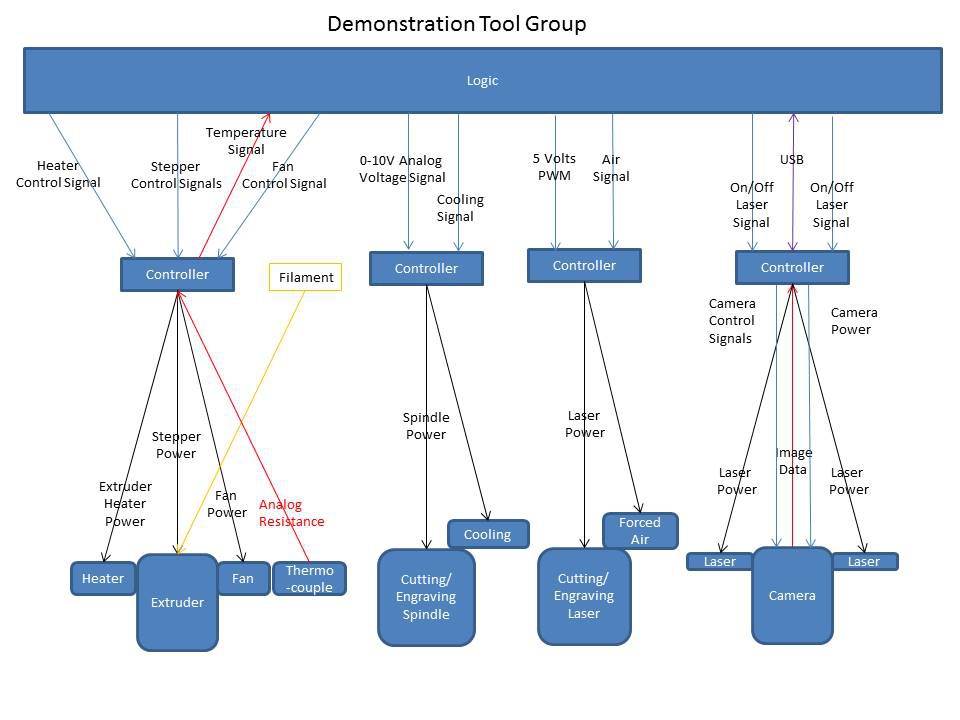

LVL 1 has many Cartesian box tools. They are simply different shapes of a tool holder. Each has a mean time between failure based on how comfortable people are to making adjustments. The comfort of adjustment seems to be based on how enclosed it is. Laser cutters are dangerous and fully enclosed and therefore seldom adjusted. 3D printers and small CNC boxes are wide open and prone to adjustment. But adjustments being made are usually the tool and not the box. So I thought, "What if I made them a box with easily removable tool (spindle, extruder, laser, etc) and kept the box mechanics enclosed?". The device would be usable while any single tool was comfortably adjusted. This is the enclosed box and open tool idea. After all, most people come for tools and stay for fellowship.

Quick note: not all adjustments were merited or advisable.

cabrera.101

cabrera.101

Andy

Andy

JasMoH

JasMoH

Ampeater

Ampeater