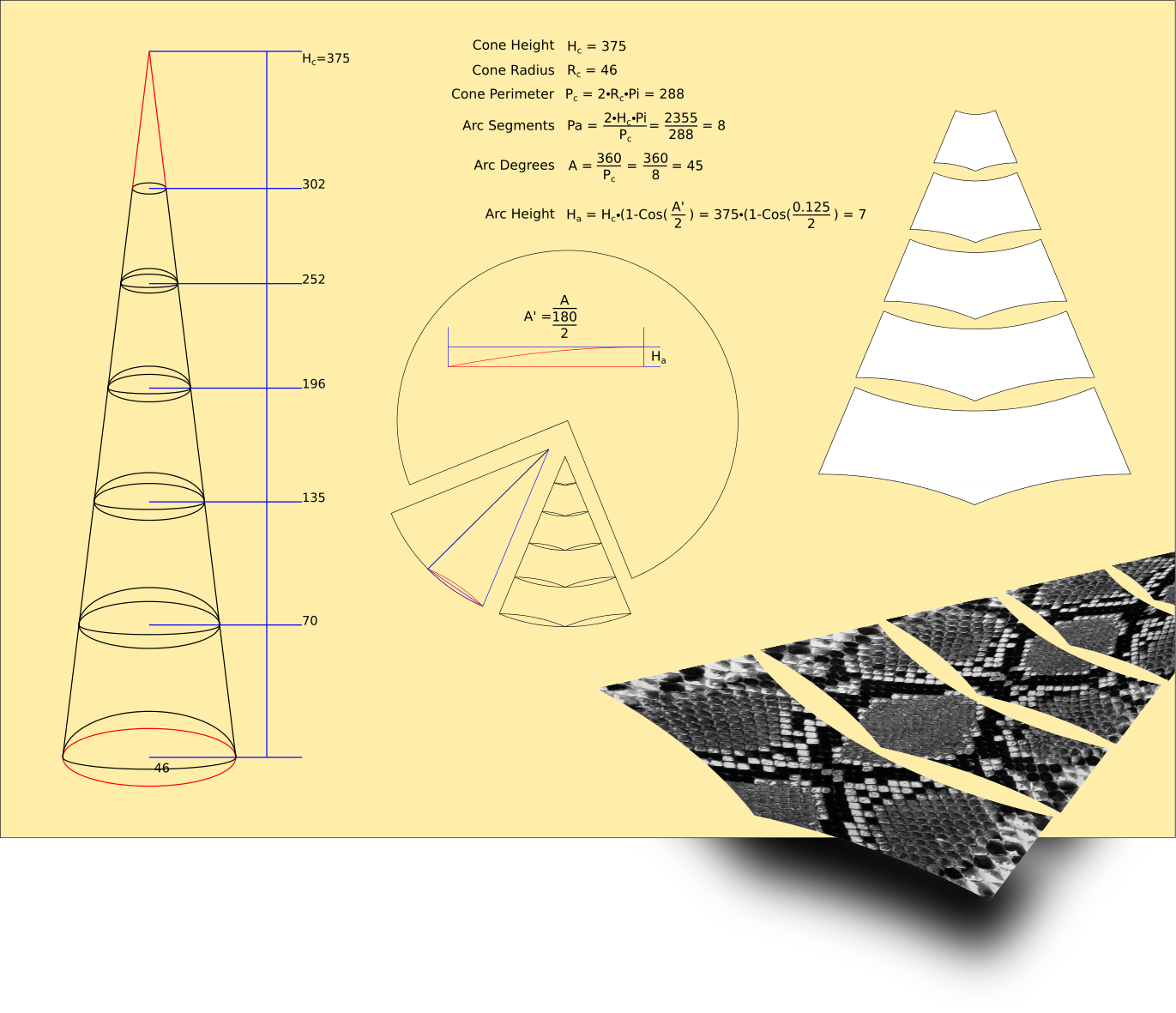

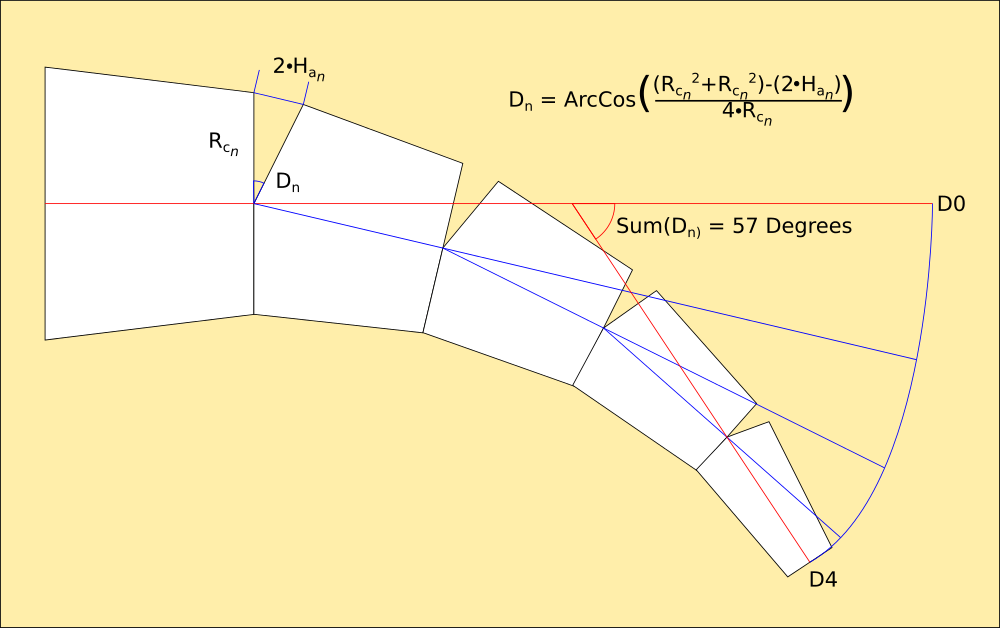

This looks overly complicated, and it is. Mostly because I need to learn the maths involved with flexible architecture, but also because its the only way I can skin this beast without using proprietary software.

The skin geometry is only the beginning.

In order to get the body to flex and transfer weight over the leg BOA stands on while moving, I'm using Bendertech. This isnt trivial, to give the processor an idea of the body position and estimate the weight distribution it has to model the response to the servo position.

