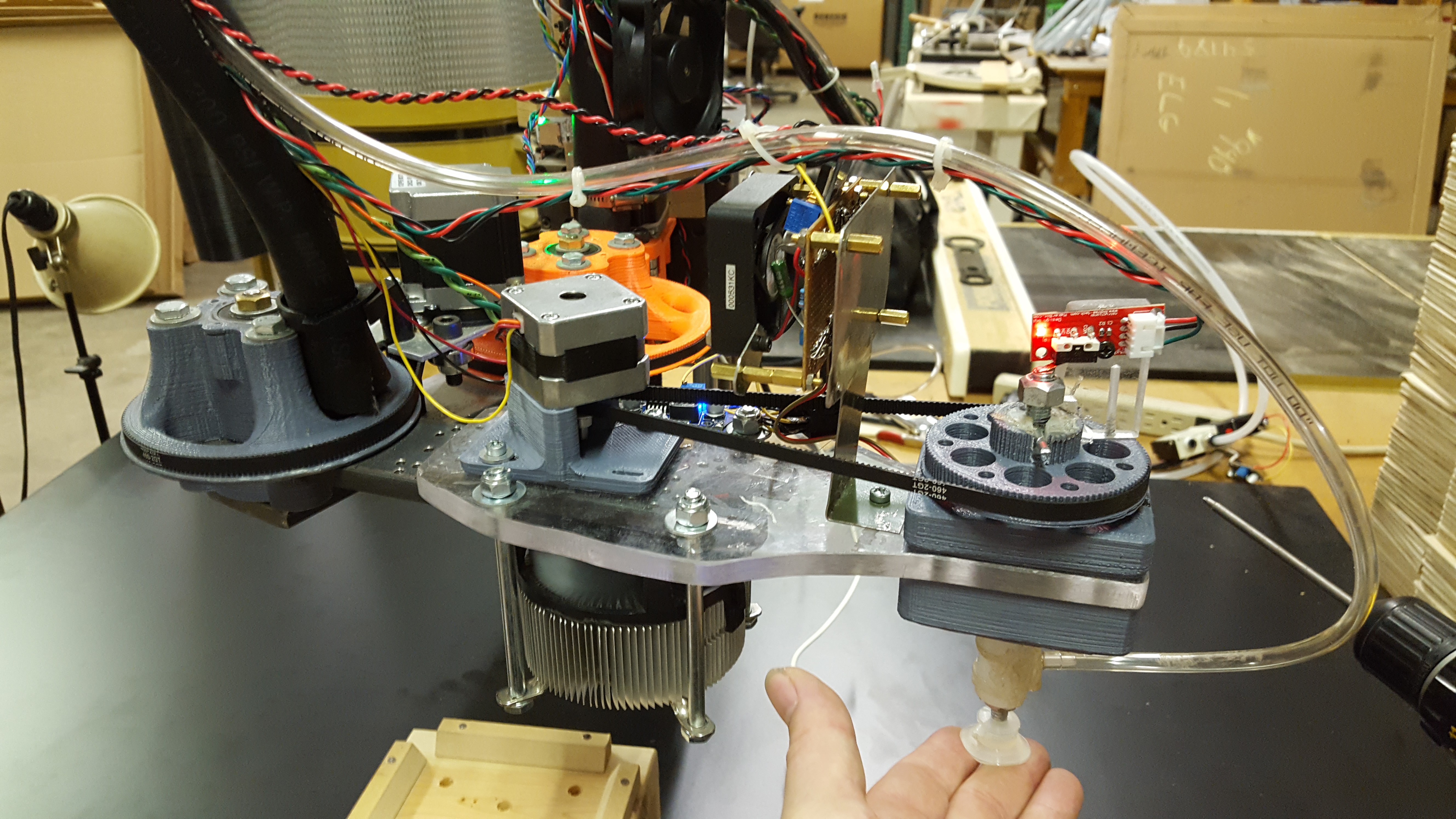

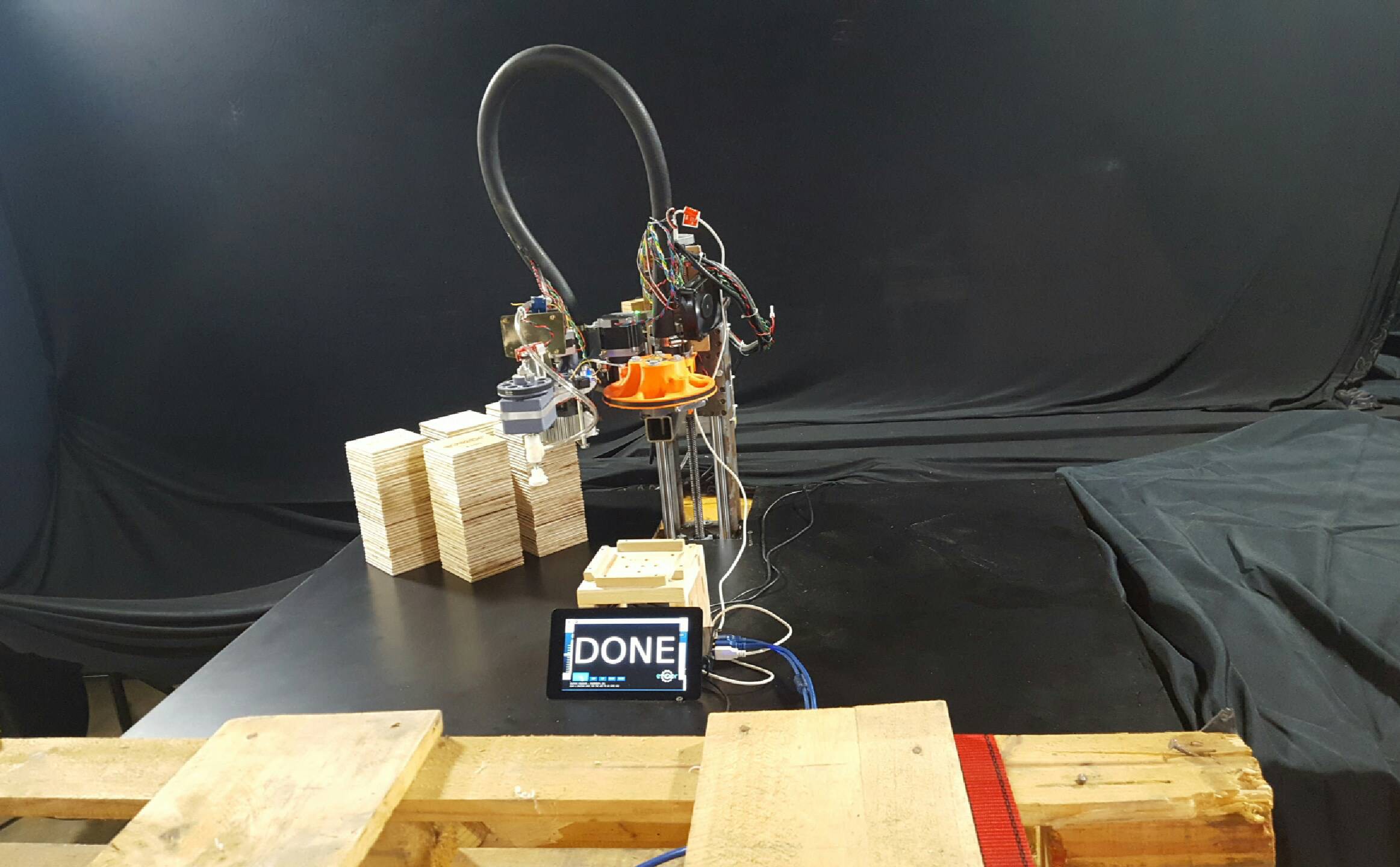

Let's automate the production of 200 coasters with no human intervention.

