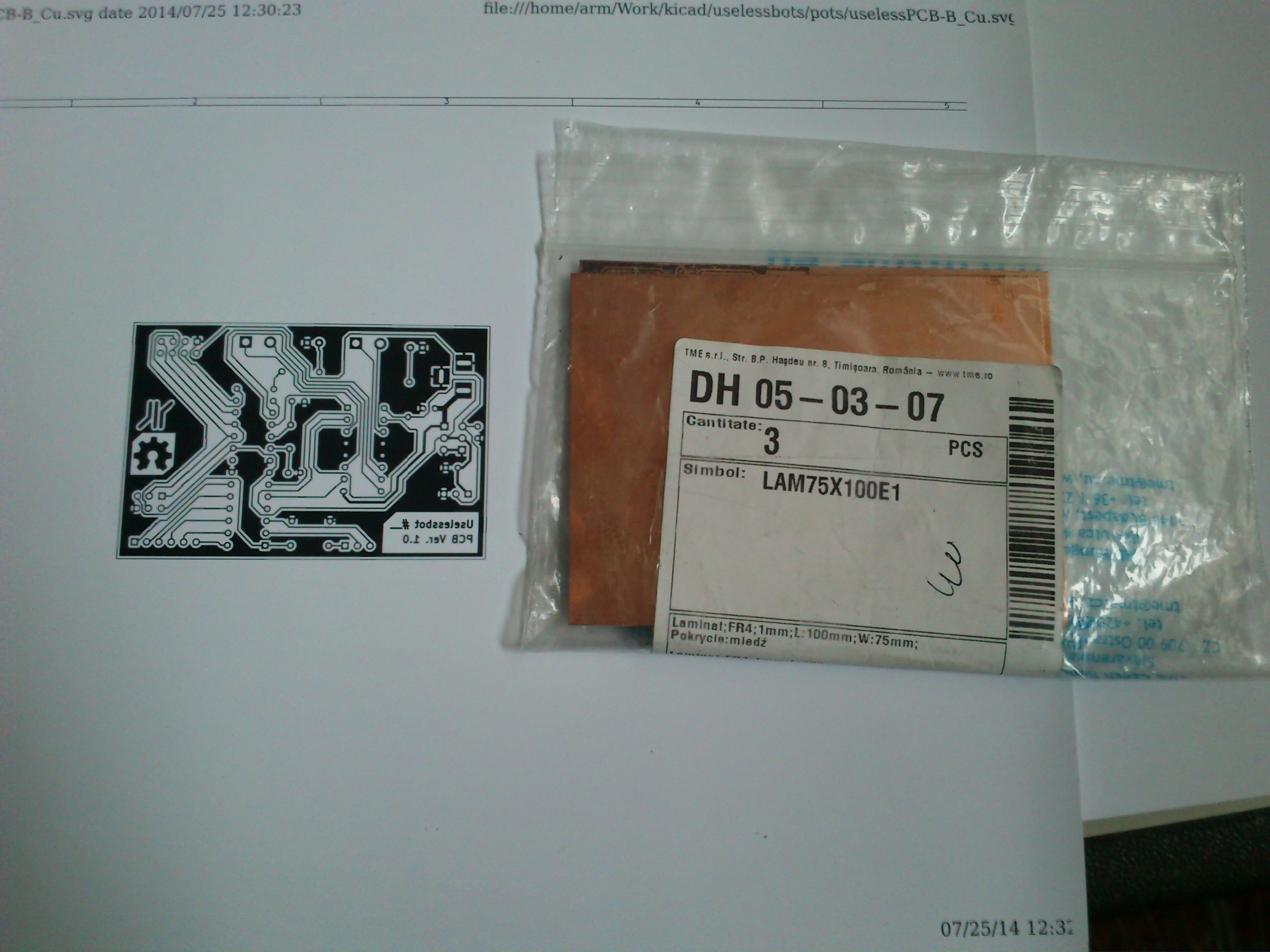

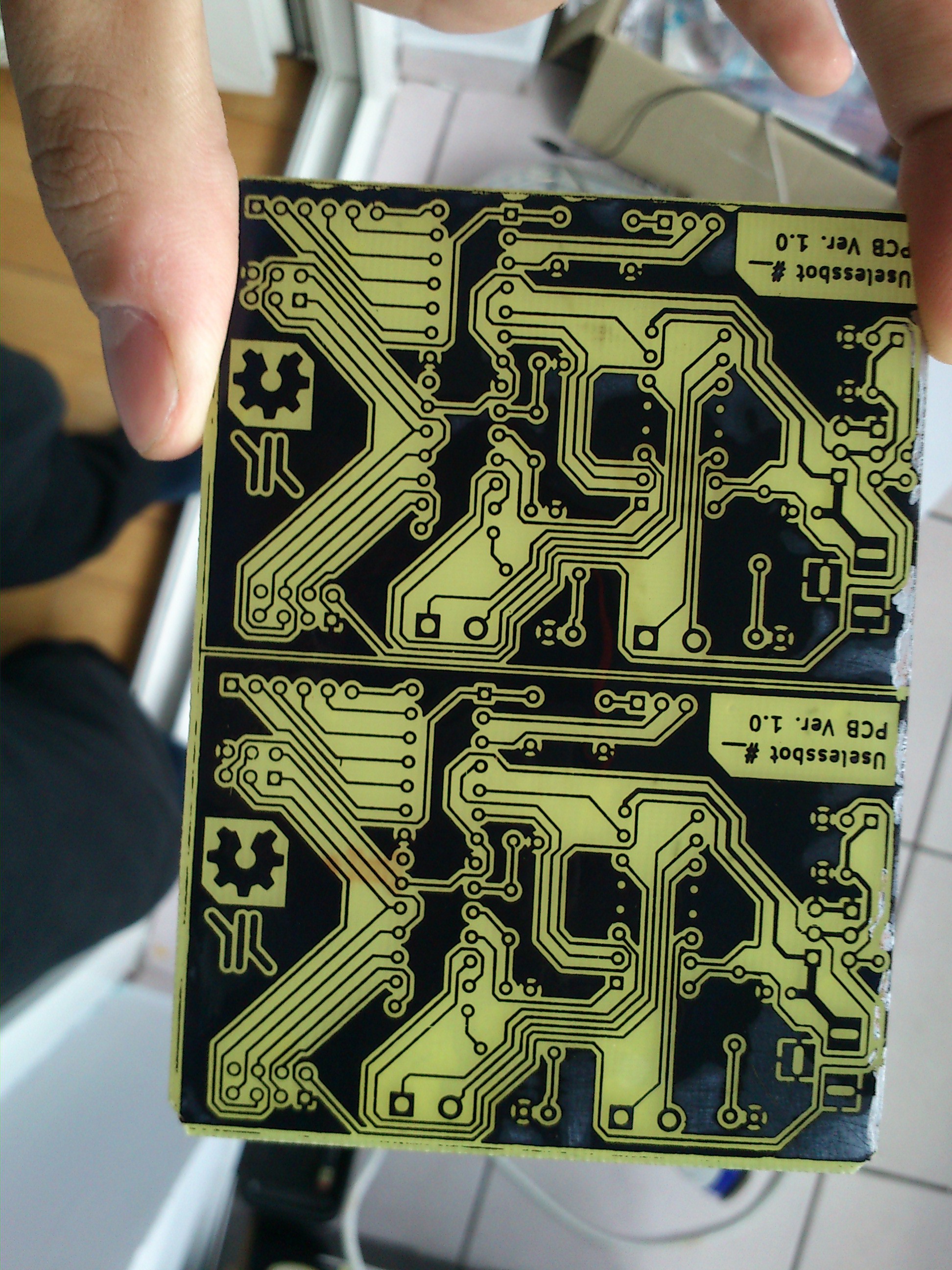

