You will find a lot of background information in #AMBAP: A Modest Bitslice Architecture Proposal and #YGREC16 - YG's 16bits Relay Electric Computer, this new project contains the latest developments since April 1st.

Logs:

1. Evolution of the architecture

2. DRAM (again)

3. PROM boards

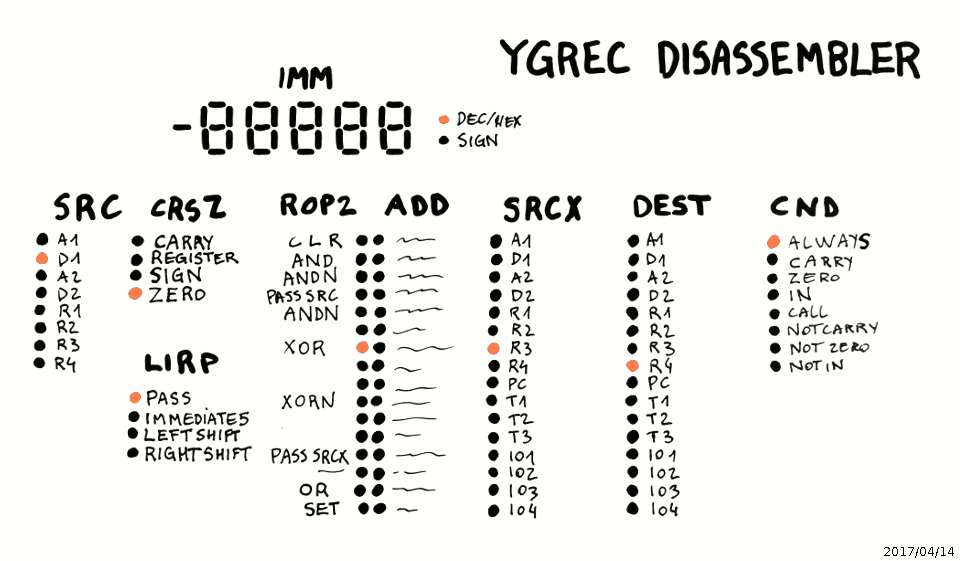

4. Assembler and disassembler

5. I hope that's enough

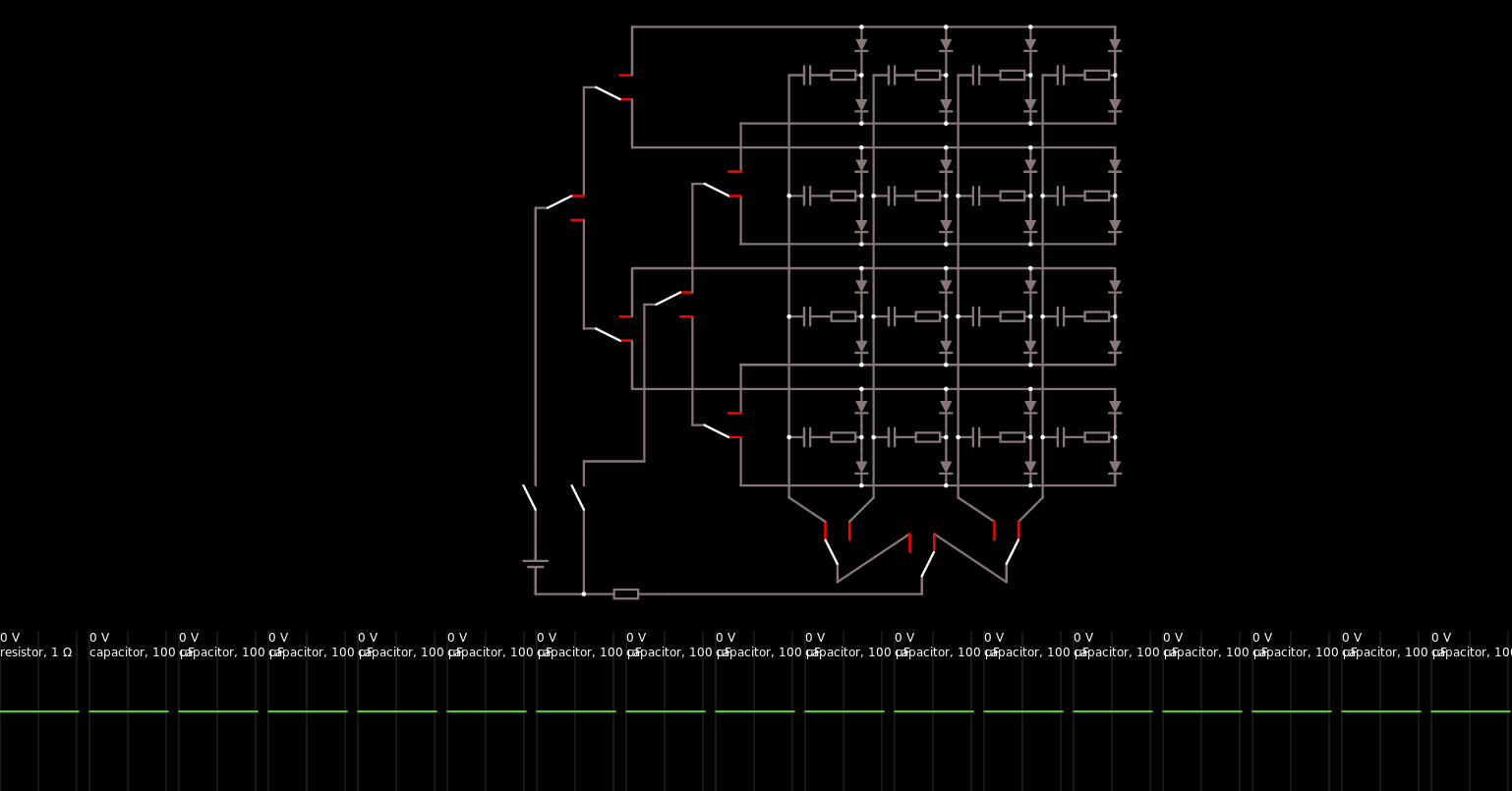

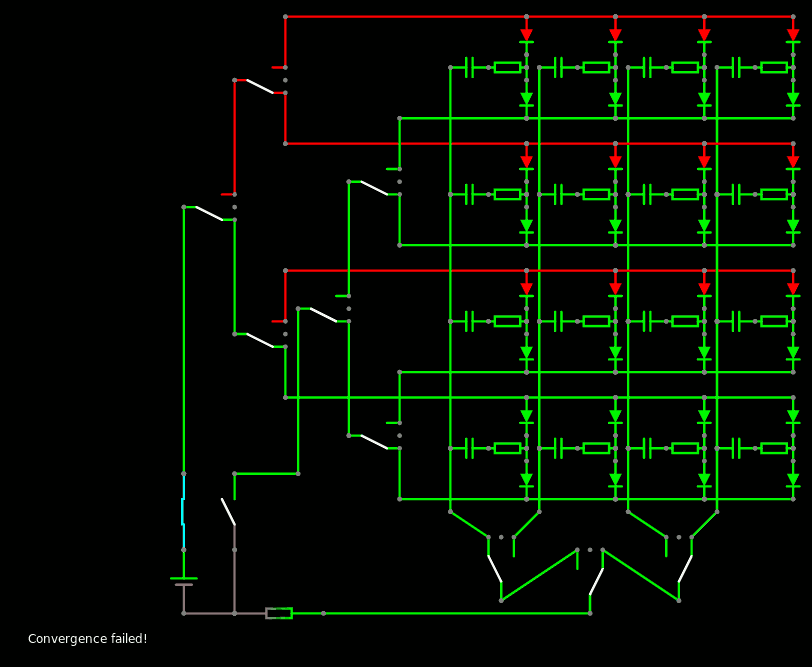

