Shared under the Creative Commons - Attribution - ShareAlike 3.0 license.

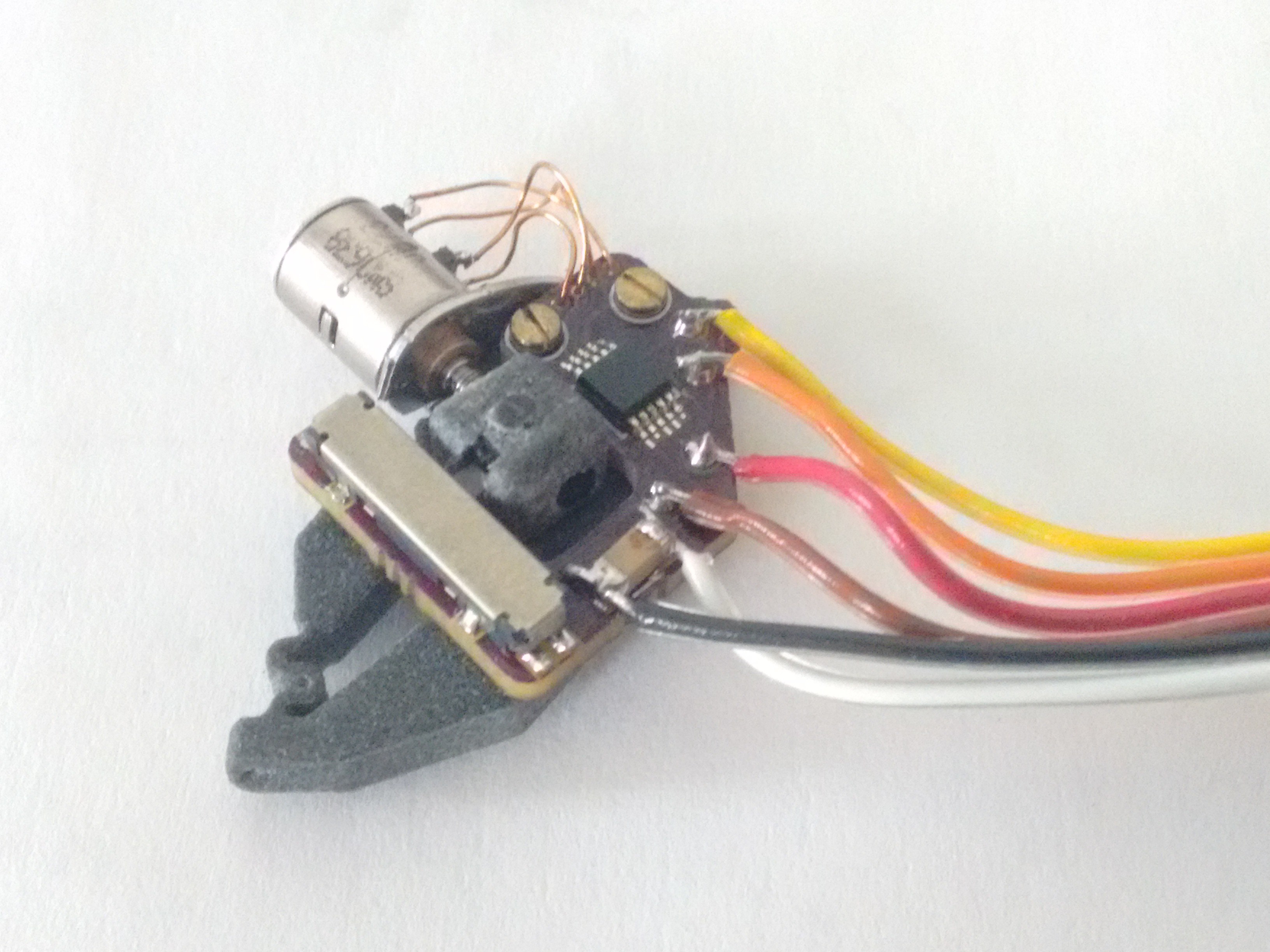

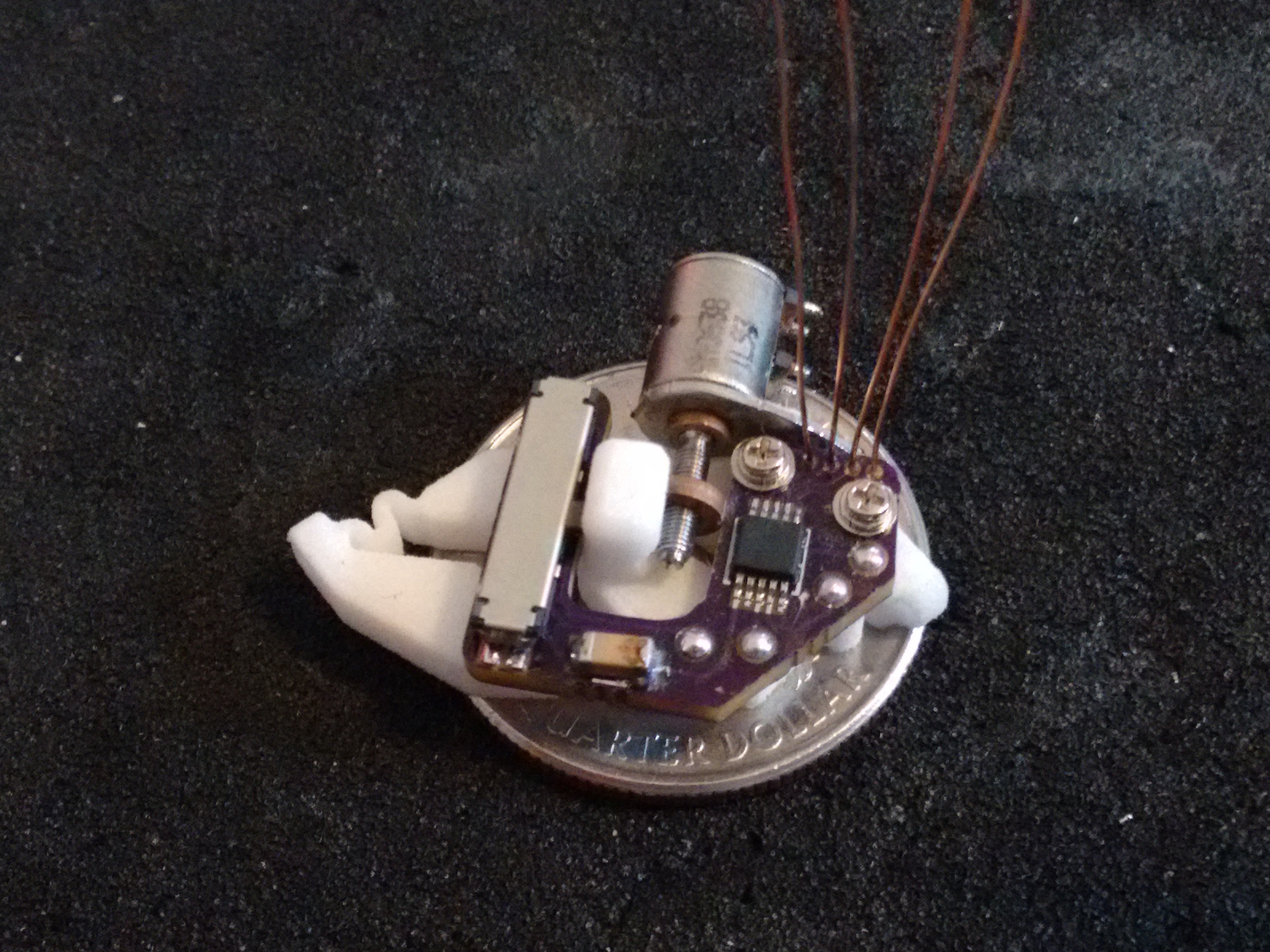

The aim is to use this manipulator to position an optic fiber in front of a laser diode (when the maximum output is passing down the fiber), the fiber is then glued in position. This is how pig-tailed laser diode modules are created.

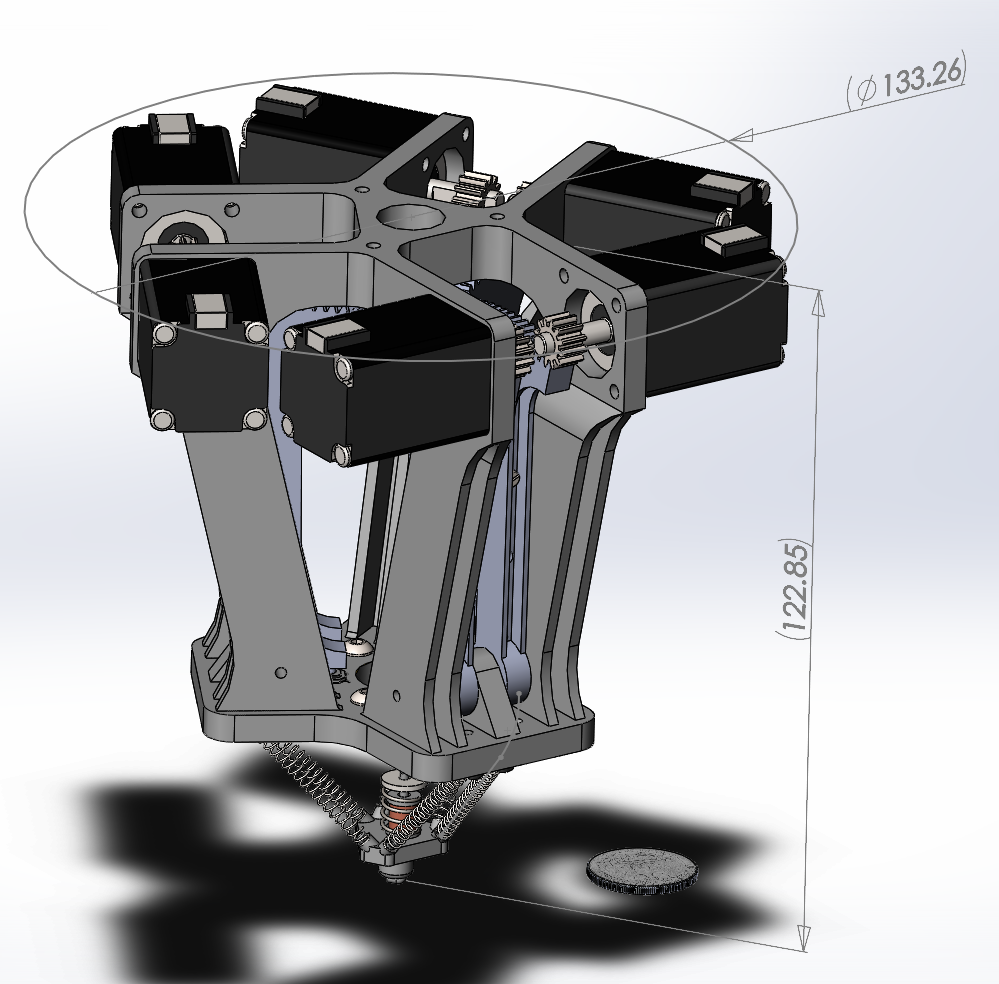

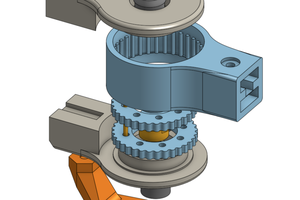

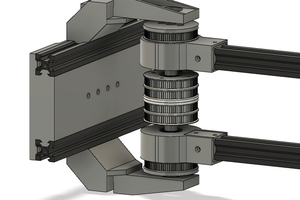

Industrially the assembly of pig-tail modules uses machines that must cost tens of thousands of dollars. These use the same layout, a Gough-Stewart platform, using six actuators to give the six degrees of freedom control.

in my case the manipulator will be manually moved so that the fiber is within a millimeter or less of the correct position and then the manipulator will make the final positioning and hold the position whilst the fiber is glued down to a support structure.

