CNC Mill

A (hopefully) simple CNC mill built without welding

A (hopefully) simple CNC mill built without welding

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

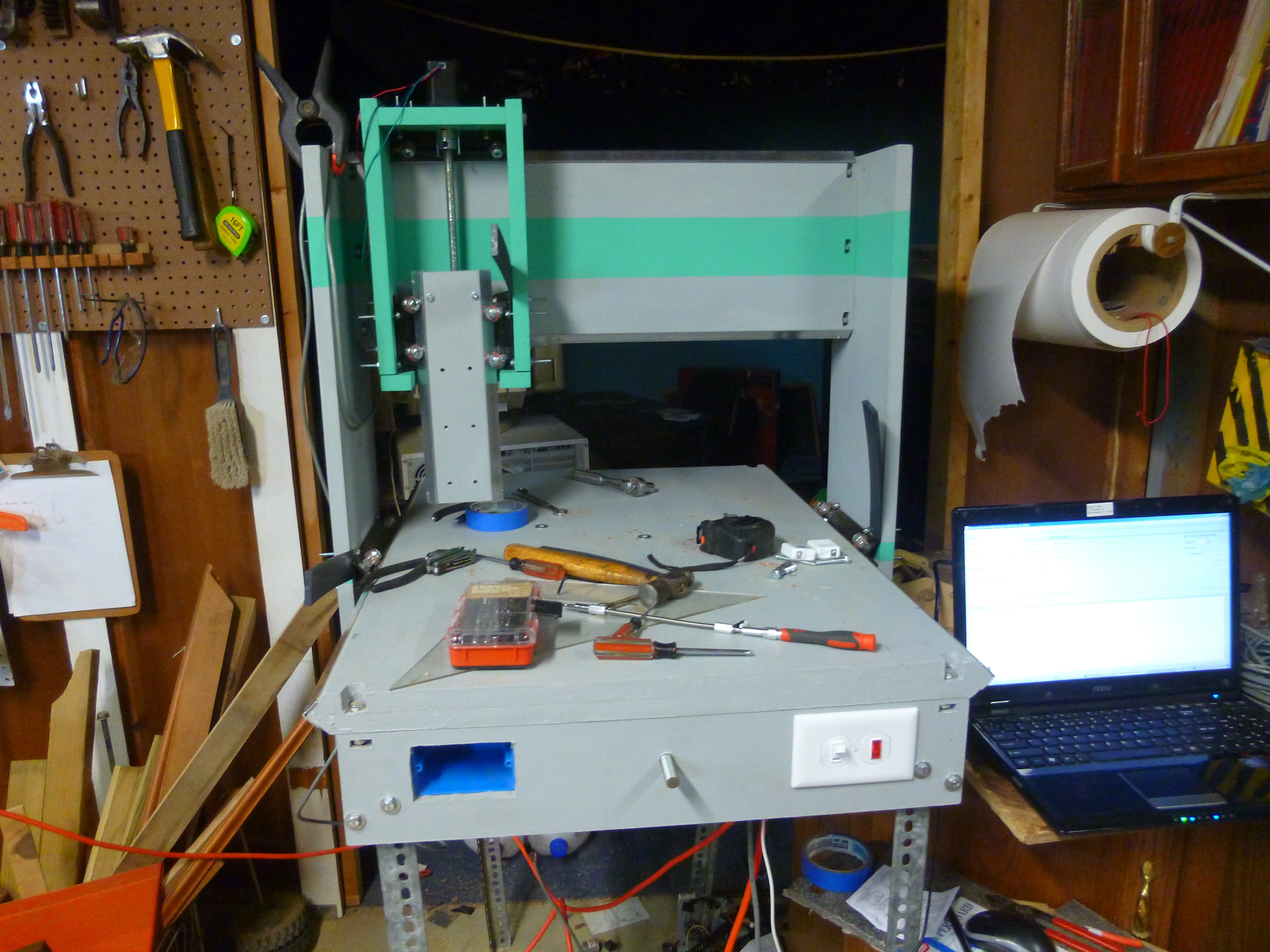

Save Yourselves! The mill is nearing completion!

