Sorry for the late. Actually, I have a prior agreement with WoW. They invested in the Kickstarter project of Ananas Steper3.0, so they need to agree on when to open source the circuit design and related software. Thank you for all your attention.

AnanasStepper 3.0 is coming!

For some special reasons, I will release the source code and design files after the Kickstarter compaign, Thanks for understanding me.

Kickstarter !!!!!!!!!

We need your support !!!

WebPage: https://ananasrobot.github.io/AnanasStepper/

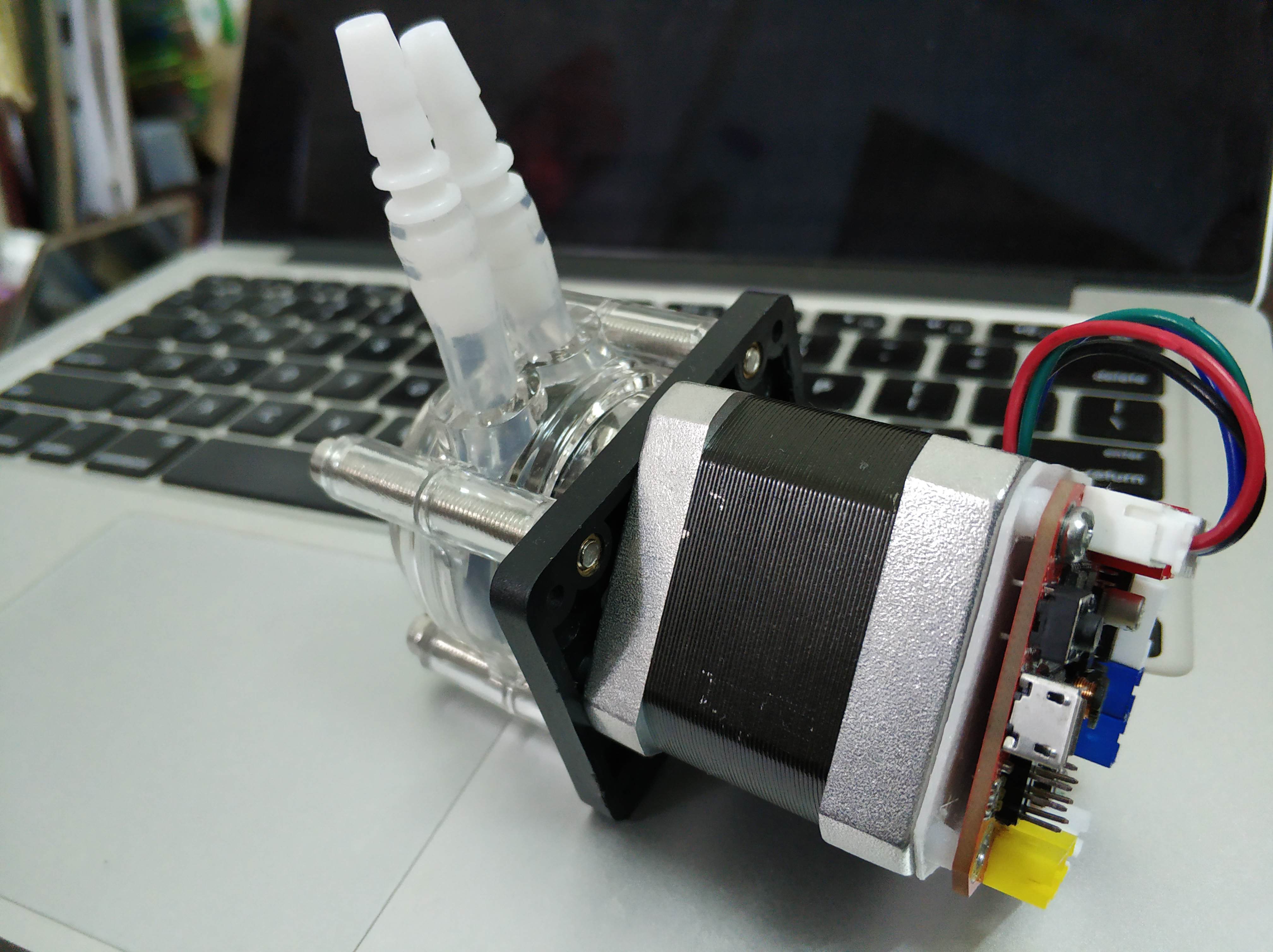

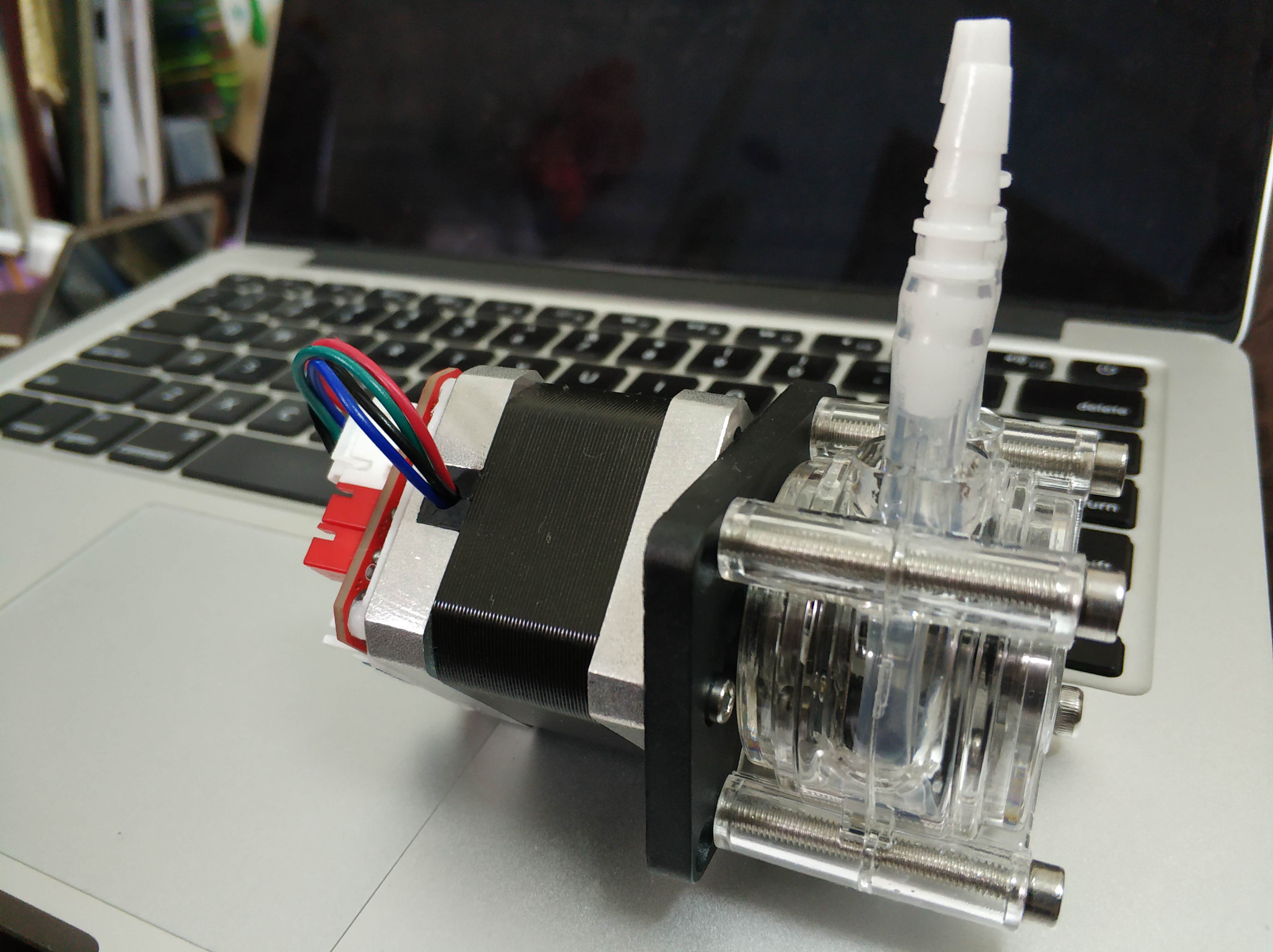

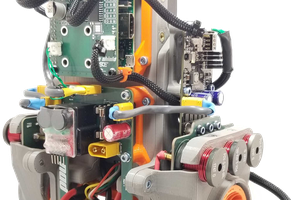

AnanasStepper 3.0

Main Feature

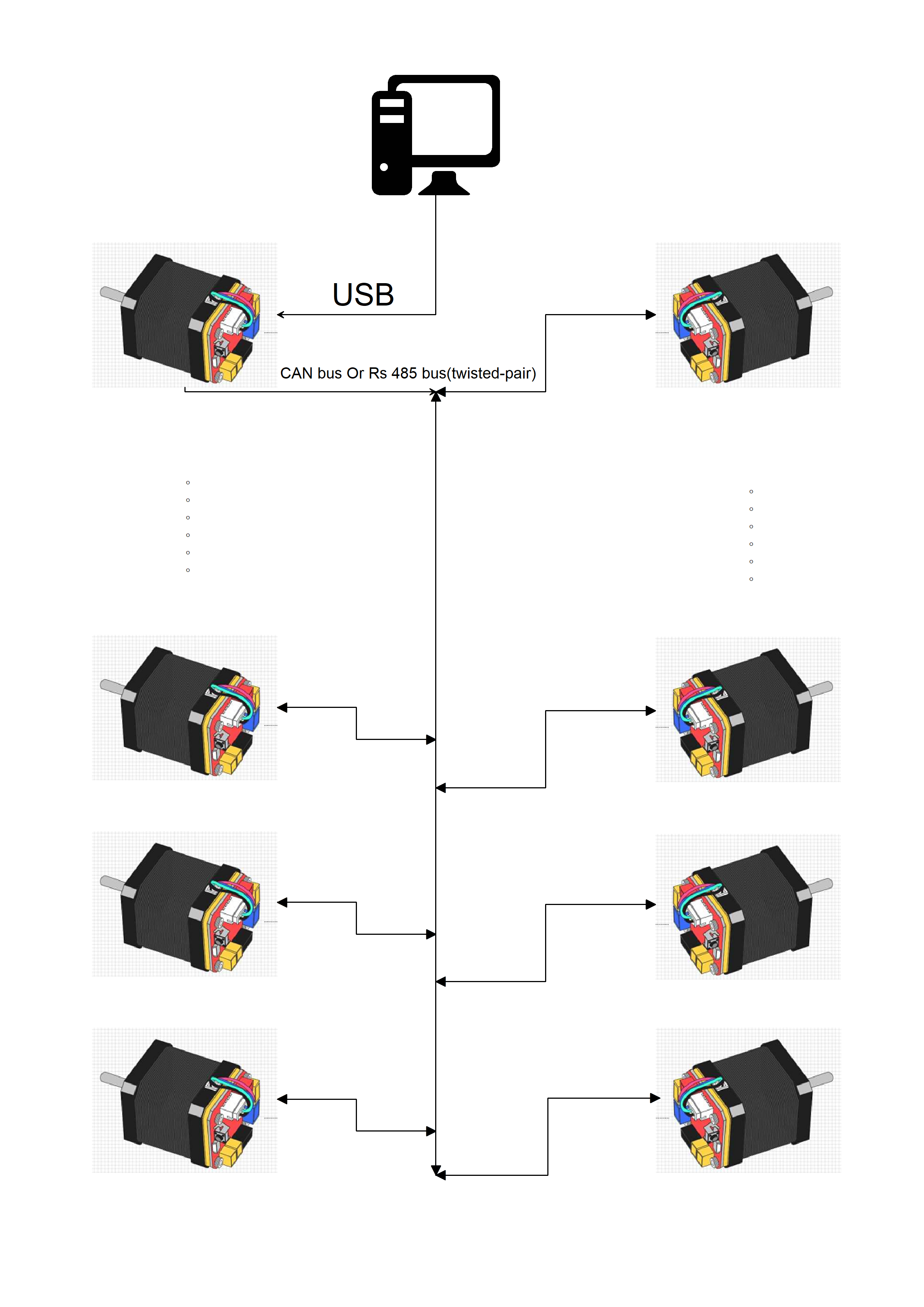

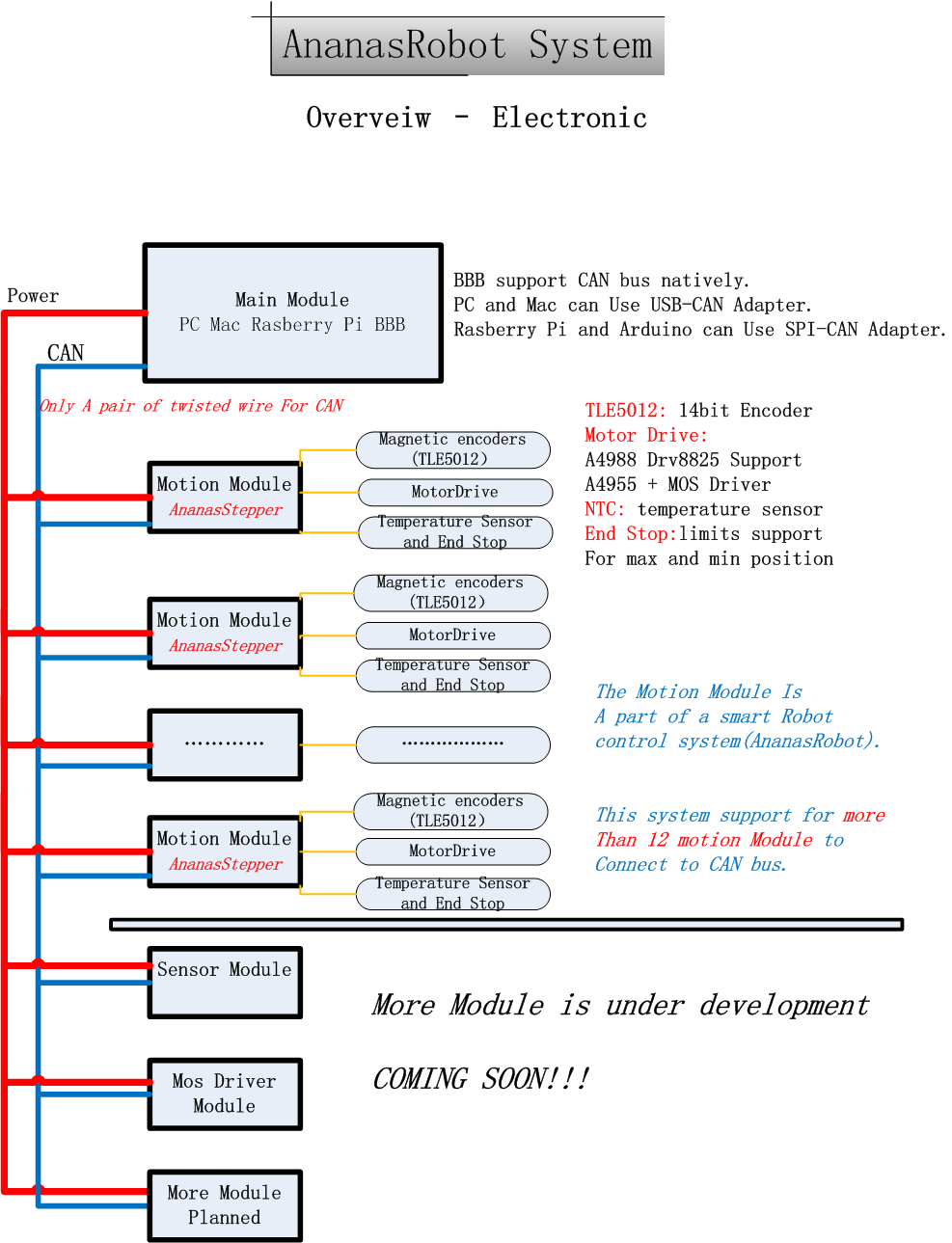

1.CAN bus based(up to 1 Mbit).

2.STM32 32bit ARM MCU(Cortex-M0 48MHz).

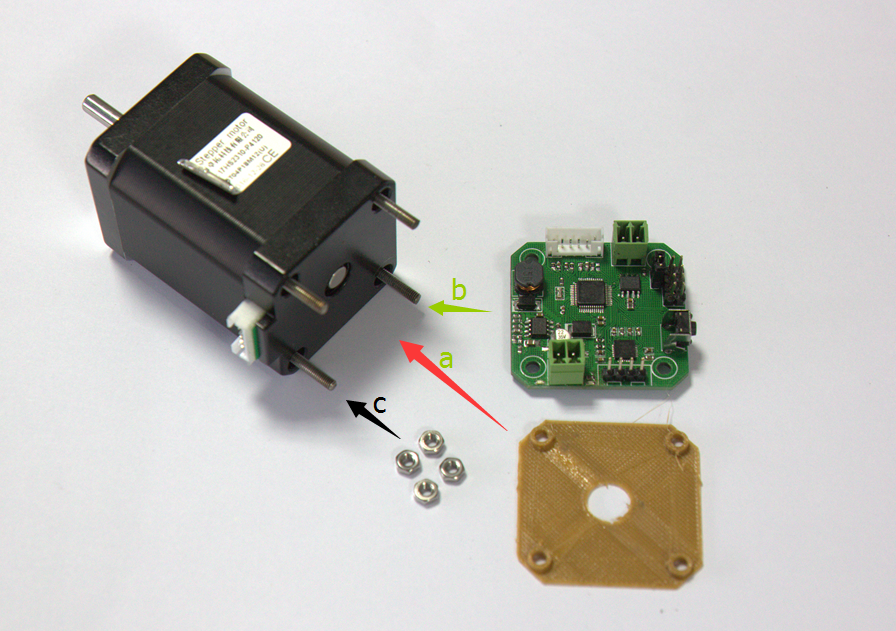

3.Closed loop control with 15bit magnetic encoders(TLE5012).

4.more power MOS Driver(A4950).

5.Extendable(For most 128 motors ), and Easy for Installation(With two twisted wires and power to get the whole system available).

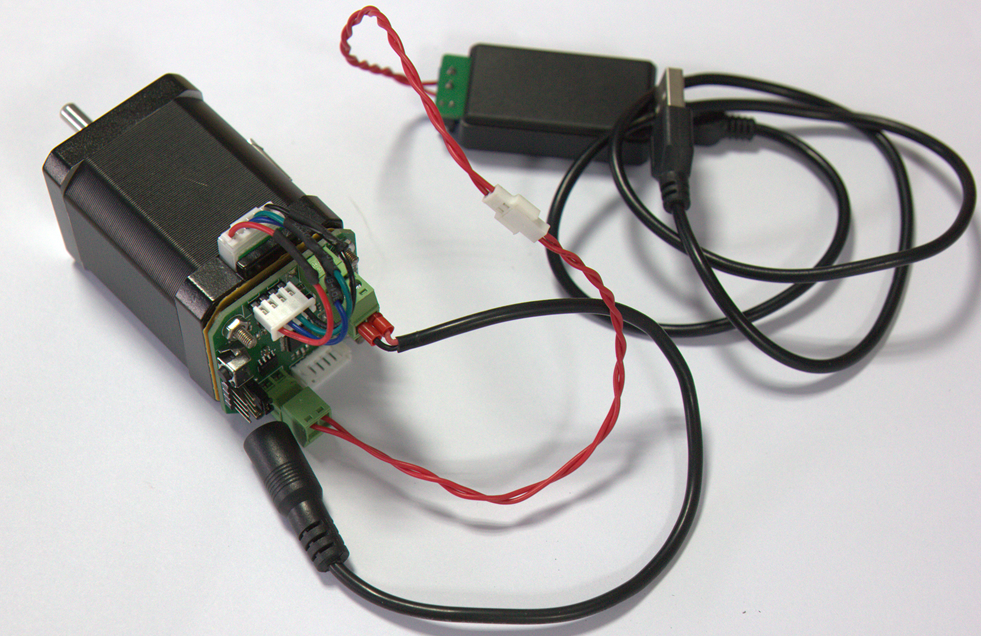

6.USB Interface for CAN bus accessing easily.

7.API for multiple control systems,Windows Mac Linux FreeRTOS ROS (Arduino Beagleboneblack RapberryPi)

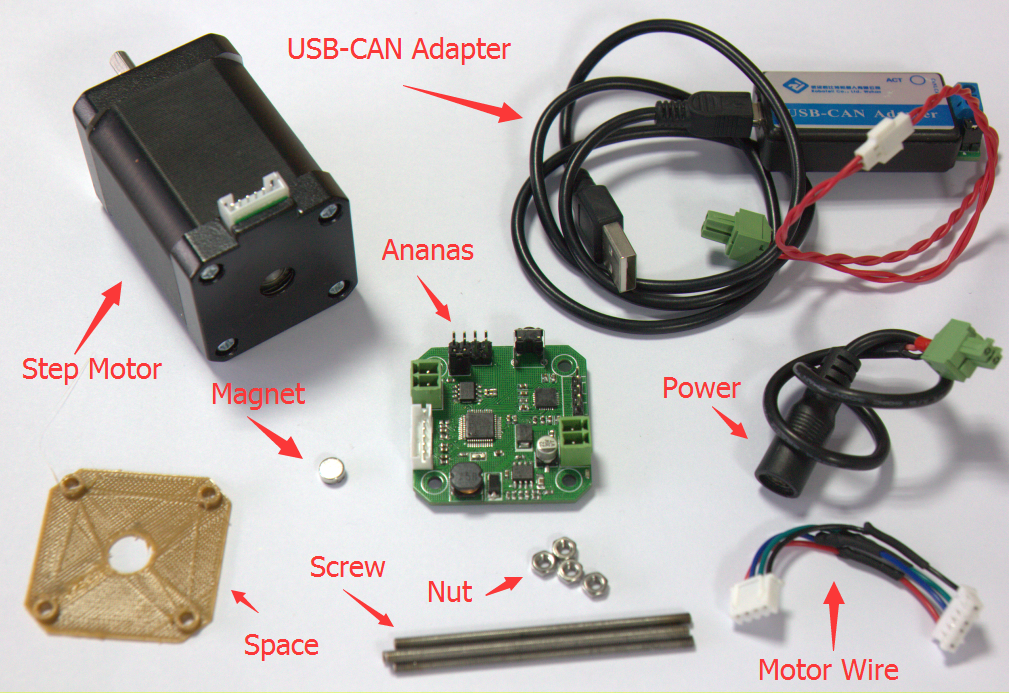

This an upgrade of AnanasStepper(https://github.com/Dark-Guan/Ananas), which is a stand alone closed loop stepper driver.With STM32 MCU, this version has more performance to driver stepper well and CAN Bus support.

