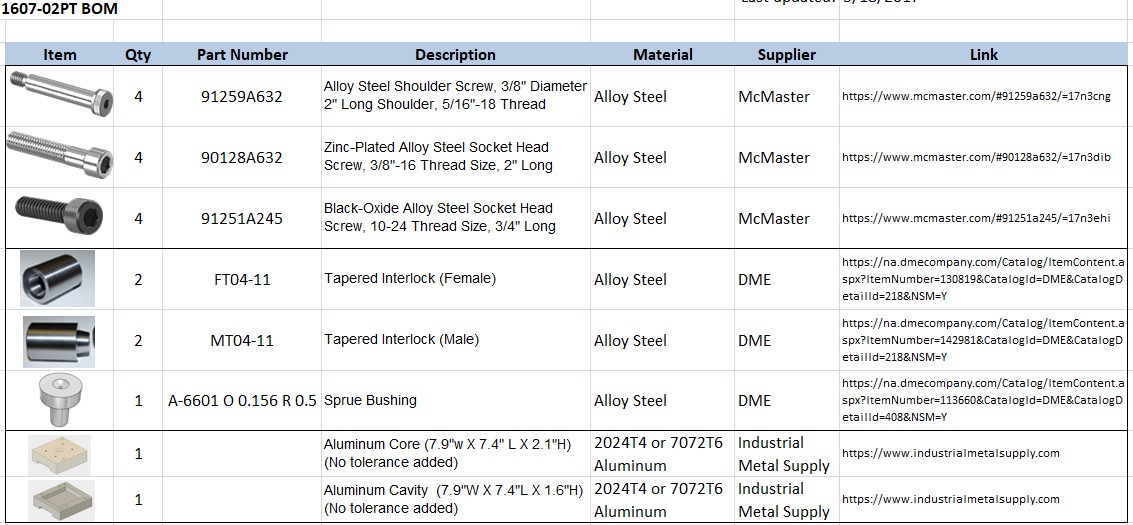

I finally completed the plastic injection mold's BOM and the parts have been ordered. Here it is! If you have any questions, suggestions, I'll be happy to talk about it. This is a screenshot, but all this will be added to the parts list. I have learnt that McMaster is a great source for specific components, but for production runs, their prices quickly add up.

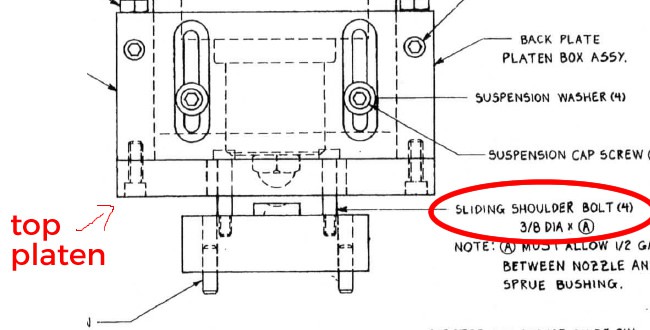

There is only one thing that has been bothering me a little and it is the mold's alignment when clamping. The Sliding Shoulder Bolts are screwed to the mold's core (top), and they hang on the top platen of the plastic injector. This is what allows the mold's core to slide up and down. Well, there is some tolerance between the shoulder bolts and the platen. It is necessary, otherwise they wouldn't slide smoothly. That tolerance is about 1/64" (0.4 mm).

The question is, will the tapered interlocks align the mold precisely? I know, there is such thing know ans alignment pins. But I did not add them to this mold. Complicated enough as it is!. And I know, we're talking fractions of a millimeter. But still :) .

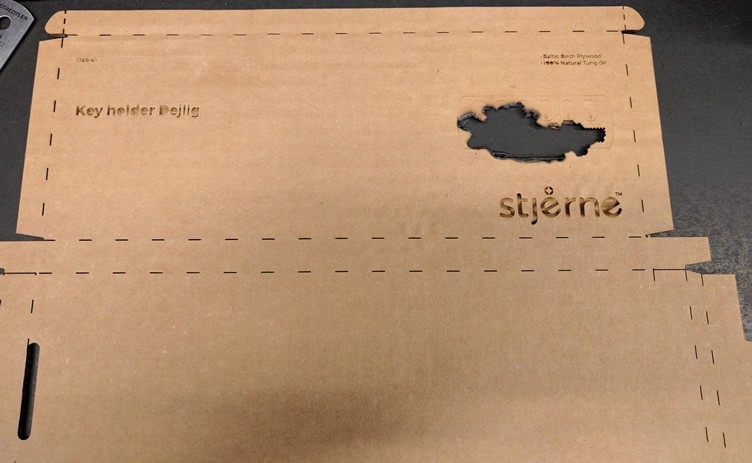

Mental note: Laser cutter are not printers.

There is another cute little project on the way. Will show more next week!

This felt like a short, productive week. And the next will be even more intense. So here is this photo from last Thursday to remind you that not everything in Pasadena is work. Cheers!

Giovanni

Giovanni

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.