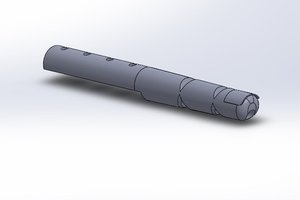

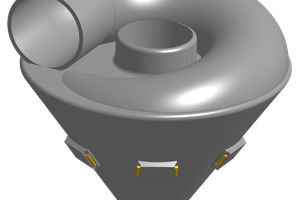

This project aims to create a clone of the body of a StickVise (http://www.stickvise.com/)

Edit: It now clones the whole vise,body jaws and all!

To make your own customized jaws please see http://www.stickvise.com/hacks/parametric-jaws

v4 now has simplified jaws built in!

Roobotics

Roobotics

Alan Chambers

Alan Chambers

Jaime García

Jaime García

Aaron P.

Aaron P.

Adam M

Adam M

This is great!! The stick vise has a great design.. And, we were talking at work the other day how cheap it would be to manufacture these. ($5-$10 maybe?)

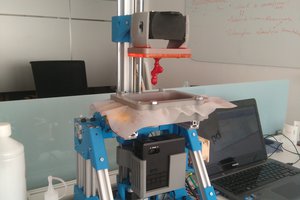

I have a question though. How did you go about grounding the 'socket head cap screw' on its inside corner??