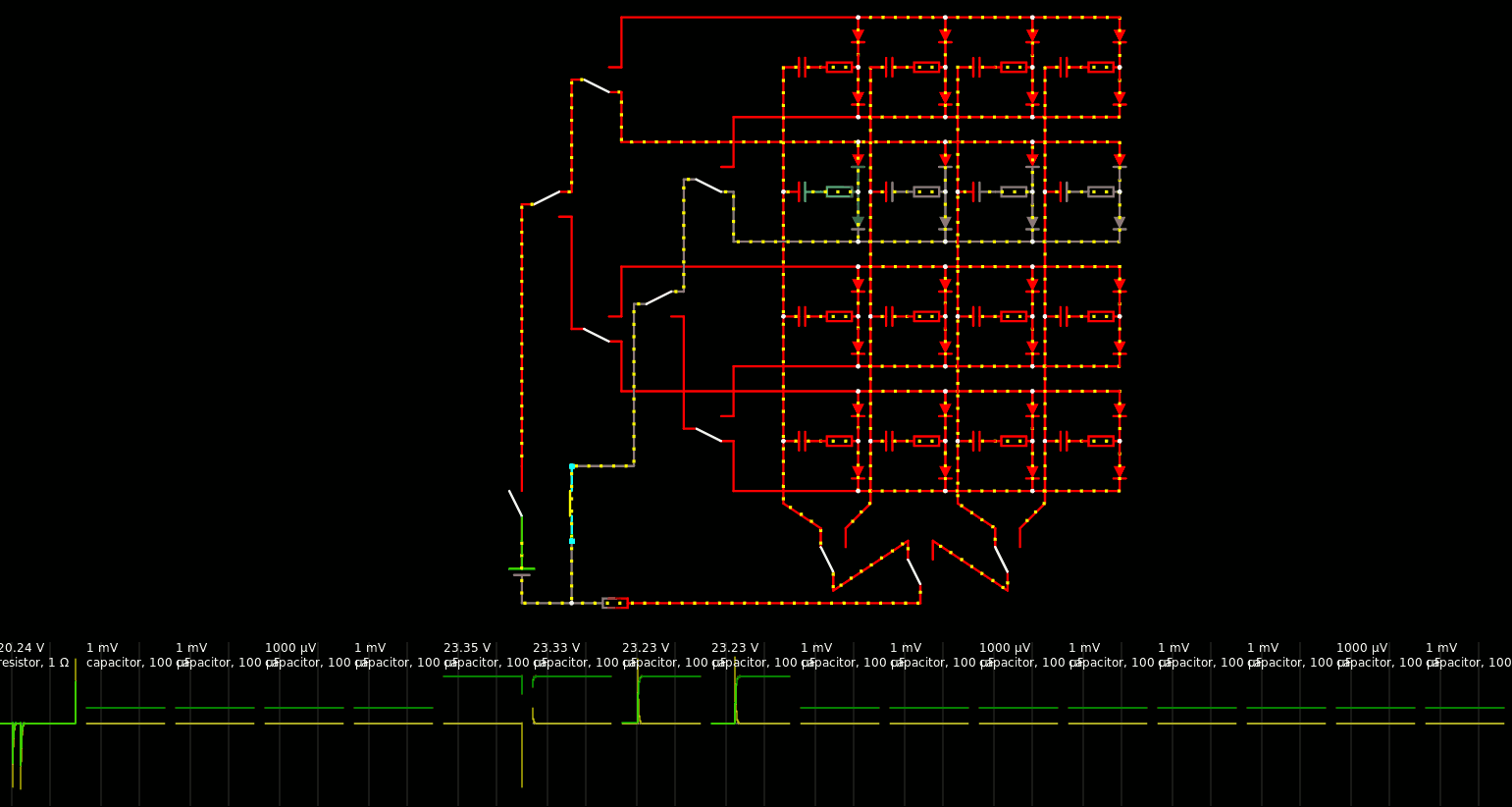

6. First DRAM array prototype

7. The Program Counter's circuit

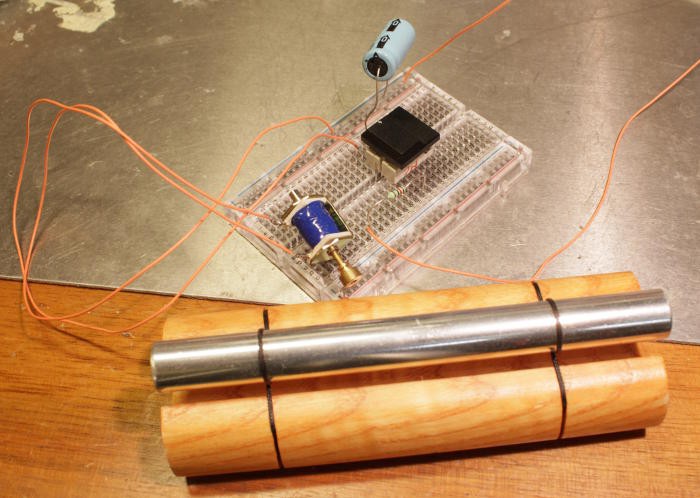

8. Tubular bell

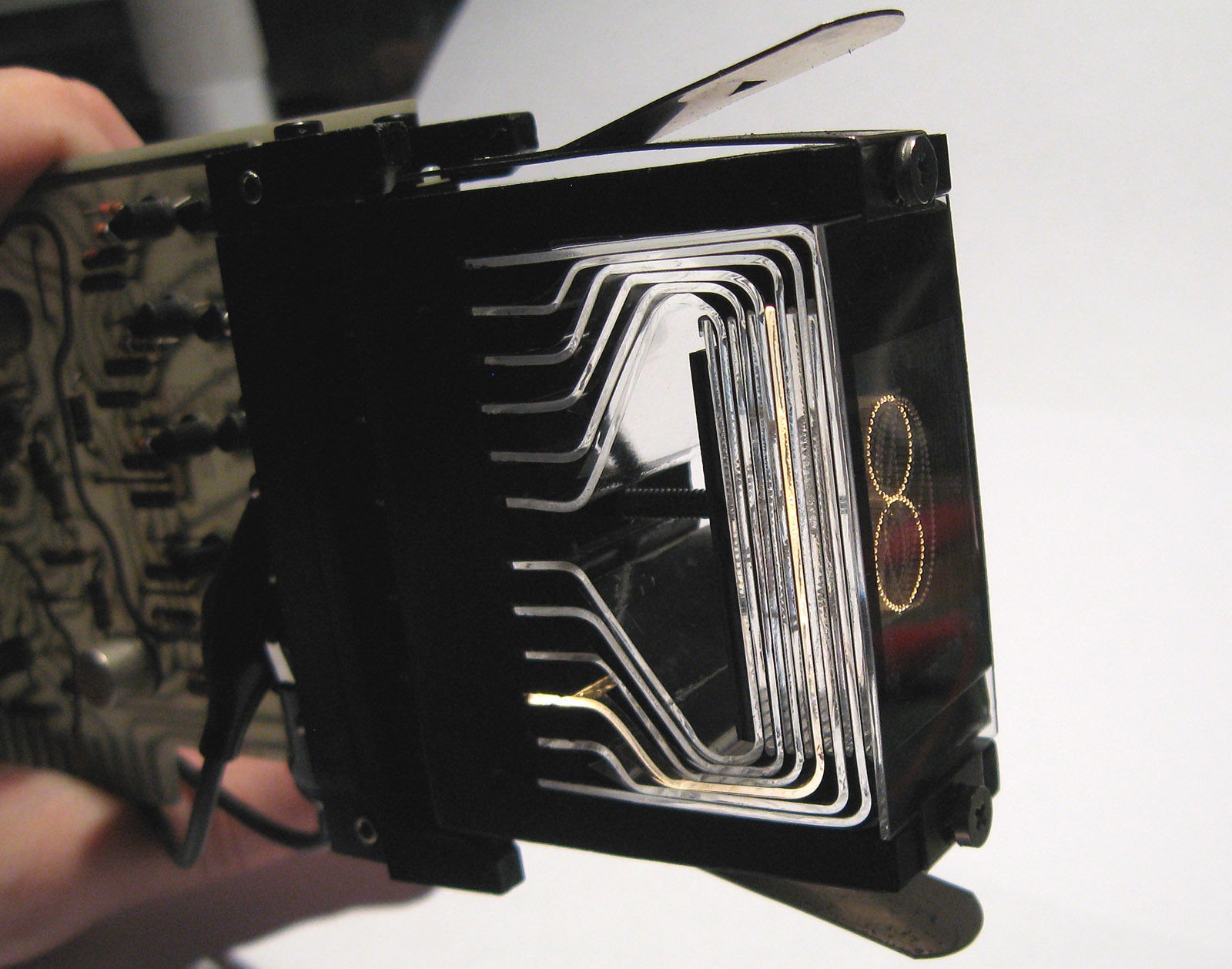

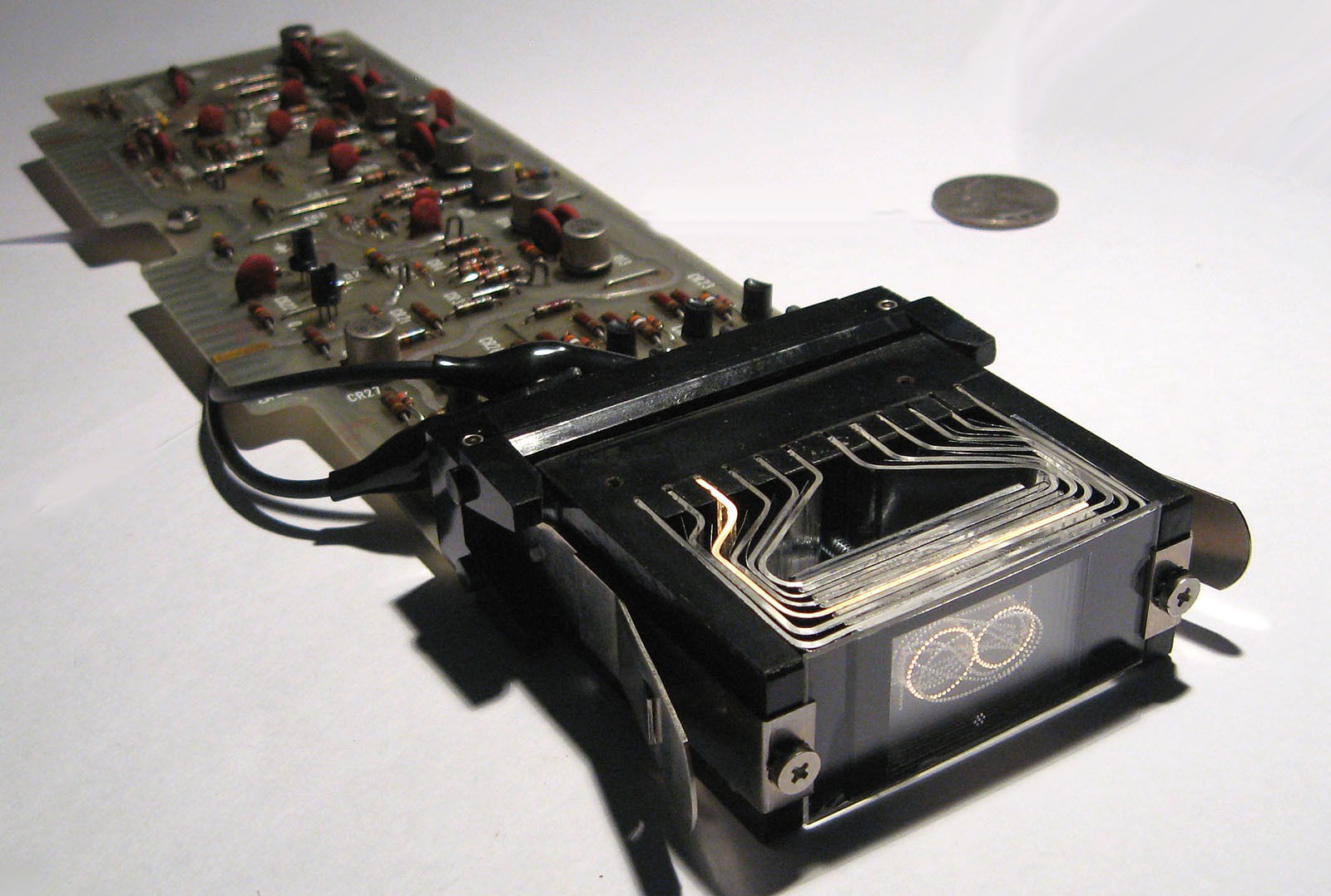

9. Flip Dots !

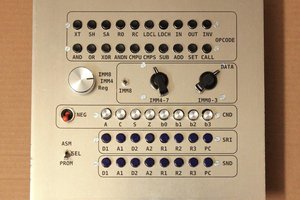

10. Electromechanical User Interface : the Assembler board

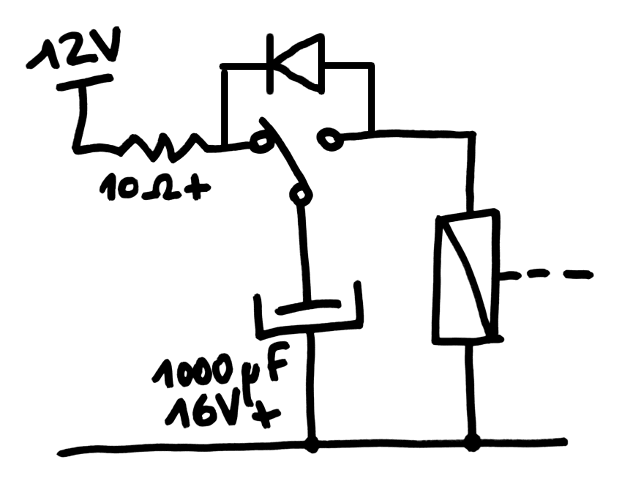

11. How to drive РЭС15 relays with a computer ?