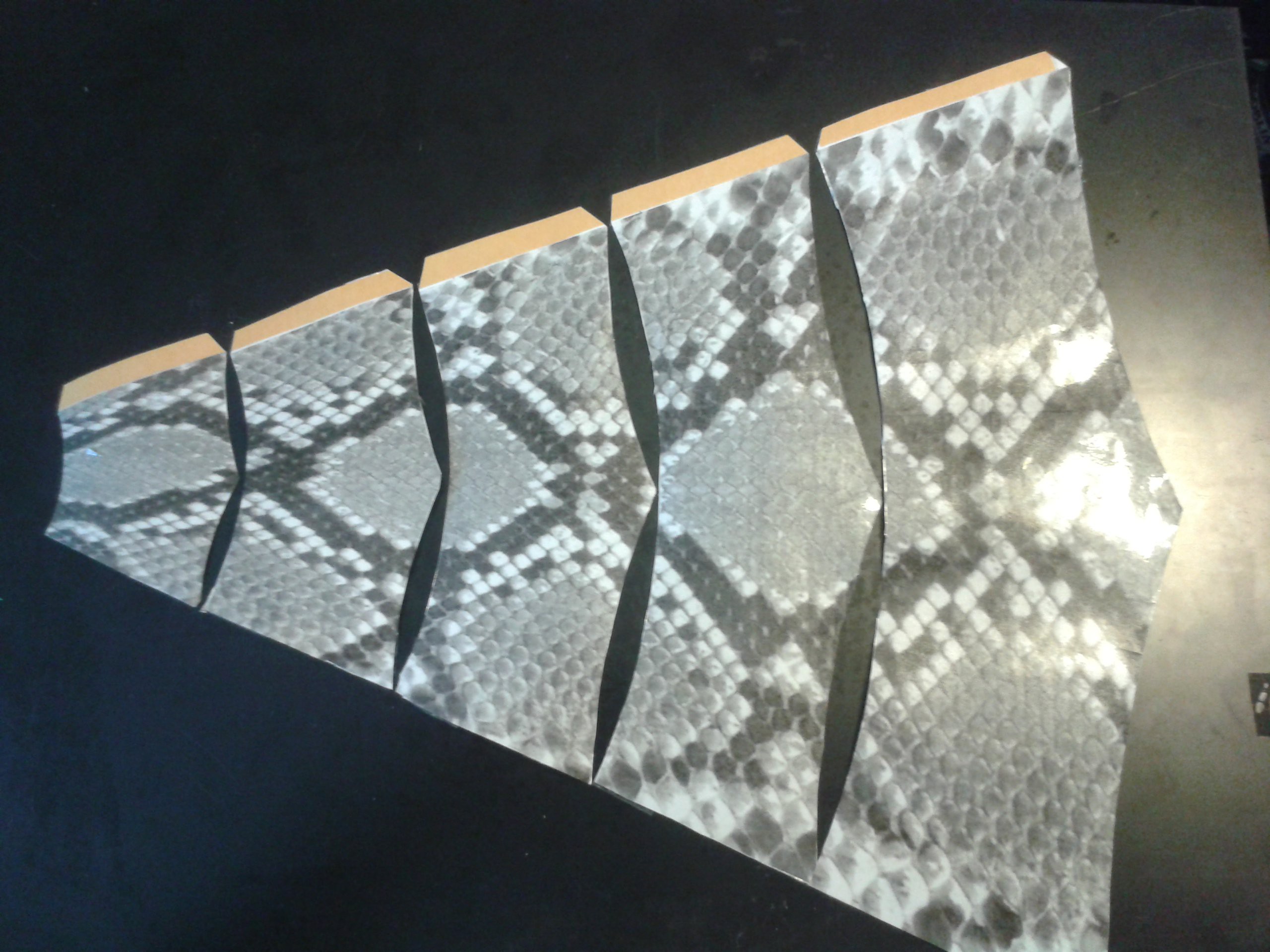

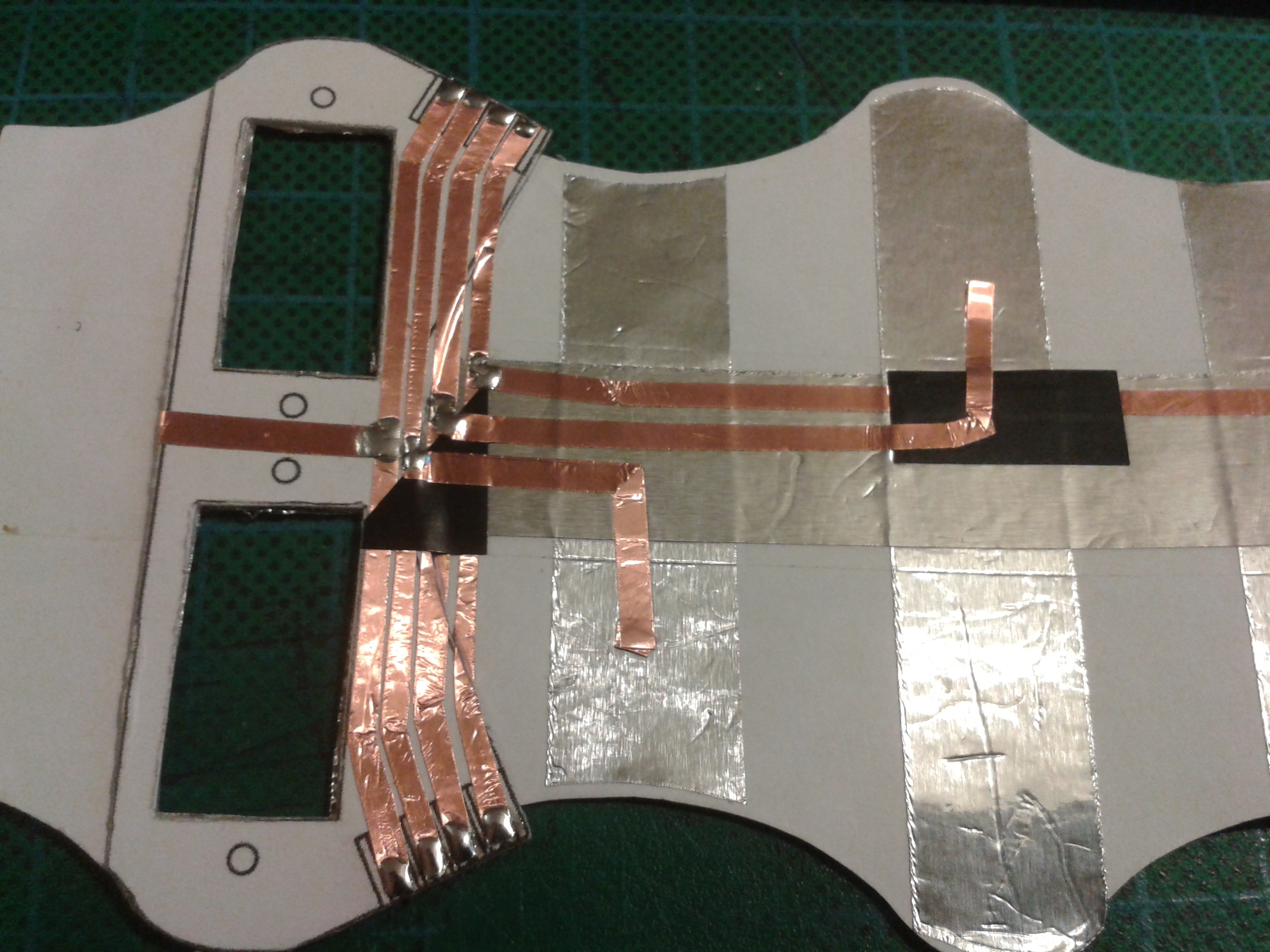

Back in the real world, after a bit of tessellation to get this through the printer on two pages of A4 the sticky-back plastic and double sided tape brings this to prototype. I save the backing paper from the sticky-back plastic, more on this later.

The other side contains the touchsense circuitry same as the limbs, to make it simple it's applied before cutting around the perimeters of the segments. The foil crossing them is isolated by a layer of parcel tape that covers the upper half of each segment, forming a shield for the 'cabling' from the outside.

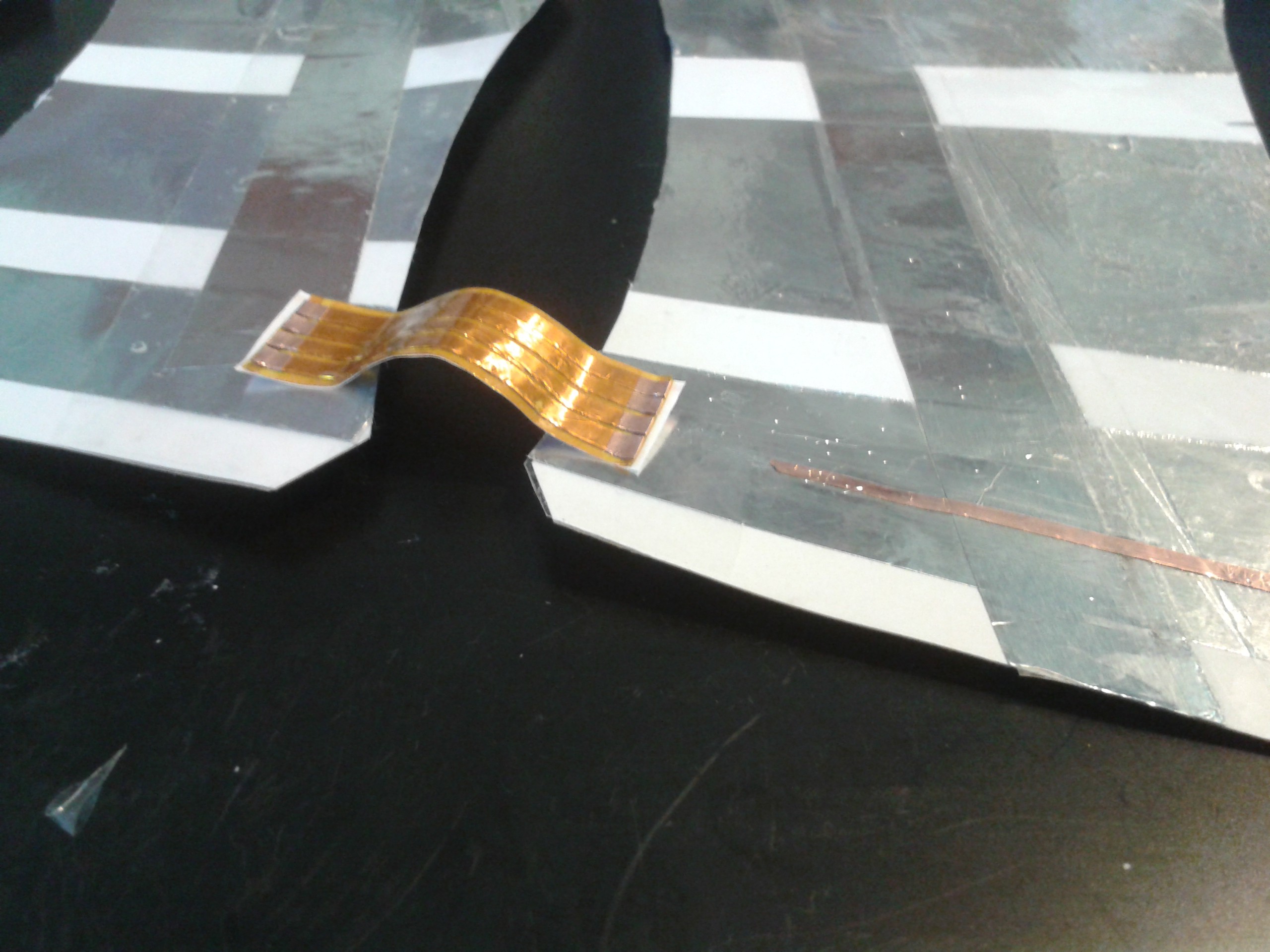

Each of the parts joins together with a cable.

