We've got a special log for you today!

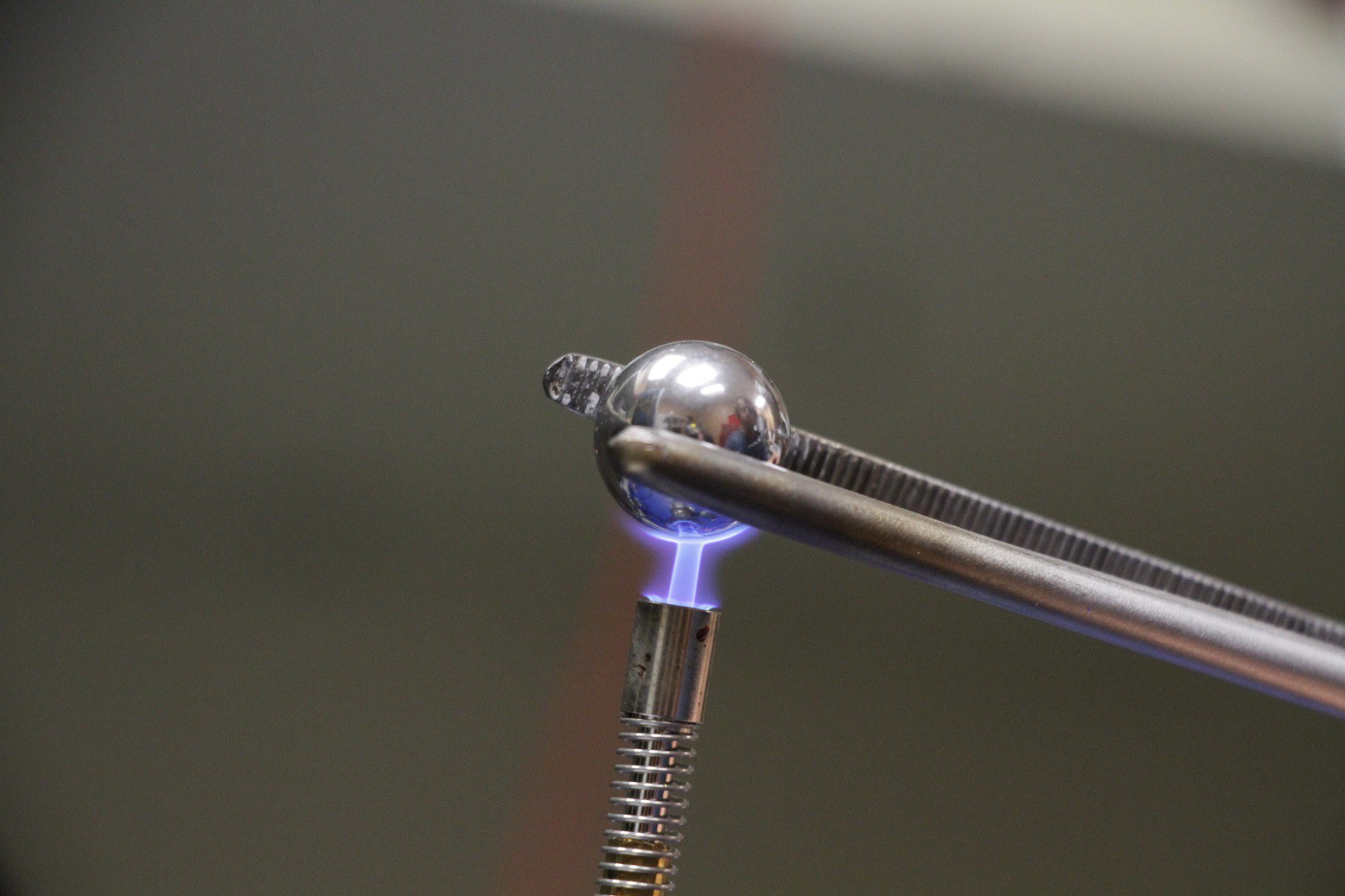

Alex is working on a neat miniature Newton's Cradle. This project included coloring 1" diam. steel ball bearings. By heating the bearing, an outer layer of colorful oxides form (actually ferrites!). Alex had been meticulously heating these balls with a set of tongs and a butane torch.

Then we thought to ourselves: "We can do this better!"

"Let's combine our current project: The Maker's Vise... with our super secret upcoming project: The Induction Forge. The steel will heat more efficiently and the oxides can form free from contamination."

We had to stand The Maker's Vise vertical, onto its own face. Then, we slid a 1" steel ball, held by a set of custom alumina jaws, between the ferrite poles of the magnetic induction forge WIP.

The result was pretty amazing [Video Below]! We could turn out thousands of these colored bearings with very little effort. This is why you need a quality vise w/ custom jaws people. Let's keep The Maker's Vise project going!!

Greg Stephens

Greg Stephens

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Bobbie Goods coloring pages are a great resource for parents and educators looking for fun and beneficial activities for children. From promoting creativity and imagination to improving cognitive development and relaxation, coloring pages offer a range of benefits. By providing your children with themed Bobbie Goods coloring pages, you can encourage their development while having a great time together. https://coloringpageswk.com/others/bobbie-goods/

Are you sure? yes | no

Wow, love the torch picture. The torch is actually a little butane torch, Bernzomatic, which was sold as kit http://www.bernzomatic.com/product/st250k-6-in-1-solder-and-repair-micro-torch-kit/ . Very handy pencil flame for small work. I also use a bigger Bernzomatic propane torch.

Are you sure? yes | no

The alumina jaws were fun... we were a little worried they'd snap, but they're pretty strong! This is appx 0.1" thick Alumina.. I believe 96%. I have a lot of it, and can cut it with the diamond saw. The ball can be held by another piece of alumina (a TO-247 insulator) with a hole in it against one face. I'm not set up to drill the alumina yet (which ticks me off royally.. I have some diamond drills but I don't want to get the garage machine wet or worse, alumina-gritted.

Are you sure? yes | no

hahaha.. cool! Yeah, I think these turn better colors with the induction heat than the torch 'cause they don't have the combustion byproducts of the propane (water vapor, much lower O2 and more than atmospheric CO2) all over them. This is just straight up atmosphere that we're all breathing. It'd be fun to try different gasses someday! The original purpose of this setup was to provide soldering heat for big-lugs-to-magnet wire, where the previous choice was contact contamination by soldering iron or setting the flux on fire with the torch. I've also used it to provide heat for soldering brass to steel.

Are you sure? yes | no

^ we have video of this. Induction soldering video coming soon!

Are you sure? yes | no