12. Programming the YGREC

13. Carry chain considerations

14. I hope that's enough this time

15. The instruction register (cont'd)

16. Now it should be enough

17. I can see now

18. Instruction display panel

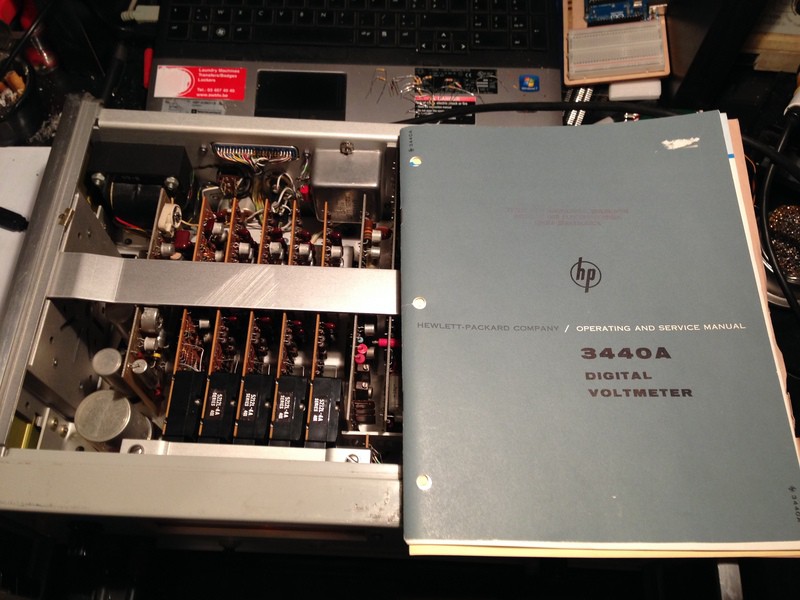

19. Relay DAC

20. Display technology again

21. Chime on me...

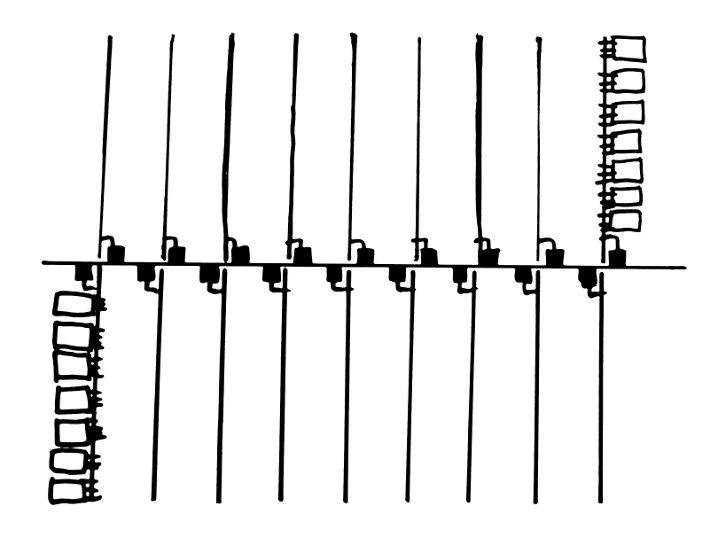

22. DIY backplane construction

23. Yet another fork

24. ...

Let's build a computer. Literally a bare metal computer, that is also funny and ridiculous !

- Ridiculously slow (20 IPS ?)

- Ridiculously greedy ( >200W)

- Ridiculously noisy (OK, that's actually desirable)

- Ridiculously incompatible (it's a brand new architecture called YGREC that I develop at the same time)

- Ridiculously limited (512 words of DRAM, a bit more instructions)

- Ridiculously unreliable (I added 2 parity bits)

- Ridiculously useless (except to compute the Game of Life to prove my point that ridicule doesn't kill)...

It started almost as a joke one year ago with #SPDT16: 16-bits arithmetic unit with relays but the joke was on me and the fun, the learning, the charting of new design spaces have slowly changed my approach to computer design.

Now I have a complete architecture, an instruction set, all the needed essential parts, and I continue to put things together in the logs. In parallel, every new breakthrough is reinjected in such projects as #YASEP Yet Another Small Embedded Processor and #F-CPU (which was rebooted thanks to this project).

The YGREC architecture is pretty simple and designed to use as few resources as possible, yet run the #Game of Life bit-parallel algorithm efficiently (though it's not the original goal or purpose, there was none in fact, it was just "loooook those cute relays must be fun to use!")