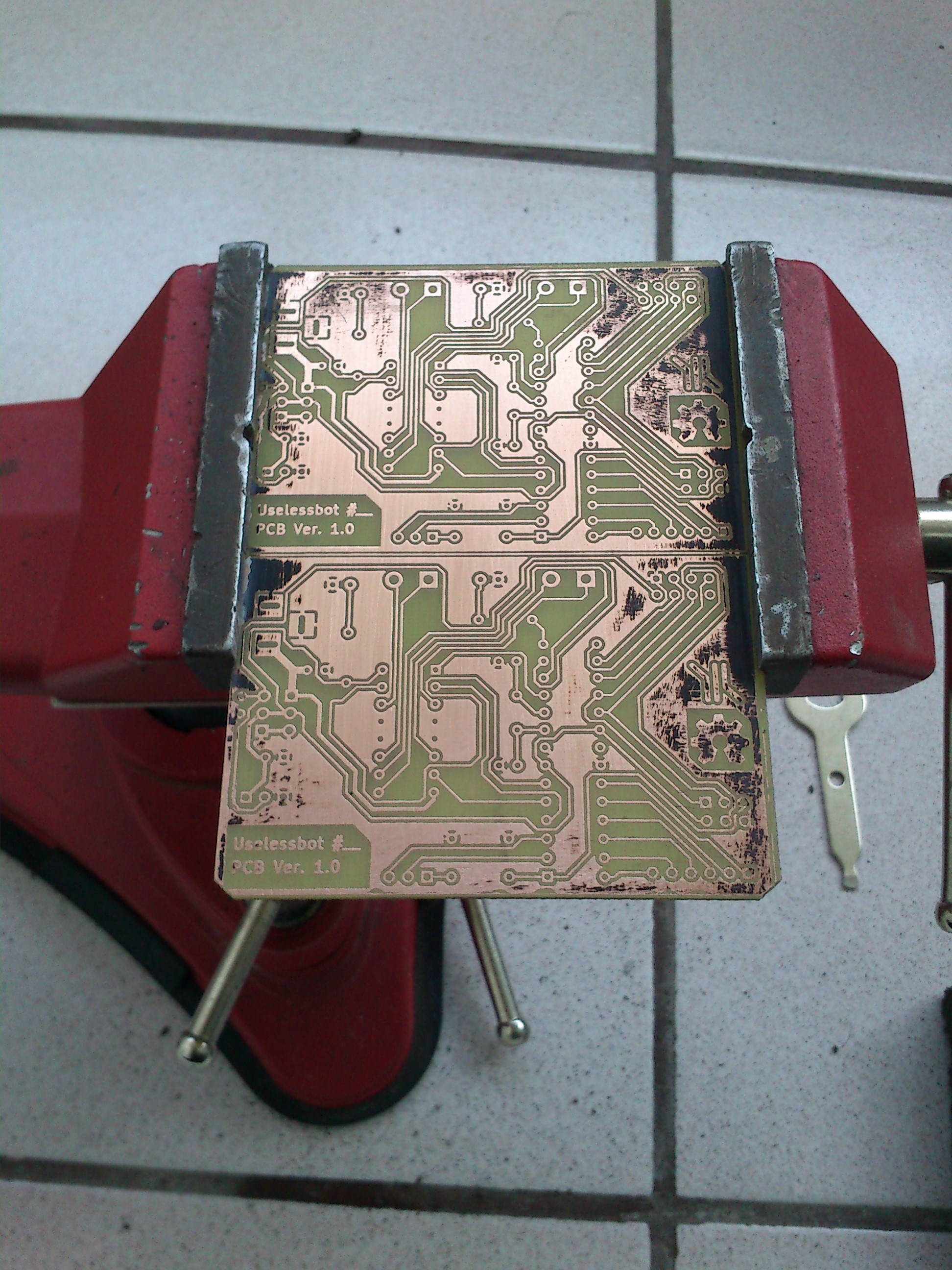

For the first prototype, I manually etched the design on plain cooper-clad boards.

Home etching is something like old arcade games : Easy to pick up, but hard to master.

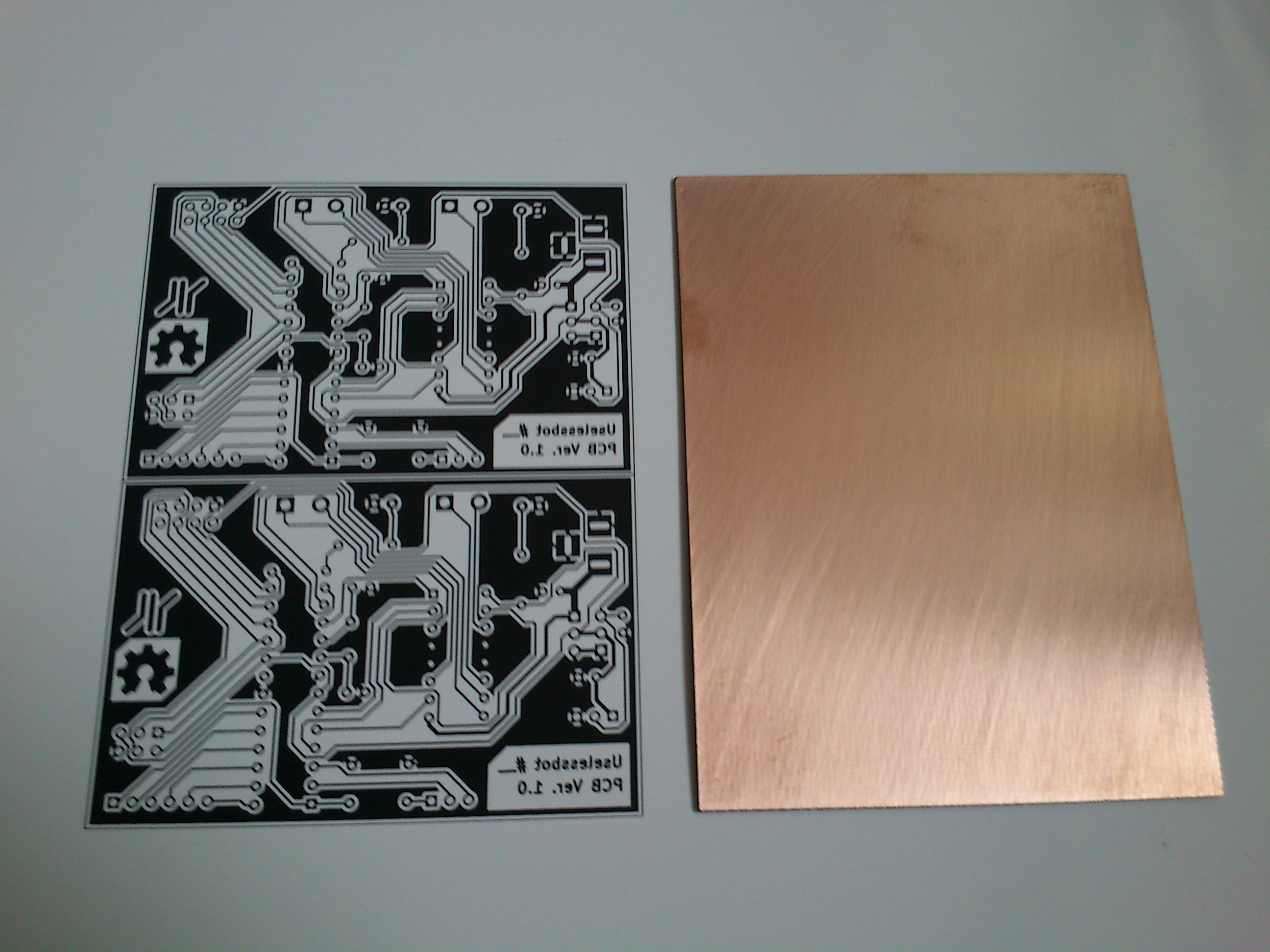

Since Ionly had plain copper boards, I chose the toner transfer method.

There are many guides on the net, but, unless you have the exact same materials, something is not going to work like you expect it to.

This usually ends in a few days of trial and error. After spending way more time than intended on wasting toner and a lot of paper, my magic combination came to :

- cheap, printer foto paper (waaaay better than glossy magazine paper.