I have the mill painted and assembled, and am nearing the end. Before I painted the mill, I rebuilt the sides of the base. The ones that I had were from before I figured out how to make the bolts fit, and was trying to get away with drilling holes.

I painted the mill with latex wall paint. because it was what I had on hand. Latex paint might not have been the best choice, because it is soft, and already is showing signs of damage from tools and clamps.

The shims are used to hold the trucks closer to the track and to compensate for any miss alignment in the wheels. Now I *simply*, need to wire the mill and work out the bugs with my wiring.

Since I last met you, I rebuilt the mount for the x axis nut, (twice), as well as the y and z axes.

The y axis is basically a box that slides on the y track, and holds the trucks for the z axis, but because of how they fit together, I had to build both axes together.

I cut the side pieces for the y axis a little longer than necessary, and clamped them to the z axis to get the width correct. After I had the width, I cut out the top and bottom pieces. the bottom piece needed a hole cut into it for the z axis to slide through. Since the bottom piece sits flat against the bottom of the side pieces, I was able to bolt it on to the sides. I then hung the assembly upside down from the y track, and slid the top piece on.

Hopefully, this won't mess up the paint.

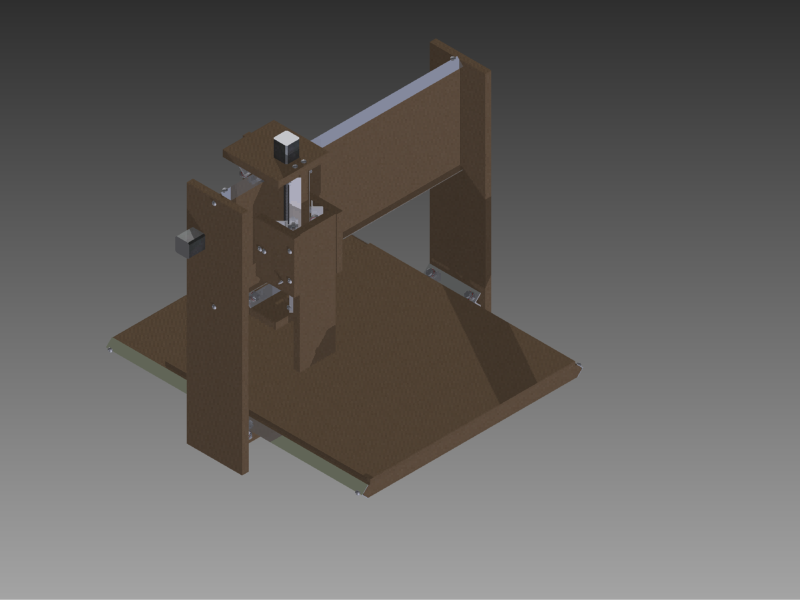

The mill is starting to come together. I have completed the x axis gantry, and am starting to get a sense of how much space this takes up.

