problème du jour:

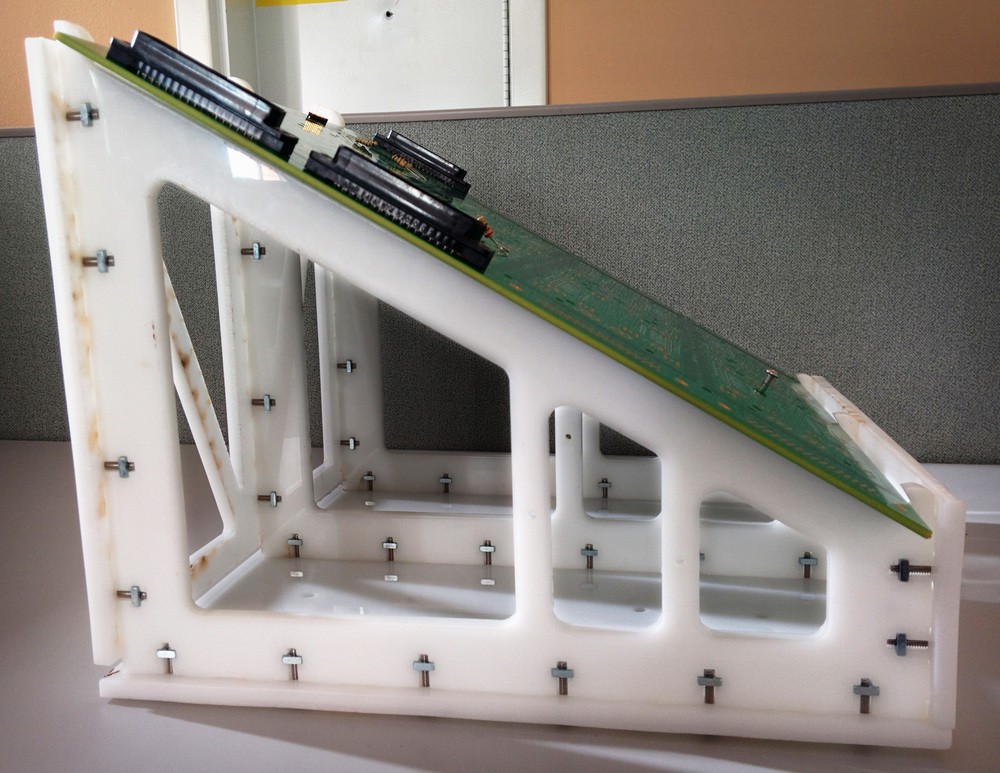

- build a fixture which holds a large circuit board three inches off the ground

- at a 30-degree angle

- with lots of space underneath for wiring

- and a temperature range of -40 to +85 Celsius

- in 48 hours.

how fun! let's go.

Constraints 1 & 2 & 3: 30-degree angle, 3 inches off the ground, space underneath for wiring

we could have accomplished 1 & 2 by stacking solid materials underneath the circuit board, until we'd built a hill, and it would have the right height and angle. but 3 won't let us do that. the thing must be supported lightly, with free space underneath.

this sounds like a precision job. a lasercutter job!

Constraint 4: -40 to +85 Celsius temperature range

now this gets thorny. lasers cut materials by heating them until they vaporize. but this material must be ok with high temperatures. conflict?

Option 1: acrylic. the laser nerd's favorite. but acrylic sheets get sad and bendy at 85 Celsius. no can do!

Option 2: polycarbonate. super tough. chill with hot, hawt with cold. when cut with a laser, it releases poison. i prefer breathing not-poison.

Option 3: white Delrin. tough enough. does its job. cuts without hastening death. Delrin it is!

with a wide temperature range, you have to worry about thermal expansion of materials. my fixture will cup the circuit board, and it will contract faster than the circuit board when things get cold, so it must be too big at room temperature.

how too big?

linear thermal expansion coefficient of Delrin: 122ppm/Celsius

linear thermal expansion coefficient of FR4: 14ppm/Celsius

difference in coefficients: 108ppm/Celsius

-40 Celsius is 65 Celsius below room temperature.

fractional thermal contraction at -40 Celsius = (108ppm/Celsius)*(65 Celsius) = 7020ppm

the circuit board is 12 inches long.

