The general goal is to make a 'kit' of reusable components for wearables.

Bluetooth BLE is the standard for communications. WiFi, etc. require too much power and anyone with a wearable likely has an Android or iOS phone. All wired connections are USB based as it is the only durable and cheap connector in the world.

Sub goals:

- Open source hardware and software (BSD, MIT, and GPL)

- Castellated modules (2.54mm)

- 3.3v only

- ARM Cortex with open tool chain

- Support Kapton or other flexible PCB

- Utilize common open prototype methods - OSHpark, OSH Stencils

Soft goals:

- Approximate module size of 0.7x0.5" or smaller

- Espruino JavaScript compatible stack

- Support open API standards for IoT

- Common GND/3.3v castellation positioning

Flexible PCB Howtos:

We made some posts some time ago on this, but never linked them in till now. This should help people get started with their own home made flexible PCB designs.

Modules:

Designed/In Progress:

- Microprocessors/Microcontrollers

- STM32 small microcontroller (STM32F401 and STM32F411)

- STM32 large microcontroller (more pins w/USB OTG and power supply)

- nRF51822 Bluetooth Smart/BLE microcontroller

- Edison Compute Module host

- Programmable Logic Devices

- Power

- USB BiPower OTG (3A 3.3V Power + 200mA -3.3v rail for ECG/EMG)

- Qi/USB charger

- LED Power Supply (Battery based)

- Utility

- Bio Sensors

- Environmental Sensors

- 12axis (LSM9DS1 9-axis ST accelerometer/gyro/magnetometer, BME280 pressure/barometer, humidity, temperature)

- Color Sensor

- Lightning Detector

- UV Index and ambient light detector

- Personal Lighting

- Mini EL 4 channel programmable driver for Electroluminescent Lights

- RGB LED strip driver/mount for APA102(C) and WS2812B strips strips and panels

- TLC5941 "Social Light" light based ID

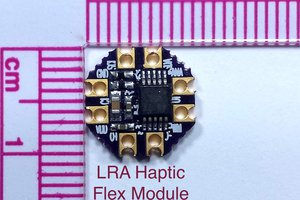

- Haptics

- Stimulation

- TENS programmable electrostimulation

- Digital Audio

- Input

Planned:

- Pressure, weight, stretch based sensors

- Electro dermal activity(EDA) (probably just a reference flexible PCB based probe design)

- Connectors, etc. as needed that don't mount on flex well

- OLED displays (SSD1351 and SSD1306 or something like Sharp's memory LCDs)

- WiFi

- LTE

- GPS

- NFC

Retired:

- USB Hi Power (No longer developed, see USB Bi Power)

- 10-axis Gyro/Barometer sensor (see the newer 12axis)

Sewable Flex Modules

Demo Projects:

- EMG body movement tracking

- Foot massager with stress monitor

- Neck massaging hoodie

- Sewable blind spot notifier

- Dance Kit - Costume lighting with health monitor and friend notifier

- Personal sound effect cosplay jacket

- Smart watchband sleeve

- Discreet notifying bracelet

- Hoodlight personal lighting and potentially camera blinding hoodie

- Lighted Skirt

- Cosplay Lux Staff

- Lighted Broach

- EL Controller for Bluetooth based EL costume lighting

Accessory Projects:

Personal Lighting

Social Authentication and Authorization

Related drivers and demos will be licensed under BSD or MIT licenses depending on original source if any. We will release online or cloud related software under AGPL, GPL, or LGPL licenses.

Chris Hamilton

Chris Hamilton

Thomas Sarlandie

Thomas Sarlandie

Nicolò

Nicolò

Paul Kocyla

Paul Kocyla

Thank you for your response.

Just for information, the smallest coils I found are these one:

http://katalog.we-online.de/en/pbs/WE-WPCC_Receiver?sid=7344797986

For bluetooth modules, I agree with you : plenty of certified nrf51822 modules are already exisiting on the market. I like the rfduino product. Small and not too much expensive.

Concerning the 4G/LTE module, or long range communication means in general, I think the smartphone approach is not in the spirit of wearable/connected object approach. The object/human to sense do not need human in the loop intervention (through the smartphone).

For Example, on your ECG project, you needed an independant/autonomous device collecting ECG data and log in SD card. So imagine the same device sending data over 2G/3G/4G in real time instead of log in into the SD card.

Shortly speaking, smartphones are made to connect ears and eyes. 4G modules should be dedicated for wearable/connected object. This is my one cent advice :-)

For 4G, I was thinking about the Huawei ME909TU module (already FCC and CE certified). As bonus, it integrates GPS receiver. Unfortunately I do not have electronics and soldering skills, I am rather software oriented. Do you have an idea on how I can get a full usable component with such module?

Thx

Michel