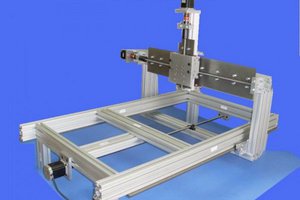

Ok you may now be thinking 'OMG - this project is way too expensive for me' ..... Well, if that is the case, I'd have to say you're probably wrong. The CNC engraving machine which I hacked is relatively cheap, especially if you buy it direct from China (it comes as a flat pack kit). Also, there's no automation so no computer or G code is required.

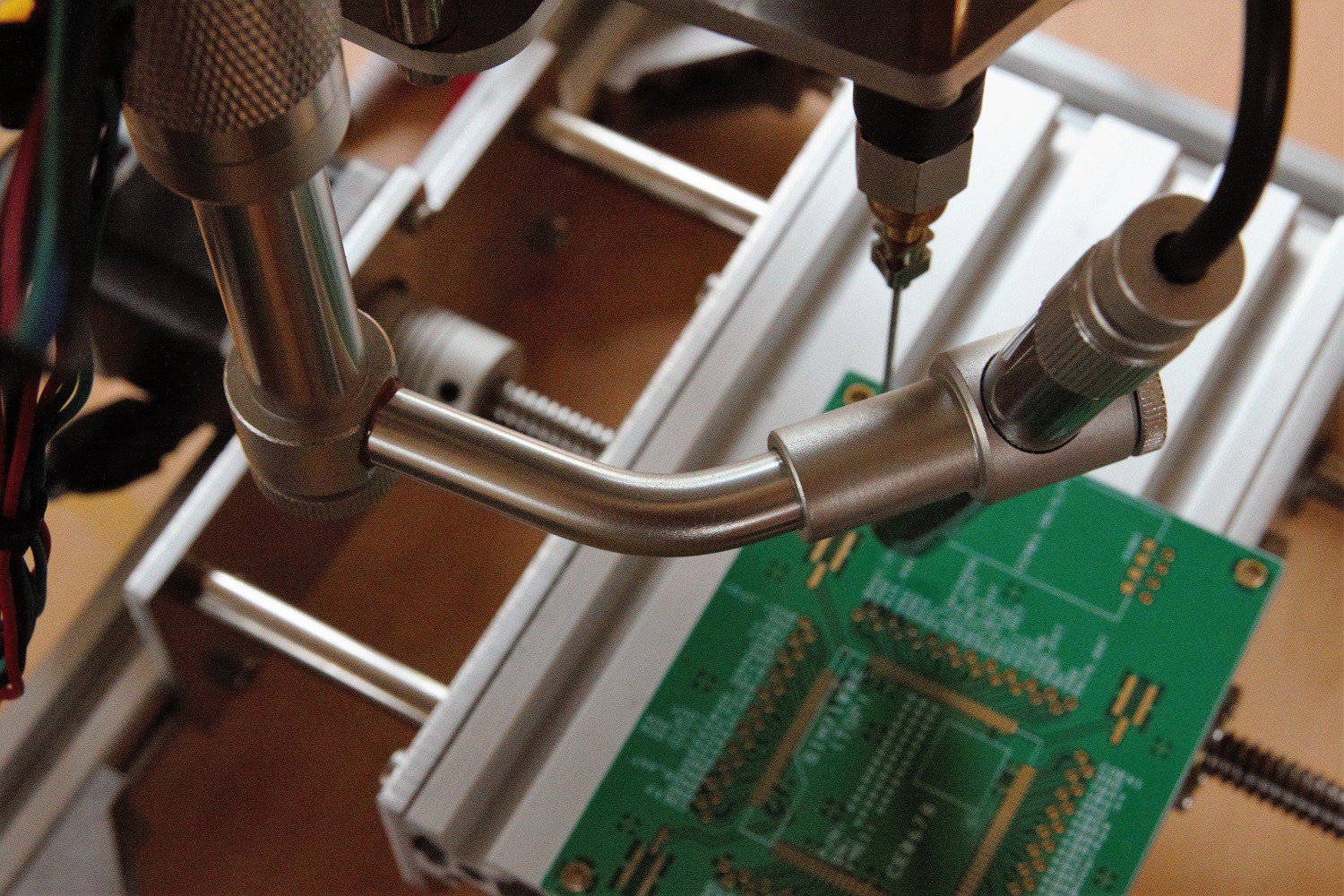

This is a manually operated machine - an array of sliders, knobs and buttons are used to pick up, move the components and place them - so its all done through finger action by looking at a small video screen for the microscopic facility.

