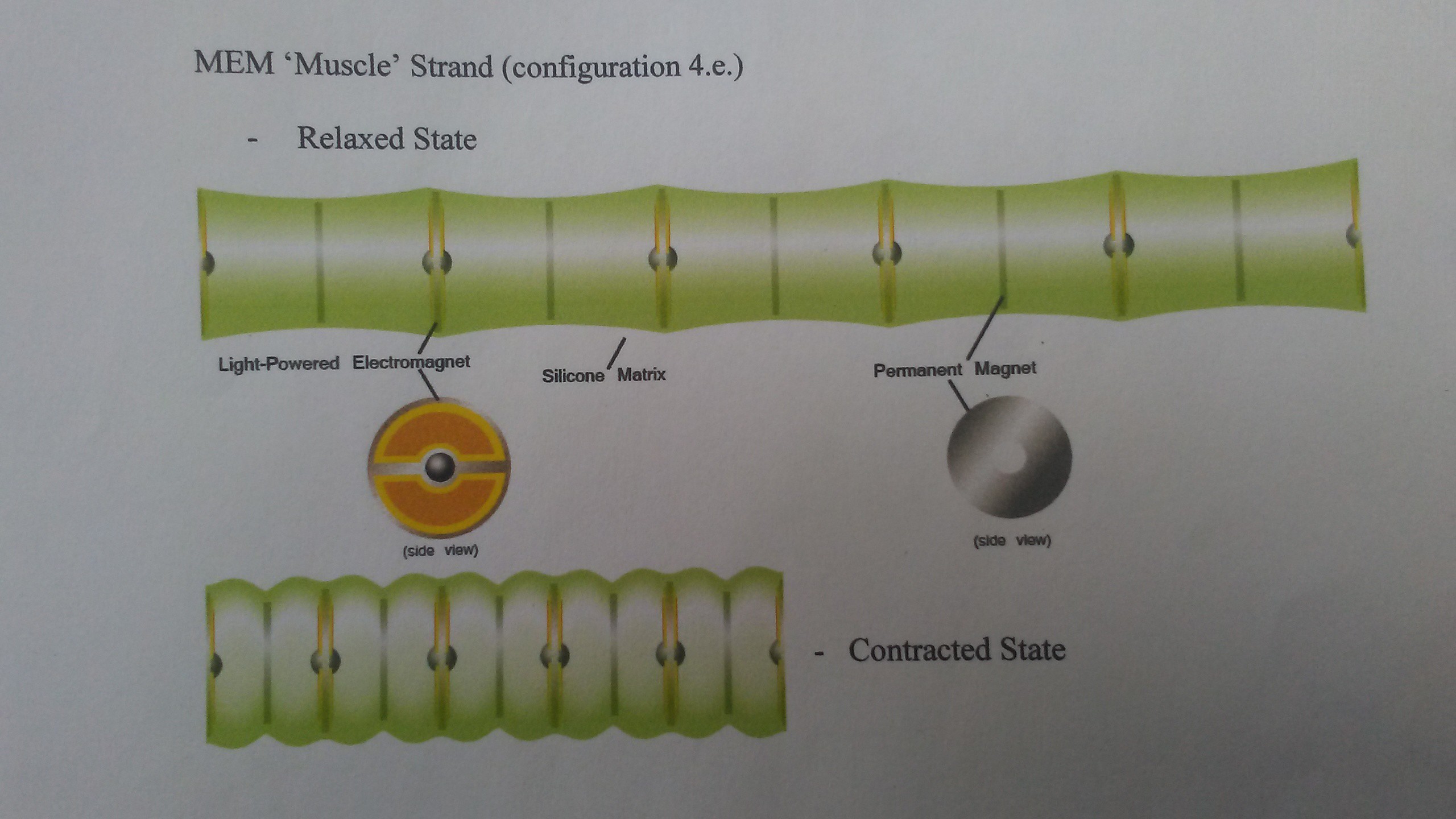

Thin ferrite cores (1 mm thick/diameter or less) wrapped with fine copper wire form the electromagnet portion of the muscle strand. The low density matrix into which these are set will most likely be non-conductive and silicone-based. Much work needs to be done to determine the best material, and form, for the compressible matrix. The polymer matrix is compressed during contraction and elastically returns to resting state.

Optimal power supply configuration is still under consideration, but the idea that an energized ferrite core will attract it's neighbor will be followed through either a DC or AC system.

Either system will be powered through conductive wire that runs through the center of the strand and the opposing polarity via a conductive lubricant or conductive sheath that is external to the strand. Contacts that extend through the low density matrix pick up power that travels through the lubrication/sheathing, while the wire (shaped like a loose spring) connects directly to the coils. Each energized coil creates a magnetic field that is attractive the next nearest coil in the array, thus when current is applied to the system, the muscle strand contracts.

[basic concept shown with dual-cores and permanent magnetic discs in a DC system]

[basic concept shown with dual-cores and permanent magnetic discs in a DC system]Although the contractive force for each strand is not strong, many strands working together like muscle fibres will provide the force necessary to actuate joints of a prosthetic limb, an accessory extremity, or a exosuit of mucle augmentation.

ken.do

ken.do

Peter Babič

Peter Babič

mircemk

mircemk