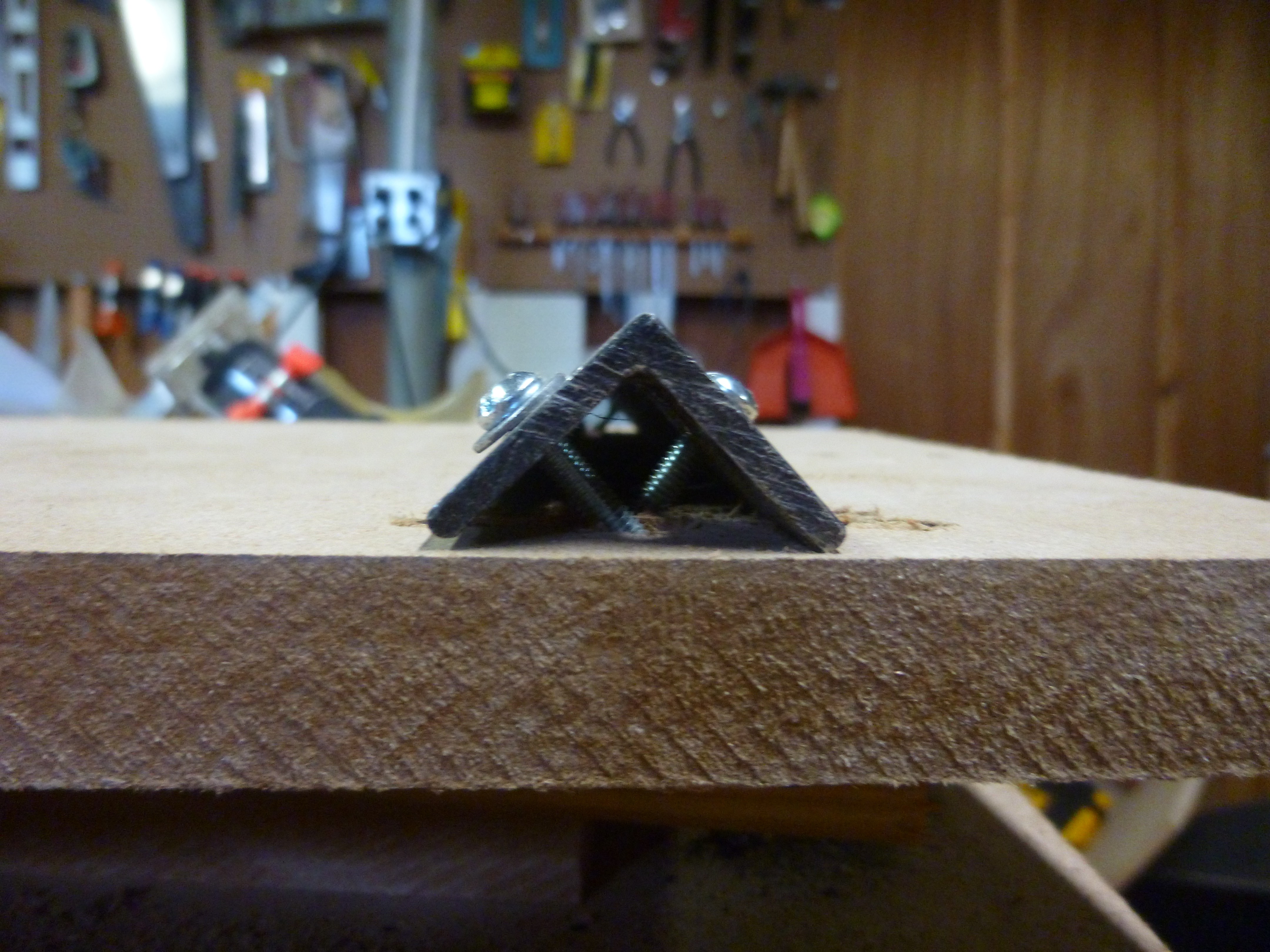

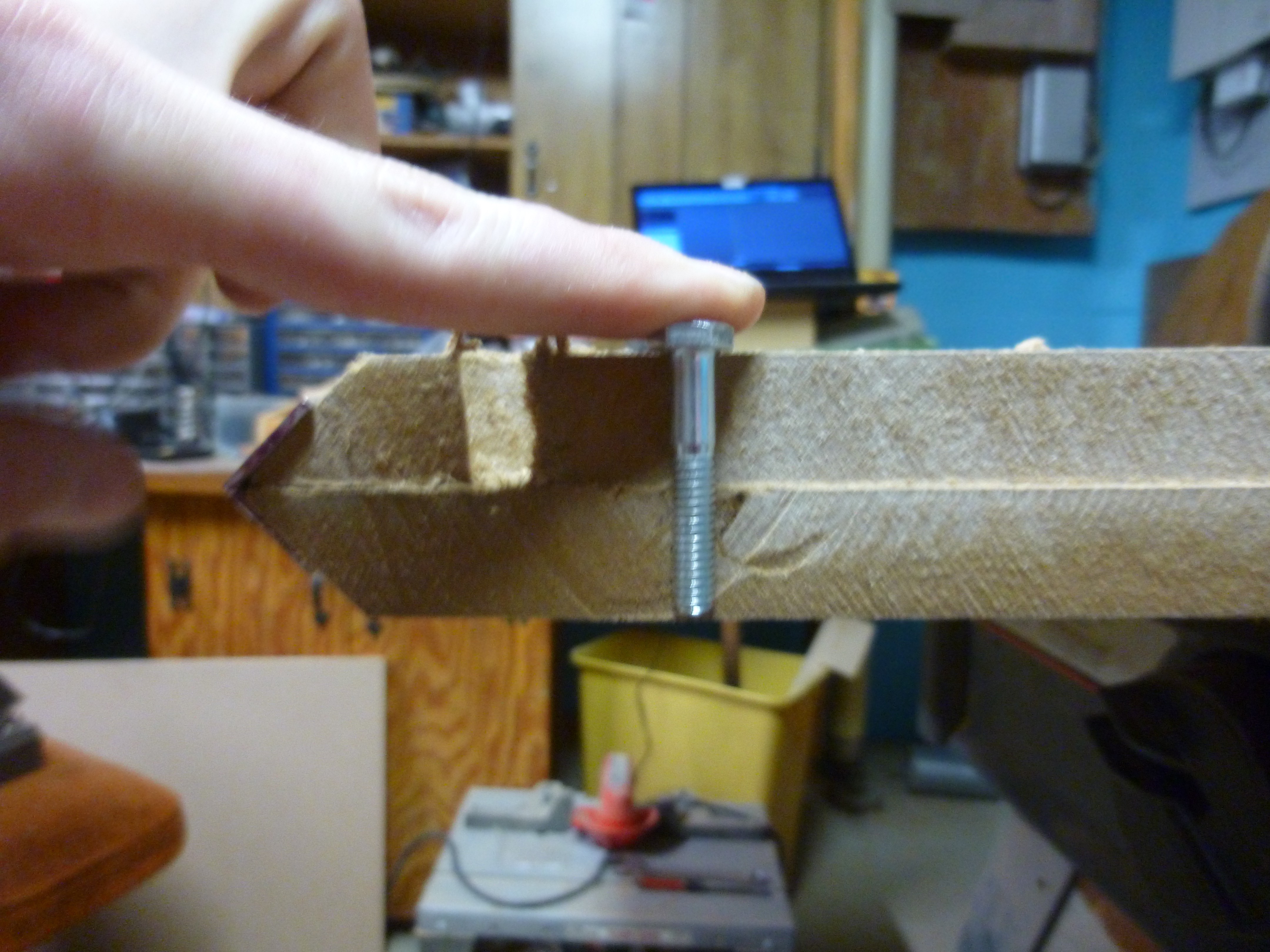

When I was originally planning out the mill, I was going to hold the trucks on with bolts holding the edge of the truck. Then I thought that this wouldn't have enough holding power and decided to instead hold the trucks with bolts traveling through the truck and board, cris-crossing halfway through. To line up the holes, I clamped the truck to the board in the correct location. and drilled through the hole in the truck to align the holes in the board. This worked, however it was almost impossible to get the angle correct, and half of my bolts were to short. To correct this problem, I routed slots where the bolts would go in the hope that they would slide in the slot and give me a way to adjust the truck.

To get the correct length for the top and bottom pieces, I had to hold the sides in the correct location. This was done with the help of some bar clamps. I built the mill sideways because I had no way to hold the two side pieces in place vertically while I also set up the clamps.

When you tighten down bolts in MDF, make sure that you have washers on both the nut and the bolt.

Also, when assembling the x axis, it helps if you bolt the top plate on first. this holds the sides in place while you slide it on the base.

Lengthening the x axis truck meant that I lost two inches from my x axis travel. some of this was regained from the z axis, however I didn't want to loose to much of my z axis travel. This meant that I had to redesign my z axis to be more space efficient. I also redesigned the mounting system for the trucks.