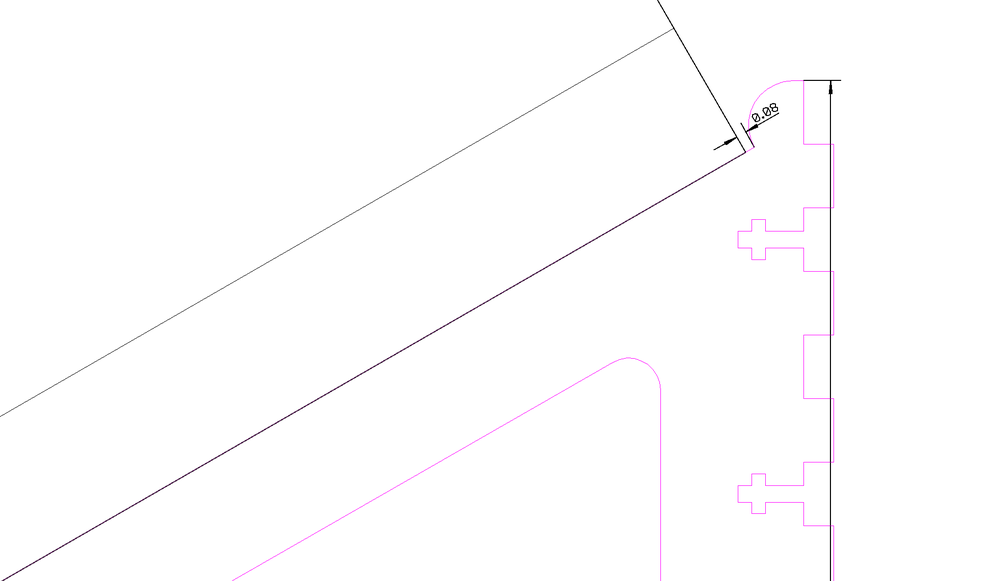

thermal contraction at -40 Celsius = (12 inches)*(7020ppm) = 0.08 inches

so we should oversize our fixture by 0.08 inches.

and there it is!

Constraint 5: do this in 48 hours

we've already started :D

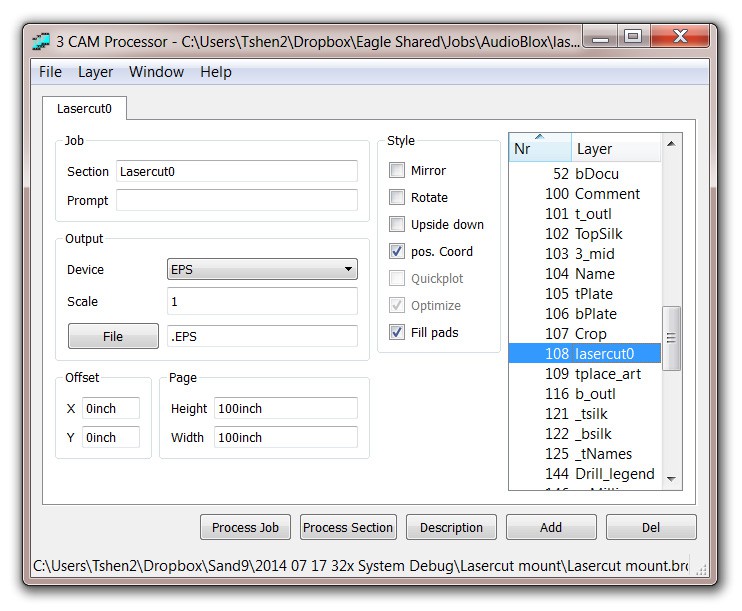

i do mechanical drawings in Eagle. Solidworks hates me for this one weird trick. Eagle is for making electronics, not lasercutting plastic. but Eagle lets you draw lines on layers, and save those layers as EPS files, and your lasercutter thinks EPS files are delicious.

now the 'lasercut0' layer is lasercutter food.

why do this? now you're designing circuits and mechanical parts on the same page, with the same software.

will they fit super-perfectly? yes. can you do cool new things? yes yes.