-laser printer

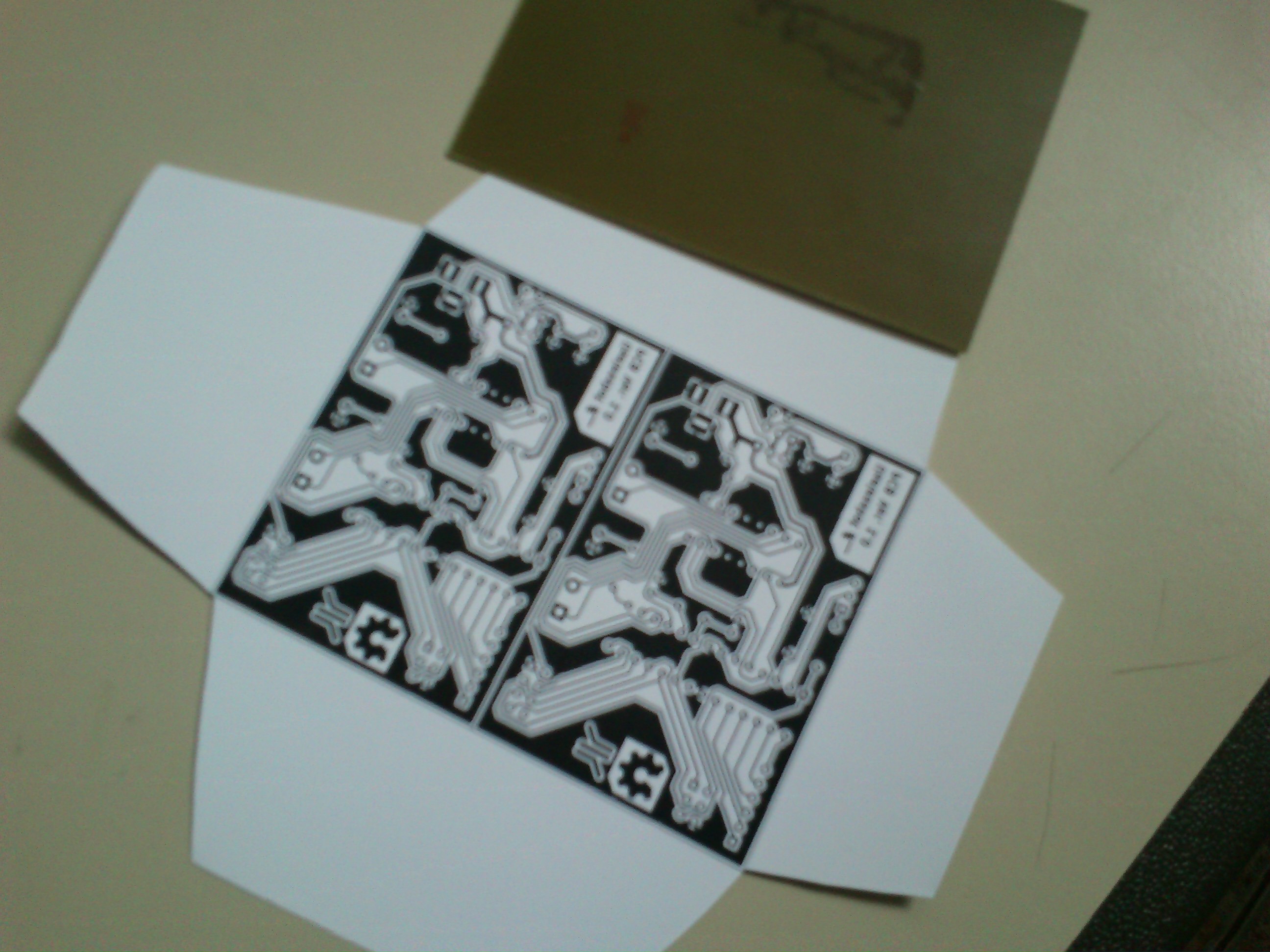

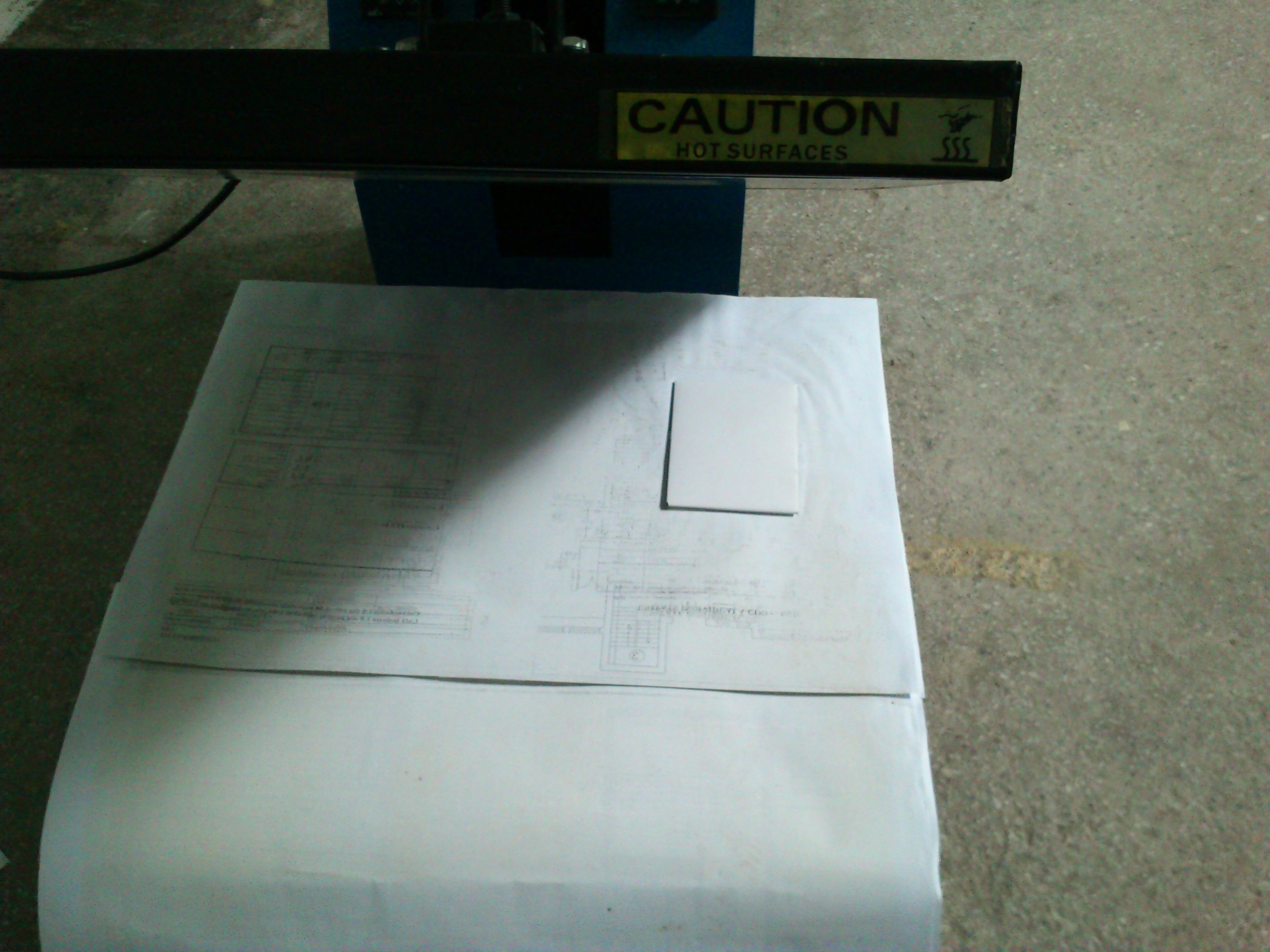

-secret ingedient: A heat press

Usually, the toner is actually transfered to the copper when pressure and heat is applied to the paper. This is done with a household iron. However, this method is sloppy and results in poor quality.

I solved this problem by chance. When I was checking out a shop that had a CNC, a heated press caught my eye. Since the CNC did not work, we borrowed the heat press and tried that instead of ironing the board. This yelded much better results because of the constant and even pressure. Usually 5 minutes in the press and the toner transfers 99%.

[ E C C 0 ]

[ E C C 0 ]

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.