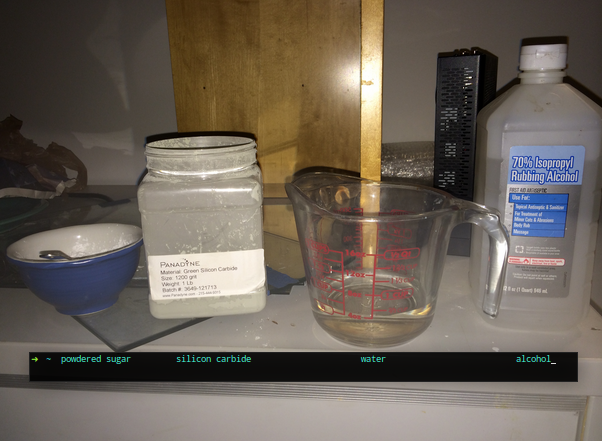

A suceptor is a material used for its ability to absorb electromagnetic energy and convert it to heat (which is sometimes designed to be re-emitted as infrared thermal radiation). The susceptor takes the microwaves and converts it into heat at a very high efficiency. A common example of susceptors everyone is familiar with may be the 'crisping sleeves' found in Hot Pockets and the like. This is used to burn away the object from within the mold. We need a tacky susceptor and used a combination of the following:

Sugar - to ensure the while the object is burning away, the susceptor does not run down the object and pool at the bottom. Sugar will carbonize the susceptor and leave it on the wall.

Water - The universal solvent, used to dissolve the sugar and silicon carbide.

Alcohol - We suspect that the alcohol will prevent the water from beading up too much.

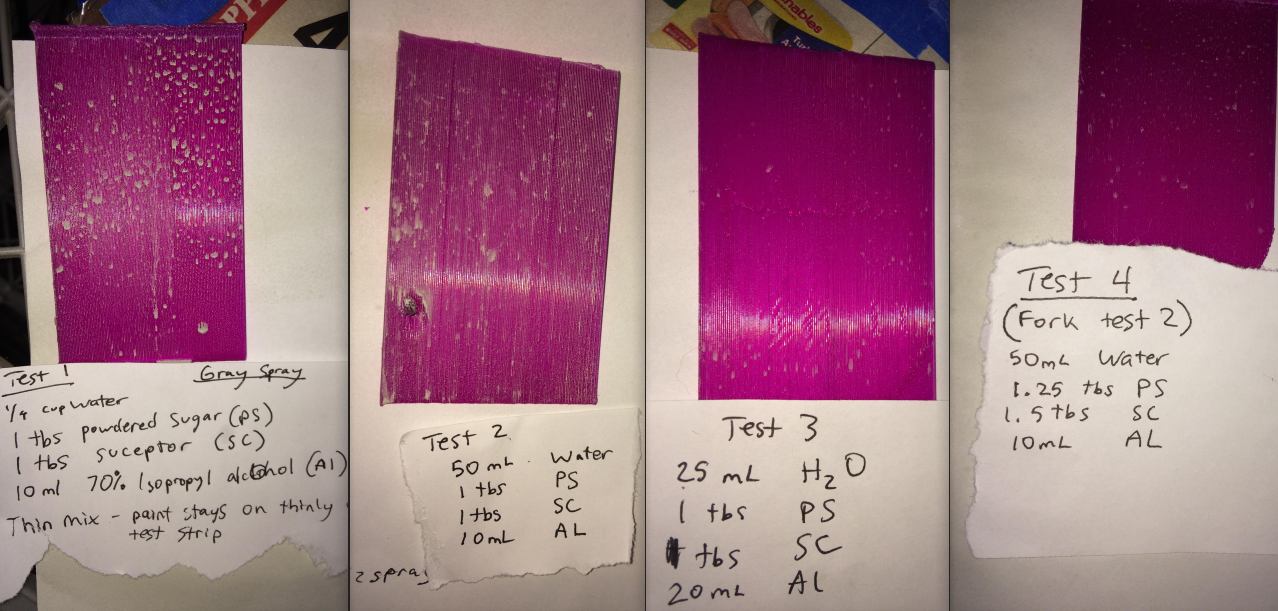

The spray is used as a medium to apply the mixture thinly and evenly across the surface area. We used some printed out PLA test strips for our experiment to design an ideal recipe.

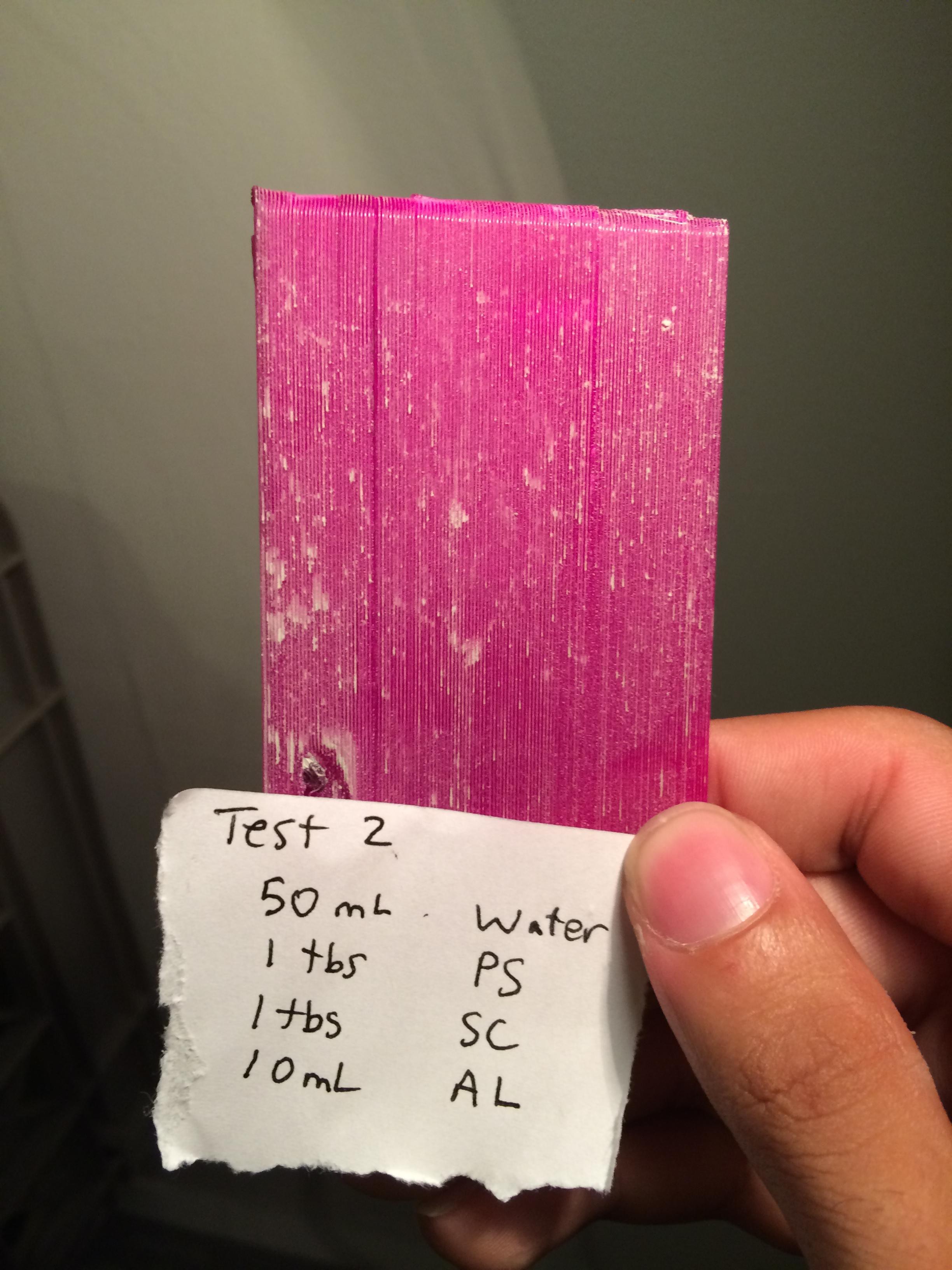

Results: Test 2 has been the most successful. Notice the clean, thin light grey layer that is produced :)

50 mL water

10 mL alcohol [70% I - AL

1 tbs powdered sugar - PS

1 tbs susceptor [silicon carbide] - SC

Use the widest available setting available for the nozzle [mist]. Hold about 6" away from the surface to avoid beading and apply a few even broad coats to the surface of the 3D printed part. We found that 2 layers with about 3-4 coatings each did the trick. Wait 15 minutes between each coat and careful not to spray too close or you will have undesirable dripping.

You will want to spray this mixture on the object, sprue, runners, and gates. Allow to dry and you'll be ready to move onto the next step, creating the mold!

Julia Longtin

Julia Longtin

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.