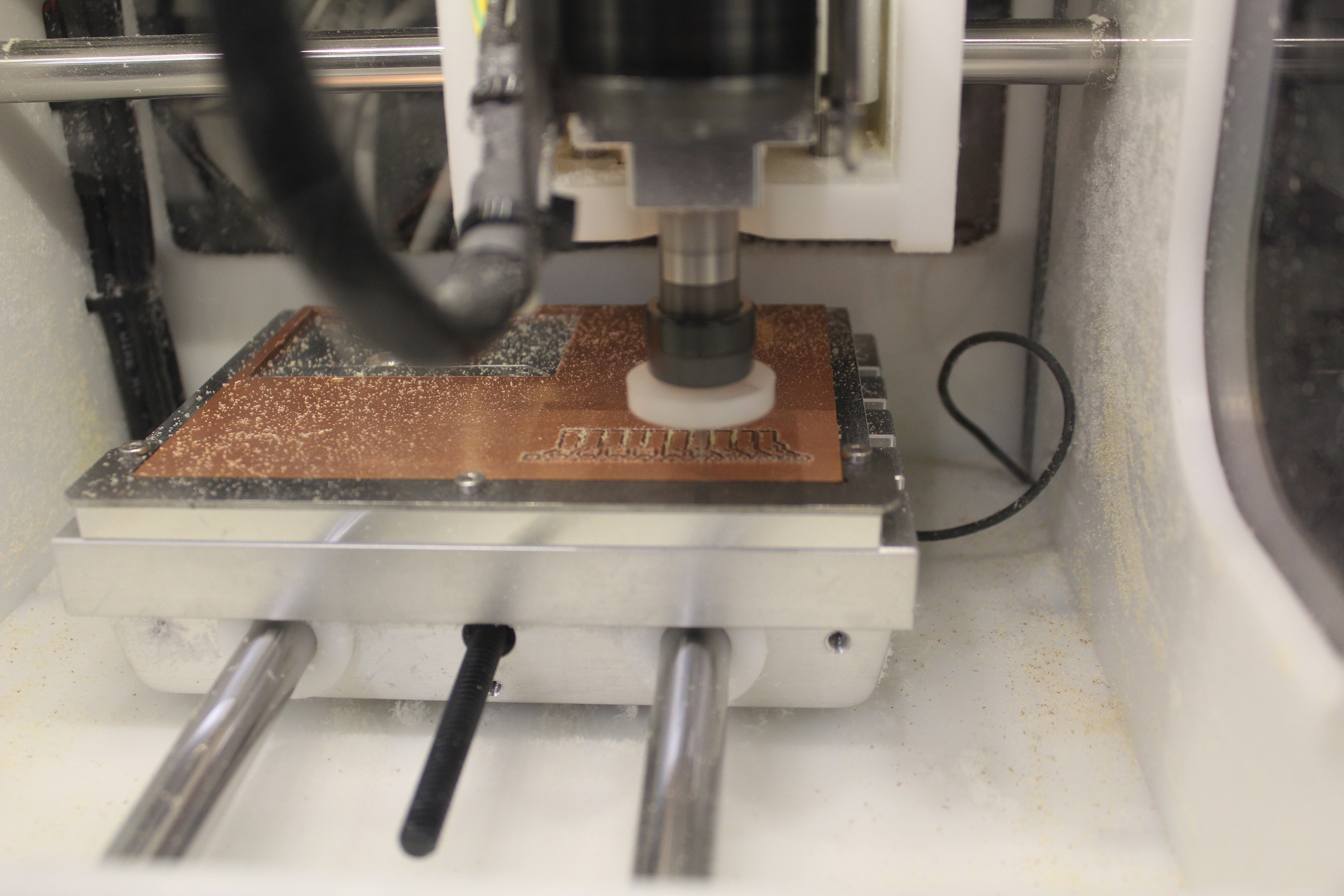

And i made an oops. Two large holes on left side are do to the v bit not making contact on the flat part of the platform on homing. Seems homing position had been changed since I last used the machine, and has since been resolved, But I'm the guy to find out all the issues. Lucky me. :)

And here is a happy family of breadboard friendly edge connectors.

Metalnat

Metalnat

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

The front most edge of the connectors could definitely use some assistance. it's a tight "snapping" fit. That's one of the reasons I went ahead and ordered my oshpark boards to see how much of a difference .13mm size difference effects to fit. If it's still a bit much, my next step is to make the front most 1mm edge a no copper zone to see if that gives enough relief to be perfect.

But all in all, it is workable and worth the effort for prototyping.

Are you sure? yes | no

How is the insertion force without a bevel on the card edge? I have considered making similar connectors for some projects and always figured I'd need to take a file to them to round the edge.

Are you sure? yes | no