The actual CNC parts come from an engraver kit which itself is relatively cheap and easy to assemble. The PCB is easy to assemble and, of course, has no SMT parts. Seriously, if your hands aren't steady enough to work with SMT components or you just don't want to mess up a complicated board fabrication then this machine might be the solution.

Here's one example: You want to use the best performing, most cost effective components and you're either a novice or slightly disabled like me. You've got a PCB requiring 50 SMT components and you paste on the solder through a stencil and start assembling the most difficult components first with a set of tweezers and a large lump of luck. At the tenth component, you accidentally smudge the solder by inaccurate positioning and have to start all over again from scratch. This is really no fun at all!

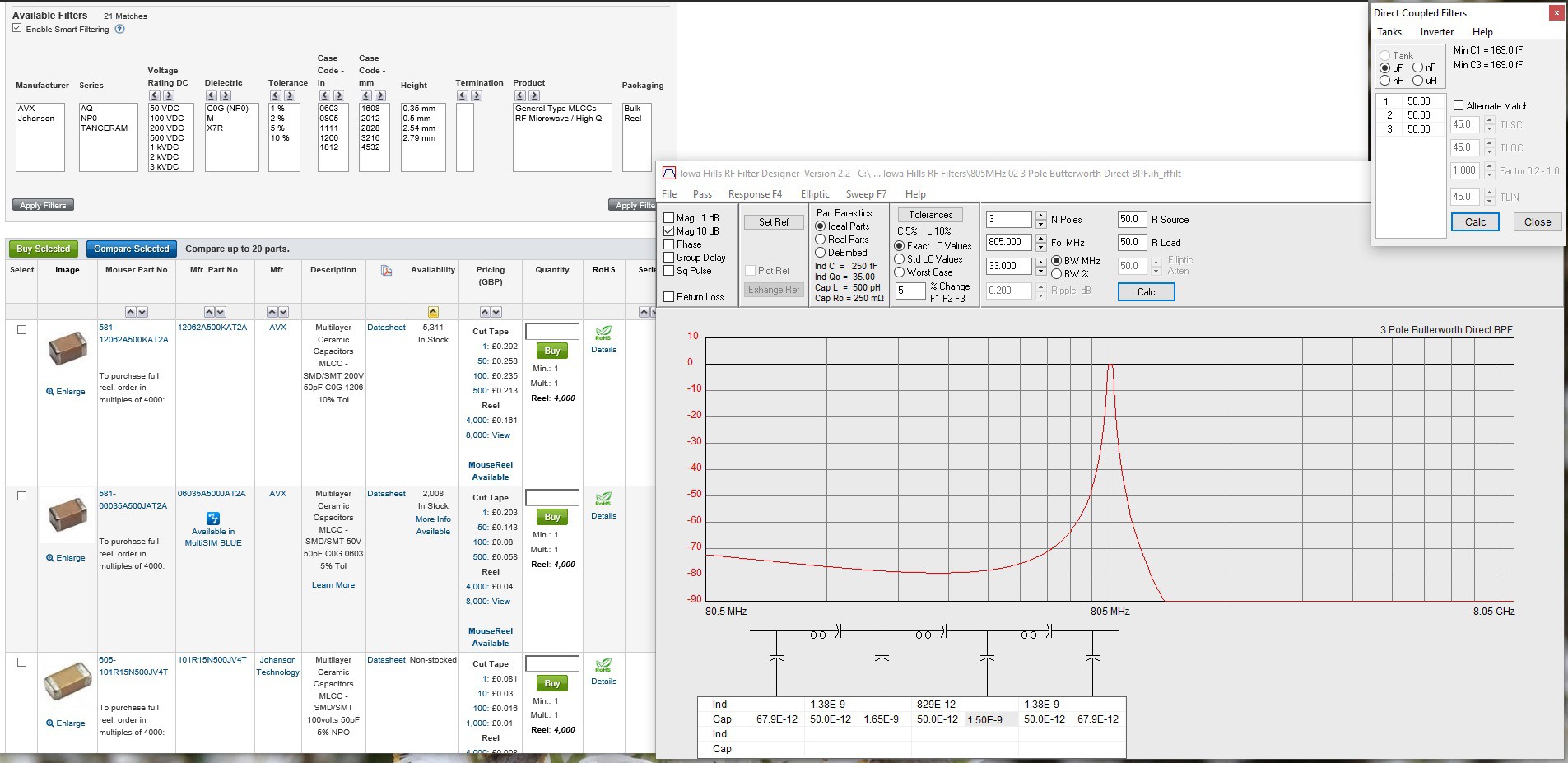

Here's a second example: Today I wanted to build up an RF band pass filter PCB. I've been using a piece of software to design the filter and checking the tolerances required on the components before I order them. After fiddling about with the numbers for a while, I realised that some of the components need to be very tight in terms of tolerance ..... and guess what ...... they're only available in 0402 package at decent tolerances, which means the component is 1mm long! Tweezers? ..... Forget about it!