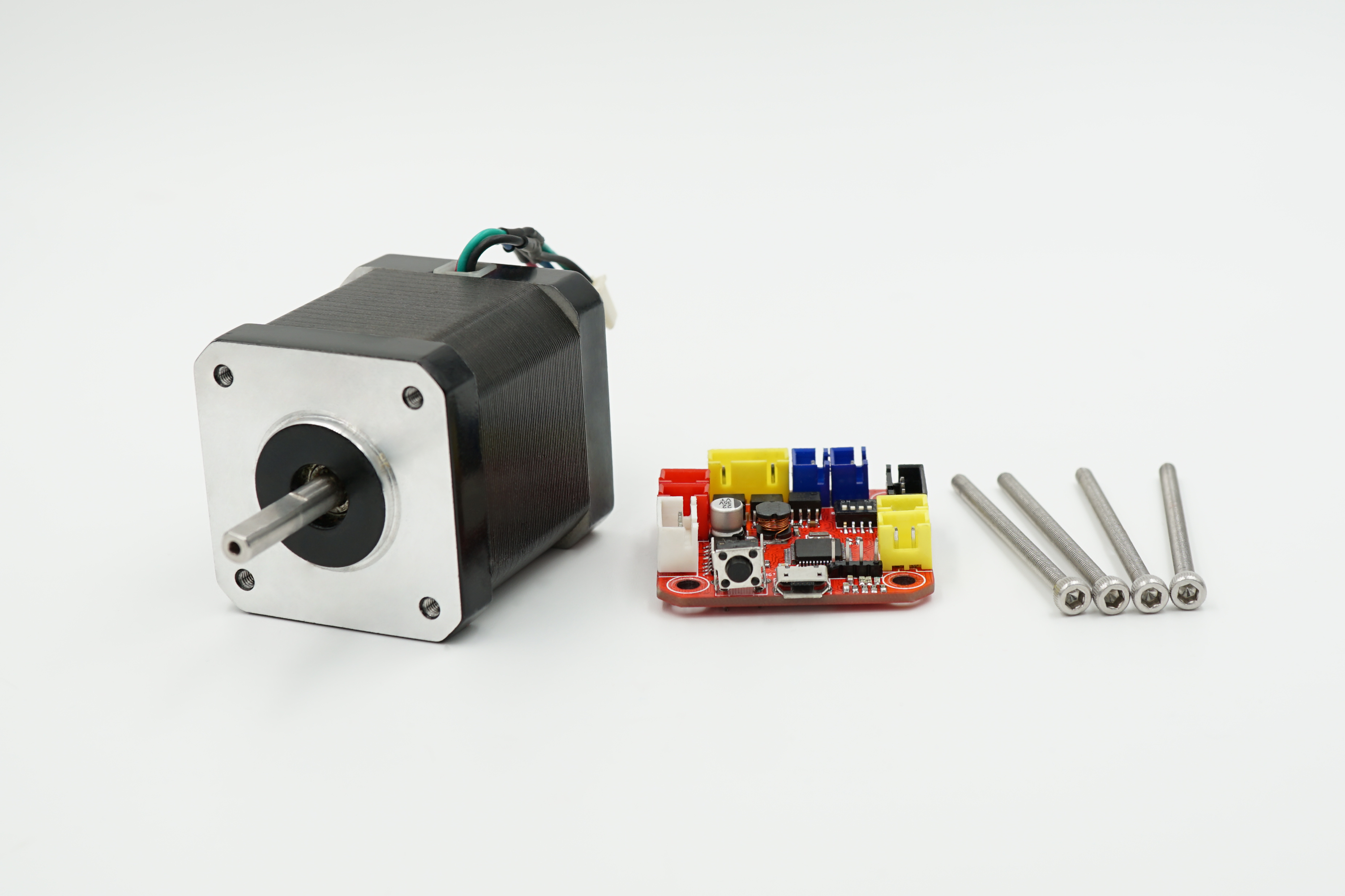

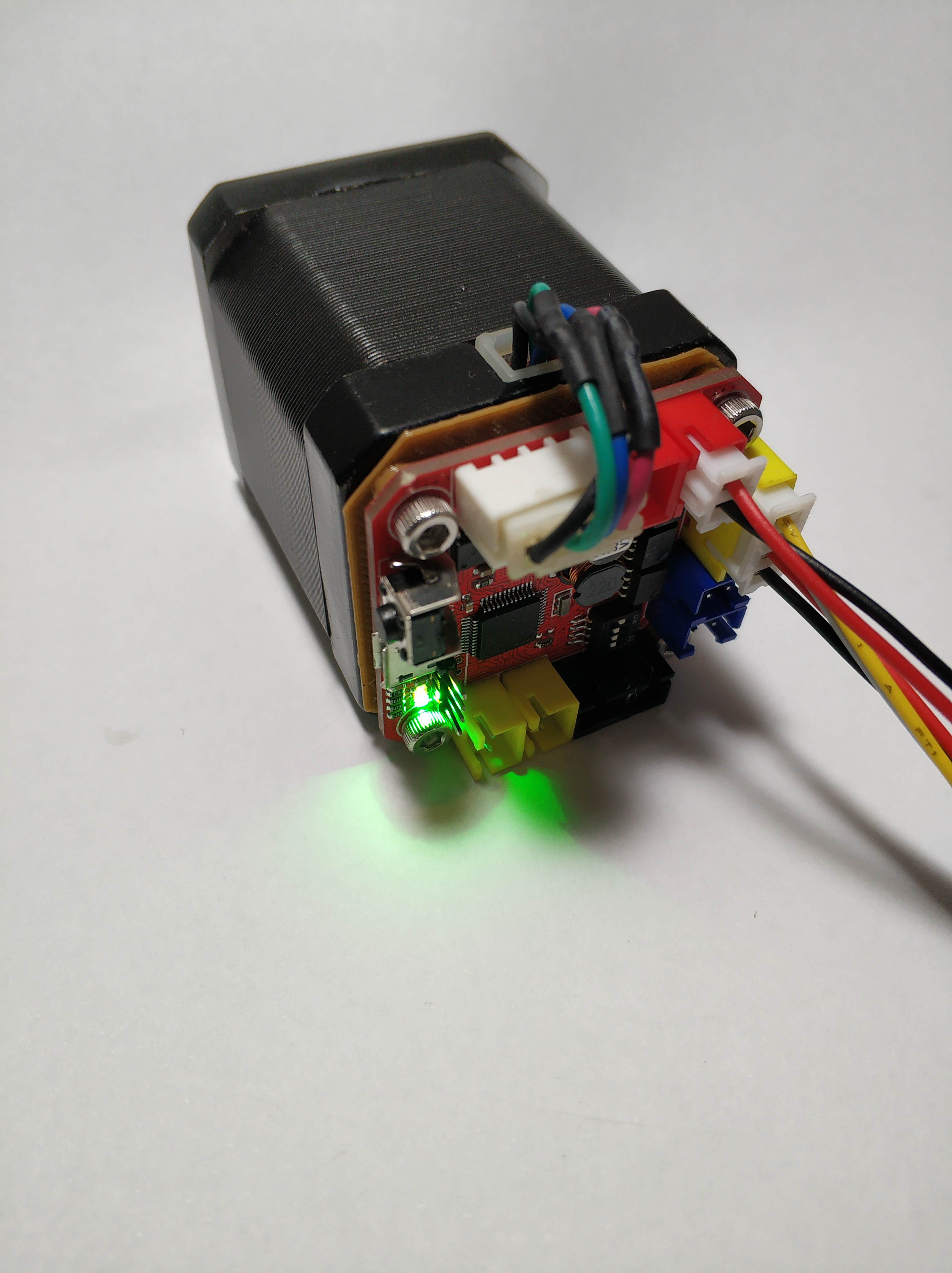

AnanasStepper 2.0

1.CAN bus based(up to 1 Mbit).

2.STM32 32bit ARM MCU(Cortex-M3 72MHz).

3.Closed loop control with 14bit magnetic encoders(TLE5012).

