Update that is also included in Project Logs, but I'll put it here non the less.

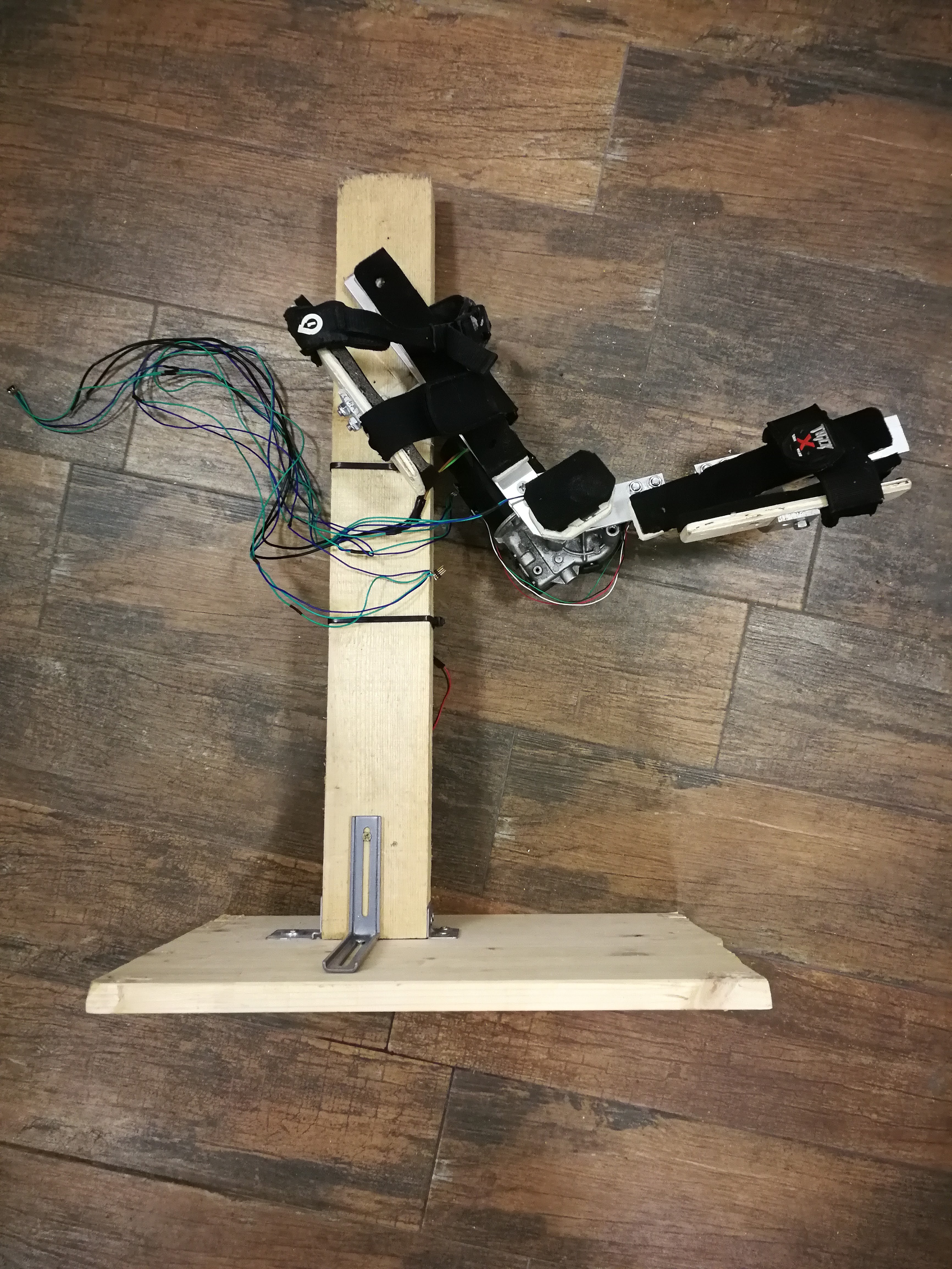

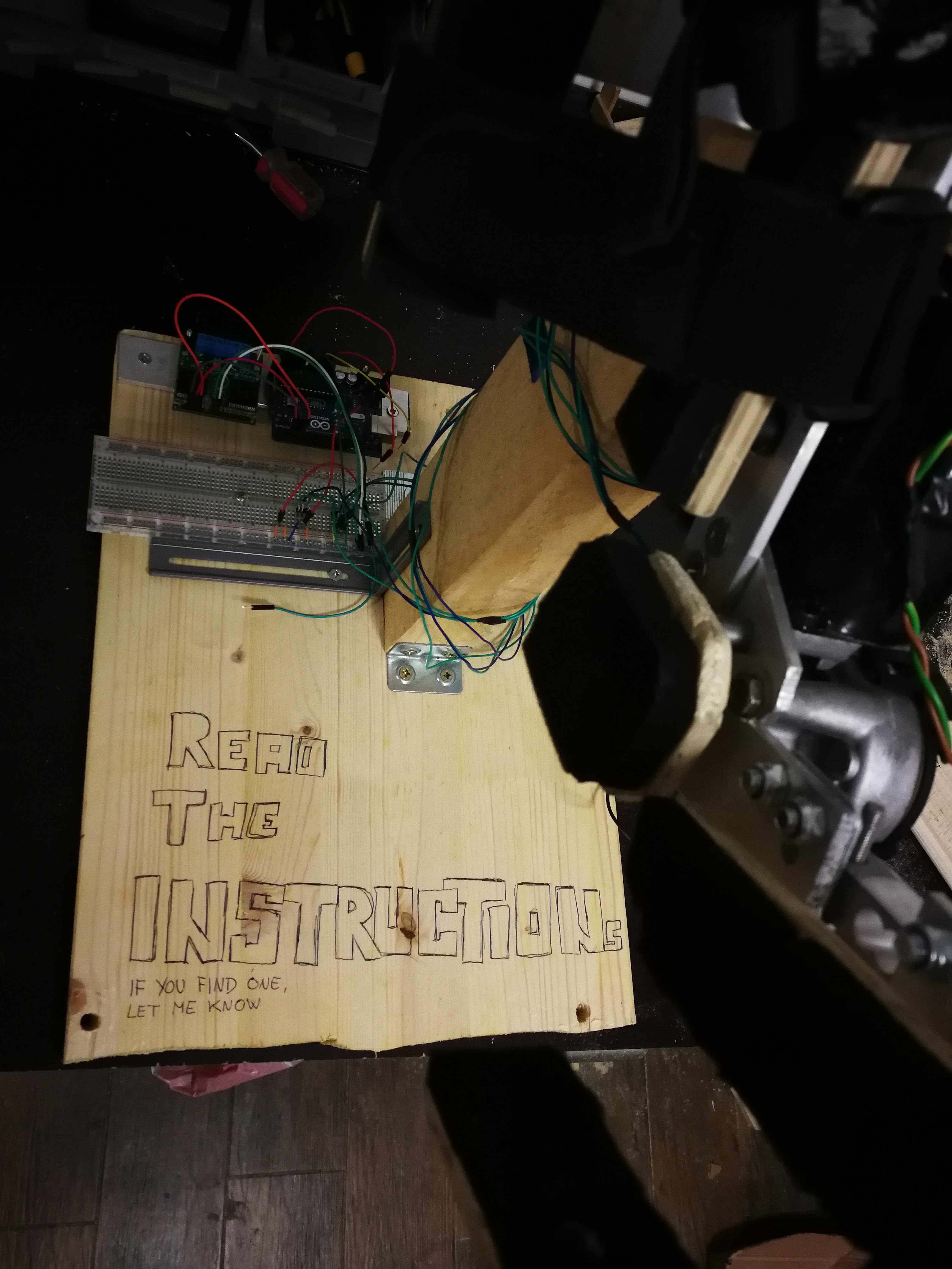