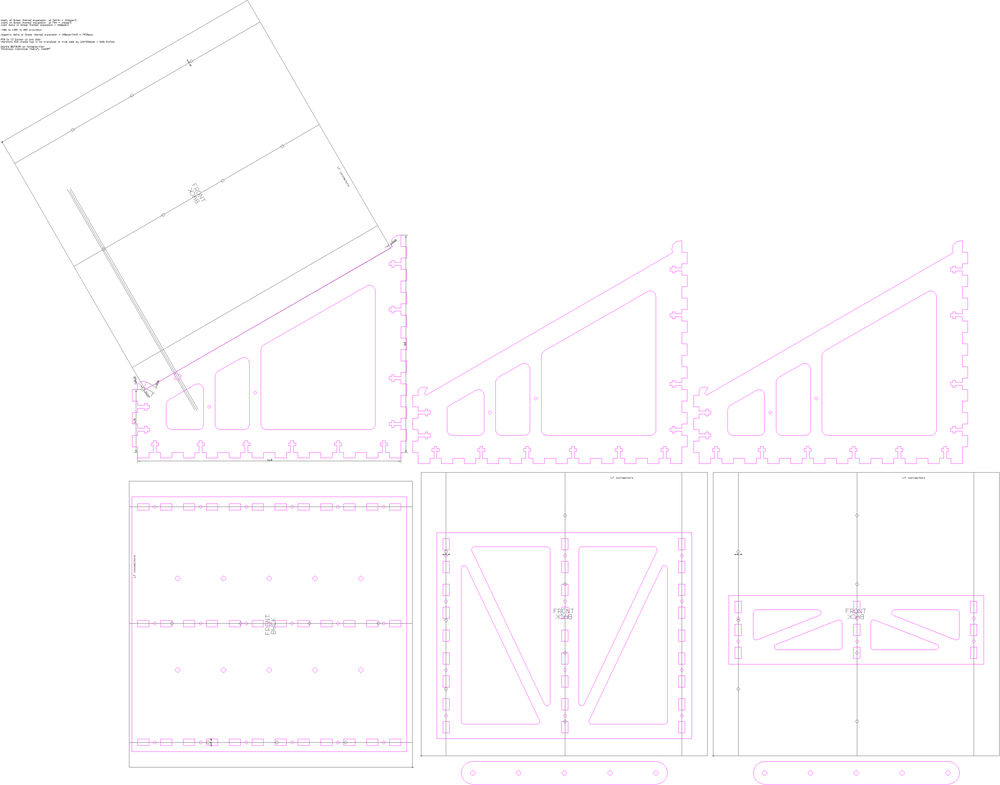

here's a map of DelrinLand.