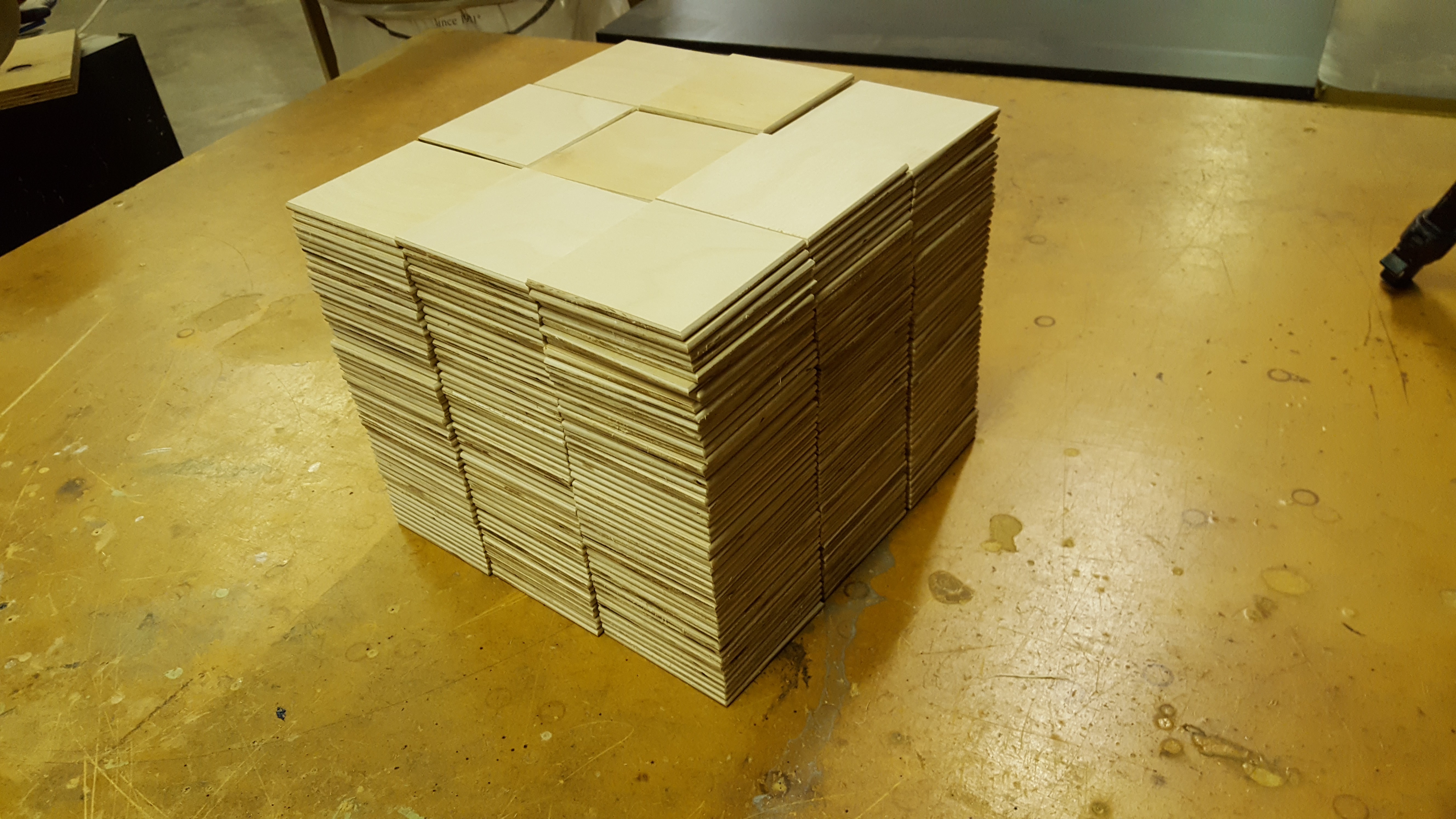

Coasters were cut from a standard sheet of 1/8" birch plywood.

All cut. That was a lot more coasters than I expected when I started.

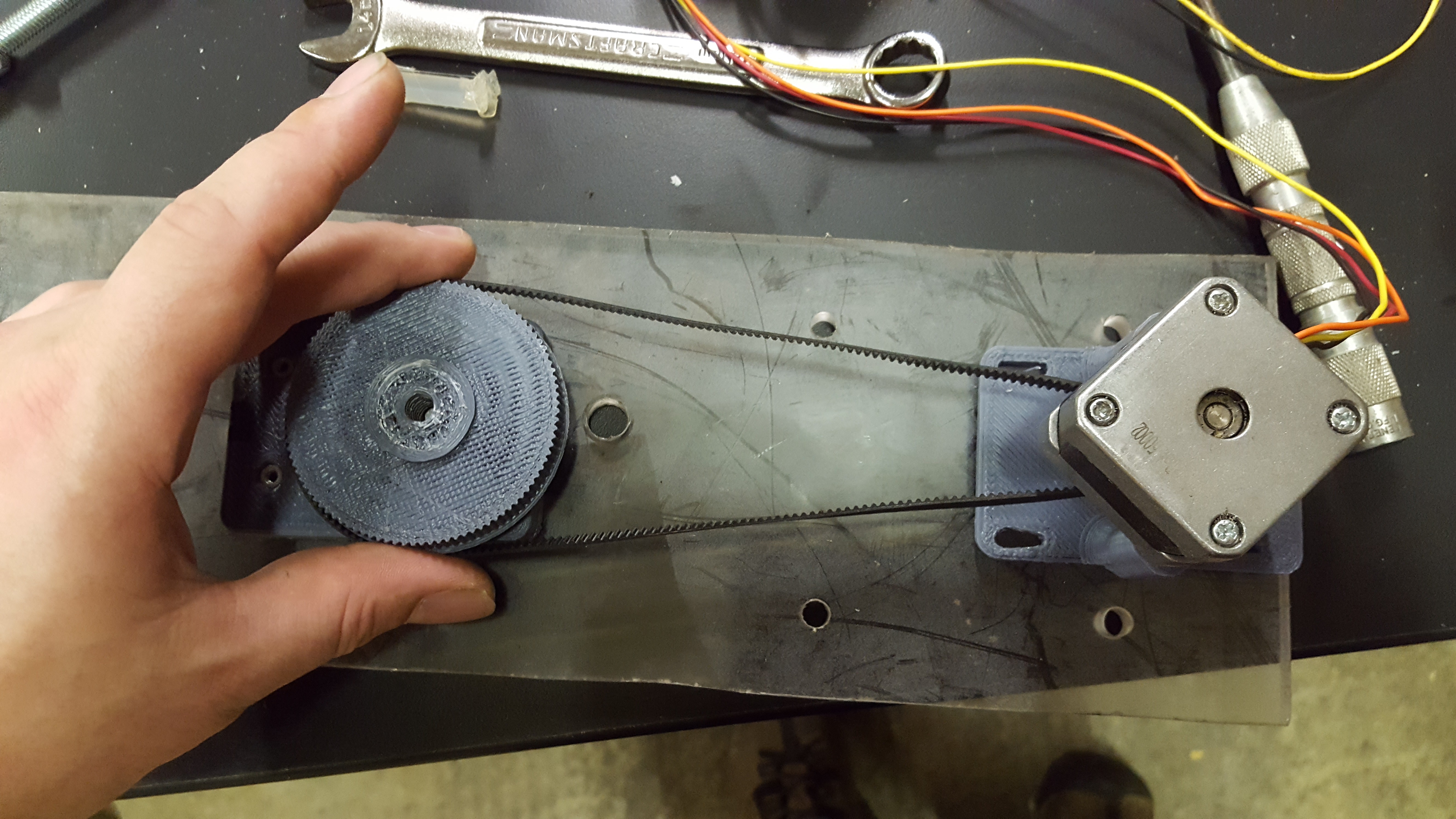

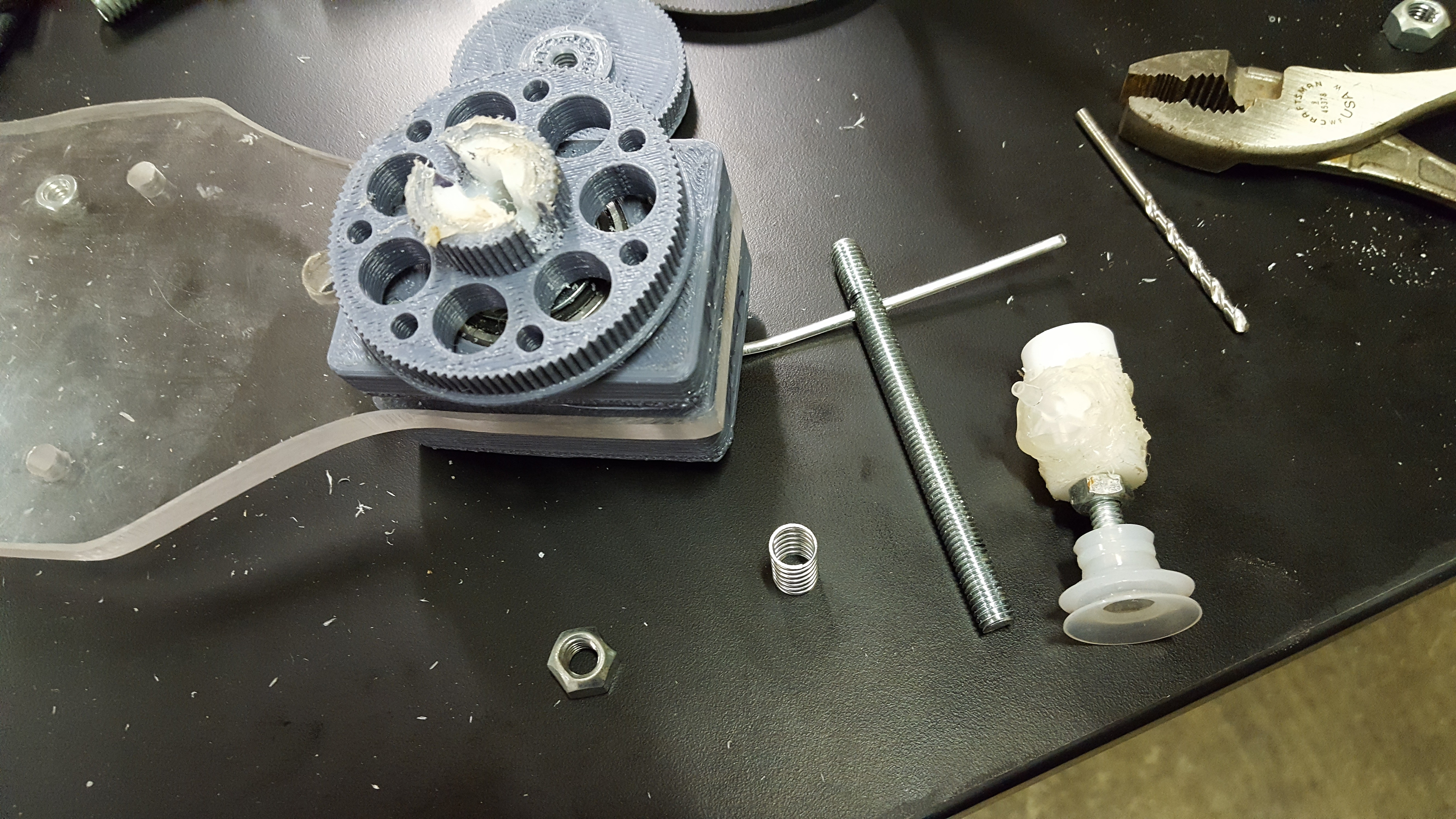

accidentally broke the smaller pulley you see above and behind. In the

end it was a good thing, I had to use the other pulley anyway.

pile. Whenever possible I like to program my robots like a drunk

walking down a hallway ;)