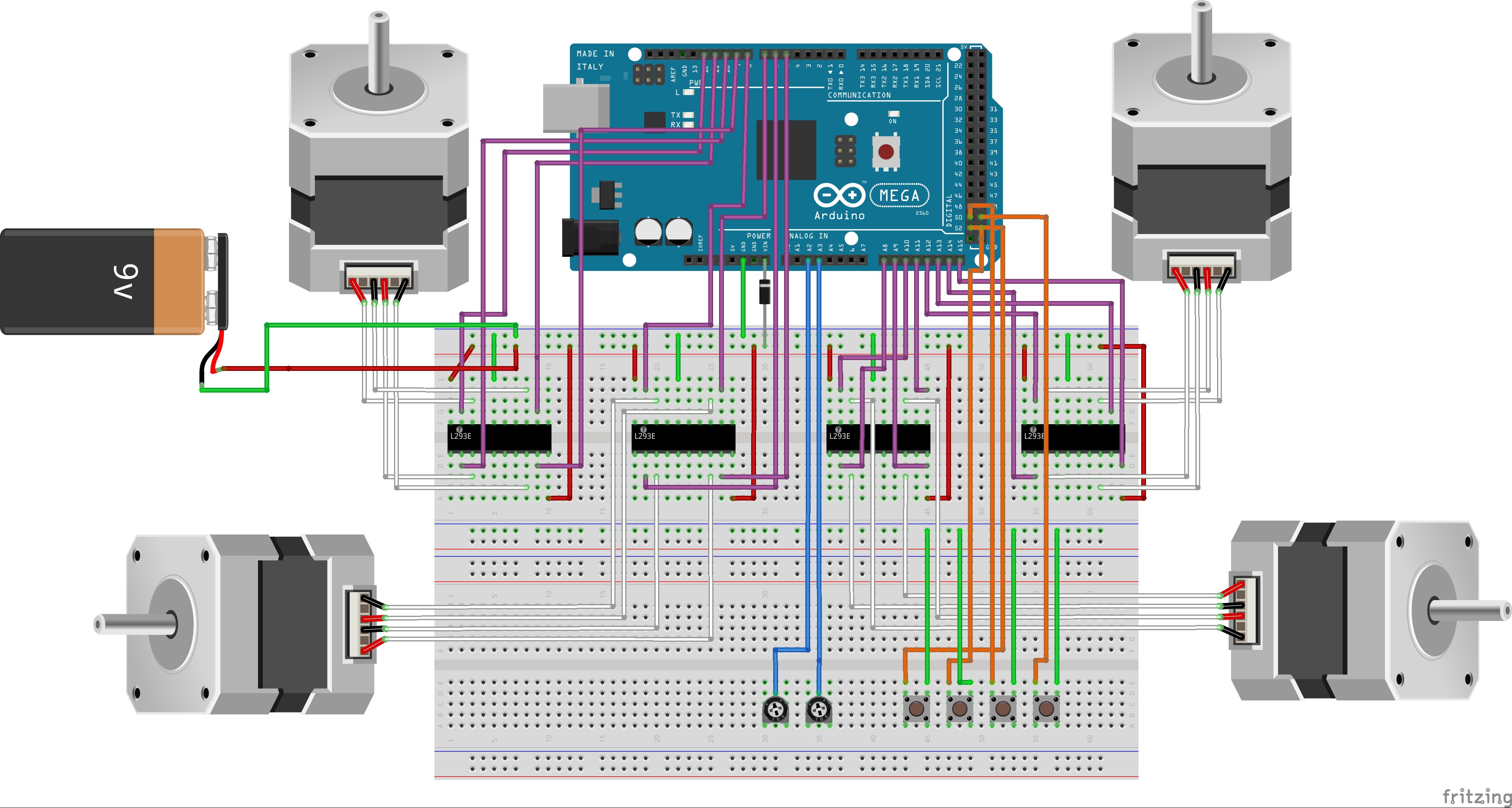

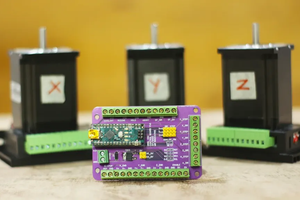

You might be wondering 'why go all through the trouble of making a custom PCB controller?' Which is a valid question since there are many solutions for 3 axis CNC controllers out there, but ......... We need four axes! After spending nearly a whole day looking for proper 4 axis controllers, whether GBRL or PC driven or whatever, I continually hit a blank wall. I really could not find a simple 4 axis CNC controller and found it astonishing that the was no readily available solution. The fourth axis is needed to rotate the SMT component, or otherwise we would have to manually rotate the PCB that's being populated which would be a major pain in the proverbial.

You might be wondering 'why go all through the trouble of making a custom PCB controller?' Which is a valid question since there are many solutions for 3 axis CNC controllers out there, but ......... We need four axes! After spending nearly a whole day looking for proper 4 axis controllers, whether GBRL or PC driven or whatever, I continually hit a blank wall. I really could not find a simple 4 axis CNC controller and found it astonishing that the was no readily available solution. The fourth axis is needed to rotate the SMT component, or otherwise we would have to manually rotate the PCB that's being populated which would be a major pain in the proverbial.