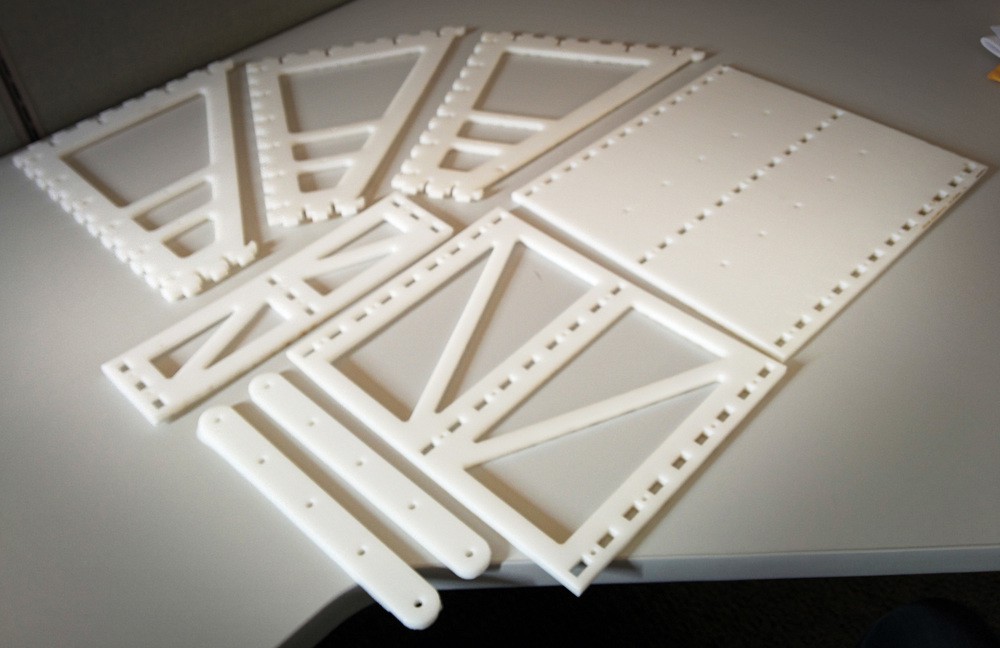

at the lasercutter, i discovered that Delrin is harder to cut than expected.

so i doubled my laser power.

and then tripled.

and then quadrupled.

and it still didn't cut through.

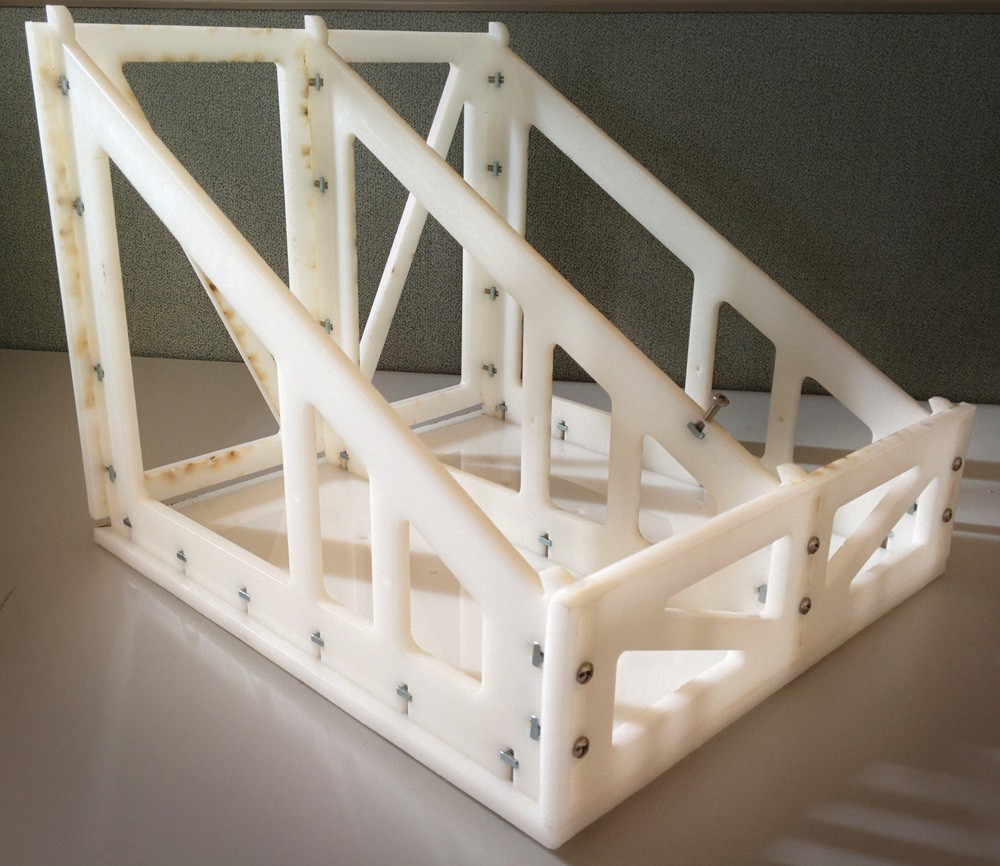

so i smote it with a hammer, and here are the results.

$350 of laser power, on the company budget

all crispy and t-nutted.

it fits!

Tshen2 2014

tshen2

tshen2

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.