I’ve been playing with DIY air muscles on and off since 2007 and I'm contemplating using them on Droidbot-thingy, providing I'll be able to control them satisfactorily. I know they're strong and can be parallelled to further increase their pulling power but are they controllable enough for this application (super precision not needed)?

BLDC motors and 3D printed gearboxes are the main alternative. Air muscles are cheap, easy, light, fast and powerful but are difficult to control and have limited stroke (difficult to get a limb to fold back on itself), whereas motors are great for positioning, easy(ish) to control and can have a limb fold up on itself with no problems. However in order to get enough torque, the gearbox must provide sufficient reduction but this comes at the cost of speed; I could have a super strong robot, a SLOW super strong robot. The gearbox is the complex bit and potentially costly. High torque gearhead motors are expensive and I need a lot of them. And I'm tight.

So I keep coming back to PAMs, at least until I convince myself there's a better way. The rig was just a quick lash-up to get a feel for the PAM performance as an opposing pair on a simple single-jointed limb. I know from experience that air muscles have a massive strength-to-weight ratio but I've never before got to the stage of testing for control, mainly because I had focused on the design of a cheap DIY proportional valve that would work at 100psi - it worked, but I didn't like it; too messy. Maybe now I could 3D print an improvement. Anyway, the muscles are directly fixed either side of the joint (containing a pair of skate bearings) without any additional pulleys (yet) and their mounts don't allow for proper articulation, but it'll do.

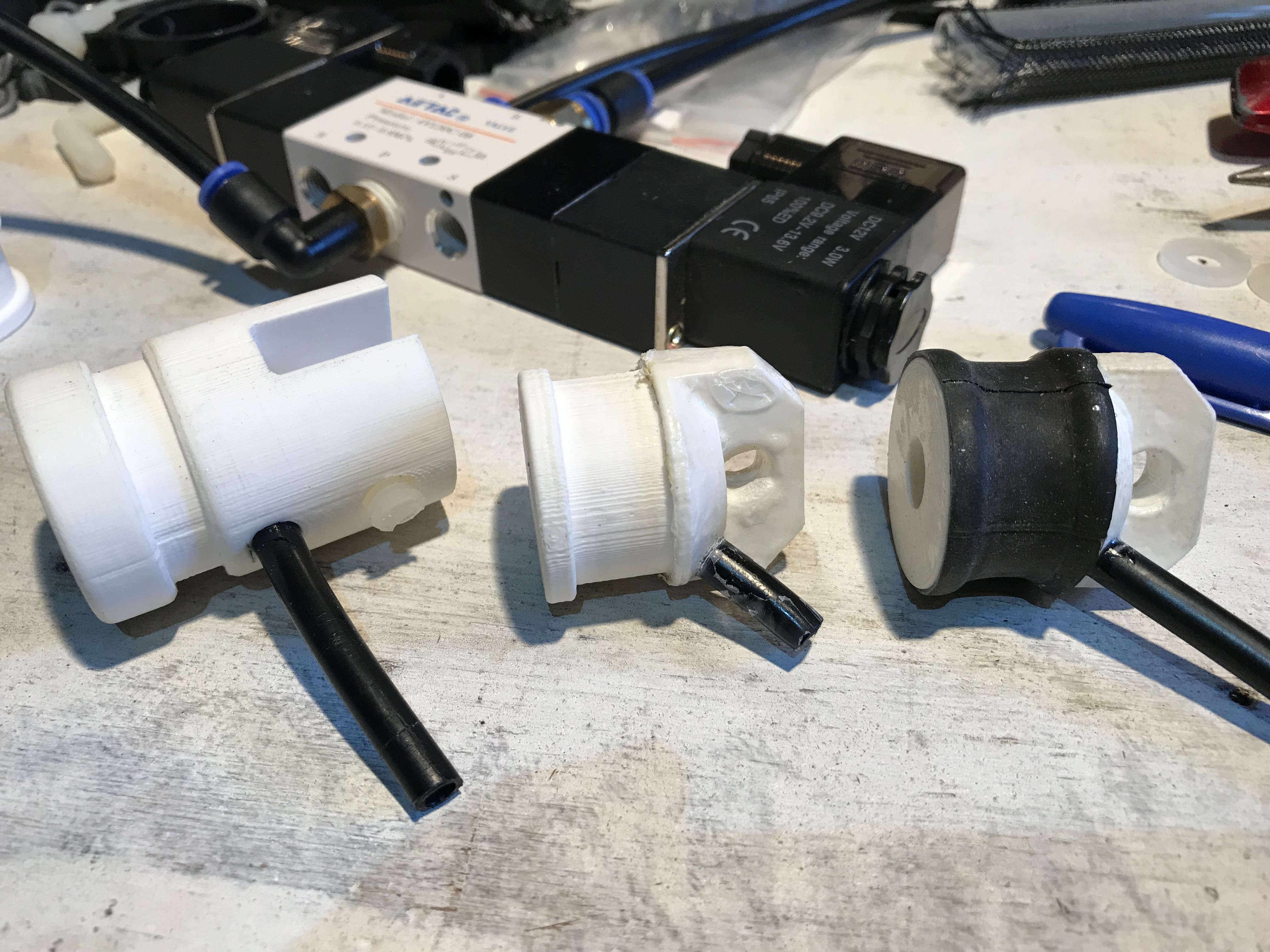

I've popped plenty of air muscles in the past and today wasn't any different. I was trying a 3D printed end cap to see if it would have any advantages (save me having to process the nylon bolts) but I was seeing a lot of leaking, before the pop.

The second cap in the above photo was printed laying flat so build lines run top to bottom for mechanical strength, but it still leaked. I tried dipping it in ABS slurry to seal it, but the improvement was marginal. The third one was printed upright. It leaked. I tried the slurry sealing again. Nope. I tried and extra layer of rubber under the bladder... I had to admit it wasn't looking good.

I had been using plastic ratcheting hose clamps as they are lighter than the normal metal worm-drive type. Though I preferred the appearance and weight of the plastic clamps, they are pain to remove for repairs and I had to switch to standard ones in order to get the required clamping force and stop the braid and bladder pulling out under load. I was also hoping it would magically fix all the leaks.

Of course I could print the cap at 100% infill but it would take over 3hrs with no guarantee it would be any better and that kind of defeated the point. I resolved to improve the existing mounts (I broke one with a high side load) with thicker M10 nylon bolts, but right now I wanted to test a pair on a limb. Raw vids below.

Next I'll attempt to add some crude position control to help me with the PAM or motor and gearbox question.

If anyone has any input, I'm all ears.

Paul Crouch

Paul Crouch

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Hey, I'm interested in making one of these myself. Have you thought of sealing with latex? I have a few 3D printed vacuum chambers printed with PLA, and I essentially just drizzled latex over it, though your parts are small enough that dipping might be a good way to go. You don't need to fill the inner voids, you just need a decently strong and air tight skin. liquid latex is also fairly cheap and it goes a pretty long way, considering how thin the layers are.

Are you sure? yes | no