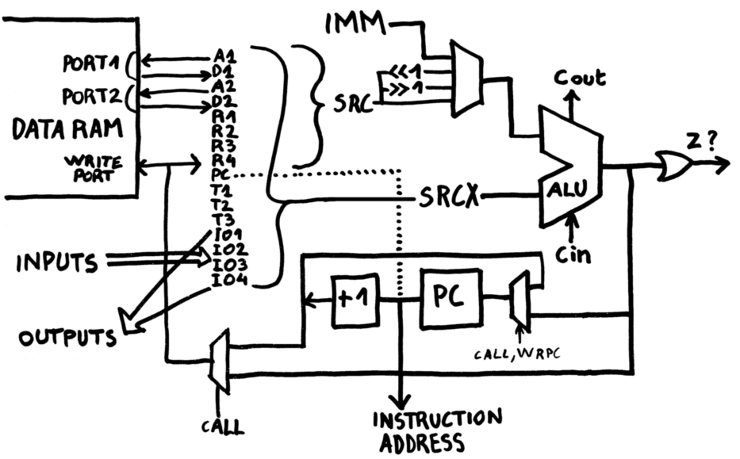

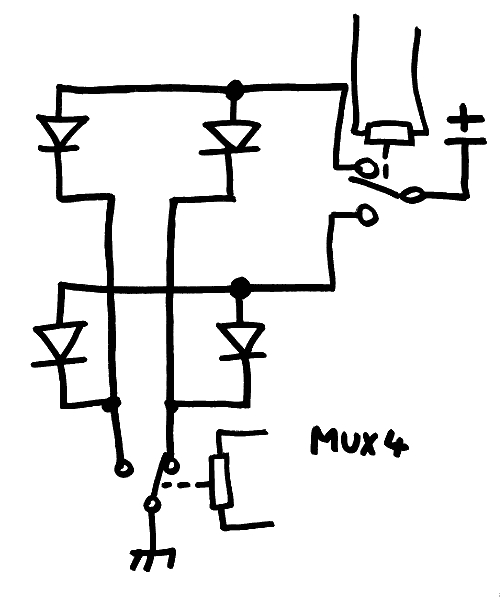

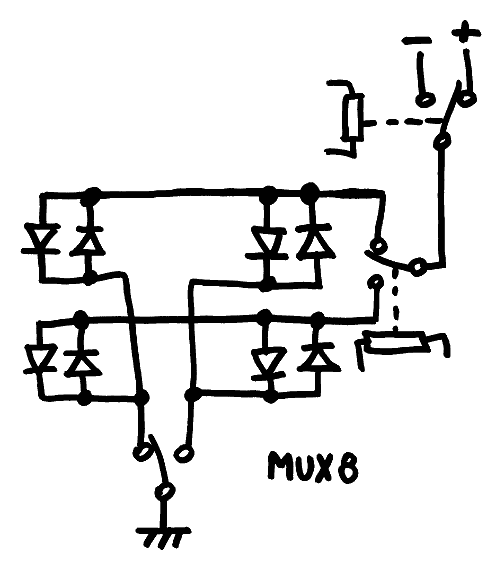

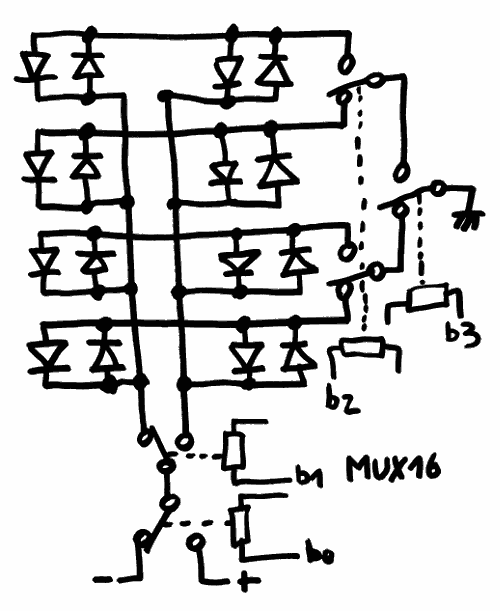

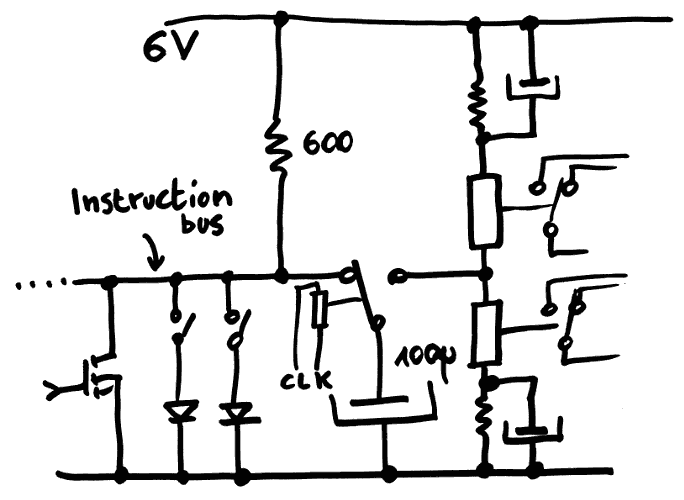

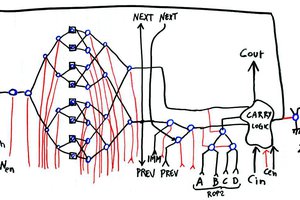

The datapath is shown below : The 16 registers (including PC) are accessed as the SRCX operand while only 8 registers are read as the SRC operand (because such a large MUX uses a LOT of relays). The narrower SRC operand can be shifted/rotated, or substituted with an immediate value from the opcode. Both operands are then processed in the ALU (either in ROP2 mode, where all combinations are possible, or in Add/Sub mode where comparison, carry and Min/Max are possible). The result is checked for being zeroed, and sent back to the register set.

Really, it can't be smaller or simpler while preserving functionality (I'm not doing a Brainfuck computer, I'm interested in actual practical architectures)

The register set maps memory addresses, memory data, the Program Counter and Input/Output ports. Only R1-R4 and T1-T3 are "standard registers", making the YGREC a hybrid architecture: it looks like some classic RISC and also behaves like TTA (for operations other than Shift/ALU/ROP2). There is indeed no actual opcode, only 32 combinations for the ALU and 16 Shift/Rotate combinations to care about. The architecture is highly orthogonal, all the essential operations can be achieved with a combination of the available fields and special registers. All the instructions are predicated, except CALL which replaces the condition "NEVER". In this case, the result goes to PC, while PC+1 goes to the register set.