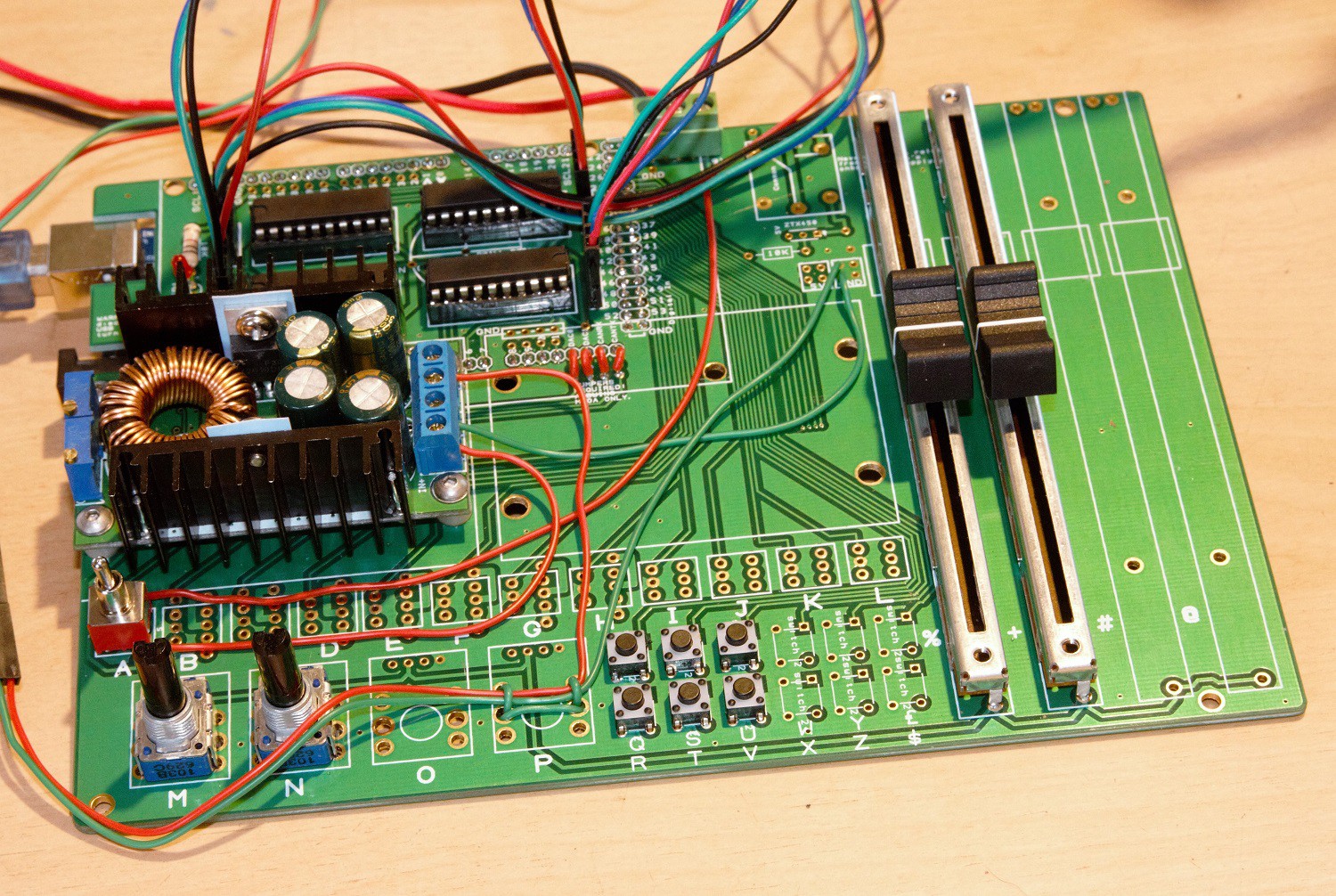

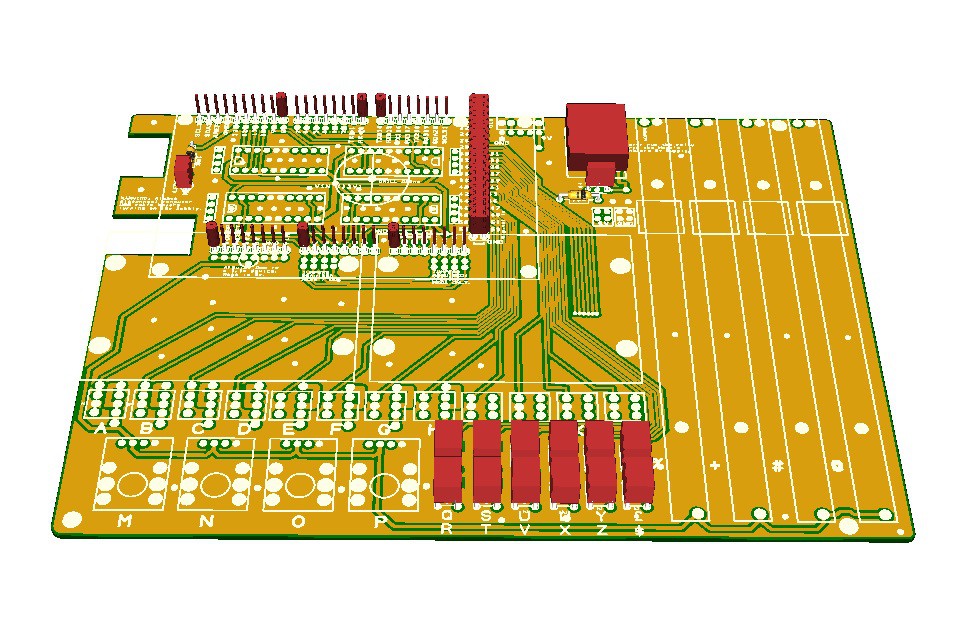