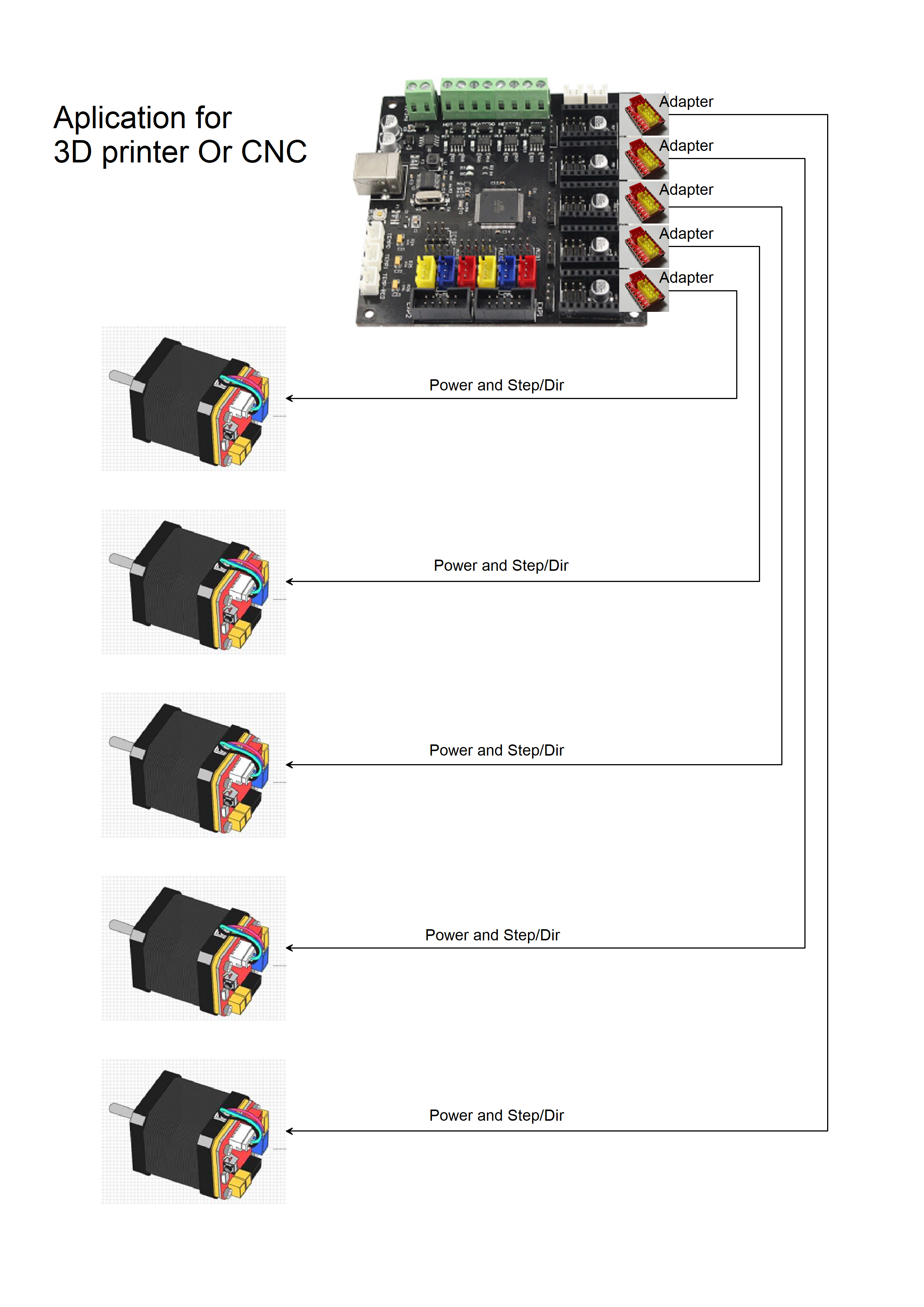

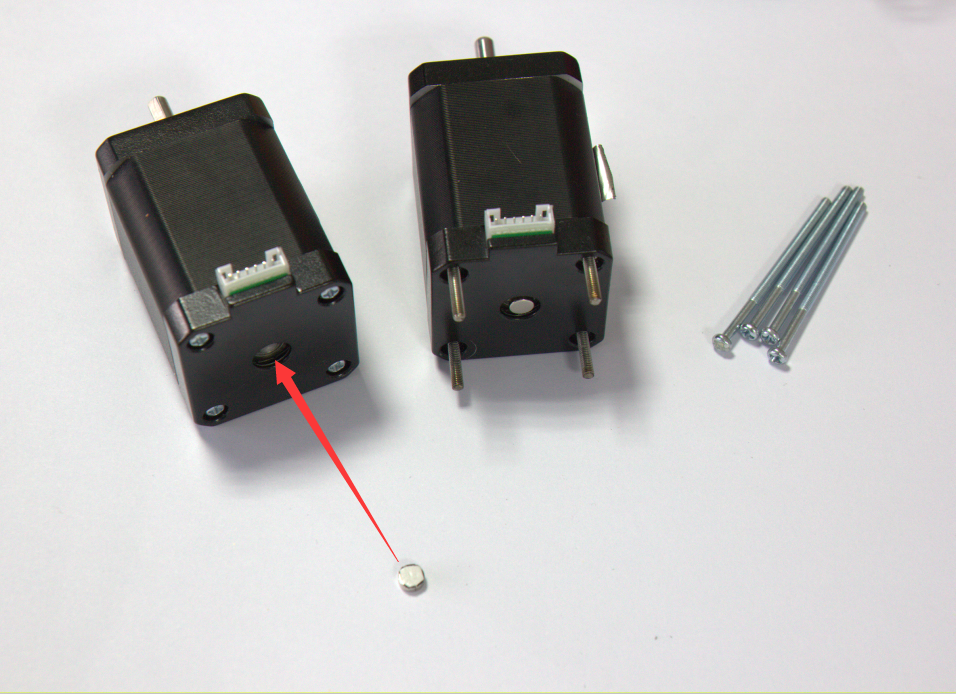

4.Driver integrated(A4988 DRV8825 or more power MOS Driver)

5.Extendable(For more than 12+ motors), and Easy for Installation(With two twisted wires and power to get the whole system available).

