Features :

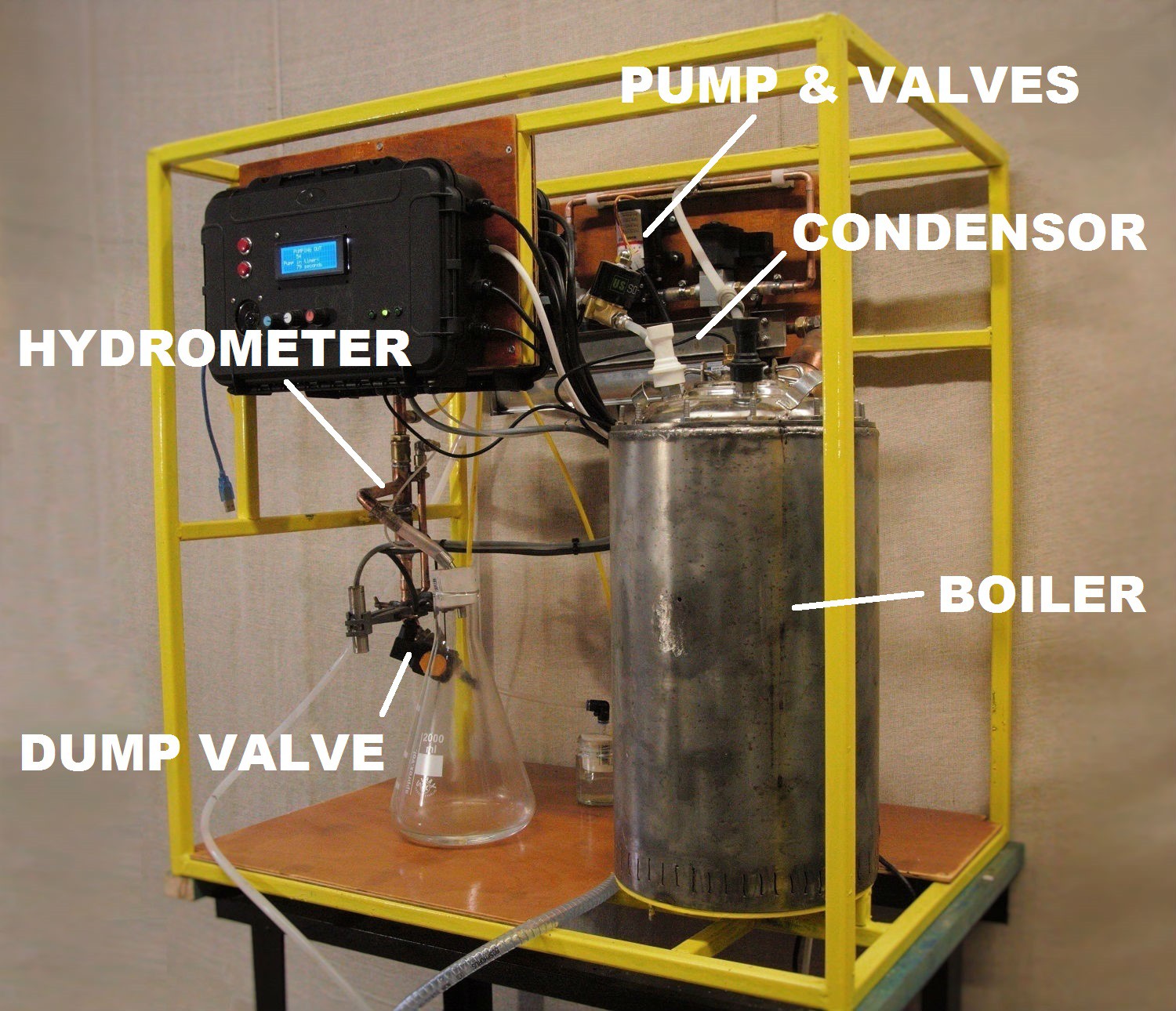

1. Alcohol sensors for detection of leaks / process errors.

2. Internet graphical user interface (GUI) via GPRS.

3. Intelligent Data to Voice (D2V) interaction - the machine describes to you what is happening at any given time with it's own intelligent 'robot' voice.

4. Fully hackable Arduino code.

5. 'Below floor' electric heating for safety compliance

6. Air cooled condenser - no cold water supply needed.

Here's the NanoStillery™ in action (Long version)

Historically, in Europe at least, it used to be very common for enterprising folk to travel around the land with their distillation equipment strapped to the sides of their donkeys providing a valuable service for owners of orchards and fruit bushes who wanted the produce turned into alcohol rather than having it wasted or eaten by birds and rats. In modern times, due to the advances of science, the equipment necessary for the process is much more sophisticated, but could, in theory, still be strapped to the back of a donkey.

It's not an old wives tale - The process of distillation used to be rather dangerous, often involving the lethal combination of naked flames, self intoxication and explosive alcohol vapours. Now, thankfully, there is much more awareness of sensible drinking and the potential dangers of industrial processes.

For me, the challenges are to automate the machine and make it as safe as reasonably possible, giving us lots of scope for using all kinds of weird and wonderful gadgets and sensors to monitor the process and minimise the risk of explosion.