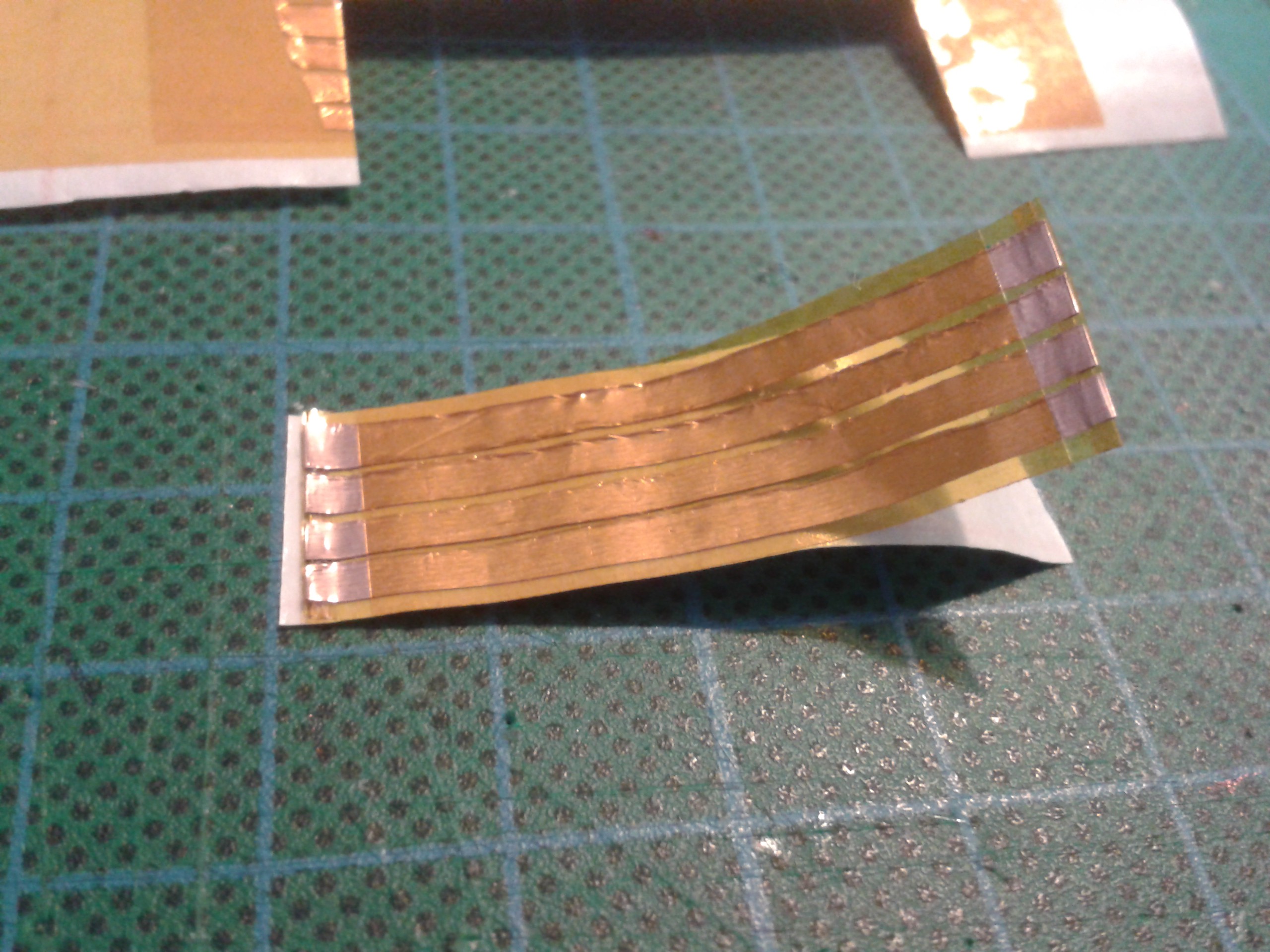

The Kapton tape arrived, and I spent a couple of days swearing at it and the even-more-unmanageable copper foil tapes until I learned how to handle them. Those tracks are barely 2mm across, and are cut from a 10mm wide reel by removing it from its backing tape and applying it to the larger backing sheet from the sticky-back plastic. This makes it easy to scalpel and layout the parts, make layers with cutouts and complex outlines and produce a single circuit that peels off a backing sheet for application.

These interface directly to the flexible circuits in the limb decals too.

I discovered that the tape I bought does not have conductive adhesive. In a way that's not so good, it makes it harder to interface to the copper, however, it does mean I can apply it to a backed sheet of Kapton and chemically etch much finer circuits out of the 10mm tape. I can get away with limited spot-solder connections to bridge joins in the tape, and the backing and adhesives on all of them are chemical resistant. A bit of salt water wont harm them in the slightest, just as well because although I can work at half that scale, I cant cut the copper any finer than this without it tearing.

Plenty good enough for the body connections, but the limb cables have to be much finer.

Morning.Star

Morning.Star

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Nice work!

Are you sure? yes | no