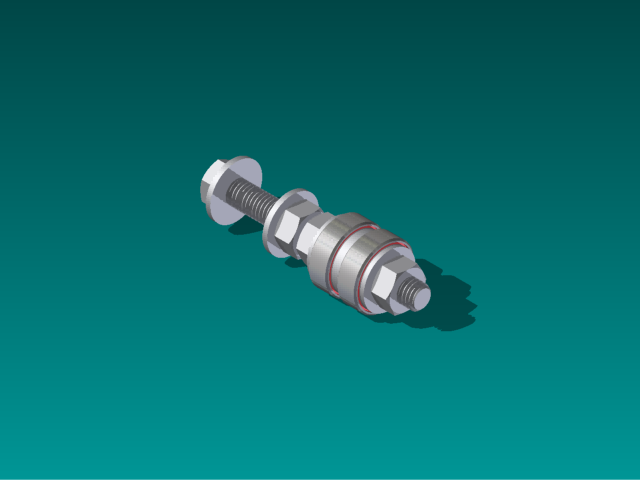

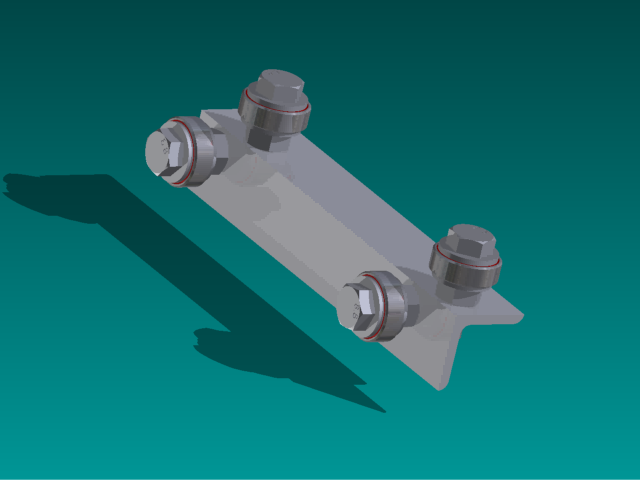

I was originally going to mount the trucks by placing screws into the boards next to the truck, and using the screw head overlap to hold the truck. I later decided to use bolts traveling through the truck and through the board. This should hold the trucks more securely, but it means that I have to disassemble the trucks so I can put four more holes into the angle before reassembling the trucks.