Disclaimers:

- Distillation of alcohol is illegal in many parts of the world so check out your local laws. Often, there is also a tax to pay on the product.

- Alcohol vapour is potentially explosive. Explosions can be triggered by naked flames, relay switch contacts, hot surfaces, cigarette smoking, mobile phones etc.

- This design uses 240 v power and should be wired up by a qualified electrician.

- Most beer and wine contains small quantities of methanol which need to be removed during the distilling process. Methanol is a neuro poison that causes permanent nerve damage with symptoms such as blindness.

- Always drink in a responsible manner. Don't make your own spirits if you're prone to alcohol addiction.

How it Works:

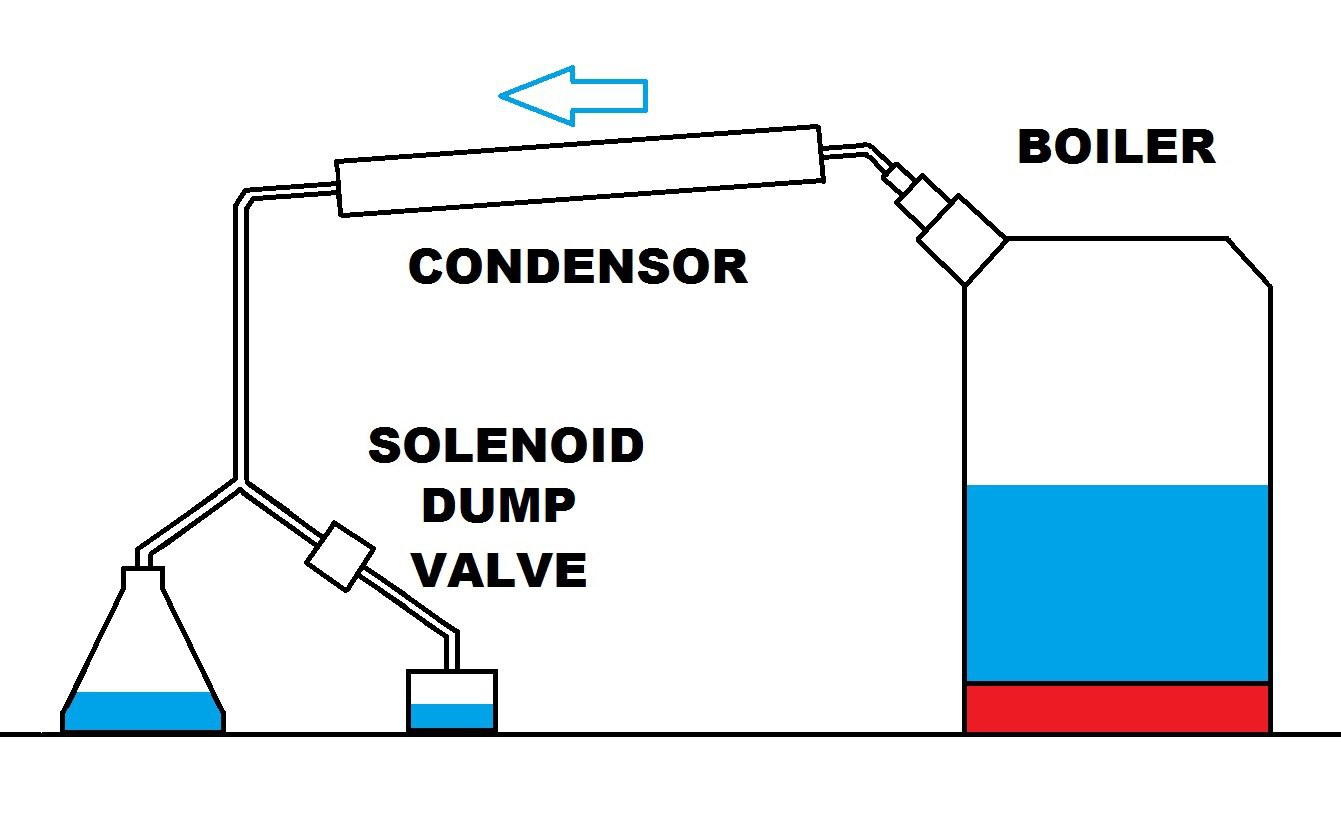

Home made barley wine (beer with no hops) or cider is pumped into the boiler and then rapidly heated to about 85 degrees C after which the power is reduced and the alcohol starts to boil off. Vapour travels into an air cooled condenser and then trickles out the other end into an inline hydrometer.

The hydrometer is connected to a pressure sensor which detects the level of fluid at any given time and a solenoid 'dump valve' at the bottom of the device allows the product to be dumped into a separate container to separate out the methanol.

The rest of the product goes into the conical flask and the process finishes when the boiler temperature hits a preset level controlled by a potentiometer on the control panel.

