Stitch and Glue Small Boat/Canoe Building

A place holder for some of my future stitch and glue small boat and canoe projects

A place holder for some of my future stitch and glue small boat and canoe projects

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

MyCanoe700S_BoatOffsetTable.xlsmThe 3D offset table for the design12 - 57.54 kB - 05/29/2017 at 08:43 |

|

|

MyCanoe700S.dcThe 3D DeltaCad designdc - 47.61 kB - 05/29/2017 at 08:44 |

|

|

MyCanoe700S.dwgA DXF version of the 3D designDWG Drawing - 102.06 kB - 05/29/2017 at 08:43 |

|

|

MyCanoe700S_2D.dcA 2D (cutout) of the designdc - 4.73 kB - 05/29/2017 at 08:43 |

|

|

MyCanoe700S_2D.dxfA DXF version of the 2D (cutout) designAutoCAD DXF - 167.78 kB - 05/29/2017 at 08:43 |

|

A design that is half way between a canoe and a kayak. The idea is to:

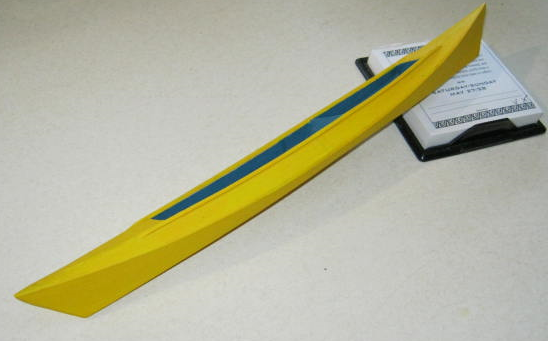

Here is the design:

(Yes it is a balsa model)

And another view:

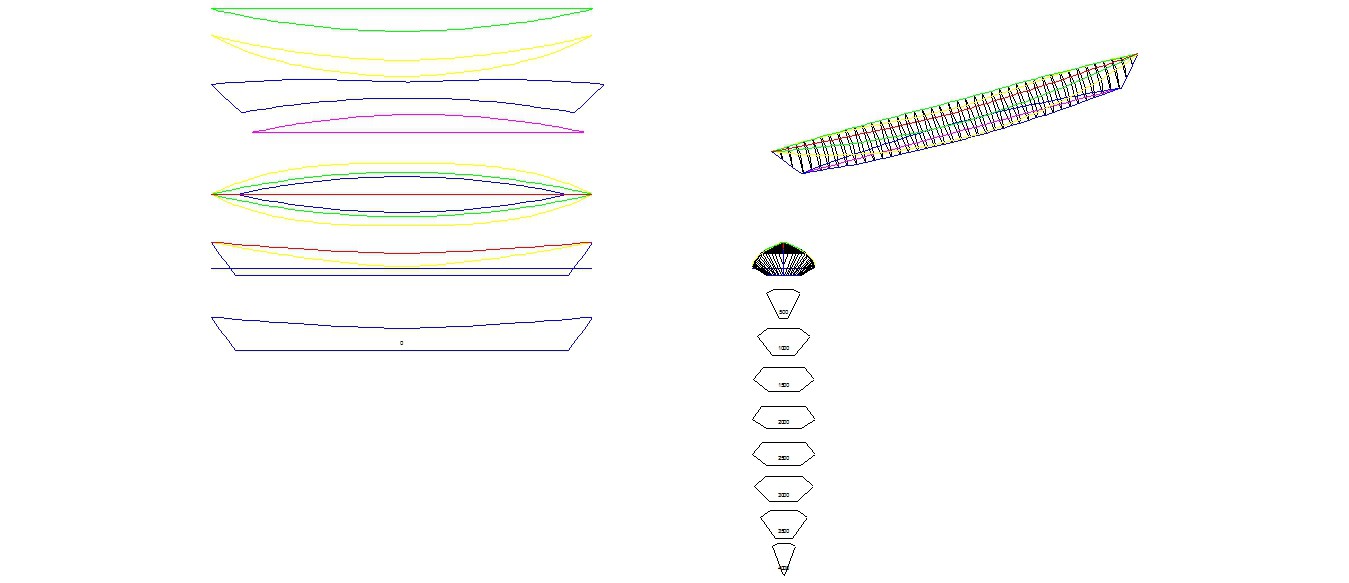

Here is the 3D design:

And the 2D design (two sets need to be cutout):

(Note: the plywood is 2500 mm x 1220 mm x 4 mm)

Here are the key files:

I have not export the 2D (cutout) data to excel for formatting.

Regards AlanX

These are the for My Canoe:

Here is My Canoe:

Regards AlanX

This design is covered in the Process log so just the key files here:

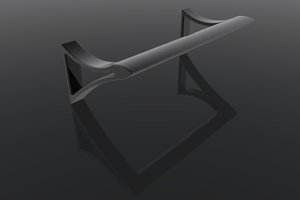

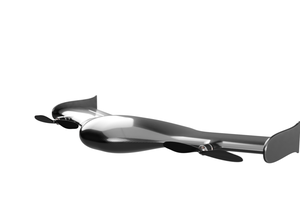

The pontoon (i.e. the outrigger):

Regards AlanX

If you are interested in boat building, especially using “stitch and glue” plywood construction, then Carlson Design Hull Designer (http://carlsondesign.com/projects/hull-designer/) may be of interest to you. You will need to run this program in XP compatibility mode otherwise some of the options will not work.

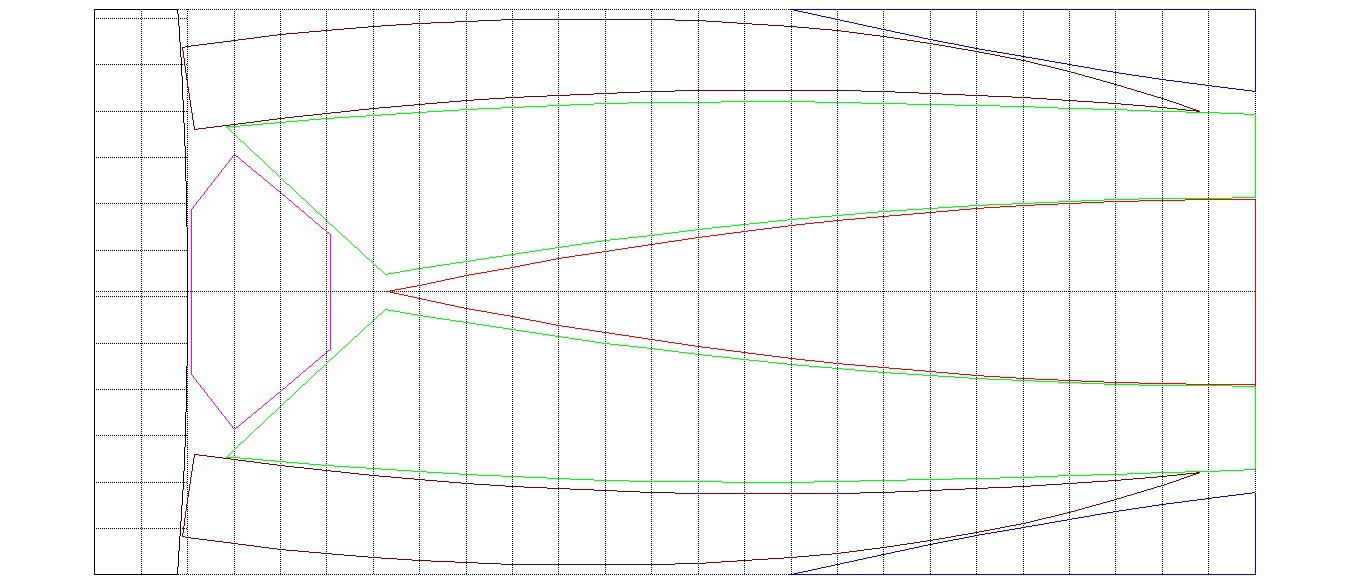

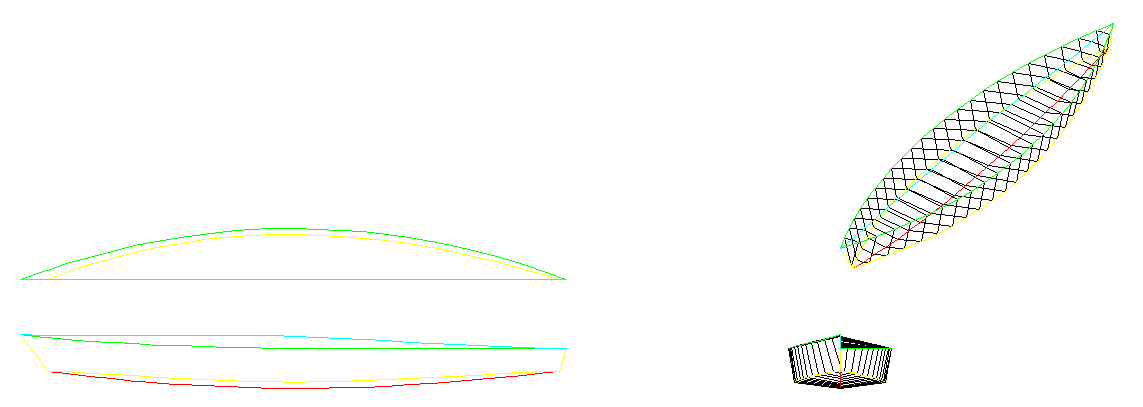

The main objective of these hull design programs is to create a 3D hull and then to “develop” or “unfold” the frames/bulkheads and planks/cut-outs for construction. Below is an example of a “stitch and glue" pontoon for my outrigger canoe.

The 3D design:

The unfolded (cutout) design:

The cutout offset table:

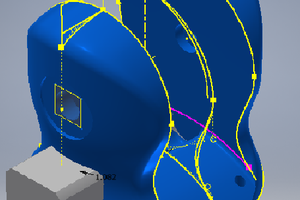

The lofted design:

The lofted design:

The wired up (stitched) panels:

The glued (epoxy filleted) seams:

Top glued on, ready for sanding and Dynel (rather than fiberglass) tape:

Coated with epoxy and trial fitted to the canoe:

Done, fitted and painted):

The following describes the process and the two key programs I use.

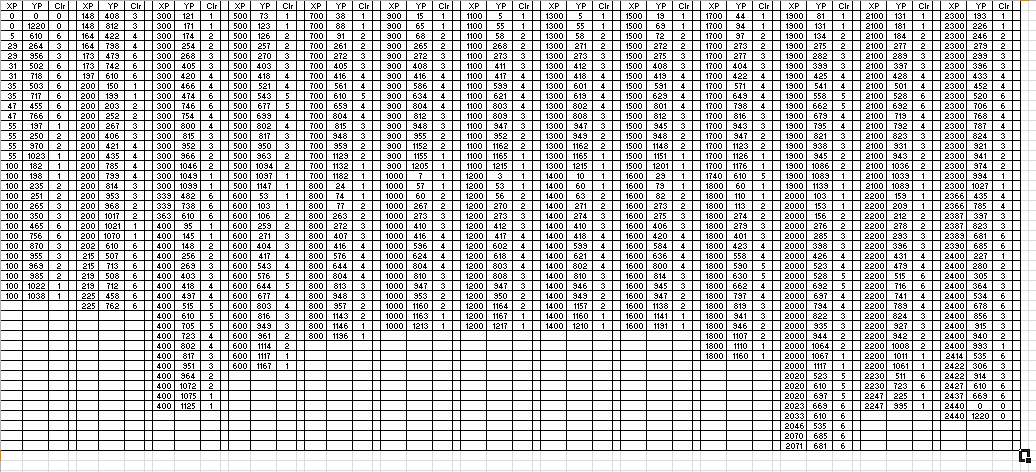

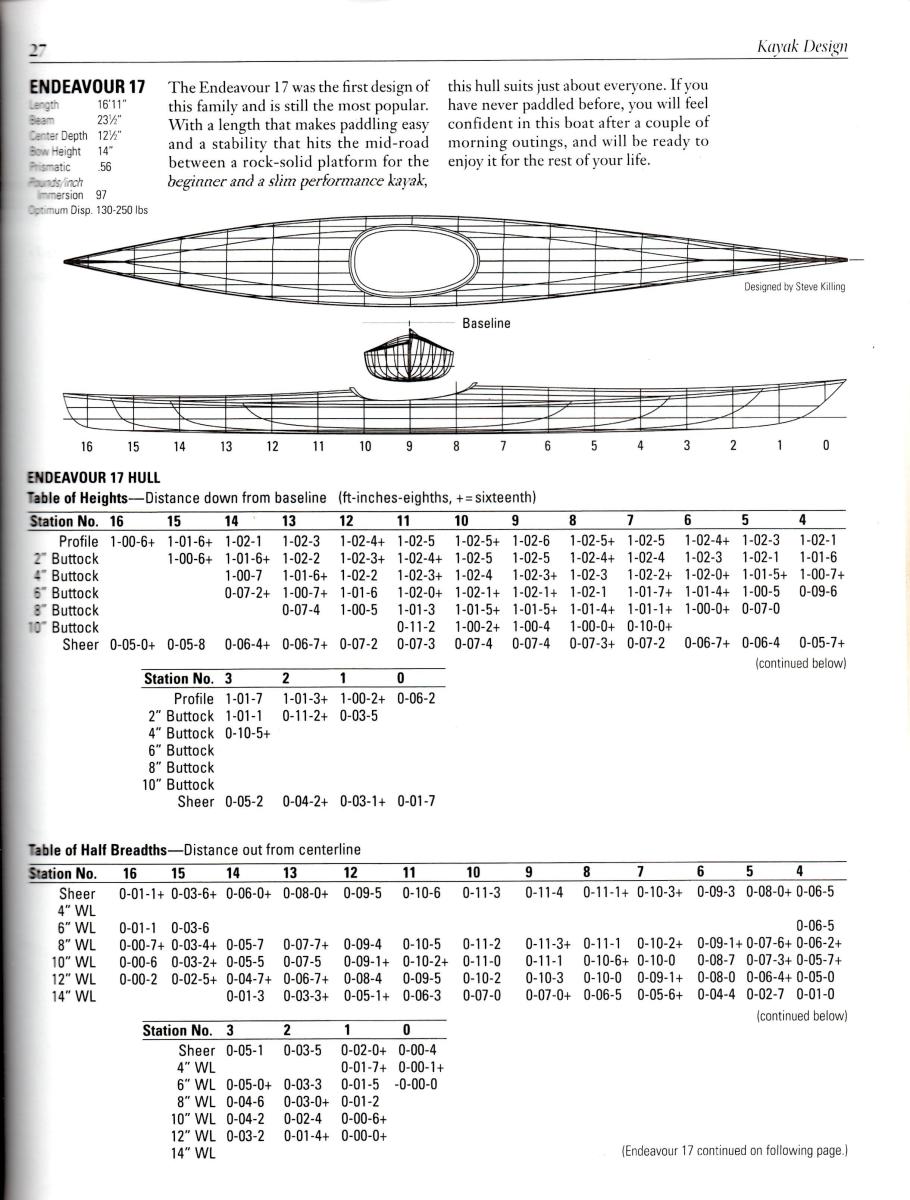

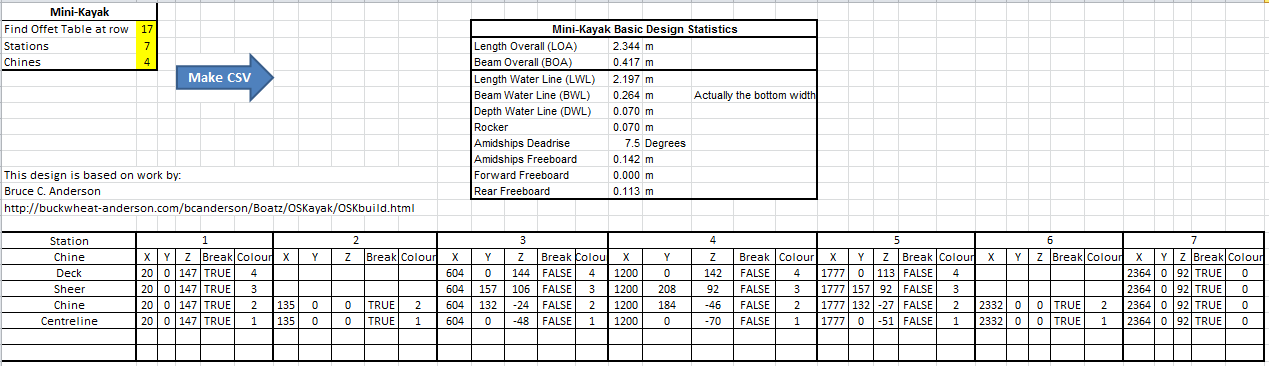

The Excel file and macro allow you to enter the offset table and then to export the design to a CSV file for DeltaCad. Blow is an example of an offset table for a kayak:

(source: https://hubpages.com/sports/Building-a-Cedar-Strip-Kayak-The-Basics)

(source: https://hubpages.com/sports/Building-a-Cedar-Strip-Kayak-The-Basics)

The DeltaCad macro imports the CSV, draws the design and unfolds (develops) the hull.

Note: DeltaCad can be purchased for US$40 from https://www.deltacad.com.

DeltaCad does not have a suitable table entry process which is why Excel is used. Below is the Excel offset table for the “Mini-Kayak”.

“Mini-Kayak” is an adaptation of work by Bruce C. Anderson (http://buckwheat-anderson.com/bcanderson/Boatz/OSKayak/OSKbuild.html).

The actual design is too small to be of practical use as a Kayak (refer to Anderson’s webpage).

The above offset table has three additional features over an offset table:

Notes:

The offset table is exported to DeltaCad as a CSV file. The name of the CSV file is the same as the Excel WorkSheet name. To execute the macro just click the blue “Make CSV” arrow as shown above.

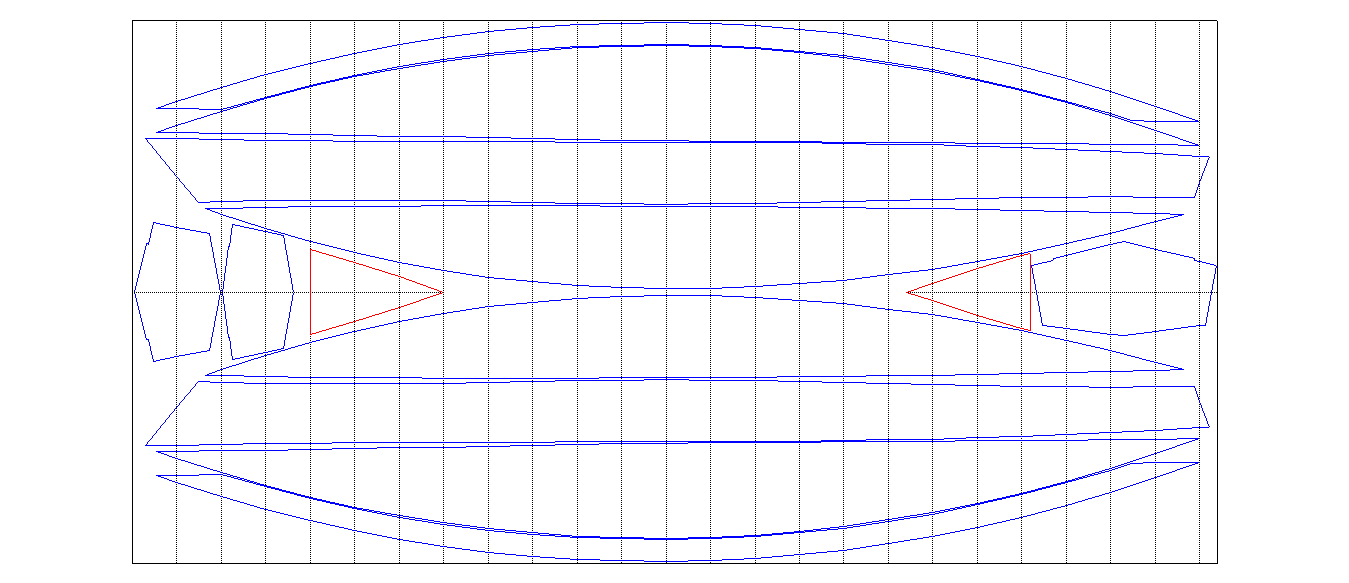

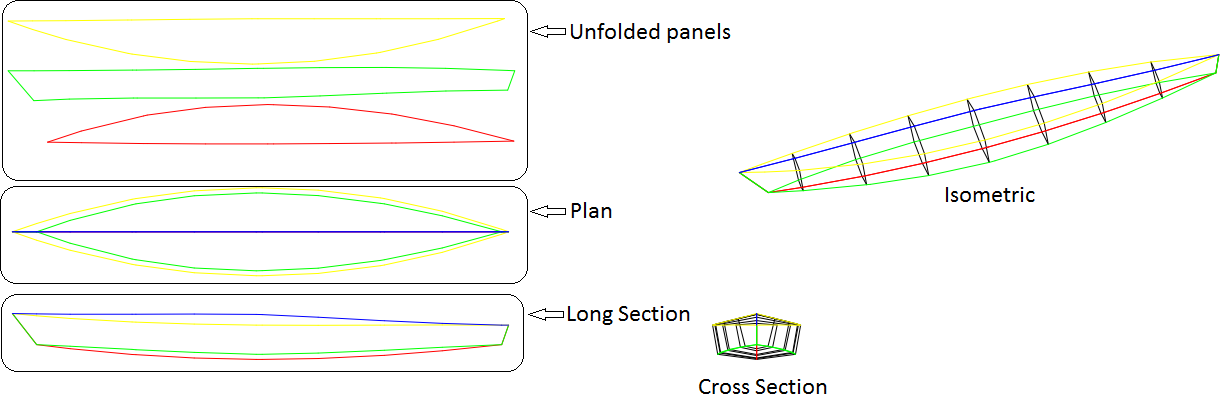

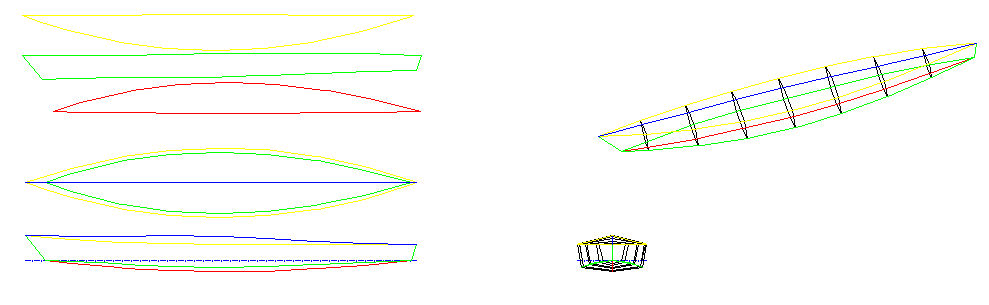

In DeltaCad the macro (“BoatOffsetTable.bas”) is run to import the CSV file and draw the design. For complex designs, the actual process is iterative (i.e. chine by chine). Below is the imported and unfolded “Mini-Kayak” showing the main drawing components.

Note: The unfolded panels are the cut-outs for the design and only one side is shown.

Macro Options

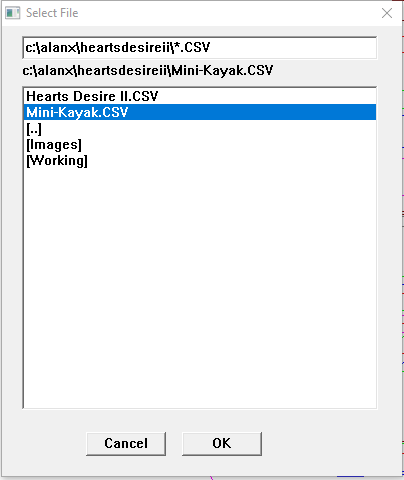

When you run the DeltaCad macro, it first presents a file manager window. It starts in the DeltaCad macro directory. You will need to navigate to your working directory (i.e. where the Excel file is located) and select and okay the CSV file. For the “Mini-Kayak” it is called “Mini-Kayak.CSV”, as shown below.

The macro then presents the “Hull Sections” options box. Set the number of frames to 7 and zero the remaining entries as shown below. This option adds additional frames to the hull model.

You should see the following design.

Other Options

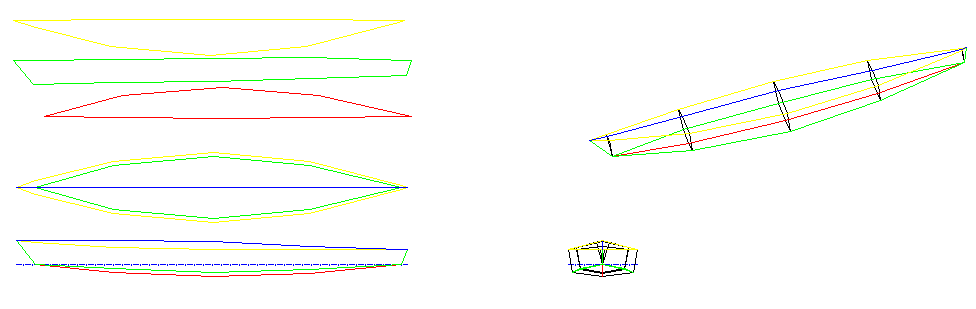

If the “Frames” entry is set to zero then the offset table as entered in Excel will be drawn as below.

The other option entries, create different sections (cross, long and plan) through the model. For example the...

Read more »

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates

TAIBHSE DESIGNS

TAIBHSE DESIGNS

Abd-el-rhman

Abd-el-rhman

Naman Pushp

Naman Pushp

Our strategic focus is on developing Electron Beam (EB) curing adhesives and next-generation semiconductor materials as we continuously improve the use of adhesives and resin materials. https://www.uvadhesiveglue.com/