Defining Requirements

With the flow sensing element being defined (ferrite-flow-capsule and hall sensor), we can now think of the architecture of our sensor device. Because we use a hall sensor for detection, we gain the freedom to have some millimeters in distance between the spinning ferrite and hall sensor.

At first, we must resist the engineer’s urge to start off designing a cool new, high tech, flow measuring, IOT drinking device (with lasers!). Something like the “Hydracoach Water Bottle”, a commercial product which comes close to what we try to develop here. It was even tested for its usability in care, and apart from many disadvantages, the test users disliked it purely for the fact that they had to drink from this massive, heavy piece of plastic. Instead, they wanted their cup back, with which they used to drink before.

Note: the device has to be somehow small and more something you put IN BETWEEN the cup and your mouth when drinking, not a new futuristic drinking vessel (even if it has lasers).

During my experiments with the flow sensor (see last update), I destroyed one ferrite-flow-capsule by drinking orange juice with tiny pieces of fruit pulp in it (the ferrite got stuck). It might be a good idea to build the device in such a way that the capsule could be replaced.

Oh, and everything in contact with liquid should survive the dishwasher. Either the electronics need to be capsuled (-> wireless charging neccessary) or the electronics must be detachable.

Solution for architecture

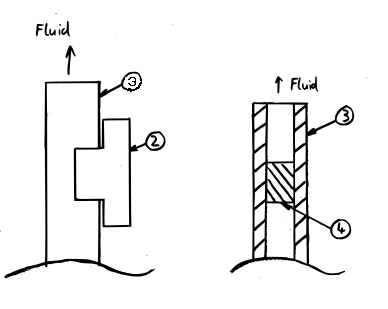

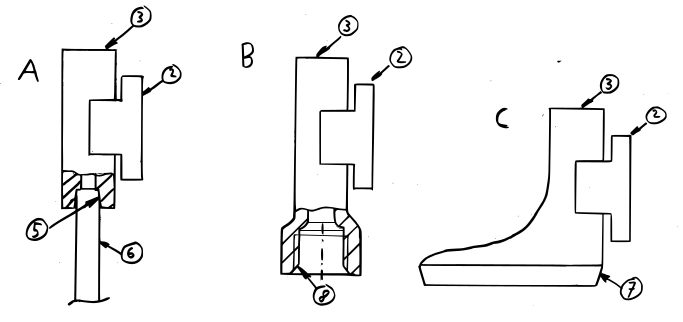

The device consists of two major units: the mouthpiece (3) and the sensor unit (2).

The mouthpiece is the part the liquid passes through when drinking. In the hollow center, the ferrite capsule (4) is fixed. Oh, yes and the mouthpiece is put to the mouth when drinking.

The sensor unit contains all the electronics, battery and the hall sensor. It is attached to the mouthpiece by a detachable connection, in a piggyback-way.

Here are the benefits of this approach:

- The mouthpiece is the unit most likely to fail during use (it contains a moving part). It is a simple piece of cheap plastic and can be easily cleaned or replaced. No electronics get wasted.

- The “personalization” of the device happens, when the sensor unit (registered to one user) is attached to a mouthpiece. With this, drinks for a whole floor of a nursing home can be prepared including the mouthpiece, not having to think of which coffee is for whom. The user makes the cup his/hers by attaching his/her sensor unit. Mouthpieces are interchangeable, sensor units are personal.

- The mouthpiece can have any desired shape, as long as the ferrite-capsule fits inside and the mechanical interface to the sensor unit is maintained. With the same electronics, various variants of the mouthpiece can be developed: it could be used with a straw (A), screwed onto a bottle (B) or as the lid of a feeding cup (C).

jflaschberger

jflaschberger

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.