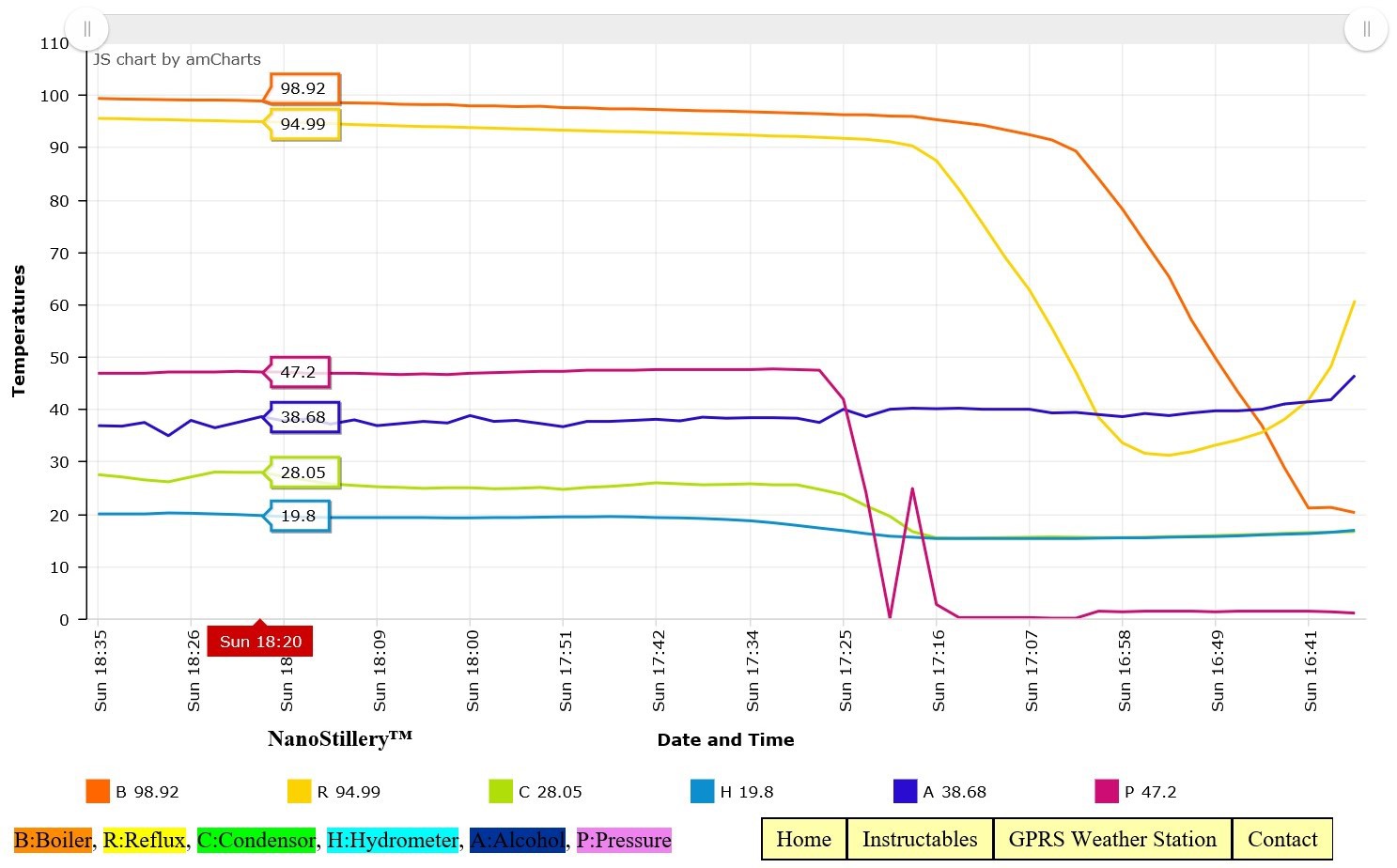

All processes are monitored graphically through a web page via a GPRS data transmitter in the control panel: You can see the results for the last batch, or even the current one, here: http://www.goatindustries.co.uk/test/index.php

You can see the results for the last batch, or even the current one, here: http://www.goatindustries.co.uk/test/index.php

Capt. Flatus O'Flaherty ☠

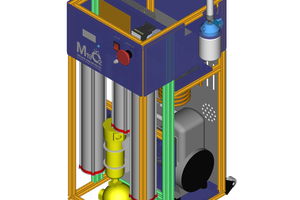

Capt. Flatus O'Flaherty ☠ A great deal of the work involved was in making the boiler. The 3D image above hopefully should show how it is put together.

A great deal of the work involved was in making the boiler. The 3D image above hopefully should show how it is put together.

The boiler is made from a stainless steel beer keg, some custom laser cut stainless rings and plates and the electric heating element from a standalone electric hob.

The boiler is made from a stainless steel beer keg, some custom laser cut stainless rings and plates and the electric heating element from a standalone electric hob.

The brass connector is screwed into the 2" socket to prevent distortion and splatter on the threads during welding.

The brass connector is screwed into the 2" socket to prevent distortion and splatter on the threads during welding.

David

David

Facundo Noya

Facundo Noya

PremJ20

PremJ20

Anool Mahidharia

Anool Mahidharia

Awesome project! Congratulations on moving on to the finalist

round!