The YGREC can be reduced to MUXes and DFF registers (which can also be made with MUXes). This maps perfectly to dual-throw relays !

Some characteristics (if you haven't read the other project) :

- Based on a bitslice architecture, with 18 bitplanes (16 data bits and 2 parity bits, one bit per byte)

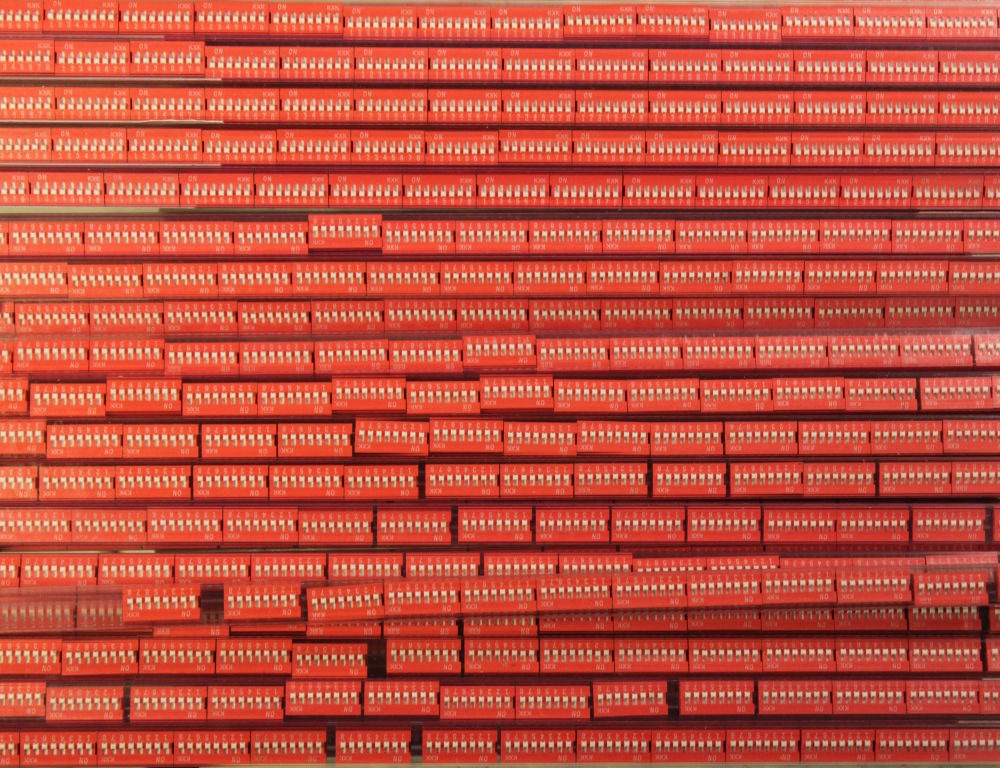

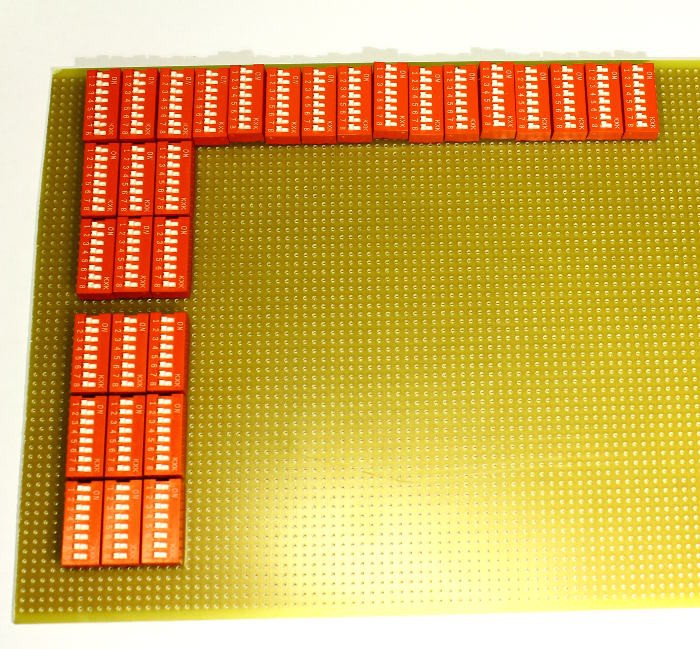

- Uses about 3000 РЭС15 relays (low voltage, circa 1989), a ton of diodes (but not for...

Yann Guidon / YGDES

Yann Guidon / YGDES

there are

there are

Love computers that use switches! :-) Check out my project, I use 256 of them but they are in 2 ICs not individual relays... I wonder how many relays would be needed to implement my CPU design - 256 (matrix) + 8 (registers) * 16 (bits per register) + x (control unit)