A few weeks ago I bought an Awelco MIG ONE welder on sale. It's a flux core gas less MIG welder with two current settings, 35A and 95A. I set out to learn MIG welding, which turned out to be harder than expected. Almost all my welds are ugly.. very ugly. But there has been some success, some of my ugly welds are strong and I have succesfully made ugly welds in thin sheet metal that would be impossible to weld with a stick welder.

From the start I was planning to eventually hack the welder to use gas. This video makes it look reasonably easy.

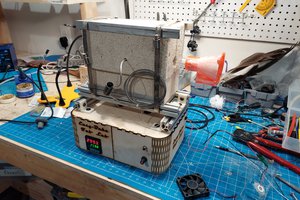

Preparing for the gas upgrade I had a look inside the welder to check if it was DC electrode negative (normally used without gas) or DC electrode positive (normally used with gas) and how I could change that if needed. It turned out it was AC. WTF? Never heard about an AC MIG welder before...

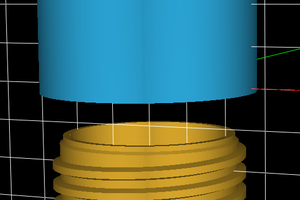

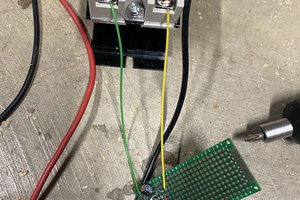

So I added 4 80A diodes to make a rectifier and a few (64) 2200uF 50V caps to reduce ripple.

ZeptoBit

ZeptoBit

Steve Hernandez

Steve Hernandez

Will Stone

Will Stone

UnaClocker

UnaClocker