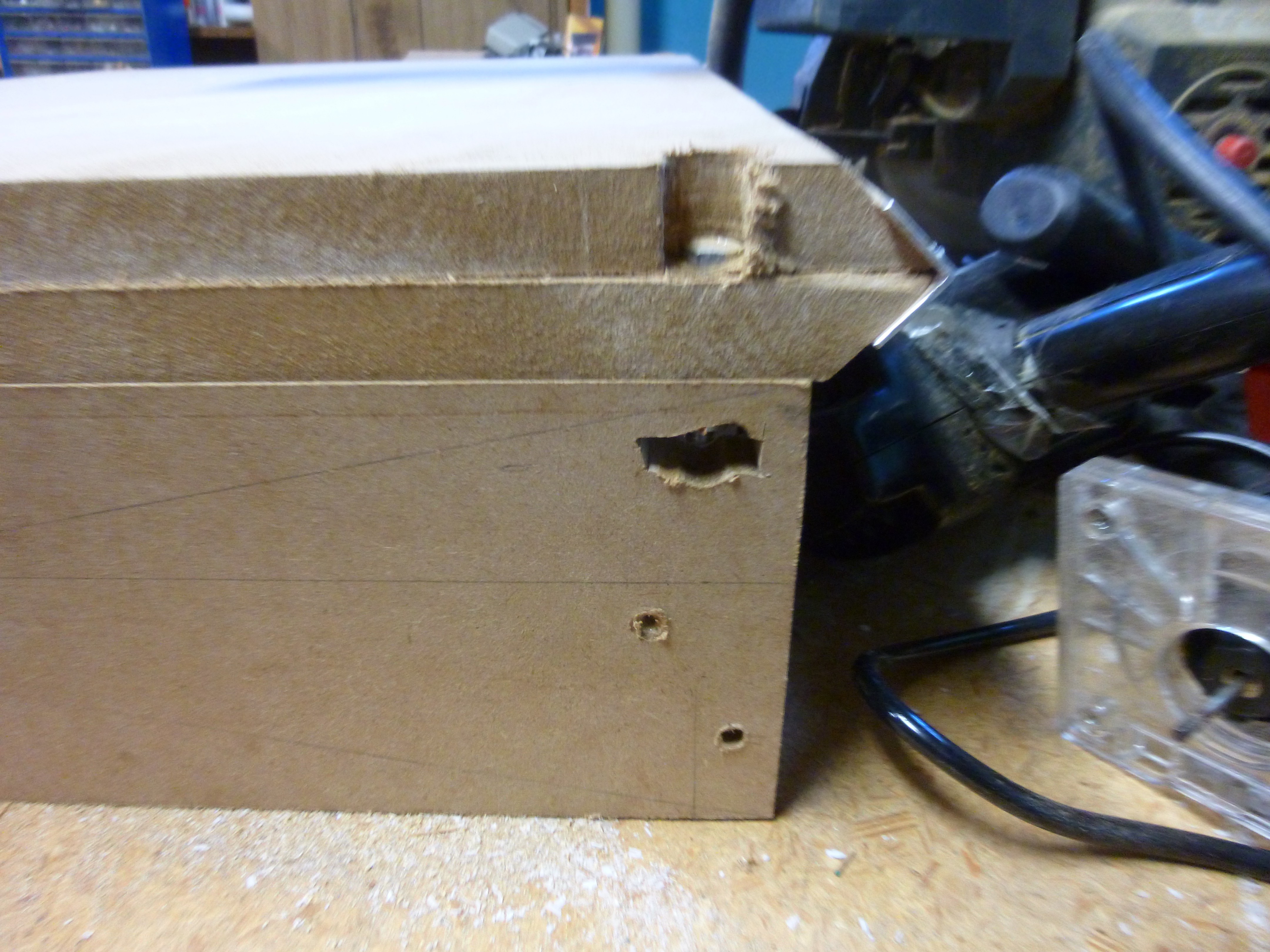

Building the base was more difficult than I imagined. First off, the base is built out of a 25"x33" rectangle, while the fence on my table saw can barely be forced to 25". This meant that the initial cut had to be made with a circular saw. I used a guide with the circular saw, however despite all my careful alignment, the cut turned out crooked. This happened twice since I was doubling up the material for the base. Fortunately, the 33" dimension isn't critical, and I was able to make the 25" cuts on the table saw, so the tracks are at least parallel. I lined up the two most right angles, and glued the two sheets together

I attached two lengths of aluminum angle onto the chamfer for a track, and started on the end pieces.

The end pieces were made out of cutoffs from the base. they fit on the table saw, so cutting was easier. After they were cut, I screwed the two pieces together, and marked and pre-drilled holes for the x axis stepper motor, and mounting screws.

The mounting holes lead to a whole host of problems. The base plate was to big to put on the drill press, so I had to hand drill the holes. These holes inevitably became misaligned with the holes in the end pieces. I also failed to take into account that the bolts I had purchased were too short to fit through the doubled up base plate, so I had to countersink the heads. The holes were of course to large to be good pilot holes, so the countersinks were slightly off-center.

I already decided to modify my plans. Instead of going with 6" trucks for all three axis's. I shrunk the z-axis down to 4", and increased the x-axis to 8".

