Wow! It's been a while since our last log post. Fear not friends, we have not fallen off a cliff. We've been working fervently on our design.

You may remember that our vise was maxing out at 500 lbs. of reasonable clamping pressure (Link Here). We promised that most of our design efforts would be focused on bringing this clamping pressure up to a more useful number. ...at least 1,000 lbs or the project would be scrapped.

We've made it! The Maker's Vise is turning into a real beast of an apparatus.

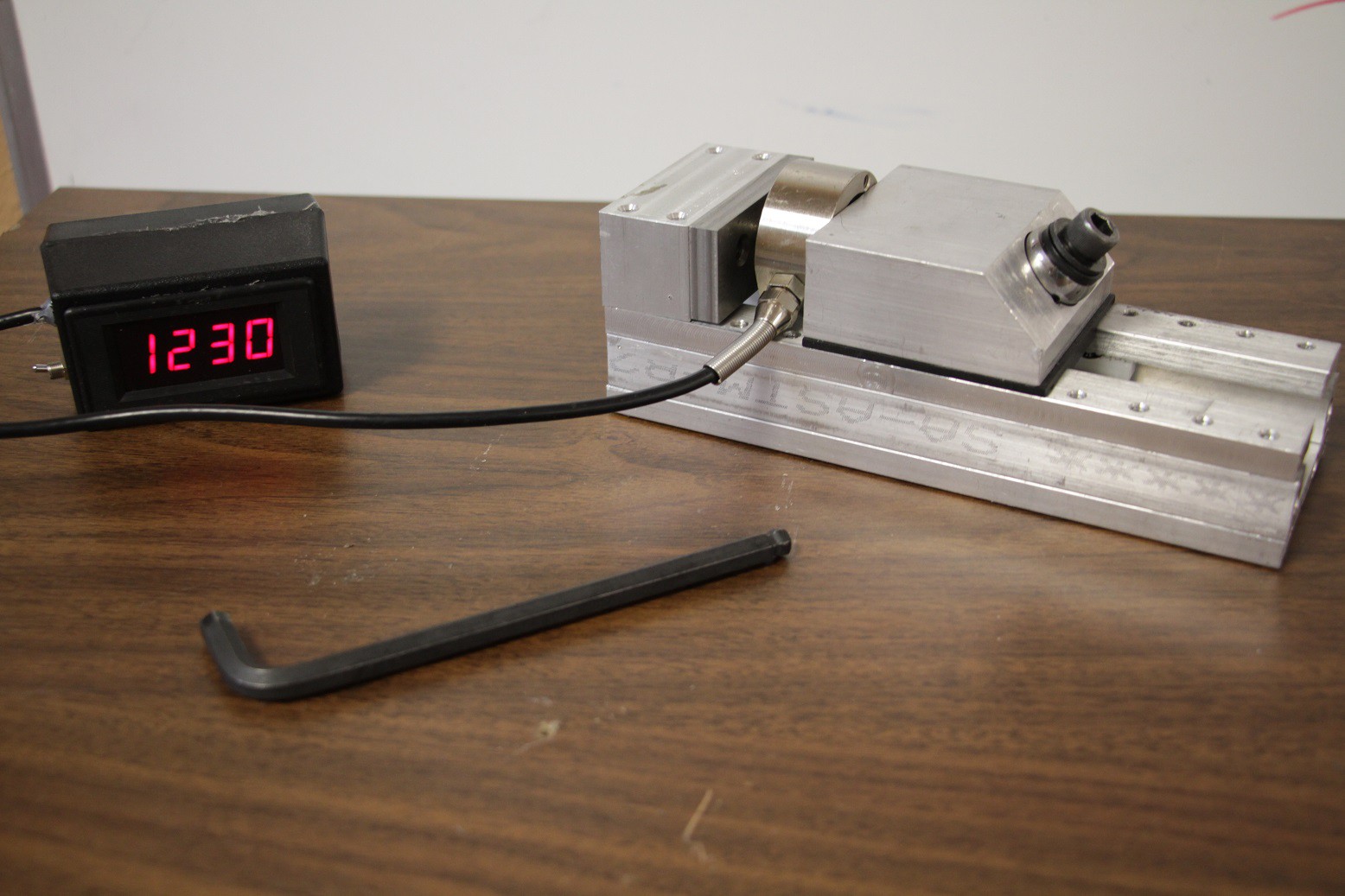

Check out these numbers:

We're now measuring over 1,200 lbs of reasonable clamping pressure!! This beats out a majority of the vises we have collected from the open market. ..which is cause for excitement.

Today is a good day!

Greg Stephens

Greg Stephens

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Impressive! However, I still think that the most significant opportunity for maker vise is to maximise the user experience. Specifically I'm thinking of hot-swappable jigs and fixtures, and the ability to rapidly transition across both the clamping force range and the clamp opening range. If the final product needs an Allen key for more than the most extreme clamping forces, it'd be a missed opportunity in my opinion.

Please take this as constructive criticism - it's brilliant that you are tackling such a deceptively profound design challenge.

Are you sure? yes | no

[this comment has been deleted]

"I don't know how to make it" - if you're talking about purely the handle, you might be able to get 80% of the way there with something already made and sold by websites like this: https://www.goodhanduk.co.uk/Catalogue/Standard-Parts

A nice little hand wheel with space to wrap your fingers (or an alu leverage bar) around for high-torque moments could be lovely. Your 45° axis may allow you to fit one in without encroaching too much on the clamped volume or clashing with the base.

Hope that helps.

On another matter, at my organisation we have a "fitted for but not with" FFBNW category to keep a product cheaper for initial purchase but allow upgrades and updates to add features incrementally. Would it be possible to make some aspect of the design (I'm thinking the jaws) FFBNW the ability to hold a load cell for people who want to achieve a specific clamping force? I don't personally but I imagine that you are not the only ones interested in that scenario.

Are you sure? yes | no

Hey, thanks Simon. It's hard to take your comments as criticism at all really. Because, I generally agree with you. And, you've been nothing but helpful. So,... don't feel like you need to pull your punches.

..

The rapid transition through the clamp opening range, we're good to go on that! It's really fast and easy to move the maker's vise head back-and-forth. There is no bolt running through the center to slow the process down. Really, the only way I feel to improve on this aspect would be to use a 'linear bearing carriage' type of "frictionless slider."

As for the clamping force range... it needs a handle, right?! I was thinking that too.. something like this:

EDIT: Accidentally deleted this post..

Are you sure? yes | no

hmm... I like it! In fact.. I like several of these handles. Do you think people would want to have several handle choices to choose from? ..or even fully customizable 3D-printed handles?

There's a fun idea! A precision vise. We can certainly make it. But, adding a load cell can easily double the cost of the vise. I bet some people would still go for it. It would need to stand alone as its own product I think,.. [The Maker Vise Super Ultra Deluxe 3000]

Are you sure? yes | no

If you plan to crowd fund the early runs, you will have plenty of opportunity to canvas your early adopters for handle preferences.

When you do the MV SUD3k, make sure you put a vernier scale down the sides, so the distance between the clamp faces can be read to sub-mm precision. Perfect for the "anodised and laser etched scale" finish!

Are you sure? yes | no

kk, will do!

Are you sure? yes | no