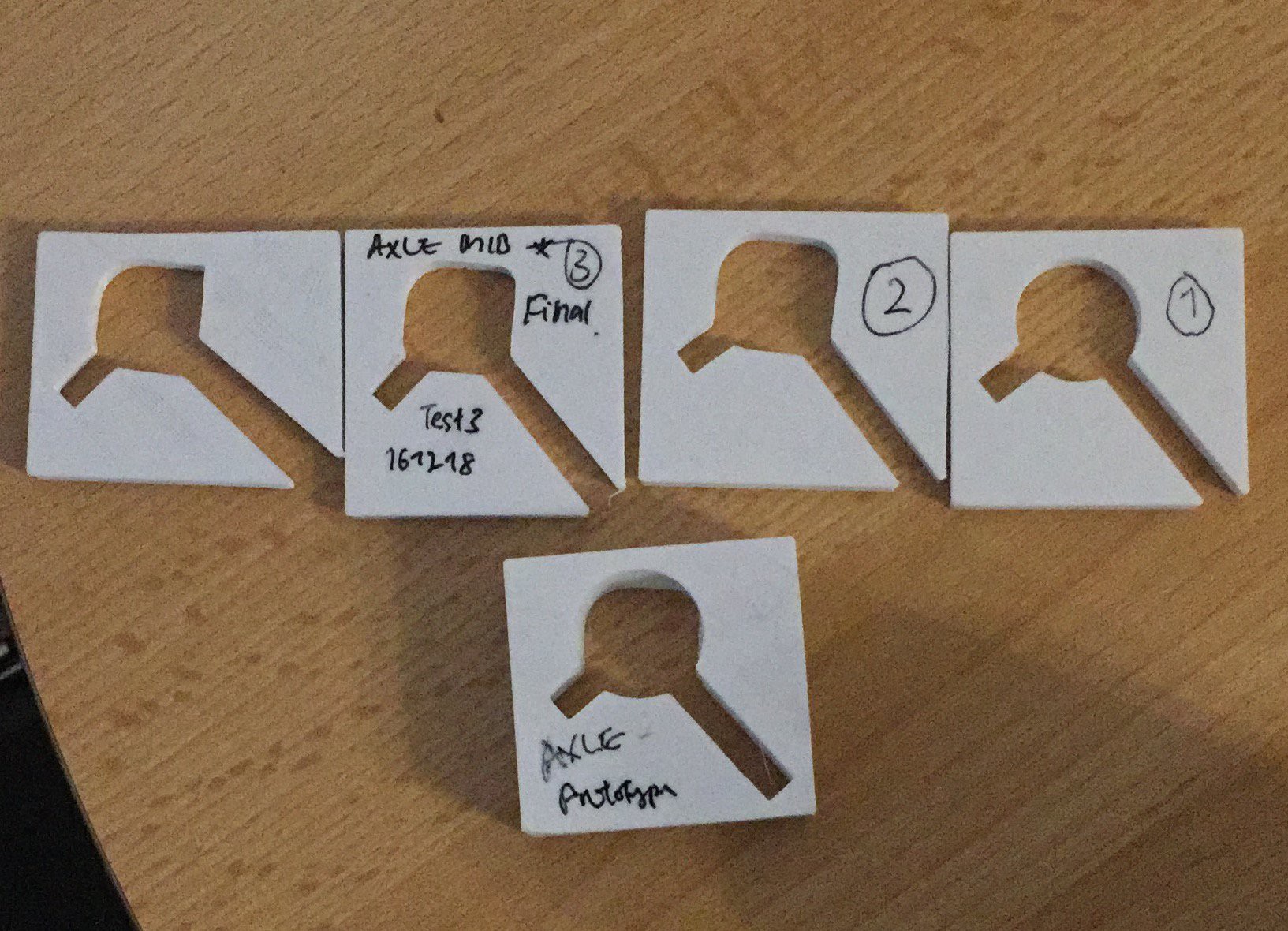

One of the challenges with plastic motor mounts was to secure it against rotational forces around the axle. Sheer clamping force would not suffice as the material would fatigue under constant load. This was the reason these trucks were chosen as a suitable candidate as it has a rib geometry on both sides. The ribs contribute to the surface area in which the mount can hold onto. It was a matter of reconstructing the varying cross-sectional areas through trial and error in Fusion 360. It the end, I combined three different cross-sectional areas and used the "Loft" function to recreate my axle. I then 3D-printed test pieces to ensure a snug fit. It took me around 7 iterations to get it right.

Motor Mount Design: Securing Mount Radially

A project log for 3D-Printed Electric Longboard

Fully 3D-printable electric longboard drivetrain with built-in idler system.

yowhwui

yowhwui

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.