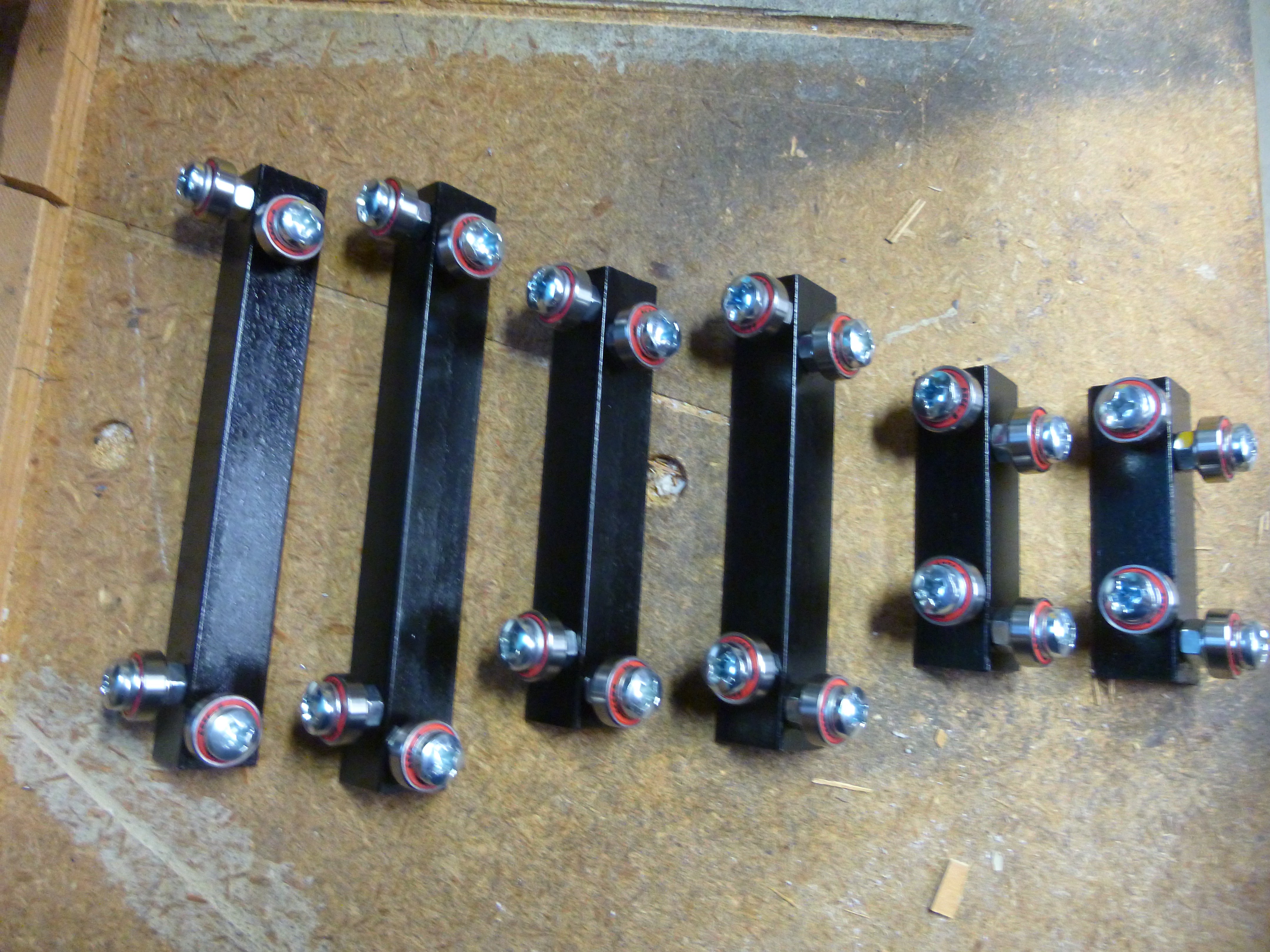

The trucks are built out of 1/8" steel angle, which was then drilled and tapped for 8mm bolts. the bolts were used to hold the bearing assembly.

I am not sure how well it shows in the image, but my jig is two pieces of scrap wood, nailed together, so the one forms a "wall" to set the angle against. I made a mark at 1" and 1/2", to line the angle against, and drilled away.

I am not sure how well it shows in the image, but my jig is two pieces of scrap wood, nailed together, so the one forms a "wall" to set the angle against. I made a mark at 1" and 1/2", to line the angle against, and drilled away.

After I drilled the holes in the ends of each piece, I tapped the holes for the m8 bolts I was using to hold the bearing assembly together.

The axes are going to slide along aluminum angle "tracks". I was originally going to use round rod for the track, and three sets of doubled up bearings to create a slot for the rod to slide in.

This would require twelve bearings per axis instead of the eight my final plan uses.

This would require twelve bearings per axis instead of the eight my final plan uses.

My final plan calls for each axis to have two trucks made from angle iron. this will hold the bearings at the correct angle to slide in on the aluminum angle.

This summer, I am planning on building a CNC mill. Along with being functional, I would also like it to be cheap. I don't know how to weld, and don't have access to a welder, so I am making the framework out of MDF. I don't know much about building a CNC, but with what I found online, I think that I have a usable plan.

To see if my design was theoretically possible, I modeled the whole thing in Inventor, before I began making purchases.

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates