I am using the cloud CAD service ‘Onshape’ to produce the model of the third generation of the glider. This allows the design to be more open (all files are public and viewable at any stage during the design process) and more accessible (Onshape is free and does not require an expensive license, only an internet connection).

I'm going to produce parametric parts with dimensions that

vary in accordance to local variables. The

third generation of the glider will be designed so that the

user can input values according to a test print and then all

dimensions of the printed components would be adapted for

the user’s printer, which

would minimise post processing. Unfortunately Onshape does not let

you specify global variables, (values that remain constant between different

parts within an assembly), so I will

design the glider

within a single “Part studio” (A multipart assembly). If

this is too complex (too many features in a single file), I will have to remove the parametric feature.

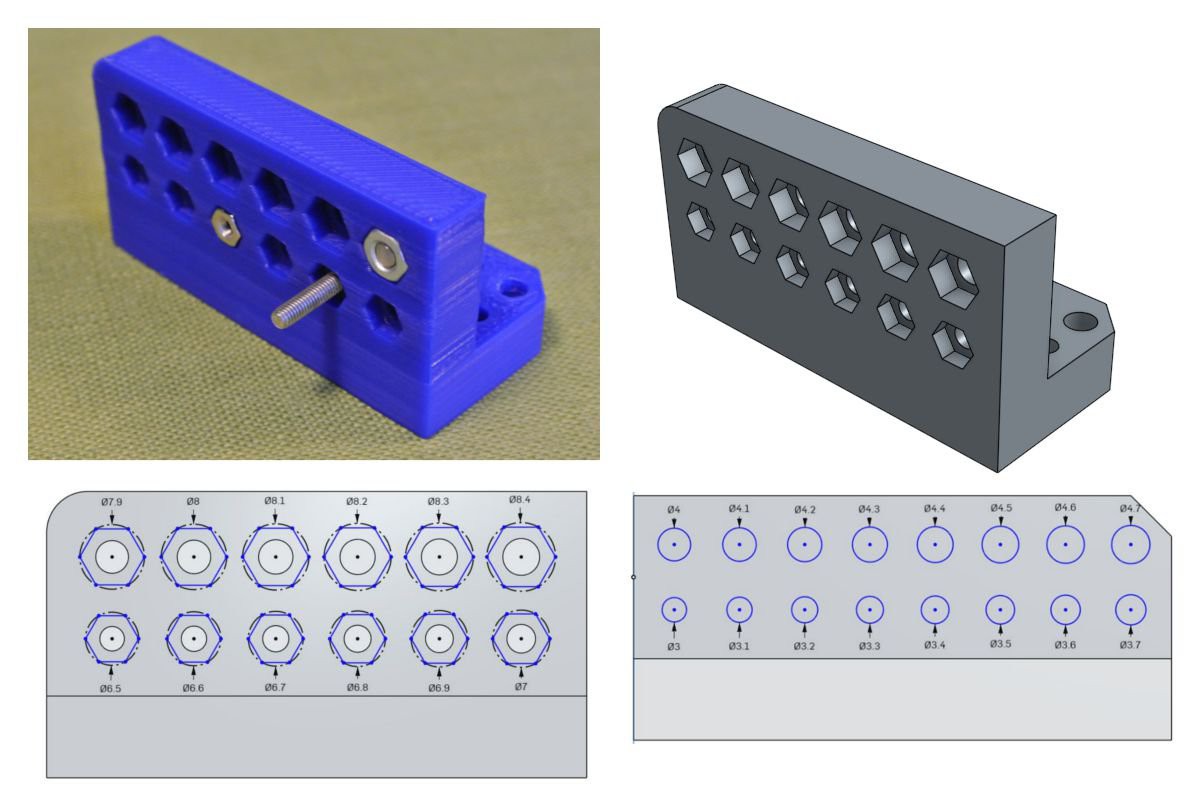

An example test piece is below and shows how a single piece would be able to determine the best values for a person's printer for dimensions such as the size of a hole for an M3 bolt through a wall.

A live version of the glider model can be found here and is updated automatically whenever I make an edit to the model.

alexw

alexw

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.