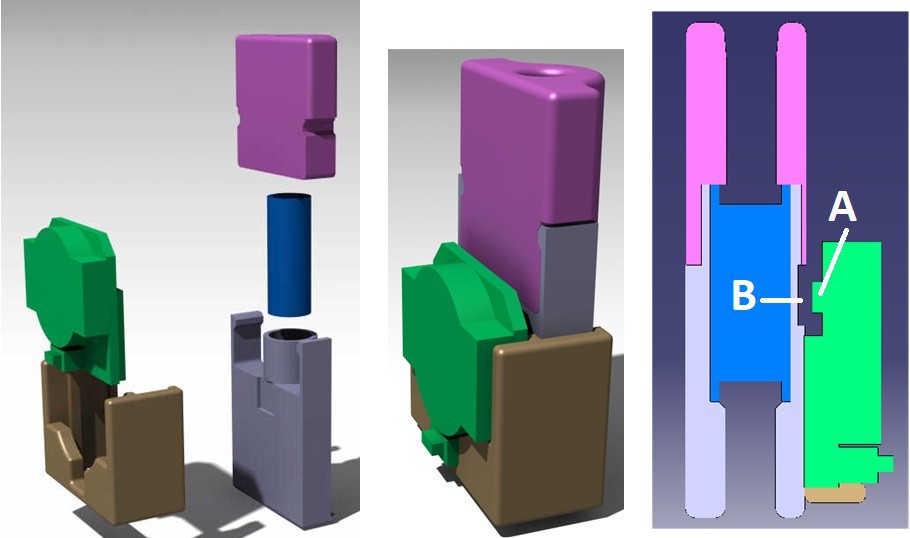

This is the first draft of the device. Simple and sketchy. The two parts are:

The sensor unit, which consists of:

- PCB with bulky coin cell holder (green)

- Holding bracket = simple housing for PCB (brown)

Both parts are glued together.

The mouthpiece, which consists of:

- Body with latches (grey). The bottom opening has a fit to insert a straw.

- Ferrite capsule (blue)

- Top piece (pink). Used for drinking.

Body and top piece snap together to tightly secure the ferrite capsule in place. If the ferrite capsule is damaged (e.g. clogged by orange juice fibers), it can easily be replaced.

The holding bracket of the sensor unit slides onto the mouthpiece, so that the hall sensor on the PCB (marked with "A") is located at the same height as the ferrite within the blue capsule. If the distance between hall sensor and ferrite is too far for detection, a metal plate can be inserted into the tiny recess (marked with "B"). Metal is multiple 1000x more conductive for magnetic field than air.

Thought vs. Reality

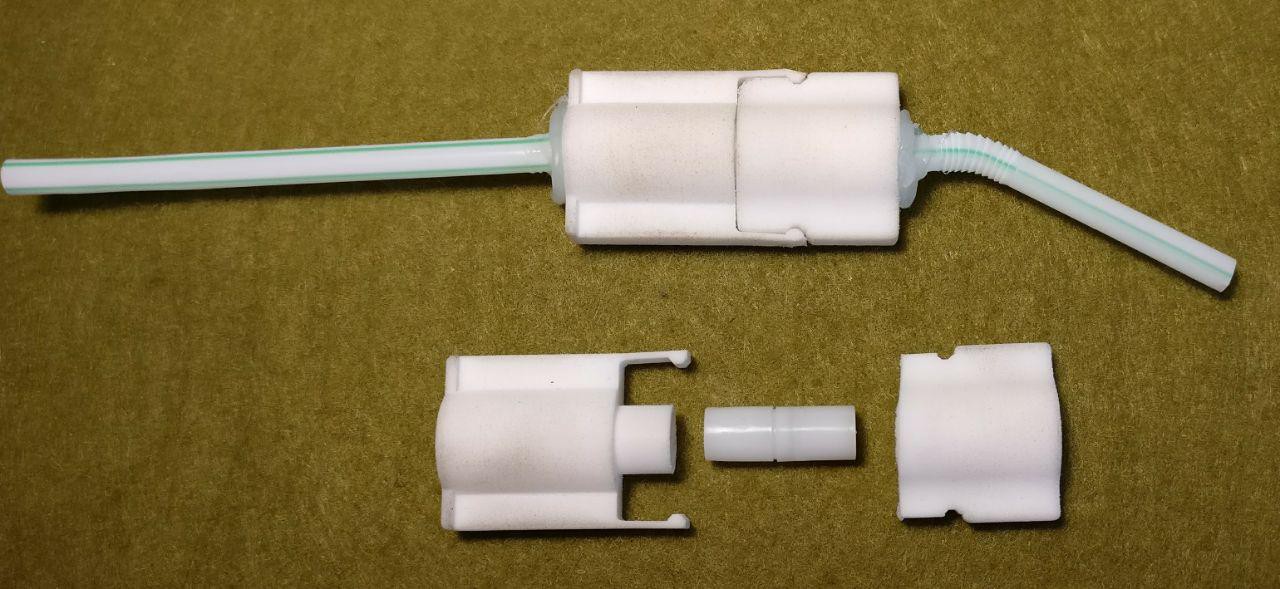

In practice, the laser sintered components of the mouthpiece don’t really fit together. It was possible to push the blue capsule into the hole, but removing it without destruction is hard. The fit between top piece and body is not really watertight…all these points could be drastically improved when using injection molded parts instead of laser sintered ones with their rough surface, but still. A fit between injection molded parts is a nightmare anyways.

Another crucial point is the weight of the assembly. If you put a mass (device) on top of a light stick (straw), it tends to fall over.

Apart from this points, sensor unit and mouthpiece fit together neatly!

Top: The mouthpiece parts and assembled, with a cut straw fixed with good ol' hot glue. Bottom: Mouthpiece with straw in a grandma cup (simulating use for the elderly).

Learnings for next version

- Reduce mass of the whole assembly. In the cup, it tends to fall over.

- The two part-mouthpiece with latches is overcomplicated. Make it simpler.

jflaschberger

jflaschberger

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.