Understanding the operation principles of the HUD, we can get down to practice.

First is the beamsplitter glass. It turned out to be one of the hardest components to source, at least in a reasonable price and the in short time frame this project have had. After a long search, we found telepromptermirror.com - a USA vendor that sells this kind of glass, custom cut to the required size. The glass had 70T30R characteristics - meaning it has 70% transparency and 30% reflectivity (70% of the light hitting the glass will pass through to the other side, while 30% will be reflected back). This ratio seem to be quite common, at it perfectly matches our application.

Now to the LCD panel. We targeted 8" panel since it looked like a reasonable size to look through comfortably. There are two main optical properties that are important here - brightness and contrast. High brightness is required since the image brightness is attenuated (30% reflectivity) and then overlaid on a background that is potentially bright. This is a big deal in aircraft application, because the data should be visible in direct sunlight condition. The ASTROGUN is not designed for such harsh conditions, so we can do with considerably less bright display. Making some experiments with the glass, we came to conclusion that brightness of ~400 mcd is sufficient (this is the brightness of many cell phone/tablet screens; for comparison, many computer monitors are around 250 mcd).

High contrast ratio is required to reduce the "gray rectangle" appearing across the whole area of the HUD, due to the light emitted from black pixels.

Finally, we settled down on a HannStar HSD070PWW1 panel. In addition to having all the optical requirements, it also has a resolution of 1280x800 and high quality color reproduction (it's IPS). It looks like a very common model, and it's easy to source along with a controller required to connect it to the Pi.

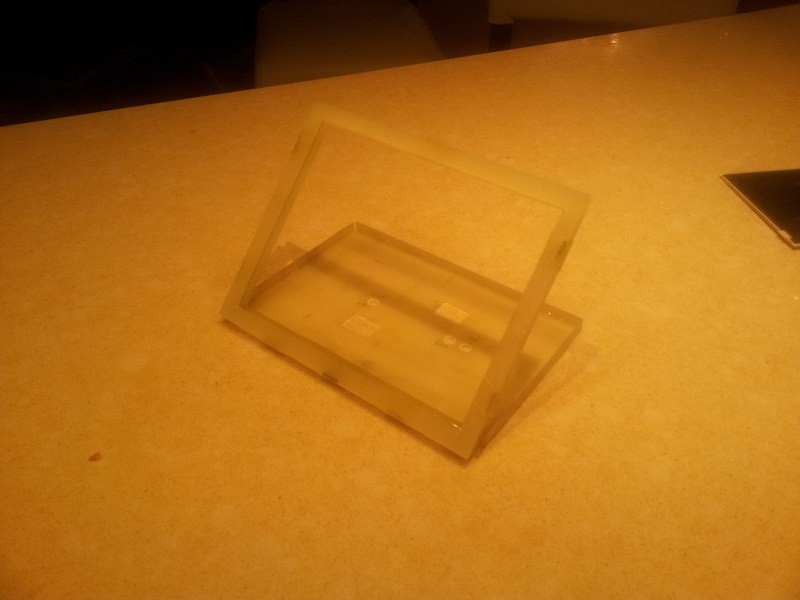

The glass and the panel are mounted using a fiberglass structure made of two parts. The upper one is built from two parallel plates that hold the glass like a sandwich. The lower part looks like a tray and holds the LCD. The panel is glued to the tray with several drops of contact cement. The two assemblies are glued to one each other in an angle of 45 degrees. Additional holes in the tray are used for mounting and, of course, to let the flat cable from the panel out.

avishorp

avishorp

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.