Other possible uses:

-

As a platform for supporting small samples in bio-sciences research, either inverted as a standard stage or with a modified main frame to allow the microscope to view down through the centre.

-

As a manipulator where both triangular frames are modified to allow view down through both parts, with end effector positioned into the centre of the platform.

-

With an alternate design of platform incorporating vacuum nozzle, discrete optical elements could be manipulated as required.

-

To support end of microscope fibre optic bundle to allow viewing around a specimen

The test code Git repository can be found in the links section below.

David Brown

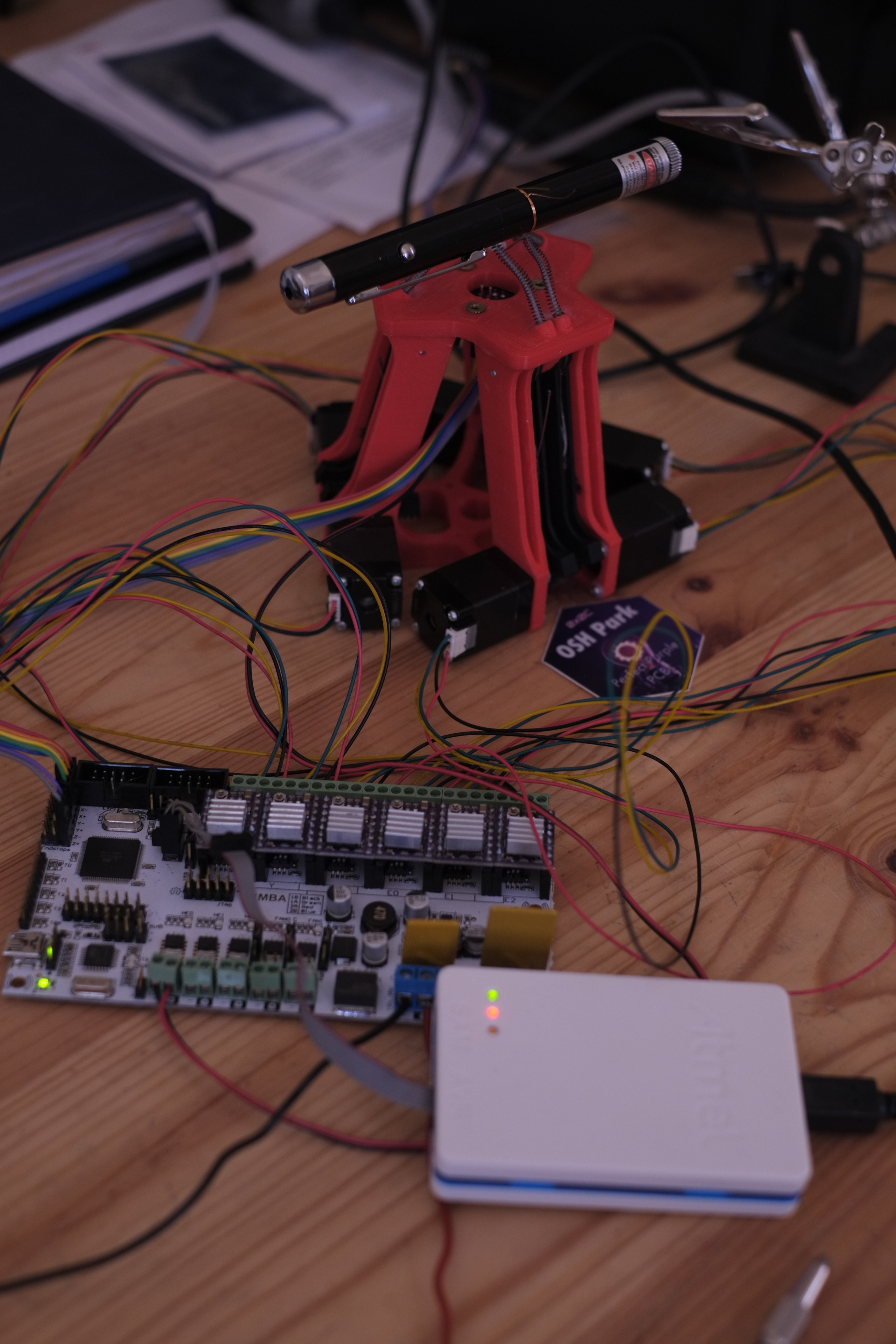

David Brown Figure; Laser pointer mounted to the platform (test rotations)