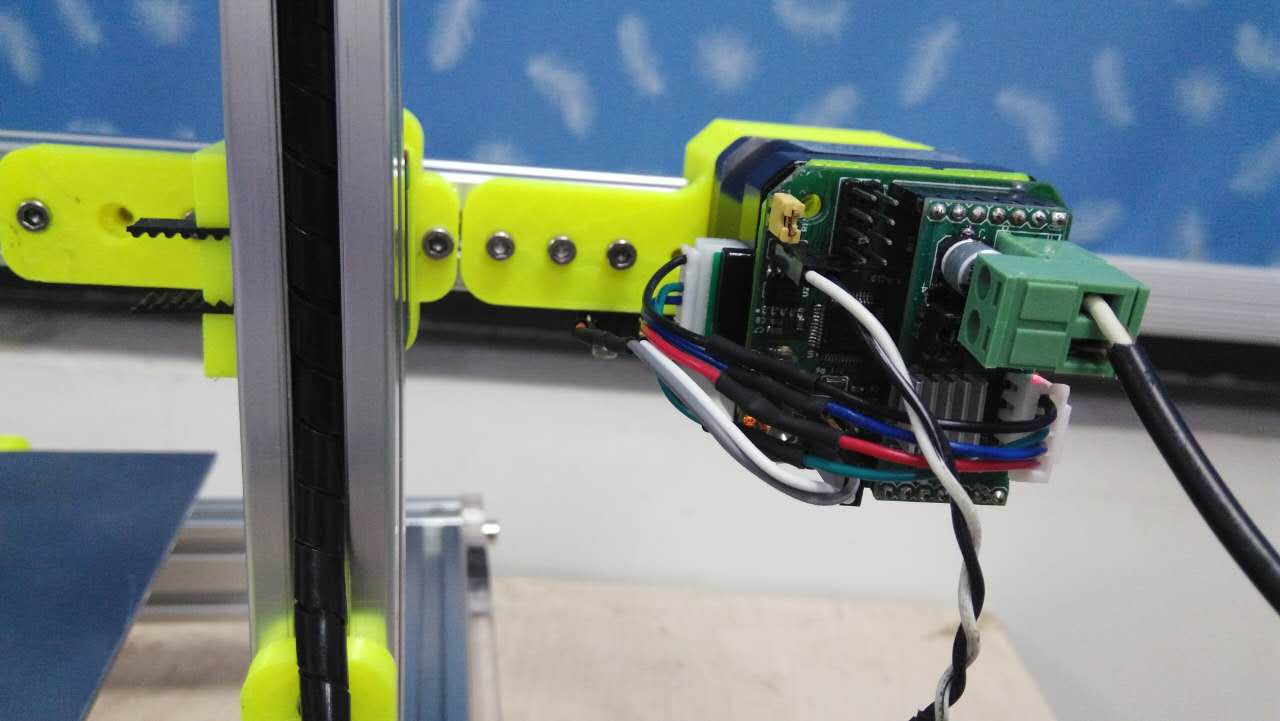

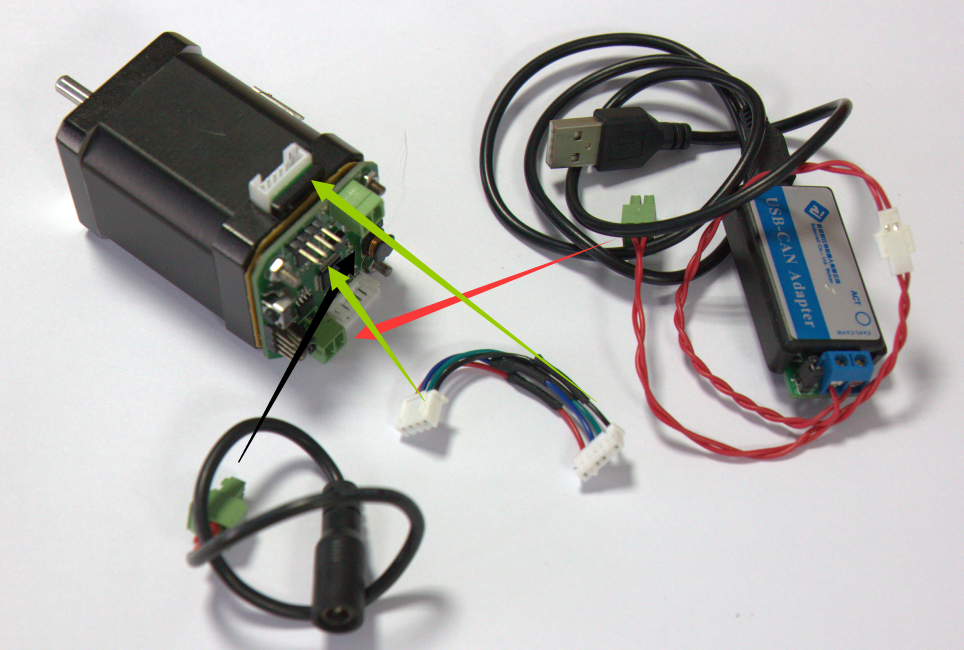

6.USB-CAN Adapter and SPI-CAN Adapter For systems without CAN bus.

7.API for multiple control systems(Arduino Beagleboneblack RapberryPi)

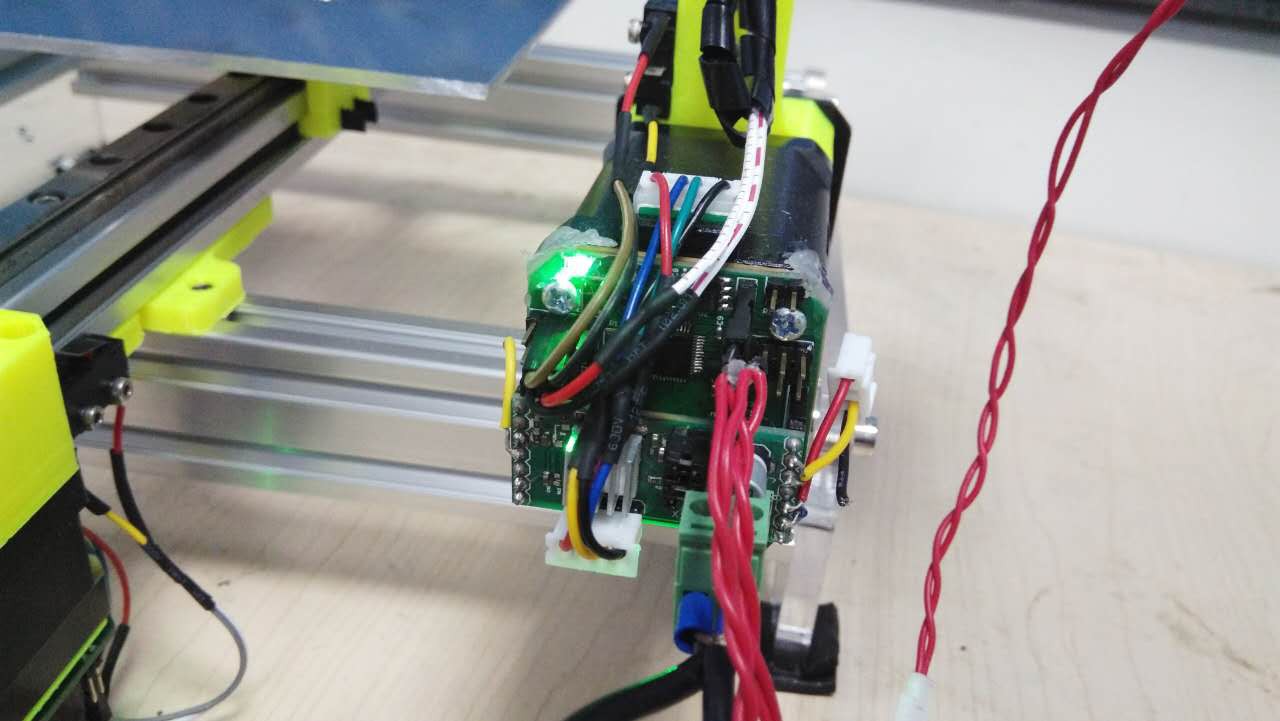

All the wiring I need is 12V and a twisted pair for CAN to link All device all together. So the main module can control all of them and monitor the state(position temprature or current) of them.

Application Of AnanasStepper 2.0

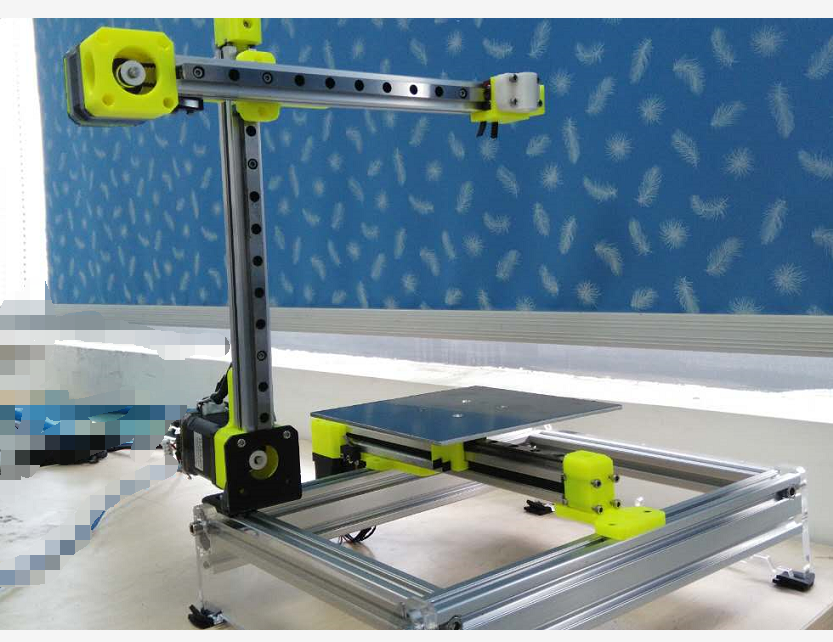

There is plan to build a system with a Robot Arm and a 3D printer working together!

Coming Soon!

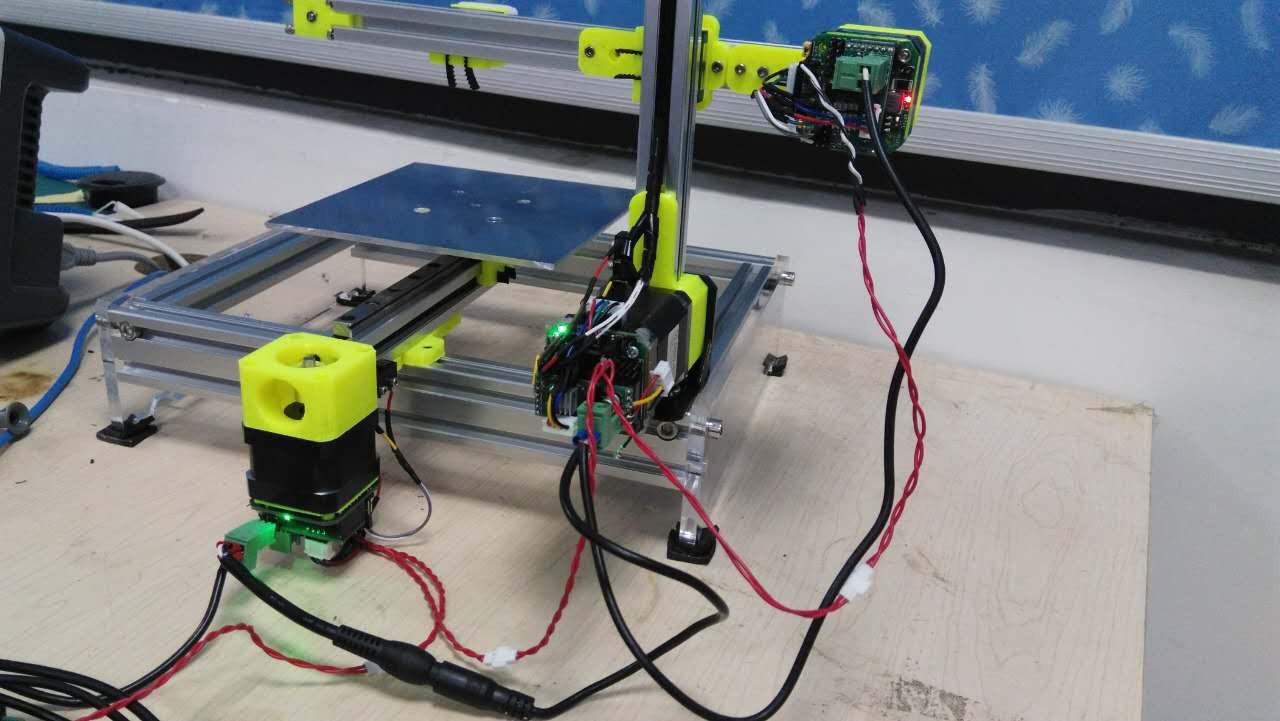

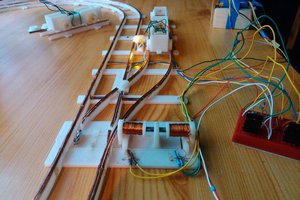

2 AnanasSteppers Do 2D plotter (test TWO Axis Gang Control)

I use 2 AnanasStepper to build a 2D plotter, Test 2D Axis Gang Control.

About https://hackaday.io/project/20980-ananasstepper-20/log/60311-2-ananassteppers-do-2d-plotter

AnanasStepper 2.0 play MIDI MUSIC

I tested AnanasStepper to Play MIDI music,And used My guitar as a loud-speaker!

It is not very nice but it works!!

Q&A:

https://hackaday.io/project/20980-ananasstepper-20/log/60341-qa-about-ananasstepper-20-1

CAN : https://en.wikipedia.org/wiki/CAN_bus

RUN CAN with SPI: MCP2515 :https://hackaday.io/project/20980-ananasstepper-20/log/61994-run-raspberry-with-can-busmcp2515

RUN CAN with Beaglebone: https://hackaday.io/project/20980-ananasstepper-20/log/62014-beaglebone-black-with-can

AnanasRobot Linear Actor:https://www.thingiverse.com/thing:2418362

AnanasStepper 1.0 :

https://hackaday.io/project/20980-ananasstepper-20/log/57101-demo-of-ananasstepper-10

https://hackaday.io/project/20980-ananasstepper-20/log/58154-ananasstepper-10-3d-printer-test

GrayPillow

GrayPillow

Juan Sandubete

Juan Sandubete

Mike Moore

Mike Moore

Szabolcs Lőrincz

Szabolcs Lőrincz

Gary, you started this project. You're the public face of it. Whatever you did with WOW is between you and WOW. When I supported the project on kickstarter you were the face of the project. I will work from now to eternity to make sure you never attempt to do this again on kickstarter. There is no website anymore, no email replies, nothing...you all got half a million dollars to make a go of this. As far as we can see you and WOW stole the money and walked away. There has been no product...if I had my way you'd be in jail for fraud and theft. Who knows, the day is young.