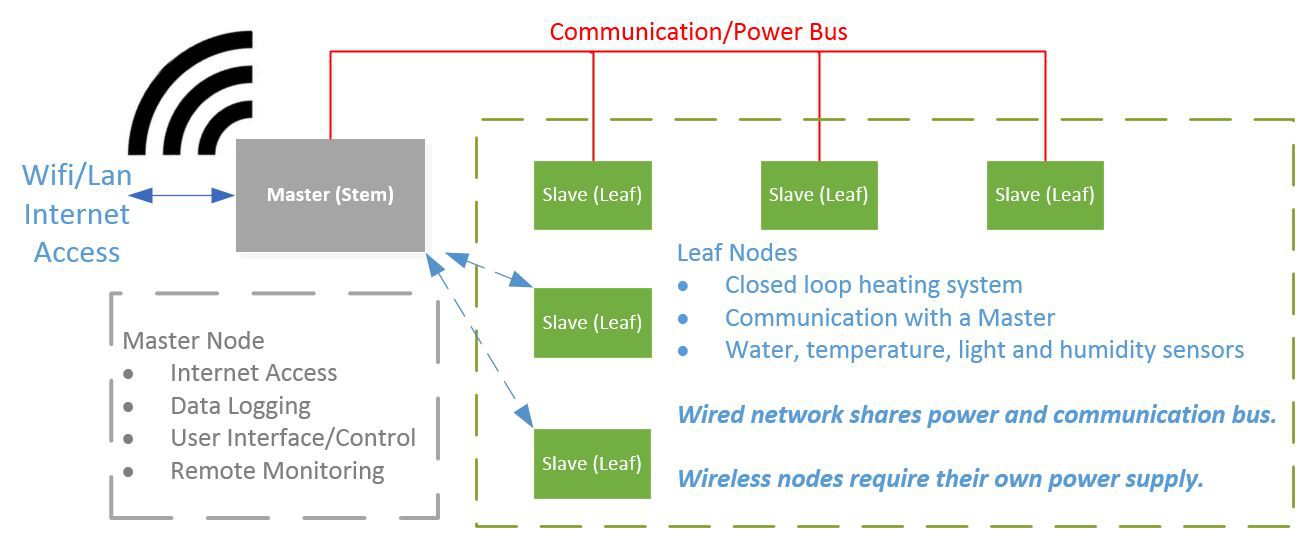

System Overview

Leaf Nodes

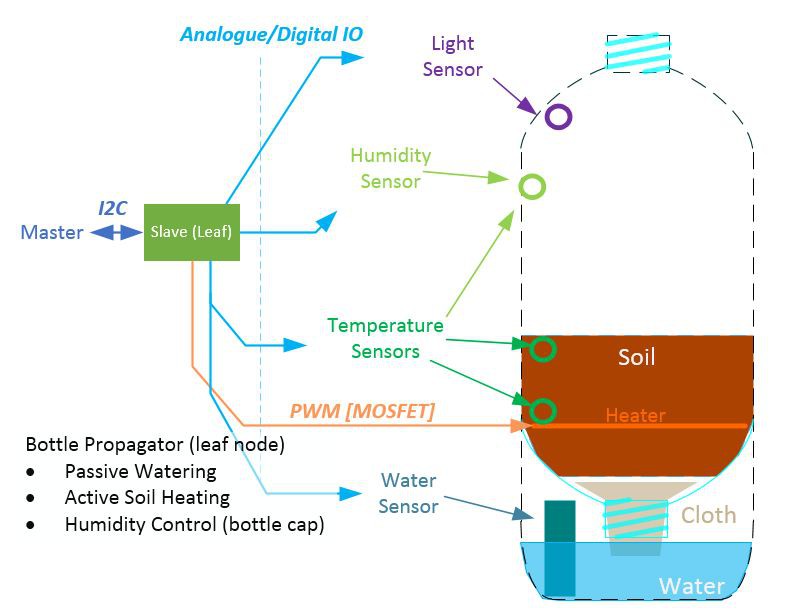

The leaf nodes will have several capabilities:

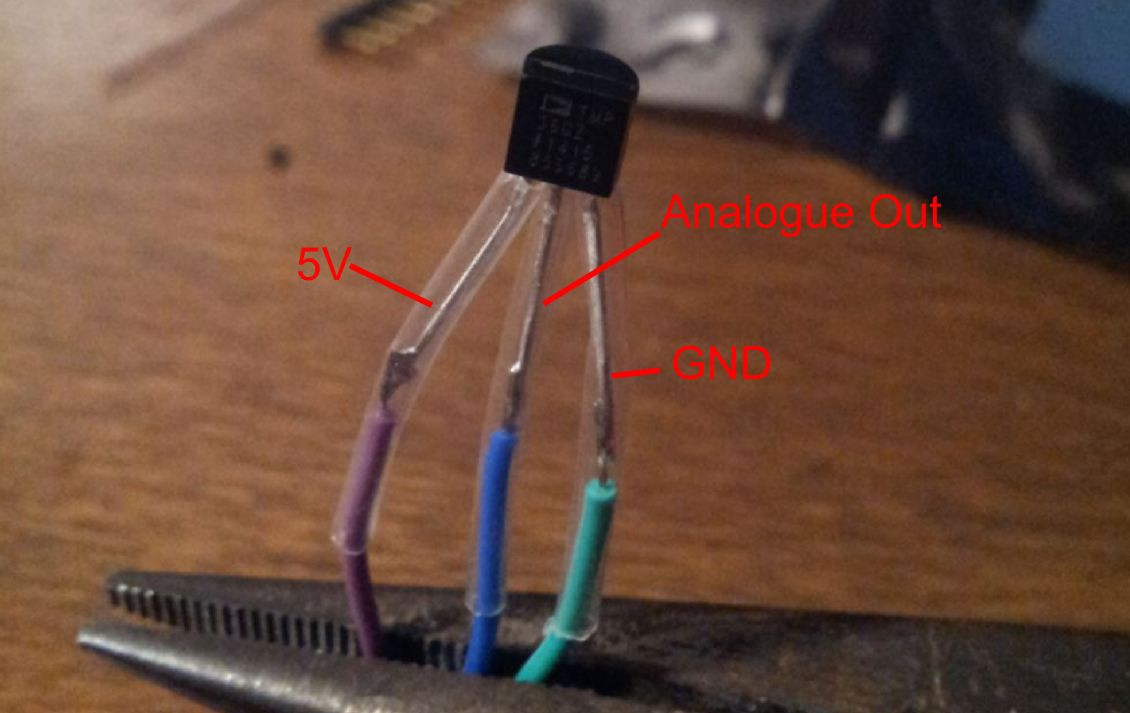

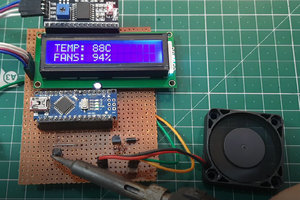

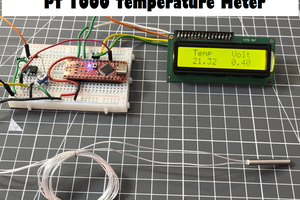

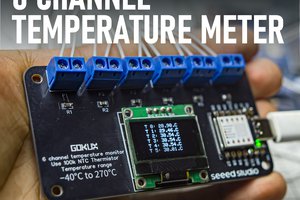

- Air, Soil and Humidity Sensing

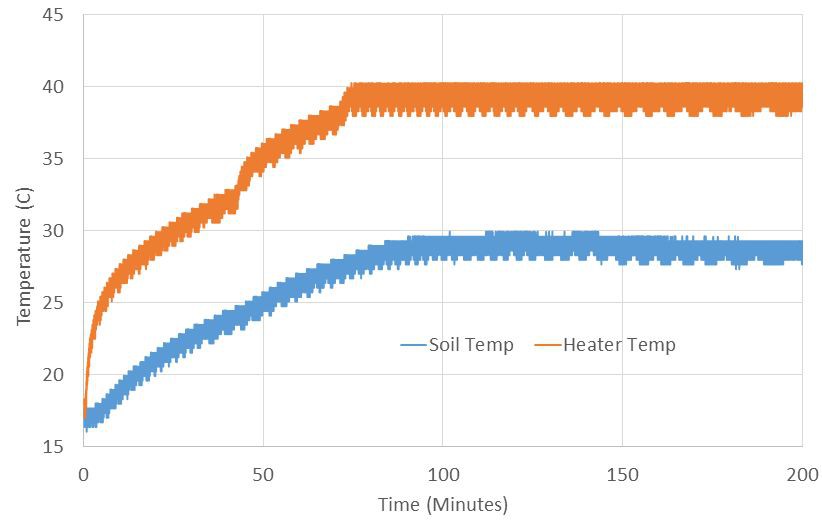