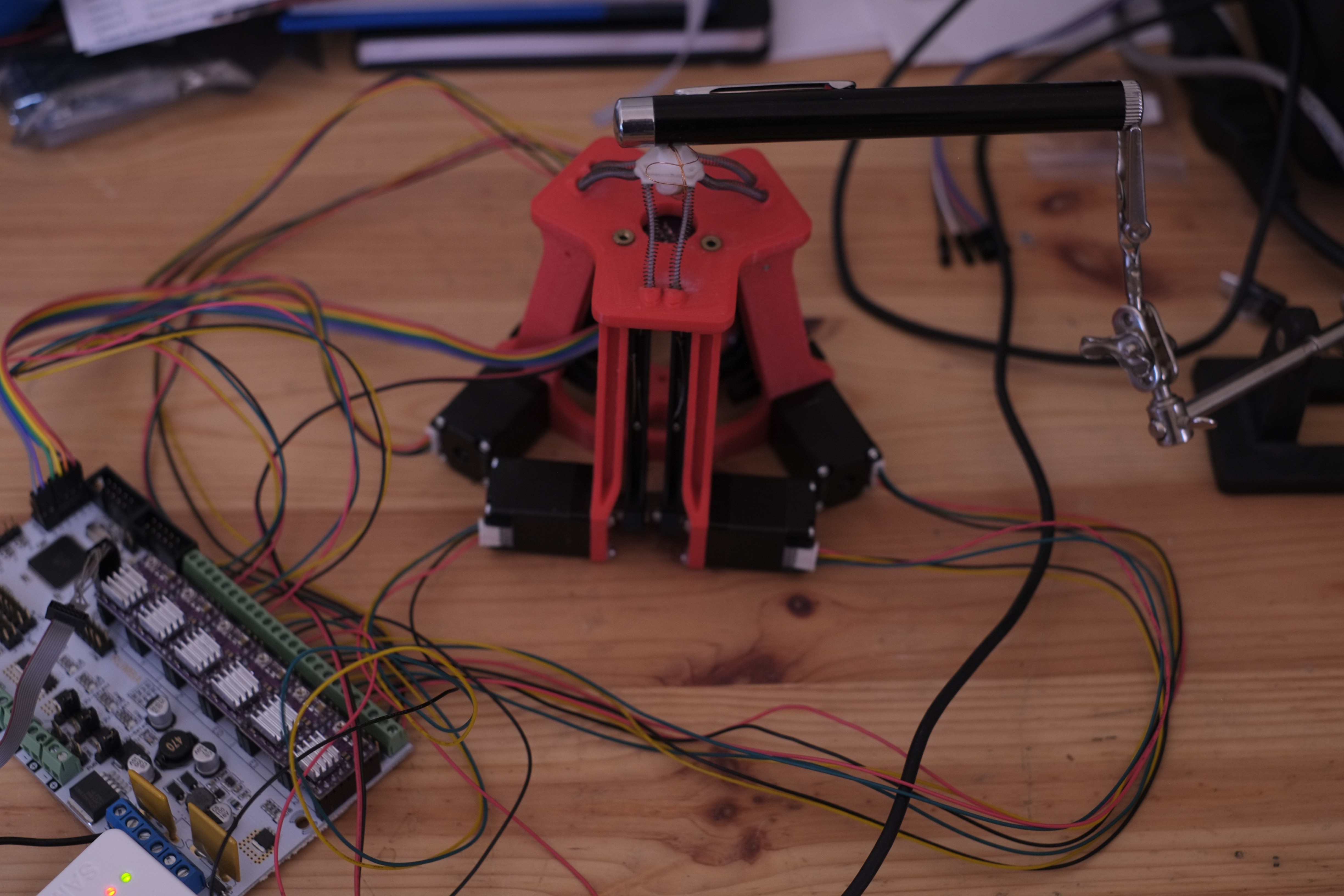

Figure; Laser pointer mounted to the platform (test rotations) Figure; one end of the laser pointer supported (test translations)