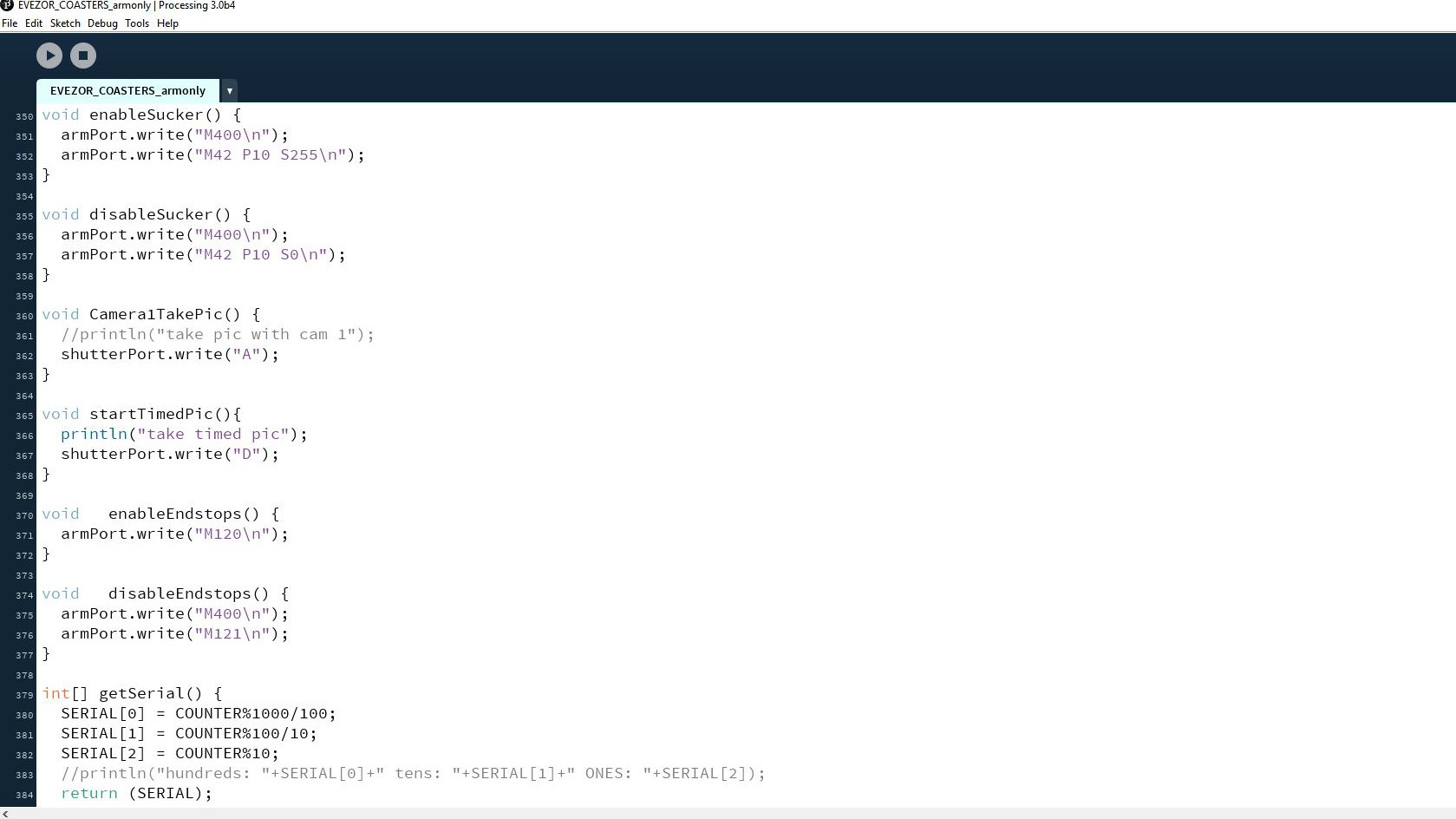

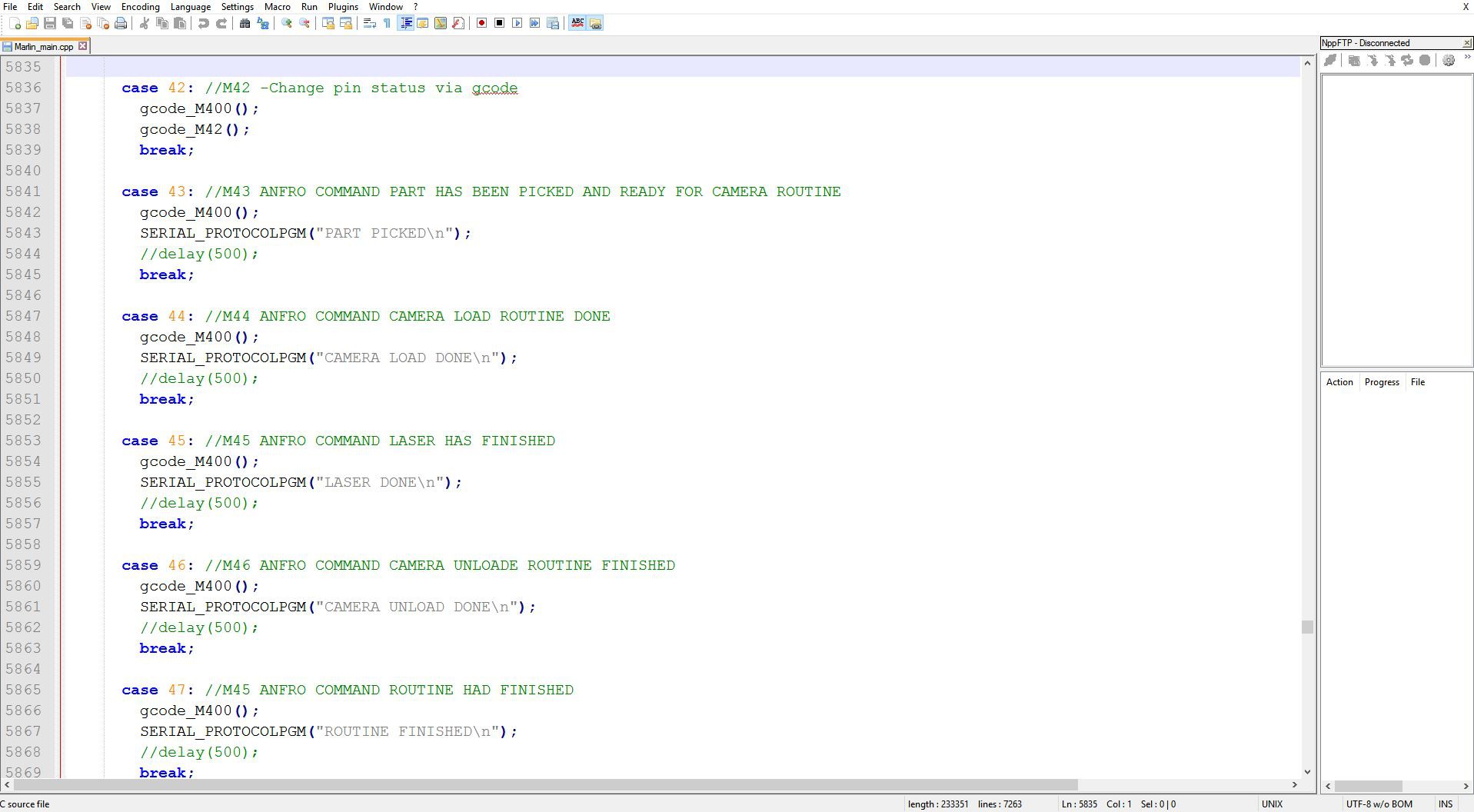

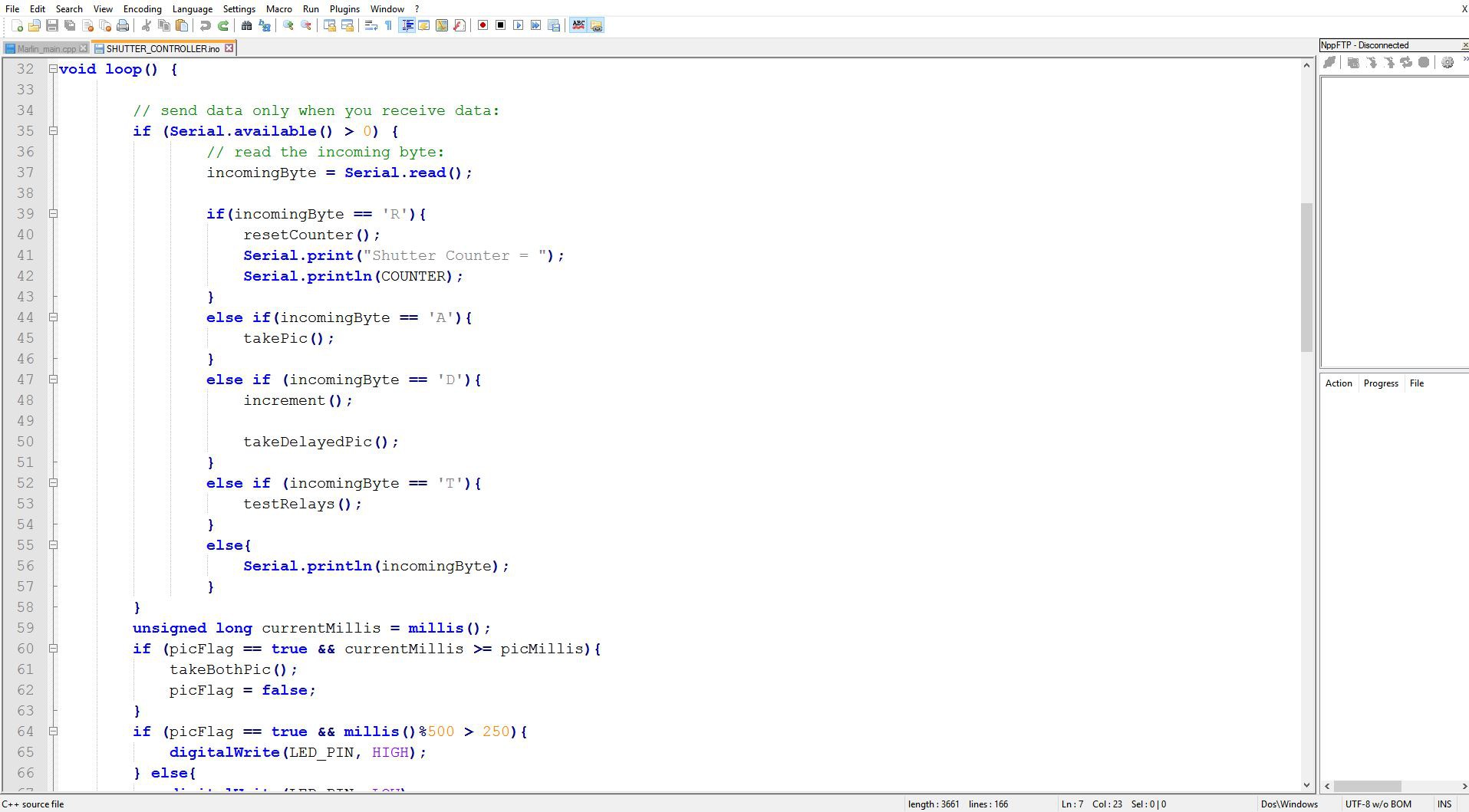

codes that would send strings out the serial port on command. The

M400() calls finish every move that's in the buffer and the

SERIAL_PROTOCOLPGM("XXXXX") commands send a string to the Raspberry Pi

which is running the whole job.

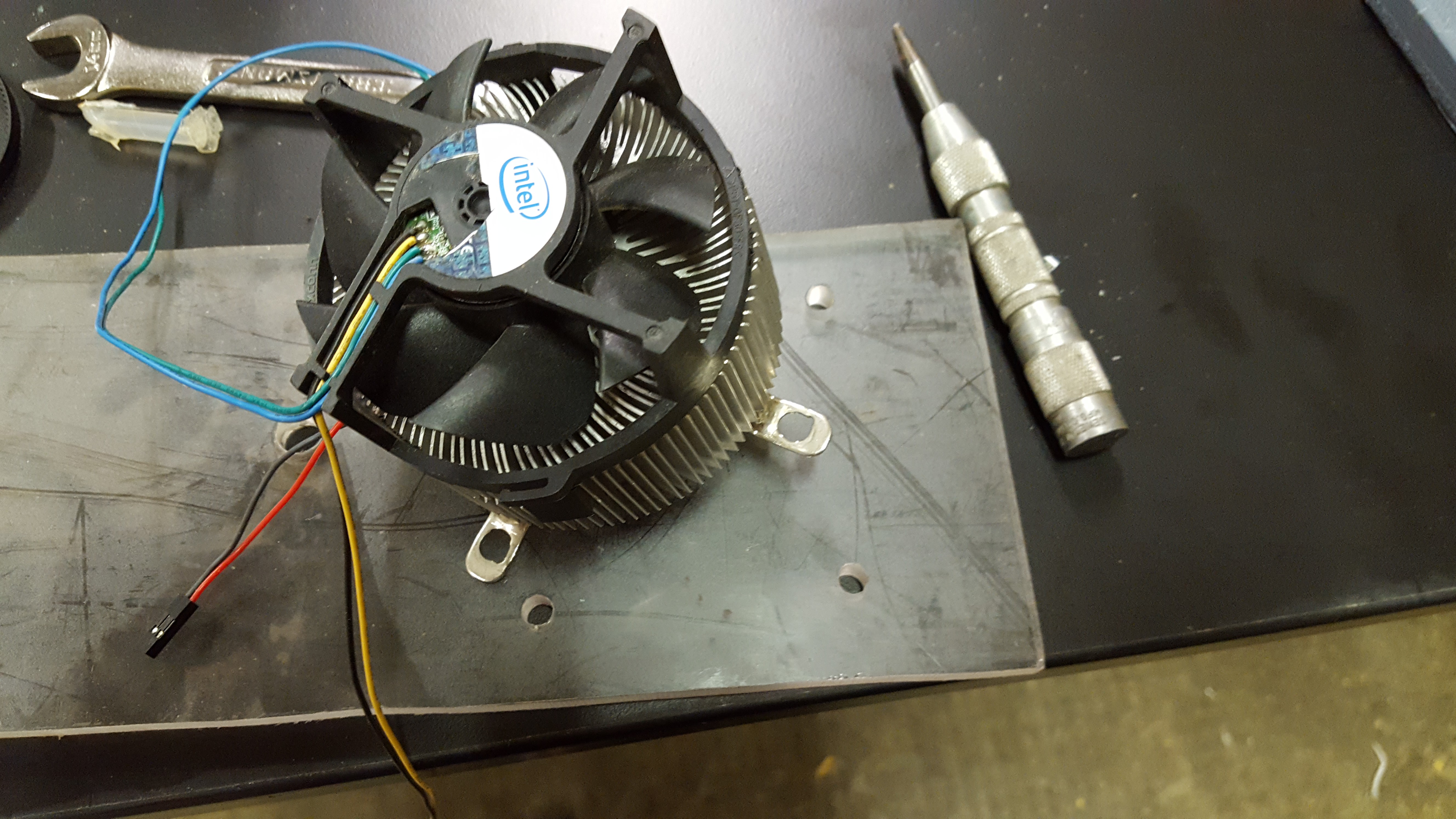

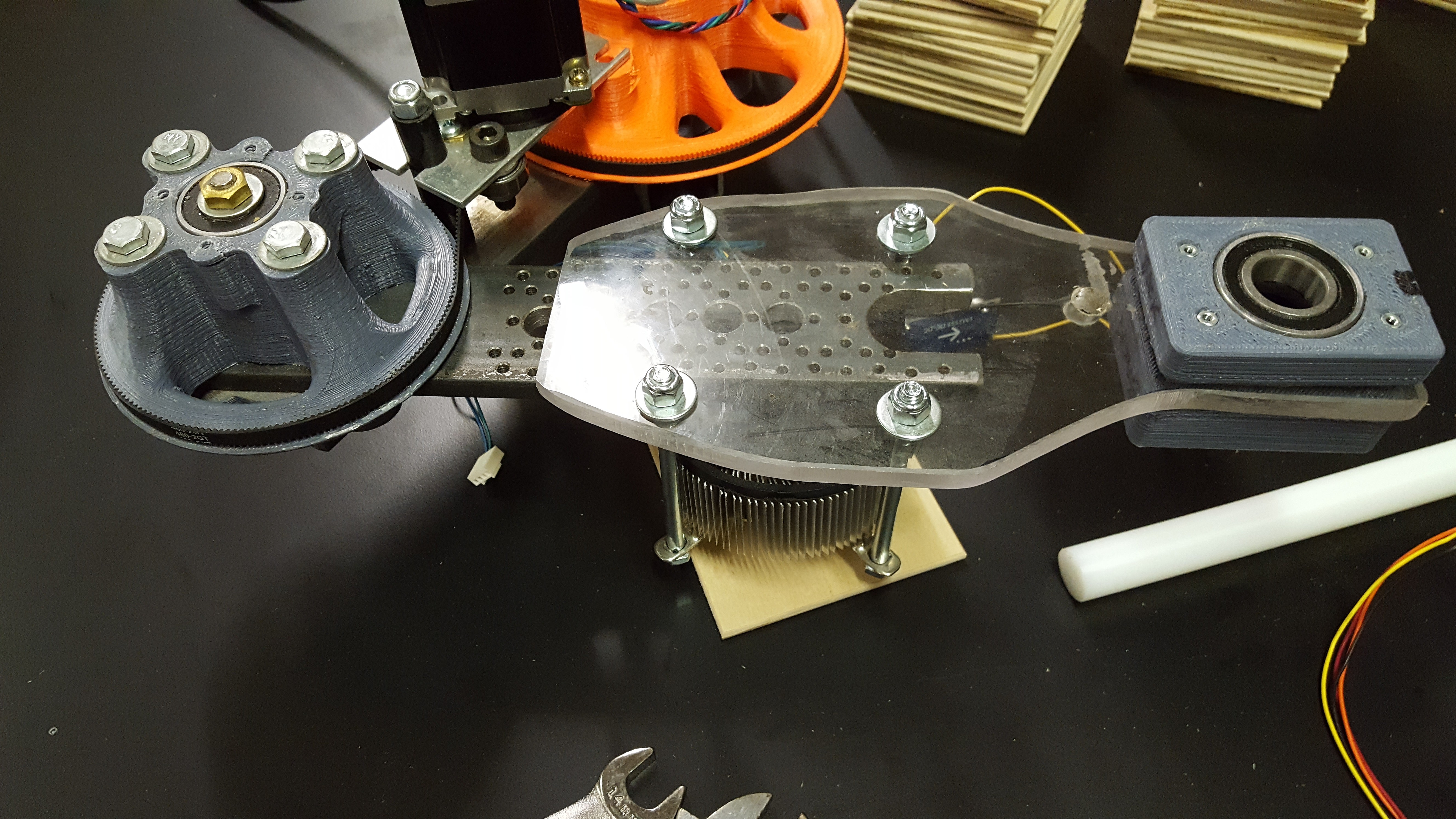

This was actually the first prototype for the evezor arm. I call

them NOtotypes (the minimum viable prototype that will test critical

aspects of a part) It failed miserably but I learned what I needed to

look for when designing the next iteration.

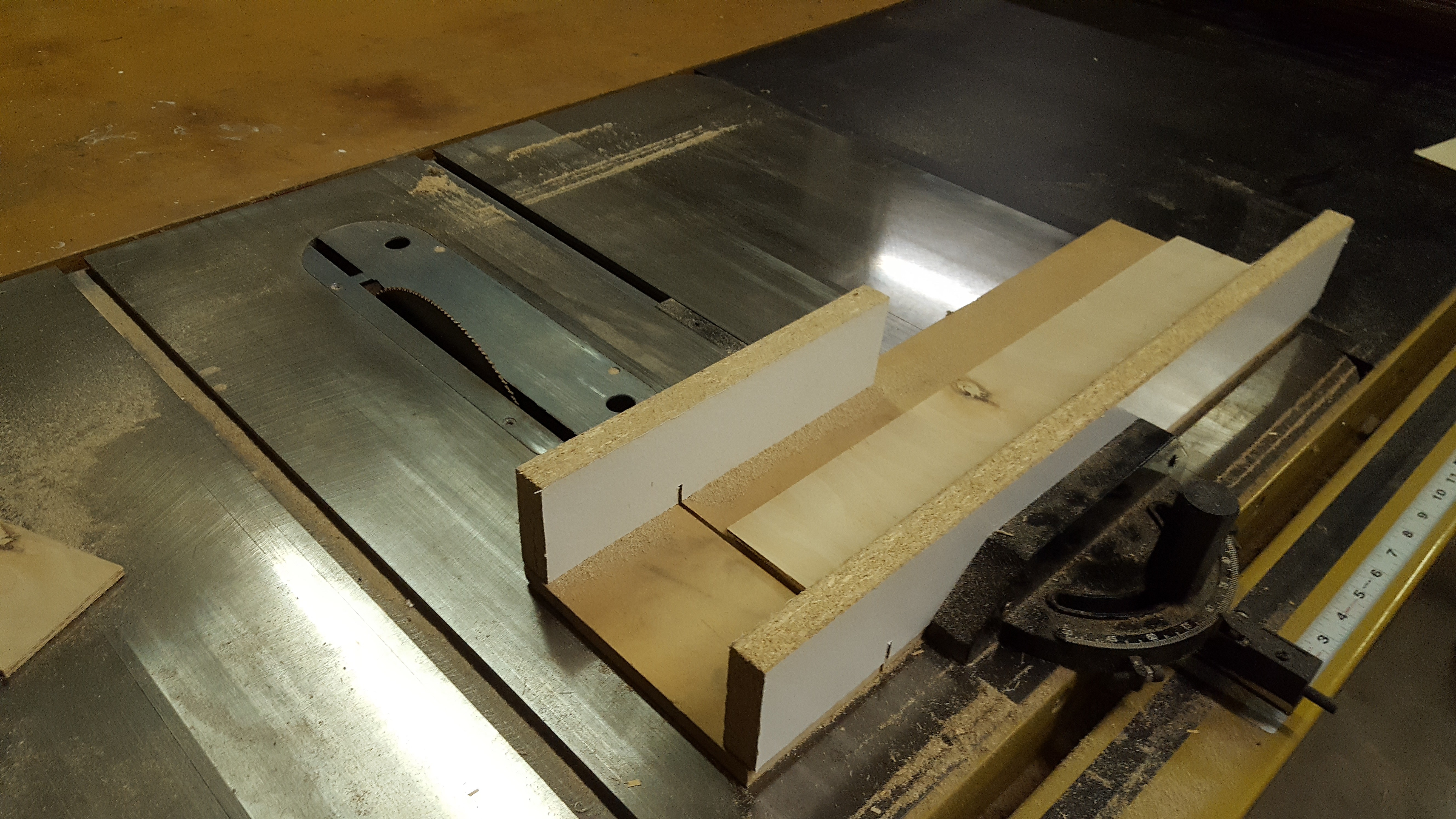

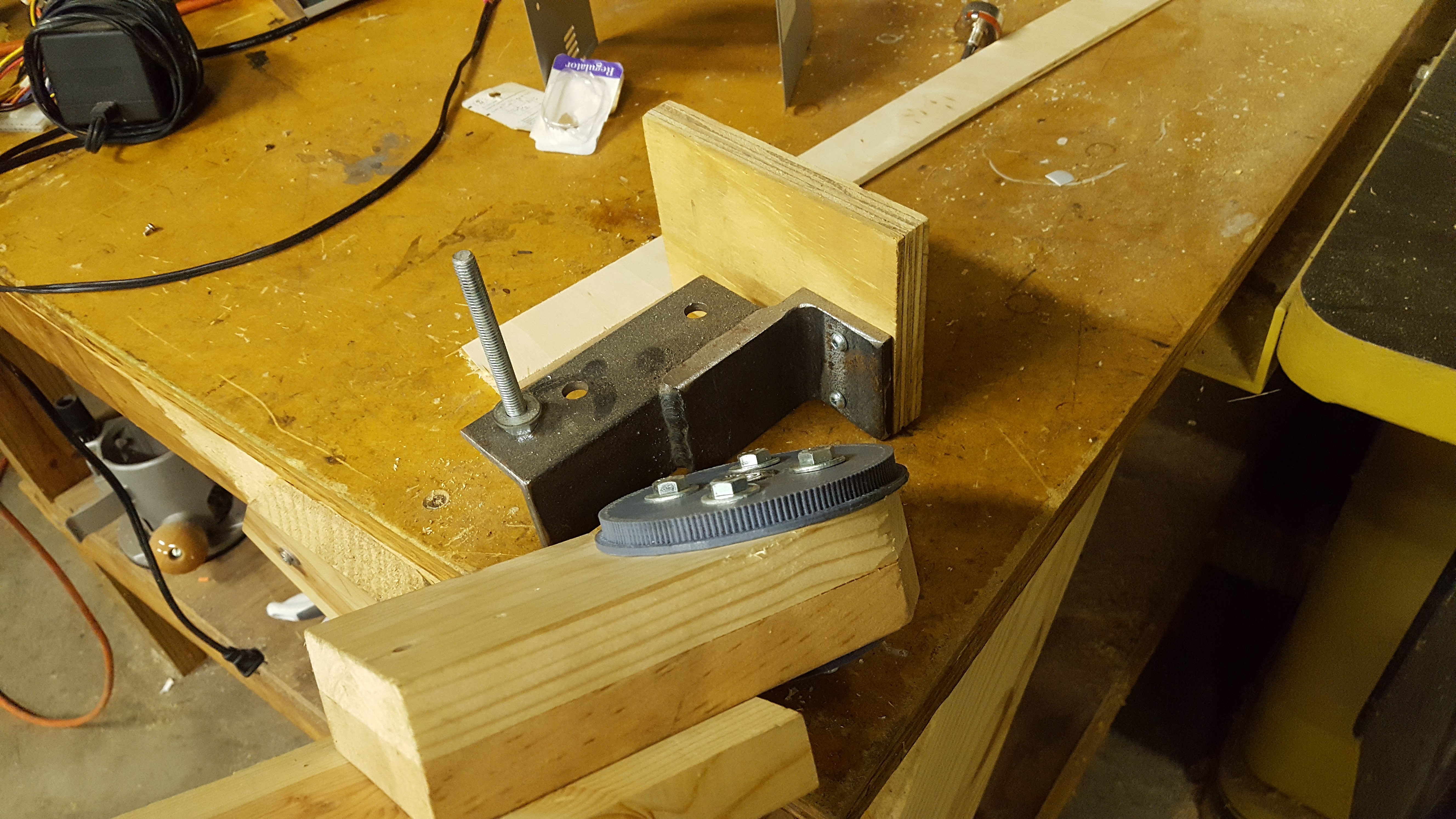

The sled would be actuated with a belt so the mounts had to be fairly strong, so I made a dado joint.

Such class ;)

The sled would be actuated with a belt so the mounts had to be fairly strong, so I made a dado joint.

Such class ;)

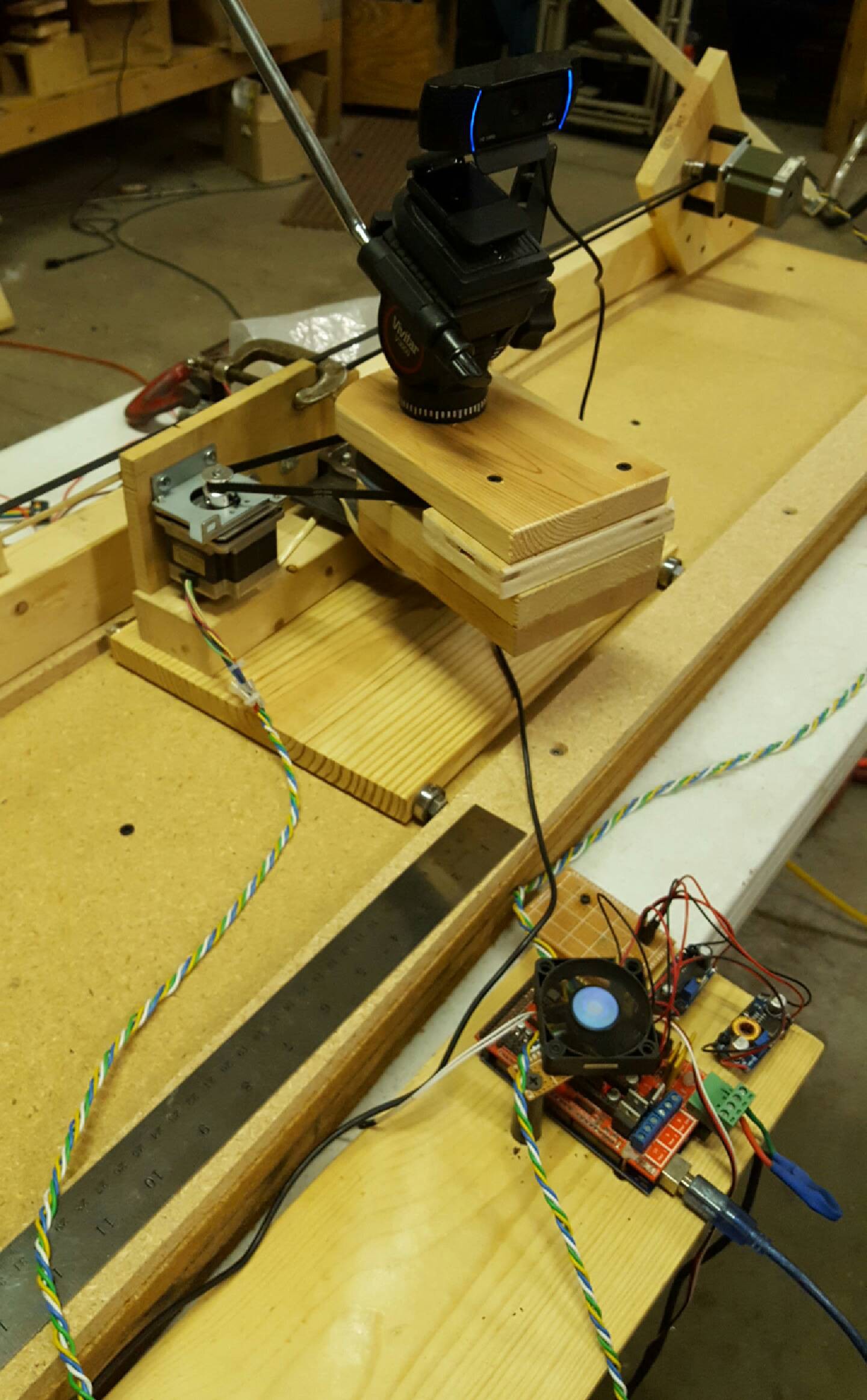

This is the idler pulley. I looked around the shop for different

materials for the belt and it turned out telephone wire performed the

best. Who would have thought?

materials for the belt and it turned out telephone wire performed the

best. Who would have thought?

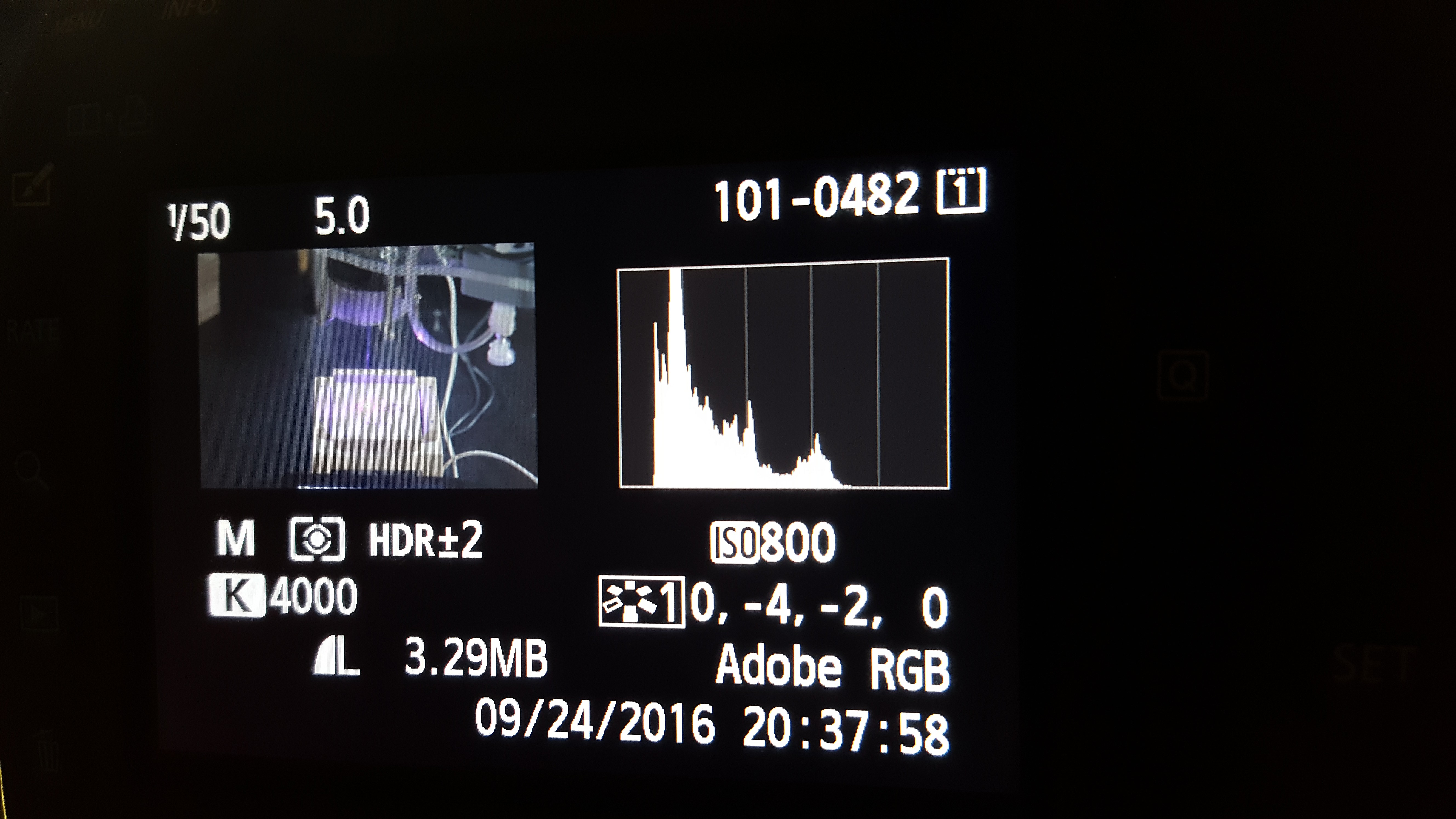

Photographer (Thank you World Touch Productions for all your help!!) to

make sure I got the right connectors for the shutter controllers.

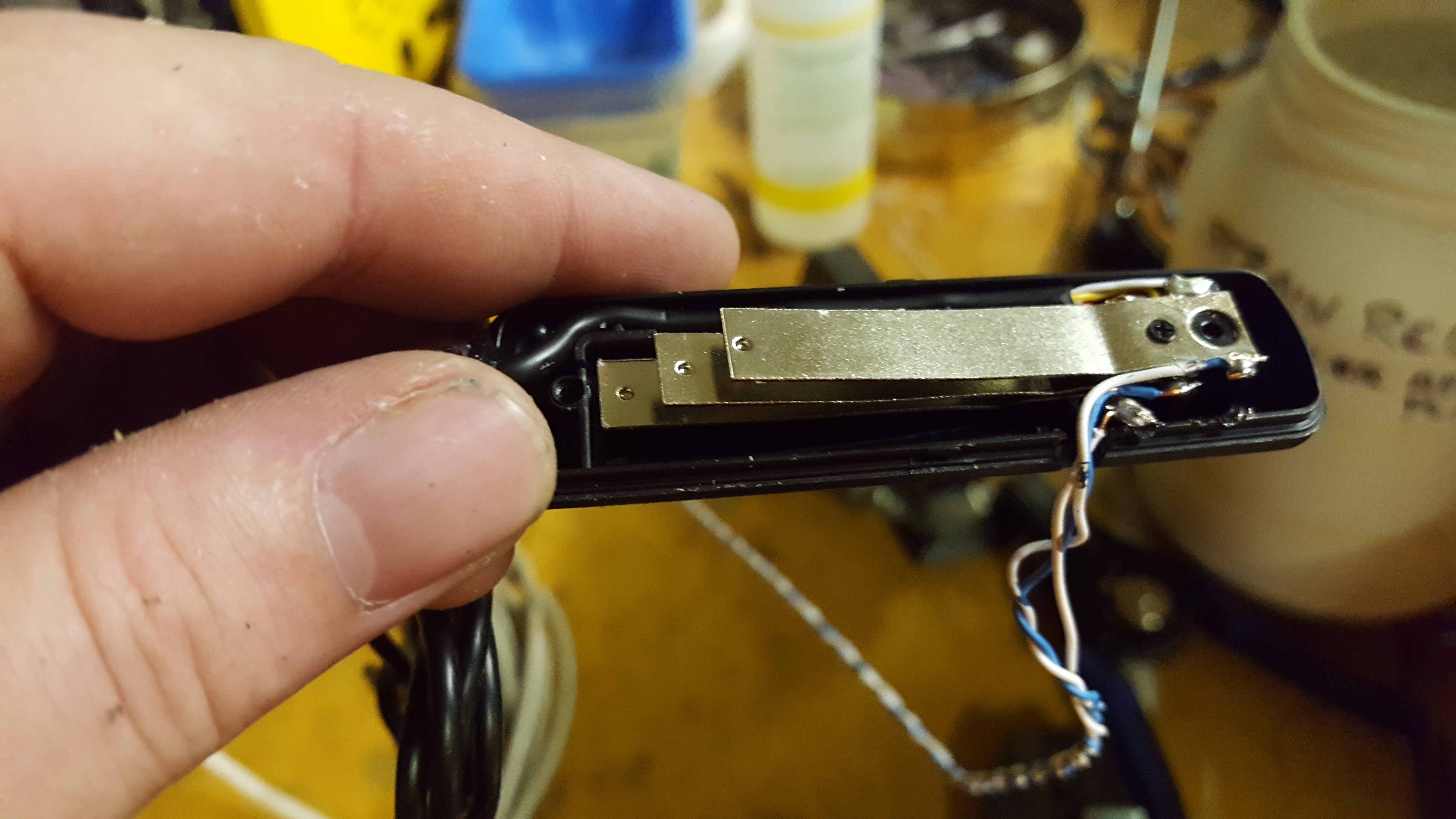

Whenever possible I prefer not to cut wires. So I soldered the

wires directly to the switches. The top contact is ground, the middle

contact is for the auto-focus and the bottom contact is for the shutter.

I carved out the side so the wires could fit through and I could reattach the tops.

I carved out the side so the wires could fit through and I could reattach the tops.

LIGHTS!

LIGHTS!

CAMERA!!

CAMERA!!

ACTION!!

Now we're really done!!

Now we're really done!!

anfroholic

anfroholic

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.