The first full prototype had been assembled and some basic firmware was written to do some simply tests. The first was a self test where the on-board ESP32 command the servos to sweep through the servo travel range. Below is the video of the self-test.

Note that the servos have way more range than is actually required. More gearing could be added, but that would mean a loss in response time. It was decided to keep the current travel range, but limit the range in software.

For the next test, the firmware was setup simply hold the blades at a specified angle of attack. The blade angle was set to a near zero lift condition (Due to the blade twist, the isn't really a true zero lift condition). The position hold functionality was tested by attempting to twist the blades by hand and the blades maintained their specified position. With the firmware functionality confirmed, the vehicle was turned on to test out the full prototype similar to the hub spin up test done a few weeks ago.

The test didn't go well. The vehicle had an unusually hard start-up, causing the vehicle to flex more than usual. Shortly afterwards the electronics on the rotor lost power. Afterwards, it's hard to determine exactly what happened next. Even at 60 fps, the blades are spinning too fast to see what's going on. However, without power, the servos can't maintain the blades. It's possible that they rotated into the belts and were subsequently ripped off.

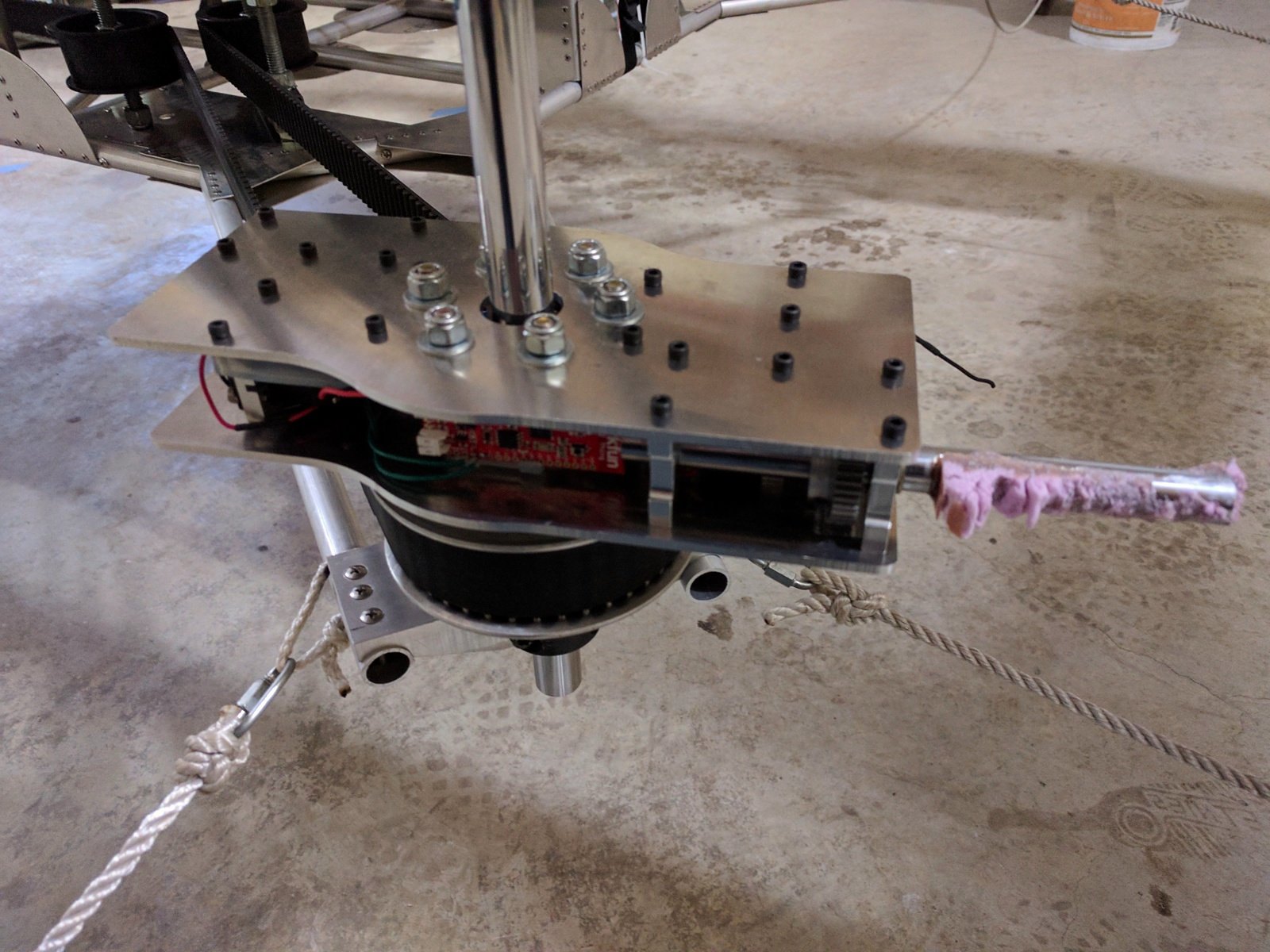

Here's a photo of the rotor after the test. One of the blades was simply ripped from the axle. It appears that the bonding between the shaft and the blade wasn't that great in places. The black wire is the battery wire that became disconnected during the test.

The other blade (the one that bounces page into the frame in the video) took the axle with it. To do this, one of the retaining rings and the steel gear had to be stripped off (I still haven't found either of those pieces in the shop). It appears that when the blade impacted the wall, the axle was kept going and popped out through the blade.

The other blade (the one that bounces page into the frame in the video) took the axle with it. To do this, one of the retaining rings and the steel gear had to be stripped off (I still haven't found either of those pieces in the shop). It appears that when the blade impacted the wall, the axle was kept going and popped out through the blade.

Repairs are in-work and shouldn't take too long. More robust power connections are needed. I'll start with slightly bigger wires and screw-down style terminal blocks. Mechanical limit stops will also be added to prevent the blades from rotating too far. It'd probably also make sense to add some additional clearance between the rotor and the belts.

Repairs are in-work and shouldn't take too long. More robust power connections are needed. I'll start with slightly bigger wires and screw-down style terminal blocks. Mechanical limit stops will also be added to prevent the blades from rotating too far. It'd probably also make sense to add some additional clearance between the rotor and the belts.

UPDATE (7/16/17 10PM PDT)

I finally found the missing gear today! The gear was embedded in the foam enclosure around the CNC router. The 2" thick foam was the best possible material for the gear to impact and the steel gear is completely unharmed.

Peter McCloud

Peter McCloud

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.