Problem Statement:

Lack of properly functioning ventriculoperitoneal shunt components have forced surgeons in some developing countries to use ad-hoc improvised devices which have a high complication rate. This paper (https://www.ncbi.nlm.nih.gov/pubmed/9299832/) from Malawi describes how surgeons simply diverted CSF from ventricular cavity into the peritoneum without an intervening valve with a 20% complication rate which included subdural hematomas and shunt associated craniosynostosis.

This other paper (https://www.ncbi.nlm.nih.gov/pubmed/26167009?dopt=Abstract) from Nigeria describes using a nasogastric tube for creating an external ventricular drain or ventriculostomy and report 28.6% MORTALITY (death) rate.

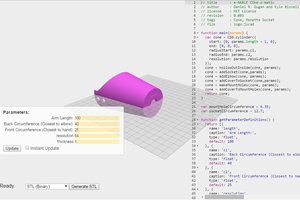

Additive manufacturing can create these shunt valve components with precision, sterility [new literature has demonstrated the inherent sterility of 3D printed parts (https://peerj.com/preprints/542/) if certain protocols are followed], and reproducibility in a resource limited setting but requires rethinking paradigm. They can be powered independent of national electric grid on solar panels.

Aims:

1) Improve outcomes of patients suffering from hydrocephalus in developing countries

2) Build partner nation's capacity for treating hydrocephalus by manufacturing parts with FDM 3D printing on site at hospitals decreasing reliance on imported medical devices.

3) Empower partner nations to design and create its own medical devices which are often expensive and drain precious foreign currency reserves.

Existing Solutions:

Commercially available ventriculoperitoneal shunts consist of a fixed pressure valve, proximal, and distal catheters. If we are to successfully manufacture a 3D printed valve we need to rethink the paradigm of the valve.

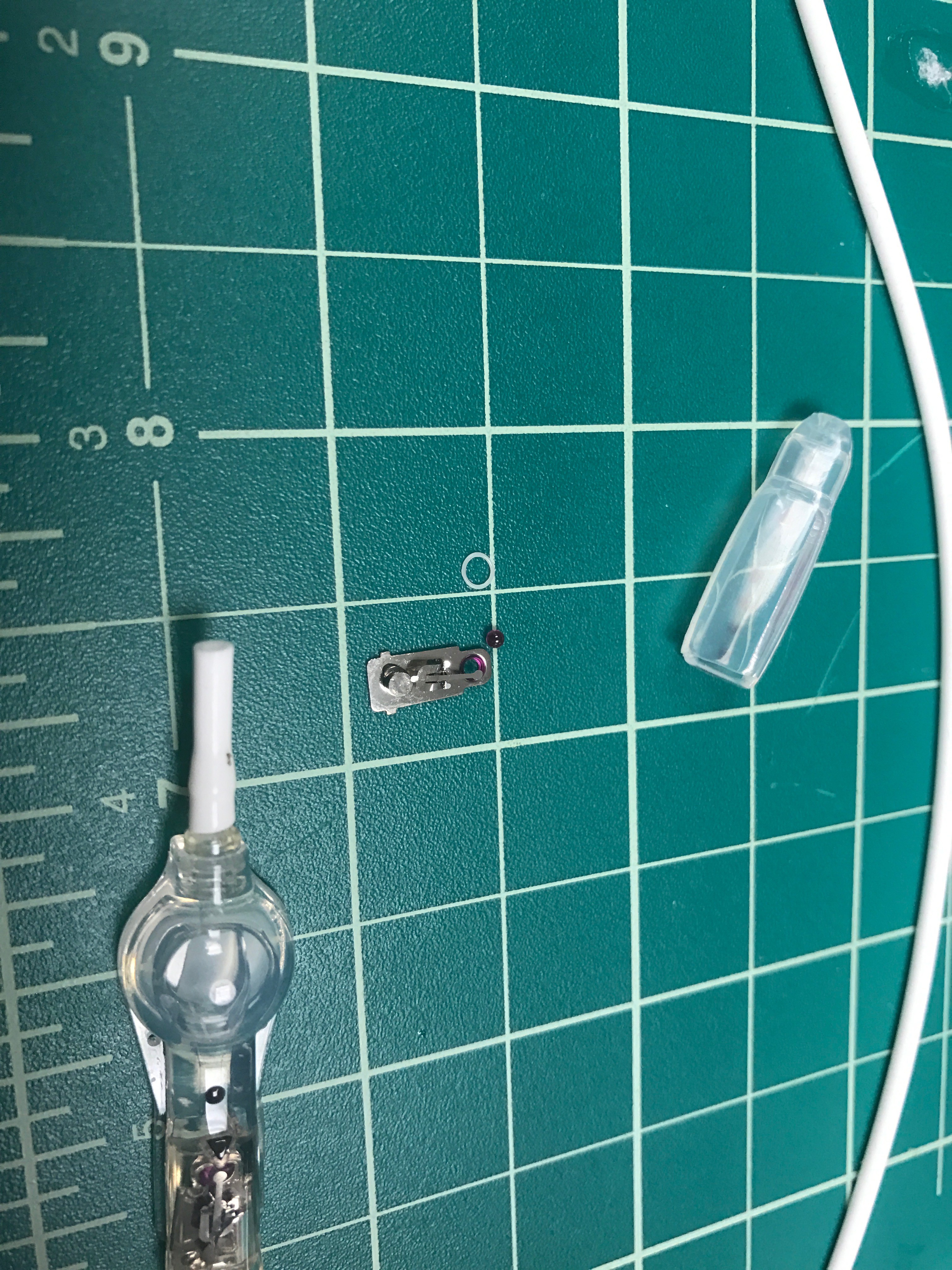

The valve housing consists of silicone. It includes an integrated reservoir (the circular part) that allows surgeon to sample CSF in the event of malfunction or suspected infection.

The valve also contains a one-way check valve (metallic object resembling miniature telegraph). In standard designs this can consist of numerous moving precisely machined parts- something that makes manufacturing a shunt in resource limited setting challenging.

Sohum Desai MD

Sohum Desai MD What you see here is a three way stopcock, manometer (vertical plastic tube marked in increments of centimeters), an adaptor for the outflow nozzle of the 3 way stopcock, and the shunt valve. The switch on the three way stopcock is turned so that the shunt valve is closed. A syringe filled with saline is then attached to the inflow used to fill the manometer. The switch of the three way stopcock is then turned so that the valve is closed.

What you see here is a three way stopcock, manometer (vertical plastic tube marked in increments of centimeters), an adaptor for the outflow nozzle of the 3 way stopcock, and the shunt valve. The switch on the three way stopcock is turned so that the shunt valve is closed. A syringe filled with saline is then attached to the inflow used to fill the manometer. The switch of the three way stopcock is then turned so that the valve is closed.

jon.knutton

jon.knutton

John Opsahl

John Opsahl

Daniel R. Dugan

Daniel R. Dugan