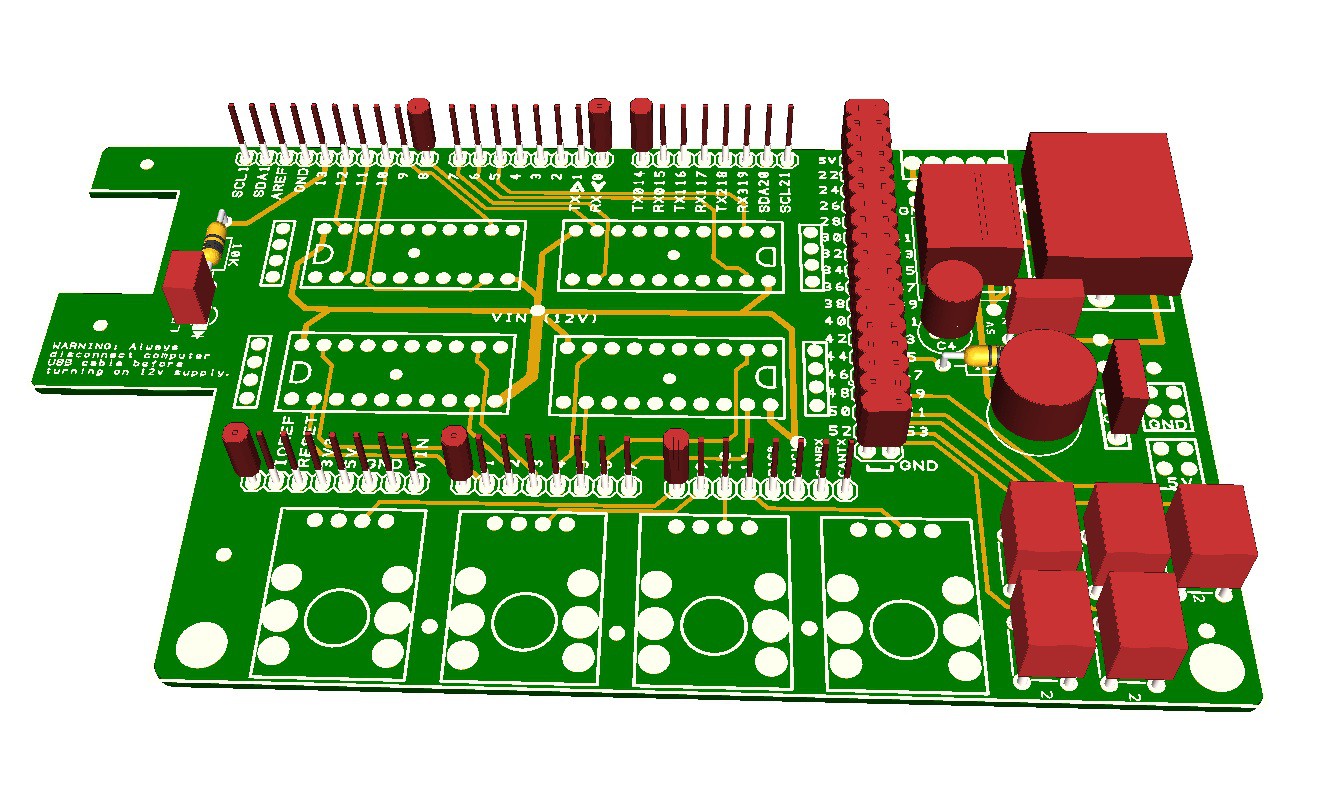

My solution: design and build a simple 4 axis controller with nice big fat sliders for manual operation.