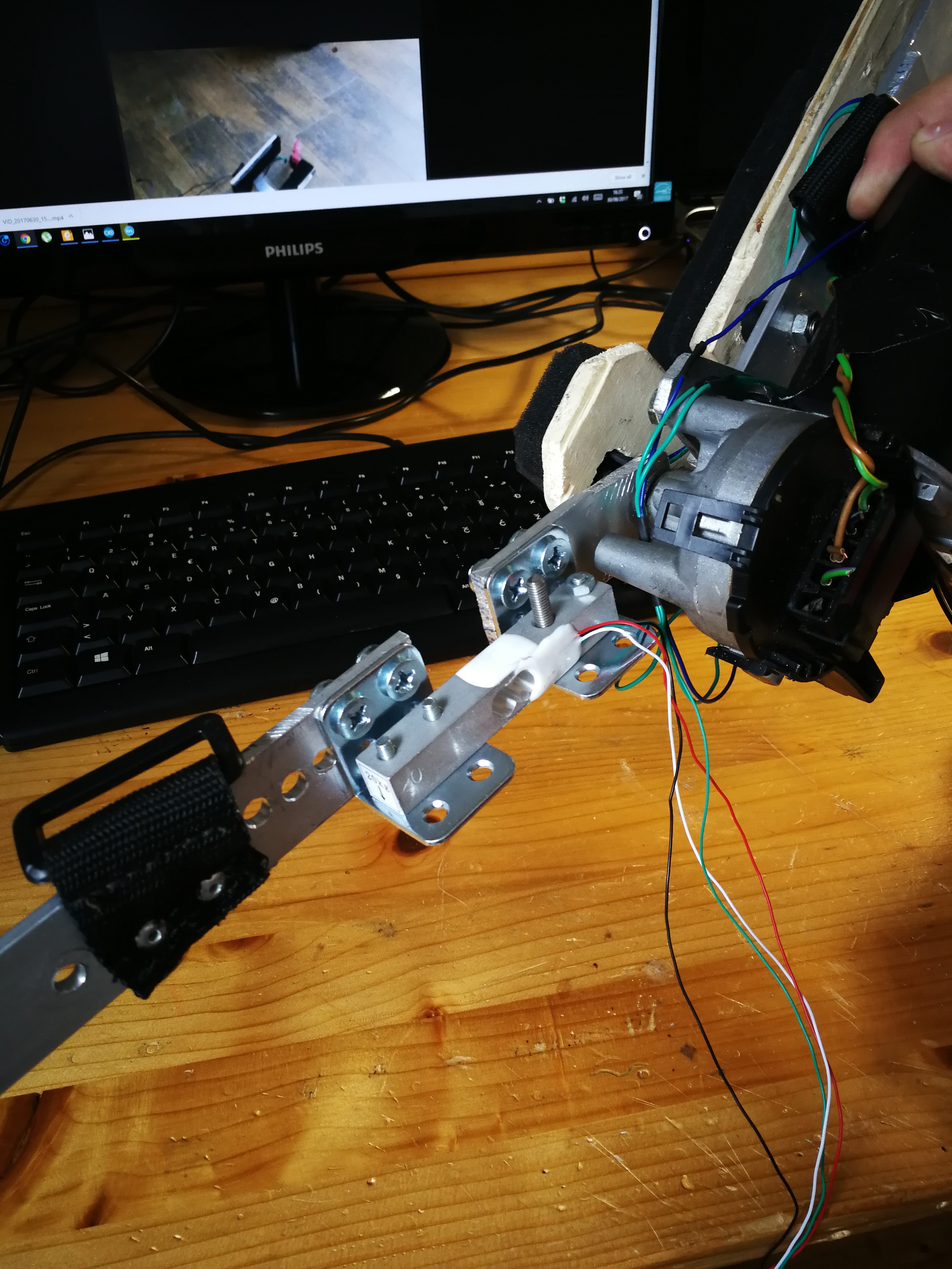

First prototype is complete!

How to make it:

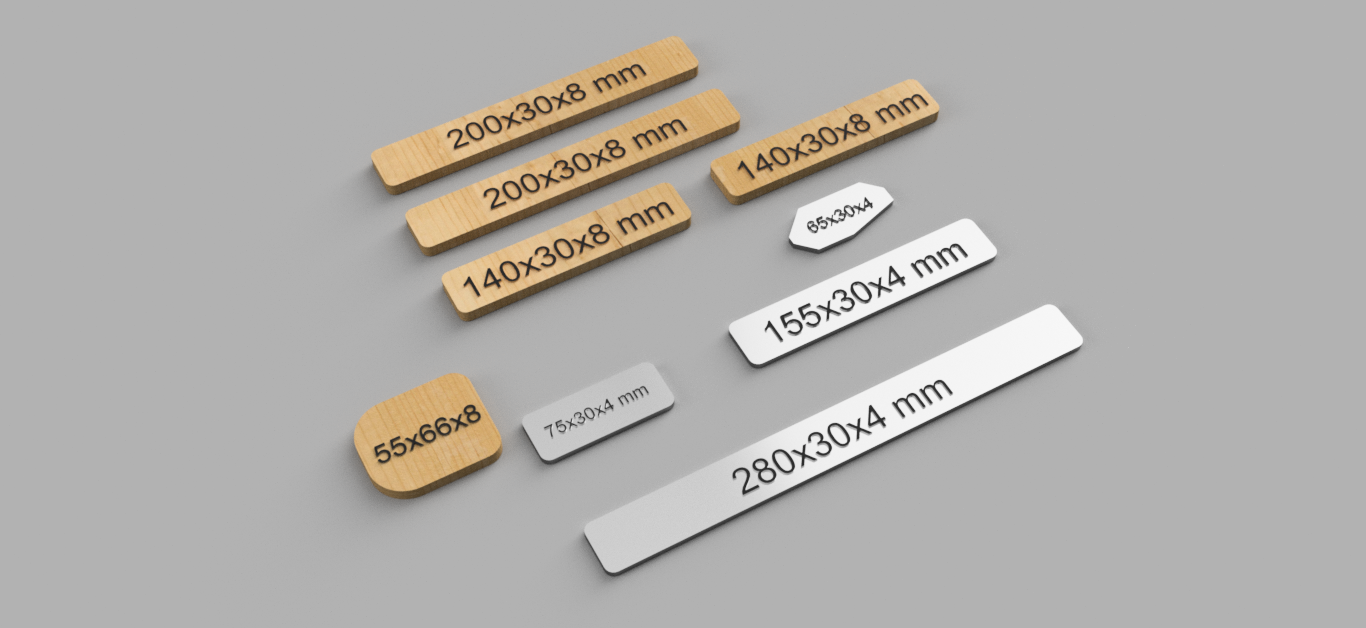

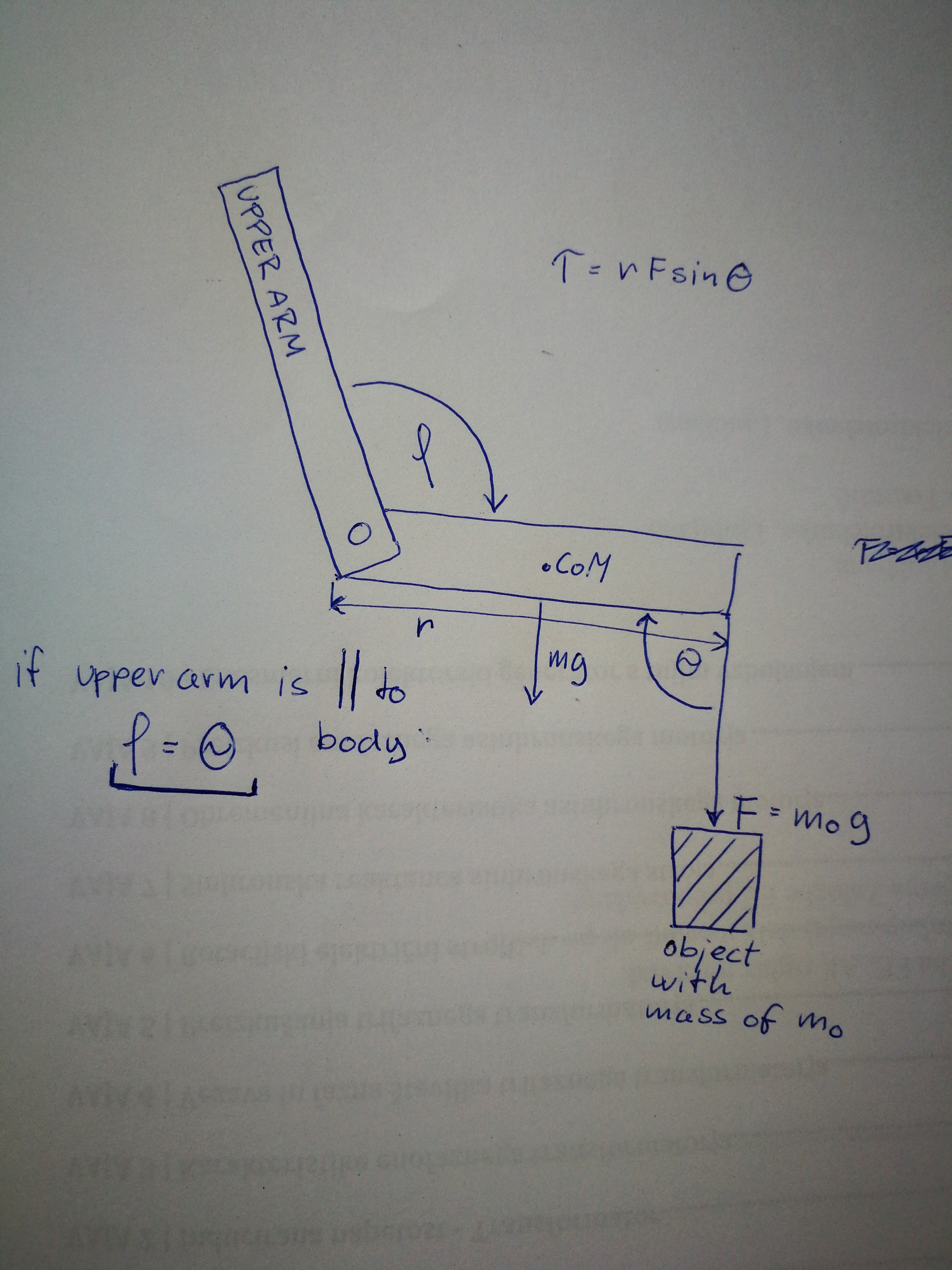

Measurements are not defined because until the arm is "universal size" the lengths vary from person to person. So the best act will be that you measure your own arm and use those measurements.

Kristjan Berce

Kristjan Berce

Dan Royer

Dan Royer

Dan DWRobotics

Dan DWRobotics

Les Hall

Les Hall

Can anyone explain me the use of strain gauge in this?