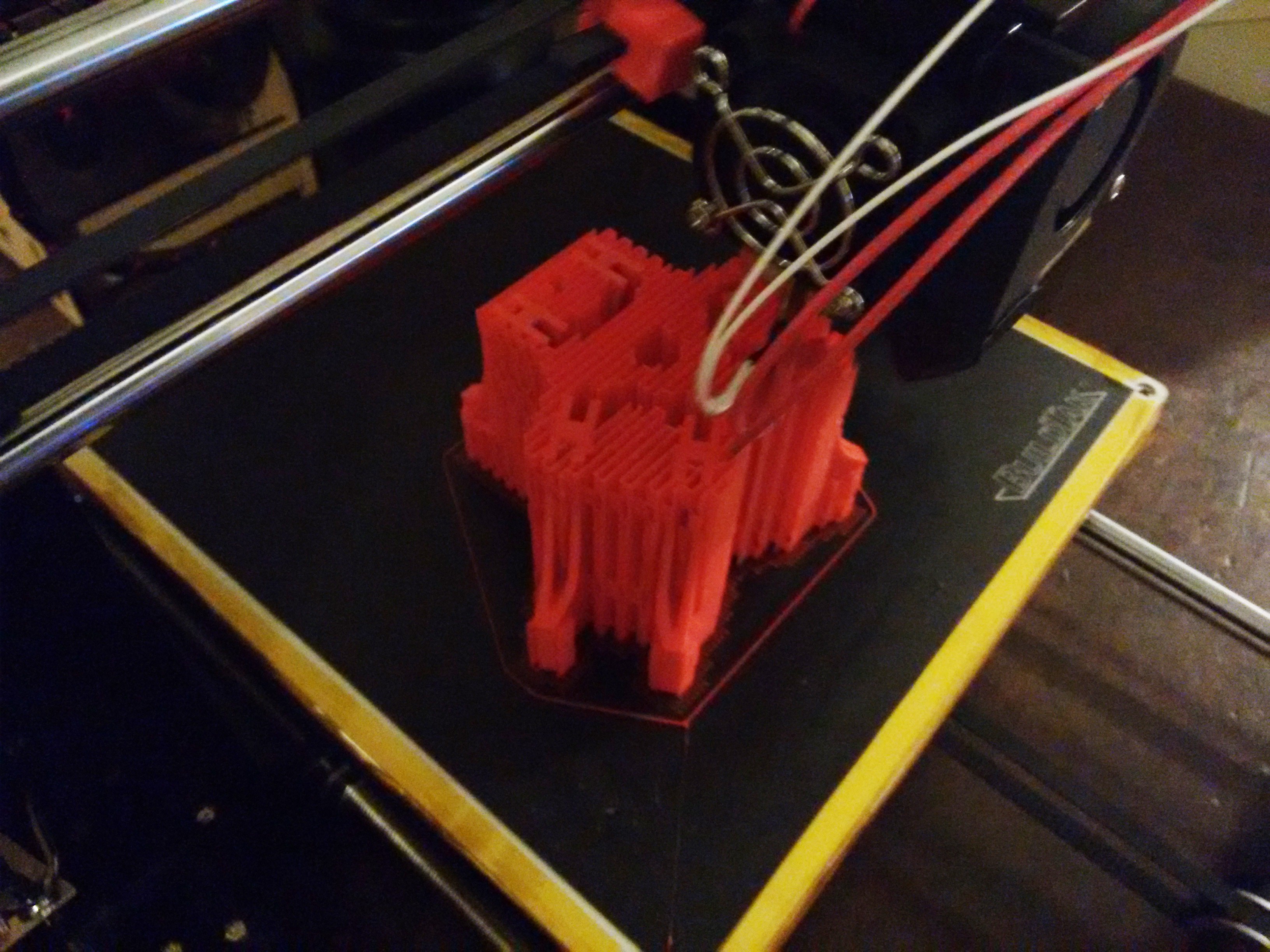

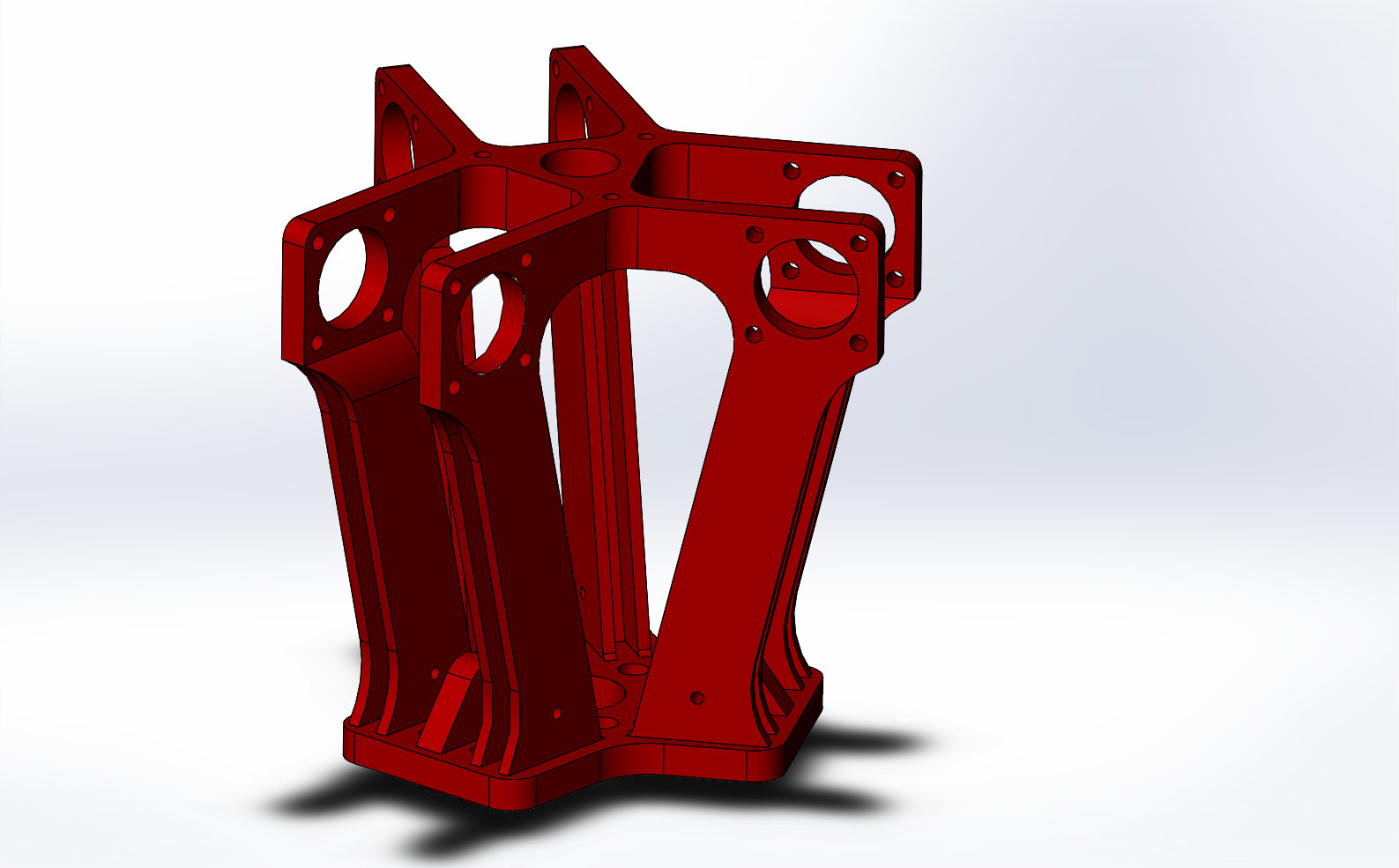

Figure; one end of the laser pointer supported (test translations) The print of the frame took 15 hours and i was pleased with the quality, given that this was using the $150 printer with all stock nozzle, etc. I'll post up the models for the parts shortly. More after break below;

The print of the frame took 15 hours and i was pleased with the quality, given that this was using the $150 printer with all stock nozzle, etc. I'll post up the models for the parts shortly. More after break below;  units = mm

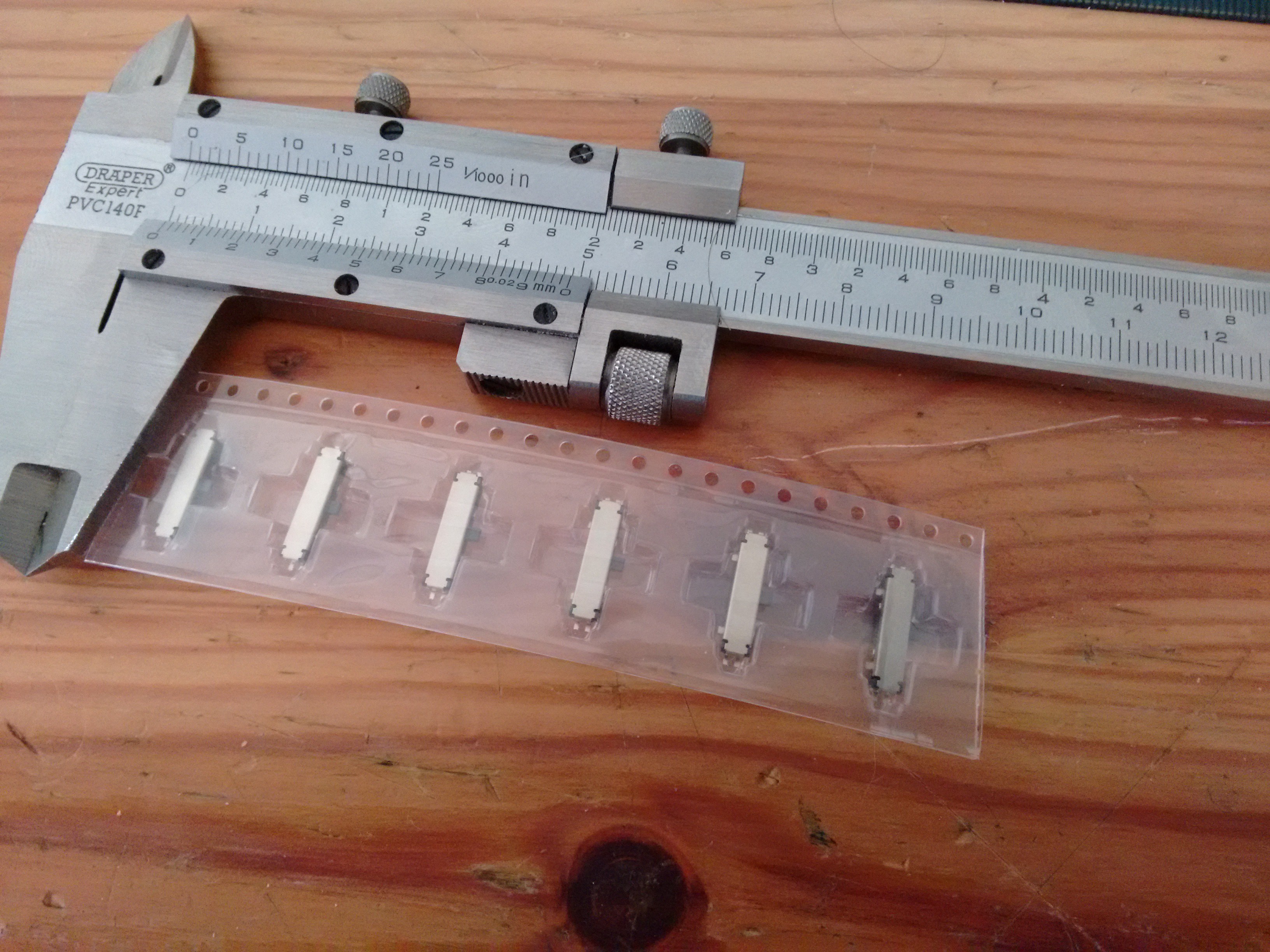

units = mm

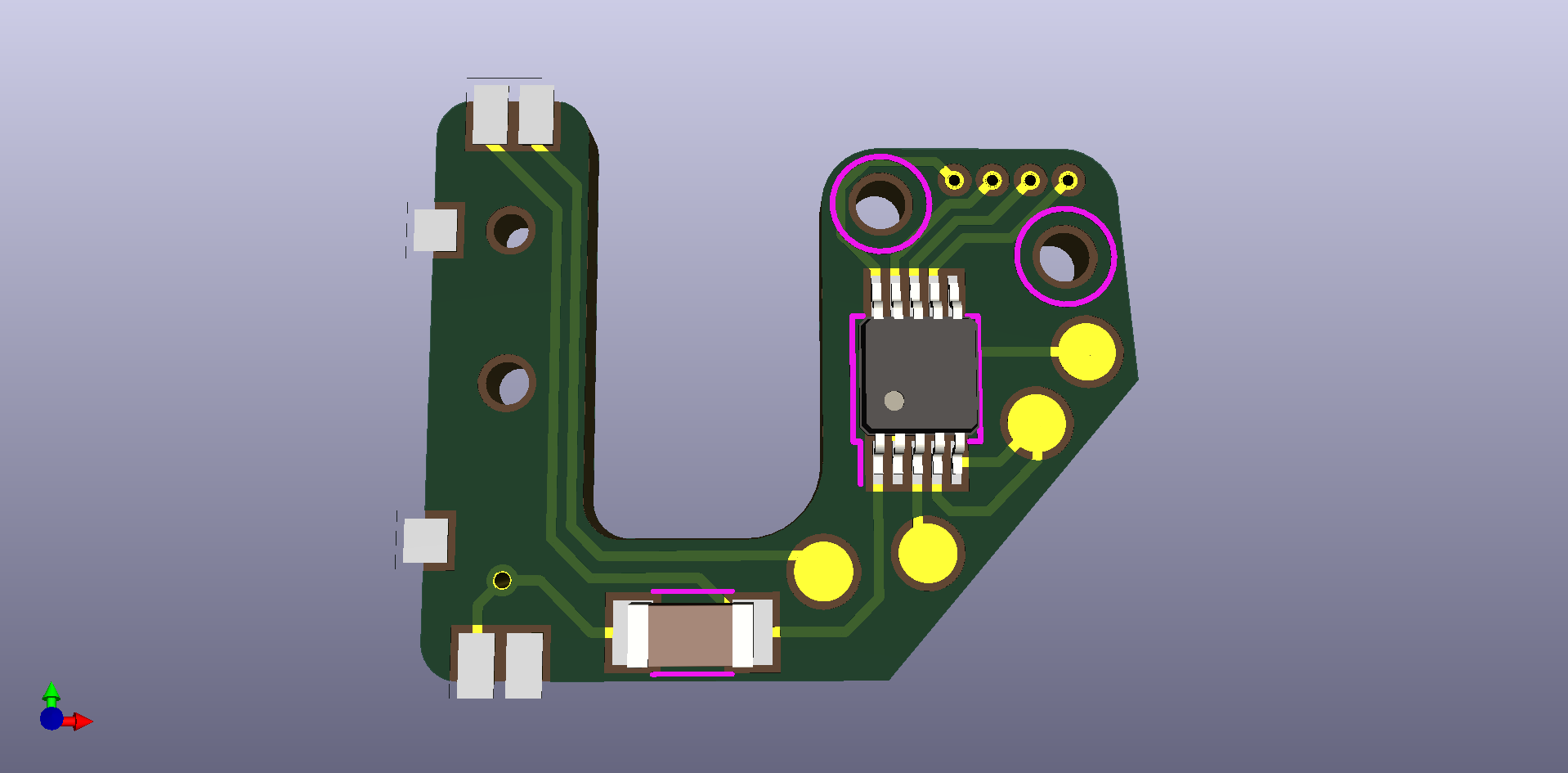

This has been designed for both the LB1935FA and LB1848MC bipolar motor control ICs, as i've still got a few pieces of the now obselete

This has been designed for both the LB1935FA and LB1848MC bipolar motor control ICs, as i've still got a few pieces of the now obselete

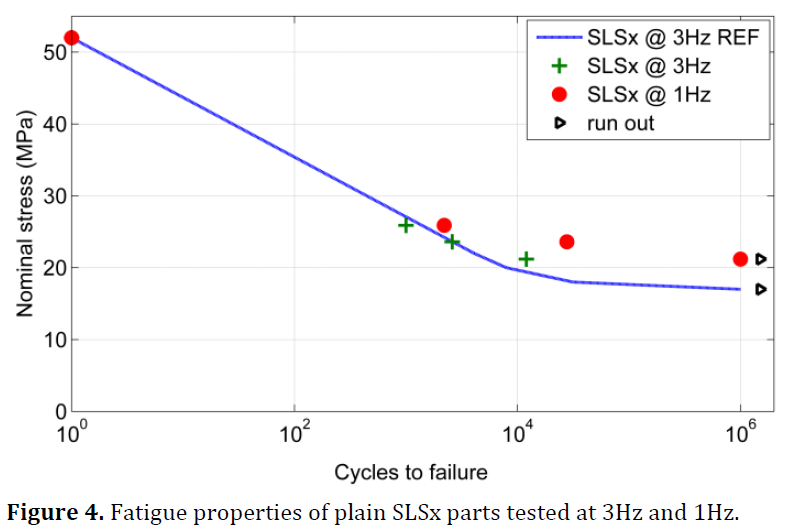

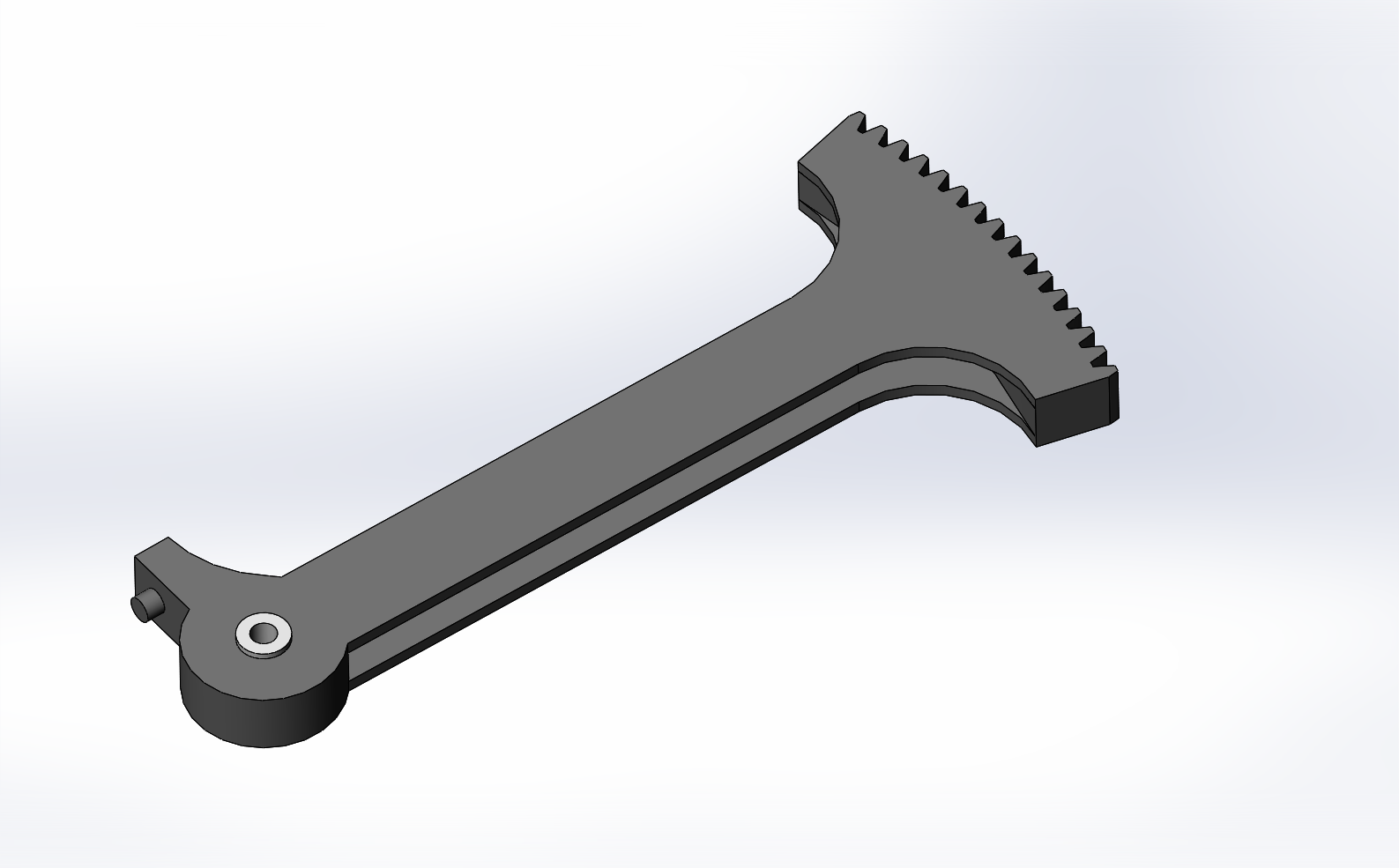

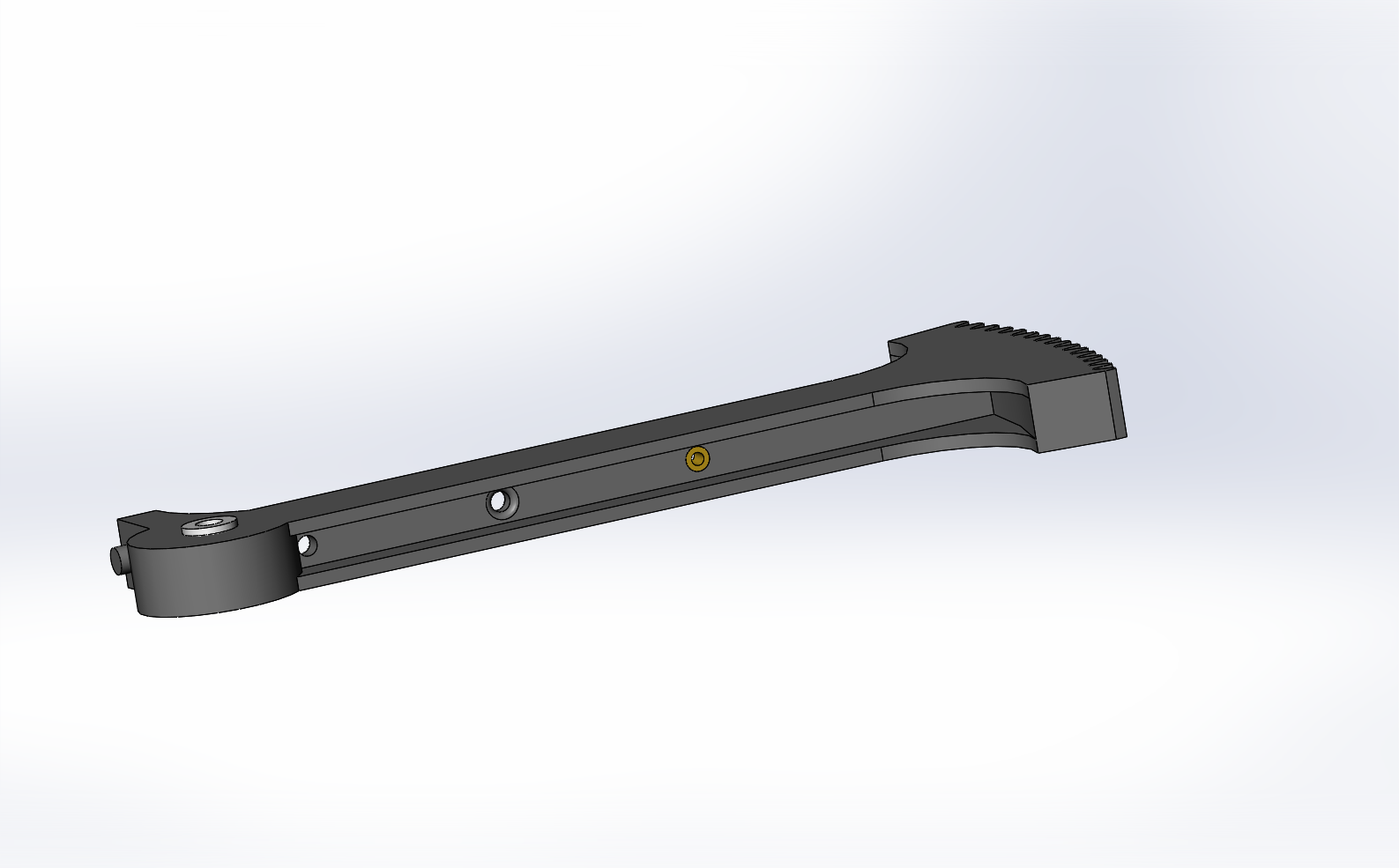

The design followed an itterative process from the initial design, extending the length of the thin hinge material. Initially simply, but when I found the fatigue

The design followed an itterative process from the initial design, extending the length of the thin hinge material. Initially simply, but when I found the fatigue

Sam Baker

Sam Baker

Bree Hoffman

Bree Hoffman

Tim Wilkinson

Tim Wilkinson

wschneider

wschneider

The actuators look they would be great for use in automated wafer alignment for semiconductor lithography. :)