Capt. Flatus O'Flaherty ☠

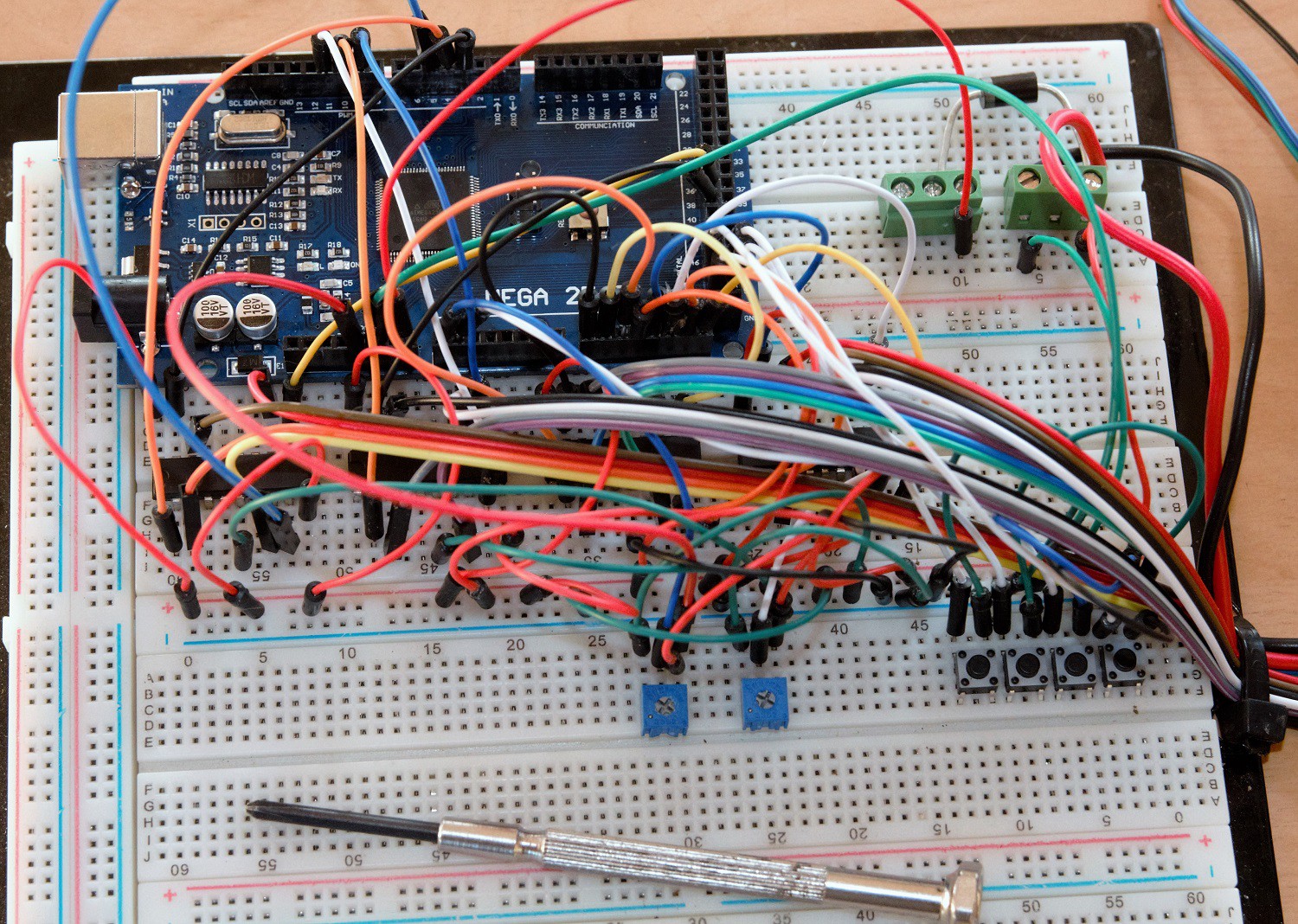

Capt. Flatus O'Flaherty ☠ The PCBs for the controller arrived today so I soldered up some of the components and tested it out. There were a few small non-critical design errors but actually it worked a treat except that I noticed that the current through the L293E's did not drop off when the stepper motor was not being used. The previous breadboard configuration was too chaotic to notice such things and I'm sure there is a simple explanation. Must dig out the L293E datasheet and look for some clues.

The PCBs for the controller arrived today so I soldered up some of the components and tested it out. There were a few small non-critical design errors but actually it worked a treat except that I noticed that the current through the L293E's did not drop off when the stepper motor was not being used. The previous breadboard configuration was too chaotic to notice such things and I'm sure there is a simple explanation. Must dig out the L293E datasheet and look for some clues.

Apart from the 4 controller chips, the design has an incredibly vast array of knobs, buttons and sliders .... and ..... yes ..... an LED!

Apart from the 4 controller chips, the design has an incredibly vast array of knobs, buttons and sliders .... and ..... yes ..... an LED!

The four push buttons, bottom right, allow any particular motor to be turned on whilst the others remain off. The potentiometers allow coarse and fine control.

