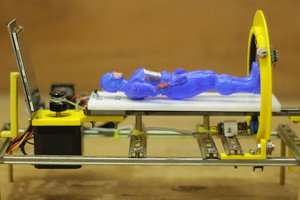

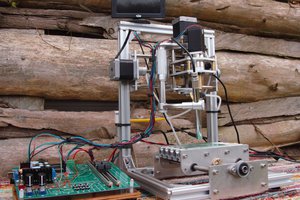

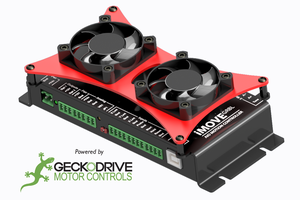

Mooov is CNC Motion Controller, a piece of hardware/software controlling the motors (Stepper motors or Servo Motors) and peripherals (Spindle, Coolant, Vacuum, Dust control, ..)

What makes Mooov unique ?

- runs on low-cost, easy available hardware

- high-quality trajectory and speed control

- simple design for high reliability

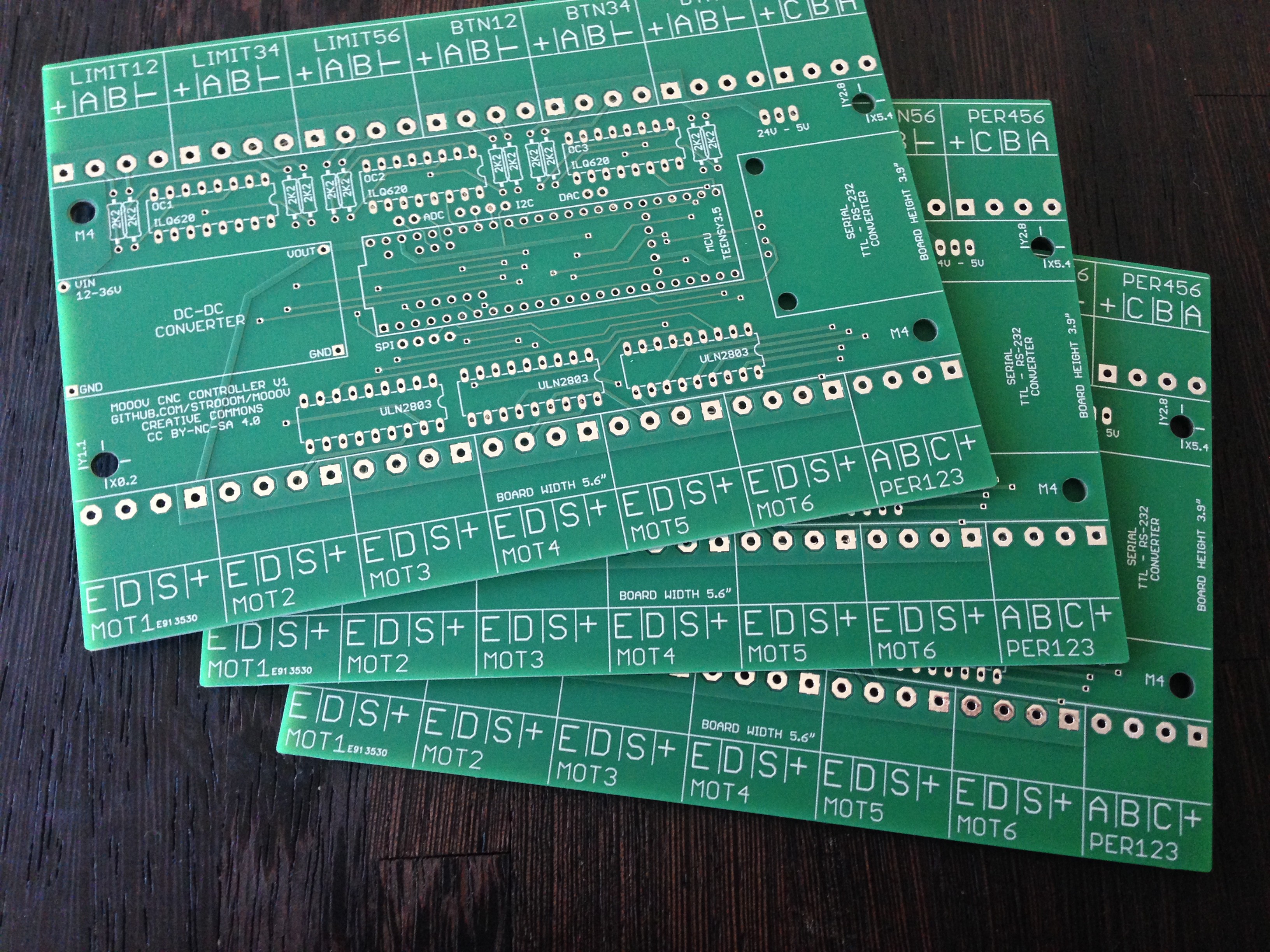

Hardware

Many existing CNC controllers run either on an Arduino, or on a Linux PC.

The Arduino is very low cost and available everywhere, however it is limited in ROM, RAM and CPU throughput.

A PC has much more resources, but this platform is not designed for real-time processing and as such it is difficult to achieve accurate control of the motors.

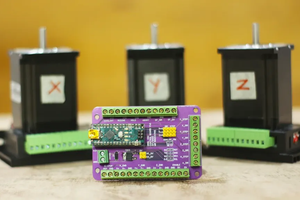

ARM-based uControllers, such as the Teensy provide a good compromise : plenty of HW resources for a reasonable cost and true real-time performance.

Trajectory and speed control

Moving the CNC along the correct path, at the correct speed requires lots of calculations. Todays uControllers allow to do accurate 6 axis linear and helical movement. At the same time they allow for higher-order speed profiles, optimizing the forces, speed and acceleration of the machine.

Complexity - Reliability

Mooov focuses on doing 1 thing only. We stick to the 80/20 Pareto 'rule'. The advantage is reduced complexity and improved reliability.

Pascal Roobrouck

Pascal Roobrouck

Mrinnovative

Mrinnovative

sandy

sandy

Capt. Flatus O'Flaherty ☠

Capt. Flatus O'Flaherty ☠

Troy Cundy

Troy Cundy

Has any of the software for this project been published? I have looked on GitHub (https://github.com/Strooom/Moovr) but I am only finding hardware documentation.

Thanks