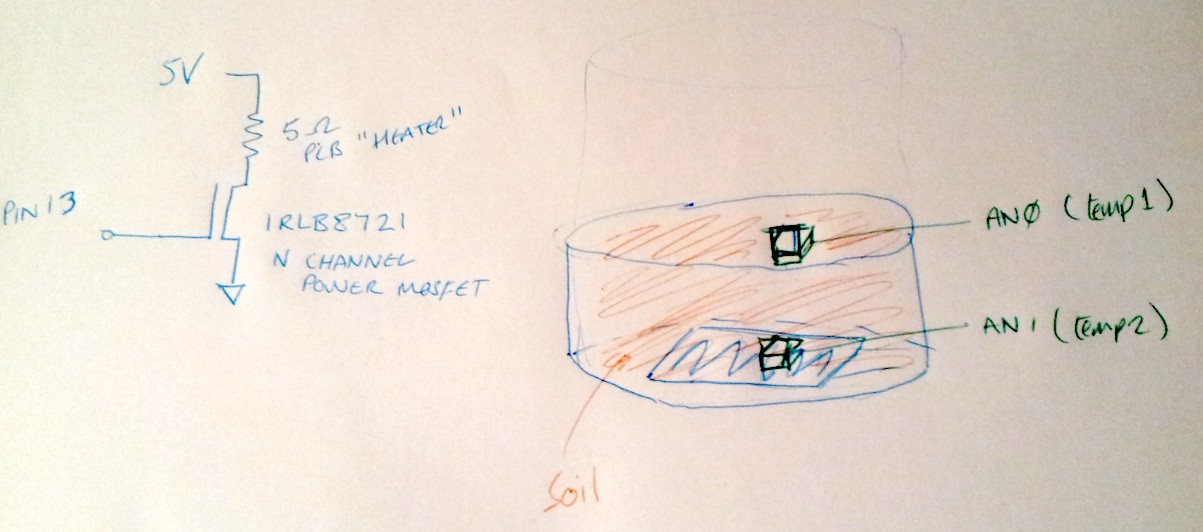

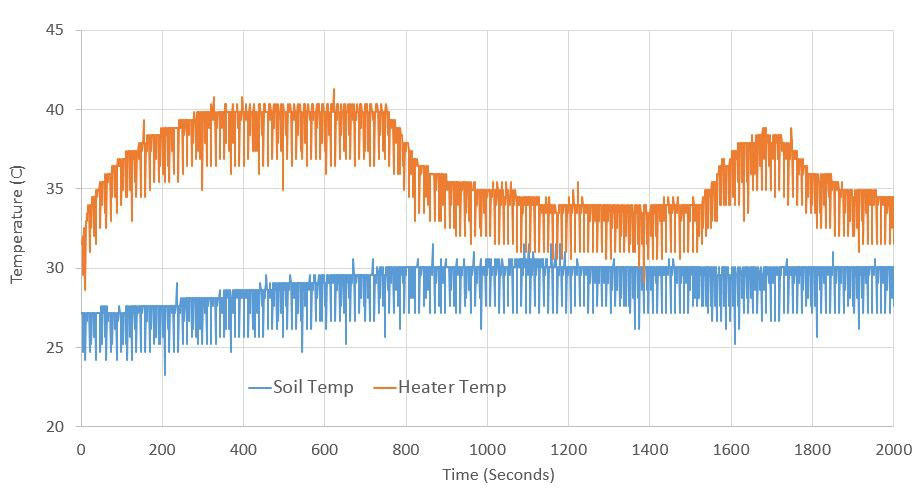

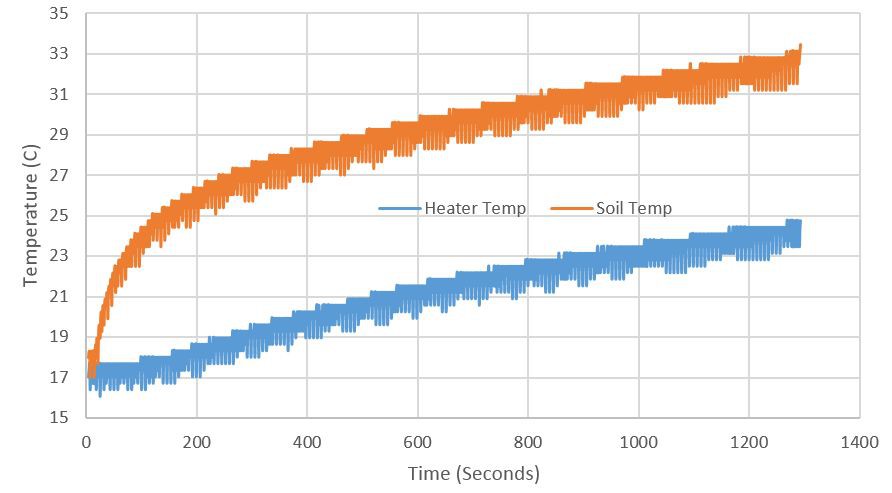

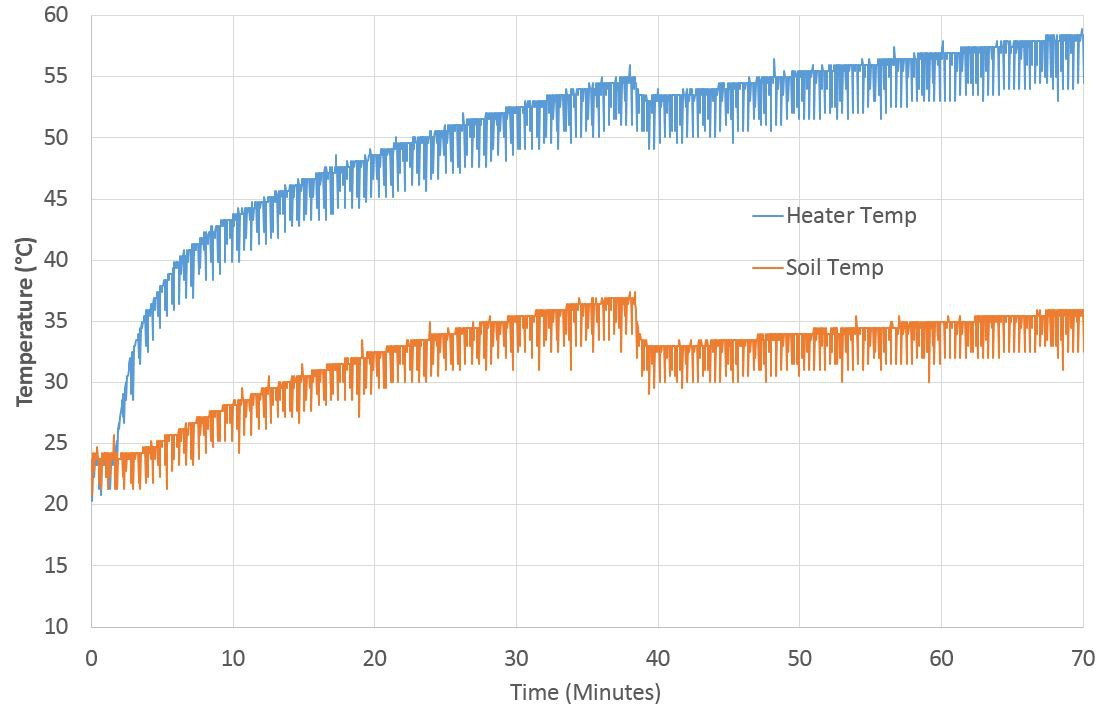

- Temperature regulation

- Water level monitoring

- Light sensing

- Slaves on a larger network for logging

In addition It would be nice to have the option of a single node and a way to configure it to keep associated costs low.

Read more » Darren Blaxcell, aka Pork

Darren Blaxcell, aka Pork

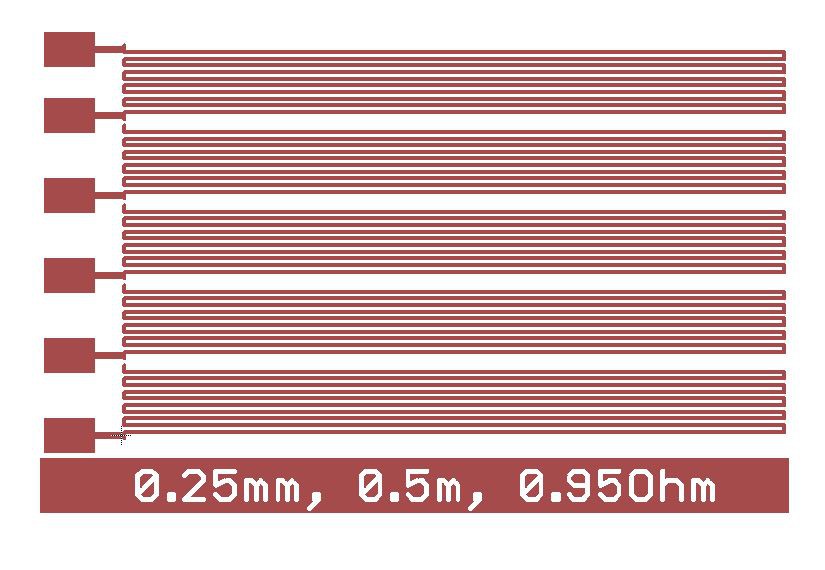

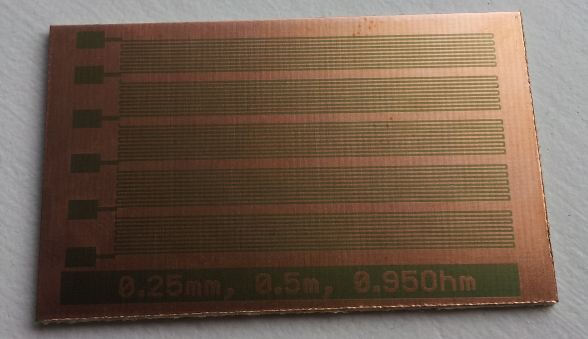

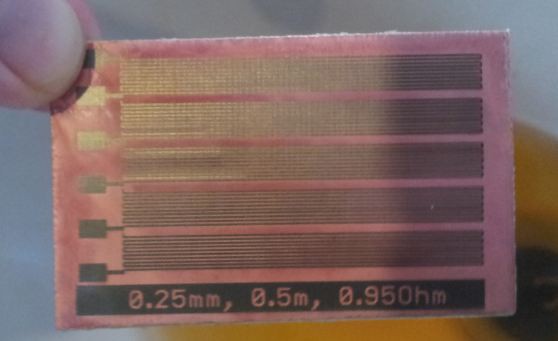

The photosensitive board was exposed and developed.

The photosensitive board was exposed and developed.

Sagar 001

Sagar 001

Kyle Gabriel

Kyle Gabriel

Lithium ION

Lithium ION

gokux

gokux