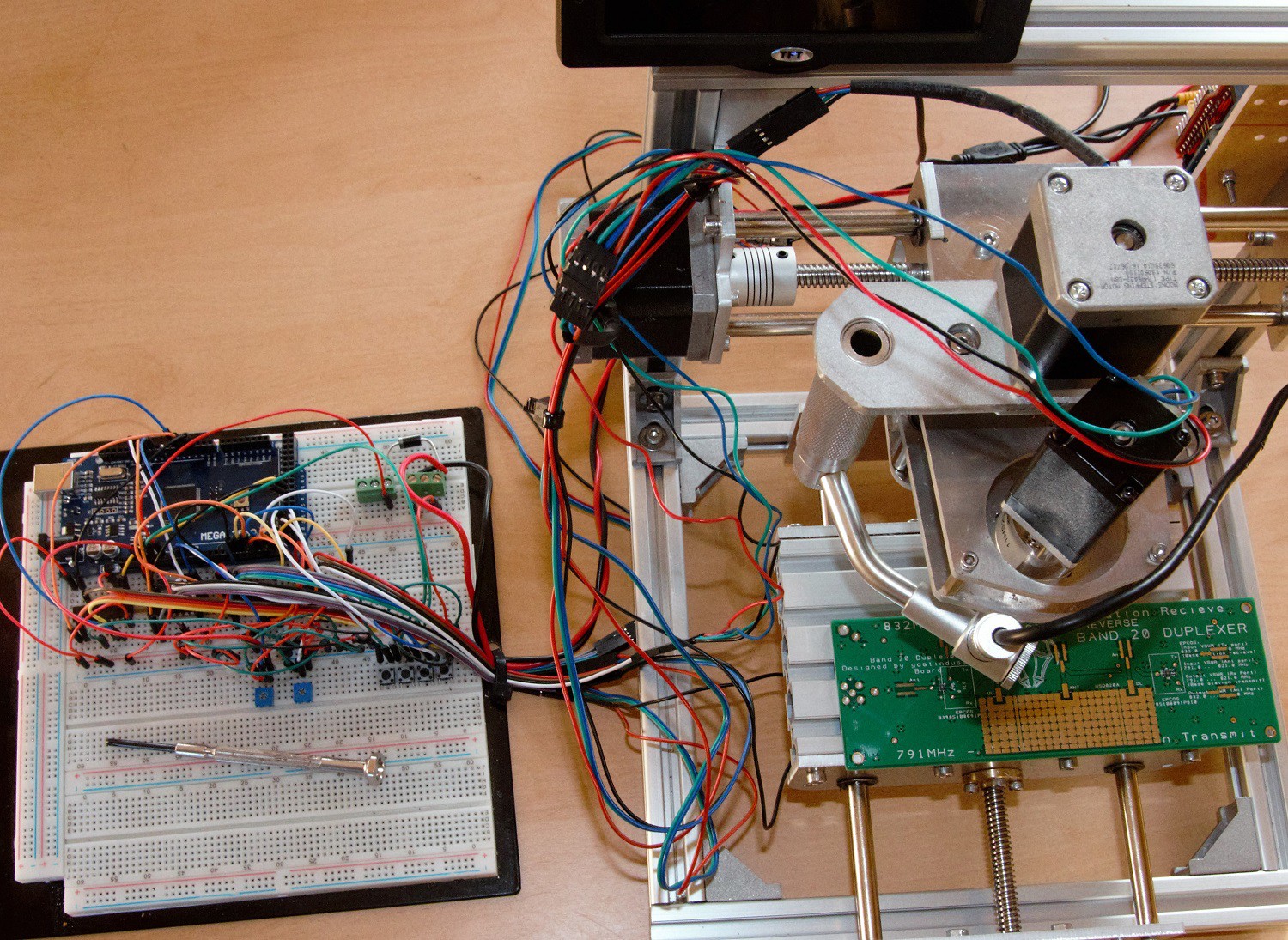

The four push buttons, bottom right, allow any particular motor to be turned on whilst the others remain off. The potentiometers allow coarse and fine control. The photo below shows it's final position:

The photo below shows it's final position:

Ian Dunn

Ian Dunn

DIY GUY Chris

DIY GUY Chris

sandy

sandy

Rhys

Rhys

Dude, nice project, but IMHO you're wasting your time. A simple $20 aquarium pump is much faster, this is how I made thousands of boards before I got a real P&P: